Injection molding is a cornerstone of modern manufacturing, enabling the mass production of plastic parts with remarkable precision and efficiency. From everyday consumer goods like phone cases to critical medical devices such as syringes, this process shapes the products we rely on daily. But what exactly is injection molding, and how does it work? In this article, we’ll dive deep into the world of injection molding, exploring its process, materials, applications, advantages, and how it compares to other molding techniques—all while providing practical insights for beginners and professionals alike.

Injection molding produces high-precision plastic parts by injecting molten material into a mold, making it a go-to method for industries needing efficiency and consistency in large-scale production.

Injection molding reduces material costs in manufacturing.True

By producing precise parts with minimal waste, injection molding optimizes material use, lowering costs in high-volume production.

Injection molding is only used for small-scale projects.False

It’s designed for high-volume production, though it can be adapted for smaller runs with proper planning.

What is Injection Molding?

Injection molding is a manufacturing process that creates parts by injecting molten material—typically plastic—into a mold. The material cools and solidifies into the desired shape, producing components with tight tolerances and complex geometries. It’s widely used across industries like automotive, consumer goods, and healthcare due to its ability to churn out identical parts in large quantities efficiently.

Injection molding1 excels at producing complex plastic parts with precision, making it ideal for high-volume manufacturing2 needs.

Injection molding is only used for plastic parts.False

While plastics dominate, the process can also handle metals, glasses, and elastomers with specialized equipment.

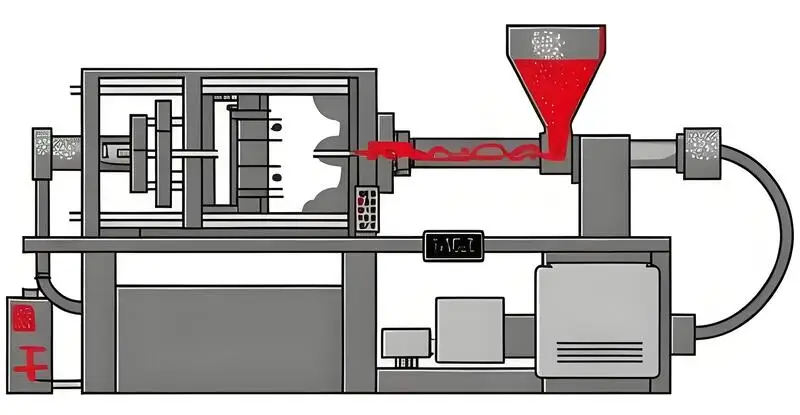

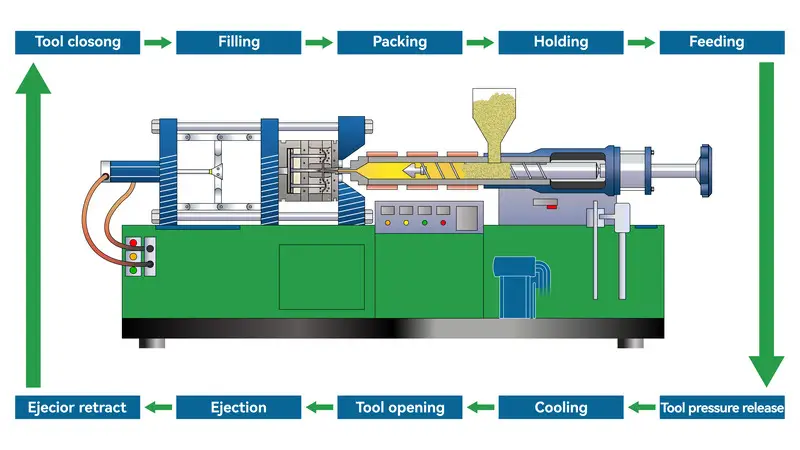

How Does Injection Molding Work?

The injection molding process involves a series of carefully controlled steps to transform raw material into a finished part. Here’s how it breaks down:

-

Clamping: The mold, typically made of two metal halves, is closed and secured under high pressure to withstand the injection force.

-

Injection: Plastic pellets are fed into a heated barrel, melted, and injected into the mold cavity under high pressure.

-

Pack and Hold: Pressure is maintained to fill the mold completely and compensate for material shrinkage as it cools.

-

Cooling: The molten plastic cools and hardens into the final shape, with cooling time varying based on part size and material.

-

Ejection: The mold opens, and the solidified part is ejected using pins or other mechanisms.

| Step | Description | Key Parameters |

|---|---|---|

| Clamping | Mold is closed and held under pressure | Clamp pressure |

| Injection | Molten plastic is injected into the mold | Injection pressure, speed |

| Pack and Hold | Pressure is maintained to prevent shrinkage | Hold pressure, time |

| Cooling | Plastic cools and solidifies | Mold temperature, time |

| Ejection | Part is removed from the mold | Ejection mechanism |

The pack and hold phase3 is critical to avoid defects like sink marks or voids, ensuring a high-quality final product.

Injection molding always produces flawless parts.False

Defects can occur due to improper settings, material choice, or mold design, requiring precise control.

What are the Common Materials Used in Injection Molding?

Injection molding primarily uses thermoplastics4, which can be melted and reshaped multiple times, though thermosets and other materials are also options. Here are some popular choices:

-

ABS (Acrylonitrile Butadiene Styrene): Strong and impact-resistant, perfect for toys and automotive components.

-

Polycarbonate: Transparent and heat-resistant, used in lenses and medical devices.

-

Polypropylene: Lightweight and chemical-resistant, ideal for packaging and containers.

-

Nylon: Durable and wear-resistant, suited for gears and mechanical parts.

Thermoplastics are favored in injection molding for their versatility and ease of processing, enabling a wide range of applications.

All plastics are suitable for injection molding.False

Thermosets, which harden permanently after heating, require different processes due to their inability to remelt.

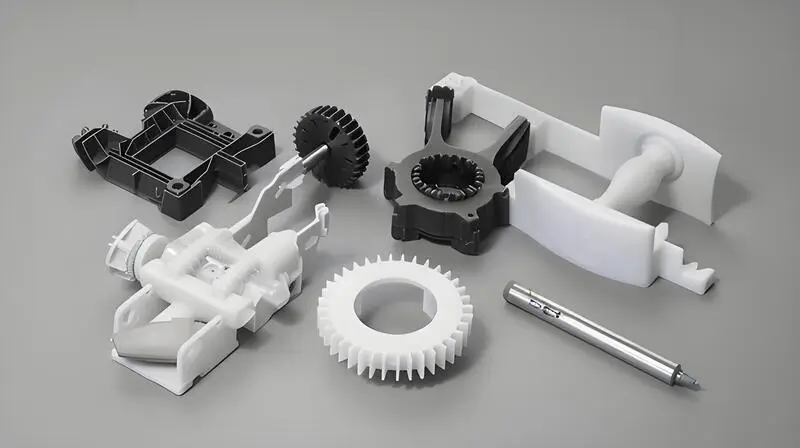

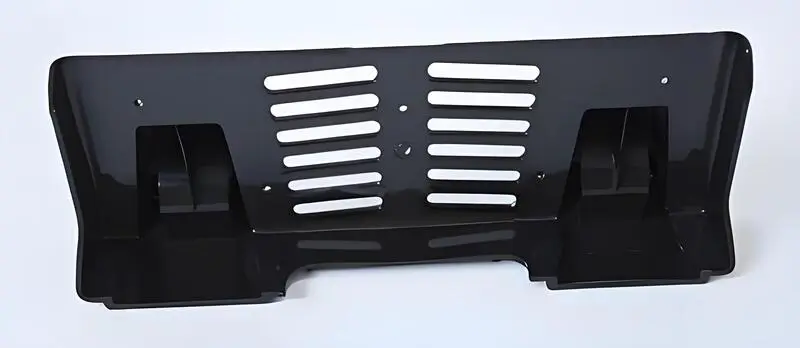

What are the Applications of Injection Molding?

Injection molding’s versatility makes it indispensable across multiple industries. Here are some key examples:

-

Automotive: Produces dashboards, bumpers, and interior trims with precision and durability.

-

Consumer Goods: Creates phone cases, toys (e.g., LEGO bricks), and household items efficiently.

-

Medical Devices: Manufactures syringes, surgical tools, and device housings with strict tolerances.

-

Packaging: Makes caps, closures, and containers for food and beverages.

Injection molding is the preferred method for high-precision, large-volume production across diverse sectors.

Injection molding is only suitable for small parts.False

It can produce large parts like car panels, though smaller components are more common due to cost and complexity.

What are the Advantages and Disadvantages of Injection Molding?

Injection molding offers significant benefits but comes with trade-offs. Let’s break it down:

Advantages

-

High Production Rates: Ideal for mass production with fast cycle times.

-

Design Flexibility5: Can create complex shapes with tight tolerances.

-

Consistency: Delivers repeatable, high-quality parts.

Disadvantages

- High Initial Costs: Mold design and manufacturing can be expensive upfront.

-

Not Ideal for Small Runs: Less cost-effective for low-volume production.

-

Material Limits: Not all materials are suitable due to processing requirements.

Injection molding shines in high-volume scenarios but requires careful cost consideration for smaller projects.

Injection molding is the cheapest manufacturing method.False

It’s cost-effective for large runs, but high mold costs make it pricey for small batches.

What are the Differences Between Injection Molding and Other Molding Processes?

Injection molding is often compared to other techniques like blow molding and rotational molding. Here’s how they stack up:

-

Blow Molding6: Shapes hollow parts (e.g., bottles) by inflating a plastic parison with air inside a mold.

-

Rotational Molding7: Forms large, hollow items (e.g., tanks) by rotating a mold to coat its interior with plastic.

-

Injection Molding: Produces solid, detailed parts with high precision and volume efficiency.

| Process | Part Type | Production Volume | Complexity |

|---|---|---|---|

| Injection Molding | Solid, detailed | High | High |

| Blow Molding | Hollow | Medium to High | Moderate |

| Rotational Molding | Large, hollow | Low to Medium | Low to Moderate |

Injection molding stands out for solid, intricate parts, while blow and rotational molding cater to hollow designs.

Injection molding can produce hollow parts like bottles.False

Blow molding is better suited for hollow parts, as injection molding focuses on solid components.

Conclusion

Injection molding is a powerhouse in manufacturing, offering unmatched precision and efficiency for producing plastic parts in large quantities. From automotive components to medical devices, its applications are vast, driven by its ability to handle complex designs and maintain consistency. However, its high initial costs mean it’s best suited for high-volume production rather than small runs. By understanding its process, materials, and trade-offs, manufacturers can harness its full potential to meet their needs.

-

Explore this link to gain a comprehensive understanding of injection molding, its applications, and benefits in manufacturing. ↩

-

Discover the advantages of high-volume manufacturing in injection molding, which can enhance production efficiency and reduce costs. ↩

-

Learn about the critical role of the pack and hold phase in ensuring high-quality injection molded products and preventing defects. ↩

-

Explore the benefits of thermoplastics in injection molding, including their versatility and ease of processing for various applications. ↩

-

Discover why design flexibility is crucial in injection molding, allowing for complex shapes and tight tolerances in manufacturing. ↩

-

Learn about blow molding’s unique advantages and applications compared to other methods like injection molding. ↩

-

Discover the benefits of rotational molding for producing large, hollow items and how it differs from other techniques. ↩