– MUD systems require specialized thermal management strategies due to restricted steel volume in the insert.

– Achieving turbulent flow (Reynolds number > 4,000) is critical for heat transfer in small diameter channels.

– Conformal cooling via DMLS allows cooling lines to follow part geometry within tight MUD insert confines.

– Proper use of baffles, bubblers, and conductive alloys (BeCu) can compensate for layout limitations.

What is the Definition and Challenge of Cooling in Master Unit Die (MUD) Systems?

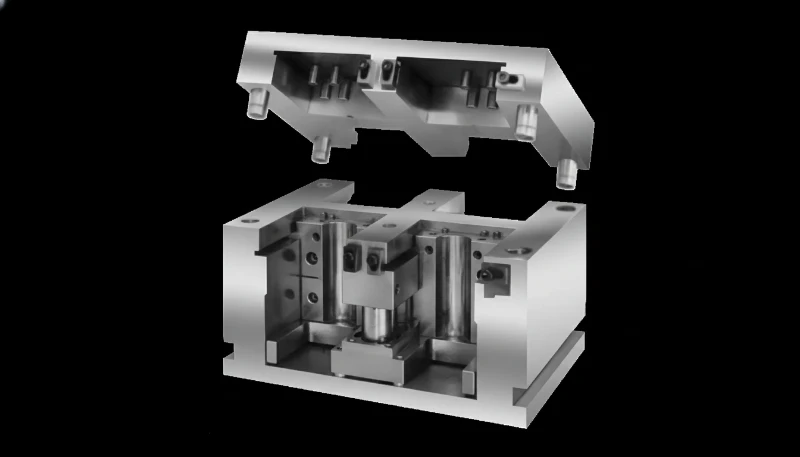

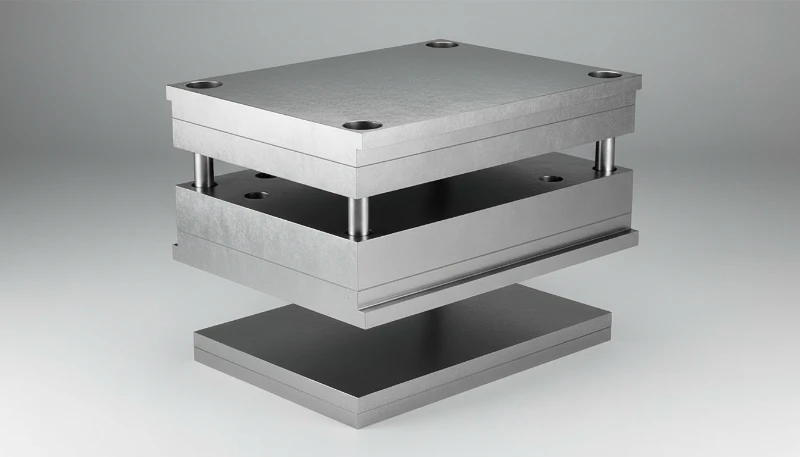

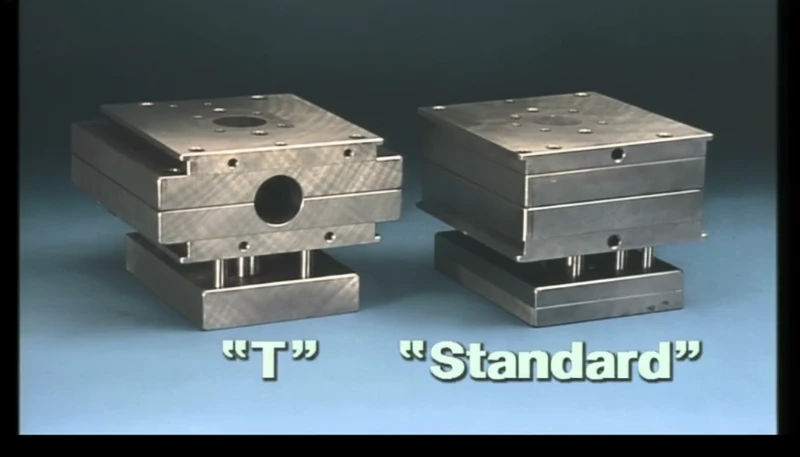

Master Unit Die (MUD) systems, also known as quick-change insert molds, utilize a standard frame that remains in the injection molding machine while only the core and cavity inserts are swapped. This system is primarily used for prototyping and low-to-medium volume production.

MUD mold cooling presents a specific engineering challenge: the "insert" has significantly less steel mass than a standard mold base. Consequently, there is limited physical space to drill traditional injection mold cooling lines. Without optimization, heat builds up rapidly in the small steel block, leading to extended cycle times and dimensional instability.

Effective thermal management molding in MUD systems1 requires moving beyond standard straight-line drilling to advanced techniques that maximize heat extraction within a compact footprint.

What are the Key Parameters for Thermal Management in Molding?

To optimize cooling within the restricted space of a MUD insert, engineers must strictly adhere to fluid dynamic parameters. The goal is to remove heat faster than the plastic injects it.

| 매개변수 | Recommended Range/Value | Engineering Context |

|---|---|---|

| Reynolds Number (Re) | > 4,000 (Turbulent Flow) | Turbulent flow maximizes heat transfer. Laminar flow (Re < 2,300) forms an insulating layer on channel walls, rendering cooling ineffective. |

| Coolant Velocity | 1.5 m/s – 3.0 m/s | Sufficient velocity is required to push air pockets out of the lines (especially in bubblers) and maintain turbulence. |

| Temperature Difference (△T) | < 2℃ – 3℃ | The difference between inlet and outlet water temperature. If △T is higher, the flow rate is too low, causing uneven cooling across the part. |

| Distance to Cavity | 1.5 × Diameter (D) to 2 × D | In MUD inserts, lines are often closer (1 × D) due to space, requiring high-strength steel (e.g., H13) to prevent cracking. |

| Channel Diameter | 6mm – 10mm (Typical for MUD) | Smaller diameters increase pressure drop; pumps must be sized to overcome the higher impedance of small MUD circuits. |

Turbulent flow is more critical for cooling efficiency than simply lowering the coolant temperature.True

Turbulence breaks the boundary layer of static water against the metal, significantly increasing the heat transfer coefficient, whereas very cold water with laminar flow isolates the mold surface.

Lowering the coolant temperature to near-freezing is always the best way to reduce cycle time.False

Excessively cold water can cause atmospheric condensation (sweating) on the mold surface, leading to water marks on parts and potential corrosion of the MUD insert.

How do you Design Injection Mold Cooling Lines for MUD Inserts?

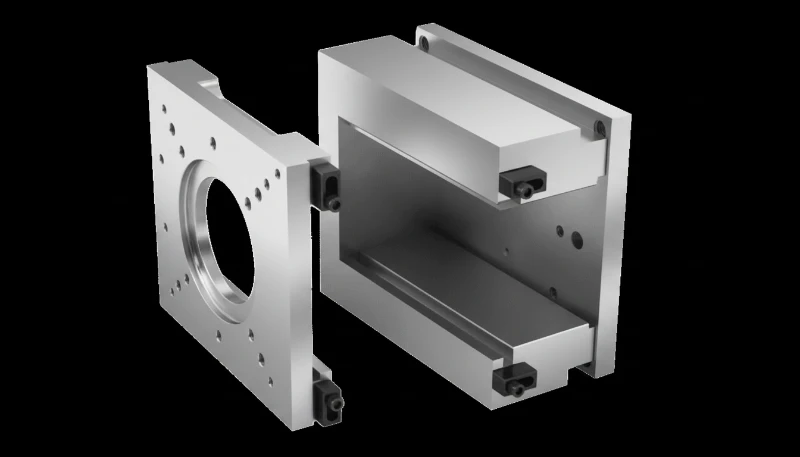

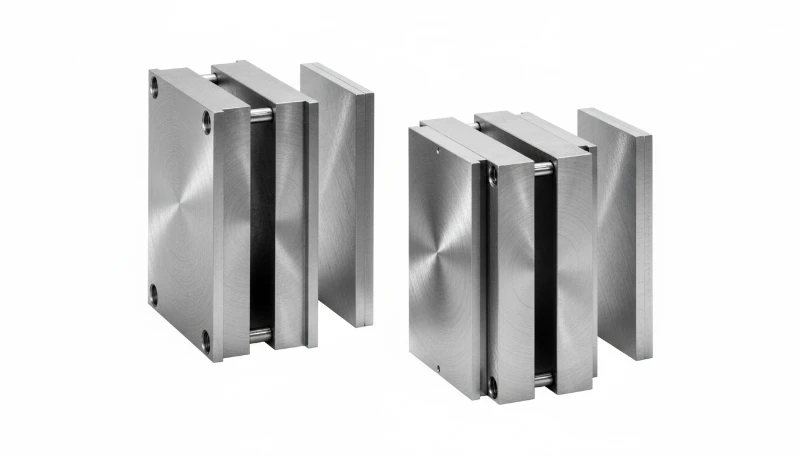

Designing for MUD frames differs from standard bases. The frame acts as a carrier, but the critical heat exchange occurs in the removable insert.

1. Baffles and Bubblers for Core Cooling

In MUD systems, there is often no room for "flow-through" lines (drilled from one side to the other).

- 버블러: A tube inserted into a drilled hole. Coolant flows up the center tube and cascades down the outside. Ideal for deep cores in MUD inserts.

- 당황스럽습니다: A twisted metal blade inserted into a channel to force water up one side and down the other. These are space-efficient and essential for MUD geometries.

2. Direct Connect vs. Frame-Through Cooling

- Frame-Through: Water connects to the MUD frame and passes into the insert via O-rings at the interface.

- Risk: High risk of leaking at the insert-frame interface if O-rings are damaged during changeovers.

- Direct Connect: Hoses are connected directly to the MUD insert using quick-disconnect fittings (e.g., Jiffy-Tite).

- Benefit: Reduces leak risk and ensures water actually reaches the insert, not just the frame.

3. Use of High-Conductivity Alloys

When water lines simply cannot fit near a hot spot (e.g., a thin rib), insert a high-conductivity alloy like Beryllium Copper (BeCu) 또는 Ampcoloy. These materials conduct heat 3 to 4 times faster than tool steel (P20 or H13), transferring heat from the part to a remote cooling line.

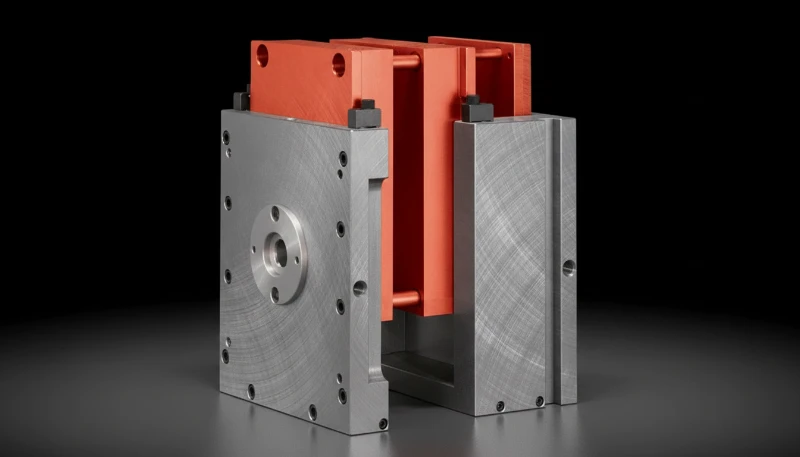

Can Conformal Cooling MUD Inserts Reduce Cycle Time?

Conformal cooling MUD solutions represent the highest tier of optimization. Unlike traditional drilling, which creates straight channels, conformal cooling uses 직접 금속 레이저 소결(DMLS) (3D metal printing) to build the insert layer by layer.

The Process

- 시뮬레이션: Moldflow analysis identifies thermal hotspots.

- Design: Channels are designed to curve and follow the 3D contour of the part, maintaining a consistent distance from the surface.

- Printing: The insert is printed in Maraging Steel or Stainless Steel (e.g., 420 SS) with the void (cooling channel) built inside.

Impact on Cycle Time

Conformal cooling creates a uniform thermal profile. For complex geometries in small MUD inserts, this can achieve significant cycle time reduction2—often 20% to 40%. It allows water to reach tips and corners that traditional drilling cannot access.

What are the Advantages and Disadvantages of Optimized MUD Cooling?

| 기능 | 장점 | 단점 |

|---|---|---|

| 효율성 | Rapid heat removal enables faster cycling, critical for low-volume efficiency. | High pressure drop due to complex, narrow paths requires robust pumping units. |

| Part Quality | Uniform cooling reduces differential shrinkage and warpage. | Conformal cooling MUD inserts are significantly more expensive to manufacture (3D printing vs. CNC). |

| 유지 관리 | Quick changeovers allow for easy cleaning of lines if direct connectors are used. | Small channels (<6 mm) clog easily with scale or rust; requires treated water. |

| Space | Utilizing baffles maximizes cooling in restricted footprints. | Complex plumbing in tight spaces increases the risk of hose interference during mold closing. |

Connecting cooling circuits in series increases the pressure drop across the system.True

In a series circuit, resistance is cumulative. Long series loops in MUD systems can result in insufficient flow velocity at the end of the circuit.

The MUD frame itself provides sufficient cooling for the molding process.False

The frame is merely a holder. The heat is generated in the insert; relying on the frame to cool the insert via conduction is inefficient and leads to slow cycle times.

What are Practical Tips for Troubleshooting MUD Thermal Issues?

- Monitor the "Delta T": Install thermometers on the supply and return manifolds. If the return water is >3℃ hotter than the supply, your flow rate is too low.

- O-Ring Maintenance: If using frame-to-insert cooling transfer, inspect the O-rings on the bottom of the insert before every installation. A crushed O-ring causes coolant to leak between the plates, rusting the MUD frame.

- Turbulent Flow Verification: Use a flow meter to ensure you are achieving the liters per minute (LPM) required for the channel diameter.

- Formula Approximation: For a 10mm line, you need roughly 3-4 LPM to achieve turbulence.

- Manifold Balancing: Do not daisy-chain multiple MUD inserts in series if running a multi-frame setup. Use a parallel manifold with flow regulators to ensure every insert gets equal pressure.

Where is MUD Cooling Optimization Applied?

- Medical Device Prototyping: High-precision parts utilizing Polycarbonate (PC) or Polysulfone (PSU) requiring tight tolerances and strict thermal control.

- 소비자 가전: Small housings requiring rapid cooling to prevent sink marks in thick sections.

- Elastomeric Parts: Liquid Silicone Rubber (LSR) molding in MUD frames, where the "cooling" lines are actually used for heating, requiring precise thermal uniformity.

- ISO Test Specimens: Producing tensile bars where thermal history impacts mechanical property data.

Frequently Asked Questions (FAQs)

1. How does MUD mold cooling differ from standard mold cooling?

Standard molds allow cooling lines to be drilled through large plates. MUD mold cooling is constrained by the small size of the insert block. Designers must use baffles, bubblers, or conformal cooling MUD techniques rather than simple through-lines.

2. Is conformal cooling worth the cost for MUD inserts?

If the part has complex geometry, deep draw ratios, or if cycle time reduction is critical for ROI, yes. However, for simple flat parts or very low production volumes (e.g., <500 parts), standard drilling is more cost-effective.

3. What is the best coolant to use in MUD systems?

Treated water with rust inhibitors is standard. For high-temperature resins (like Ultem or PEEK), hot oil or pressurized water thermolators are used. Avoid untreated tap water, as scale buildup blocks the small channels in MUD inserts rapidly.

4. How do I prevent leaks in quick-change MUD systems?

Prioritize "direct plumb" designs where hoses connect directly to the insert rather than passing through the frame interface. If interface transfer is necessary, use high-durometer Viton O-rings and inspect the counter-bores for damage regularly.

5. Can I use MUD inserts for high-temperature materials3?

Yes, but thermal expansion must be calculated carefully. The insert will expand faster than the frame. Ensure sufficient clearance and use insulation sheets between the MUD frame and the machine platen to protect the hydraulic system.

요약

최적화 injection mold cooling lines within MUD systems requires a shift from traditional "drilling" mindsets to precision thermal management. Because space is the limiting factor, engineers must leverage turbulent flow, high-conductivity materials (BeCu), and advanced geometries (baffles/bubblers) to extract heat efficiently. For complex parts, conformal cooling MUD inserts printed via DMLS offer the ultimate solution for cycle time reduction and quality control. Properly managed thermodynamics in MUD systems transforms them from simple prototyping tools into capable, high-speed production assets.

-

Understanding MUD systems is crucial for grasping the complexities of thermal management in modern manufacturing. ↩

-

Discover strategies for reducing cycle times, enhancing productivity and efficiency in manufacturing. ↩

-

Learn how to effectively manage high-temperature materials to ensure quality and performance. ↩