The plastic precision injection molding process offers many advantages over standard plastic injection molding manufacturing plastic parts.

It is precise, fast, and relatively easy to control. However, in order to take advantage of these advantages, it is important to design precision injection molds and using precision injection molding machines.

The first step is to create a prototype of the desired part. This will help ensure that the dimensions are accurate and that the mold will fit together properly.

Once the prototype is approved, the next step is to create the mold itself. This is usually done through computer-aided design software. This software will generate a 3D model of the mold that can then be used to create the actual injection mold.

Once the mold is created, it can be used for precision injection molding machine manufacturing plastic injection molded parts.

With the rapid development of electronics, telecommunication, medical, automotive and other industries, the requirements for high precision and high performance of injection molded parts are increasing day by day.

Precision injection molding requires that the injection molded part should not only have high dimensional accuracy, low warpage deformation, but also excellent optical properties, etc.

Injection molding is one of the most important plastic molding methods. How to improve the level of injection molding technology, produce high precision plastic products and create high value-added products, the design of the mold is an important link.

Special considerations for precision injection molding design include the following

1) In order to get the product with the desired dimensional tolerance, consider the appropriate mold dimensional tolerance and mold surface.

2)To prevent the molding shrinkage fluctuation.

3) To prevent deformation of the mold.

4)To prevent deformation of the mold.

5)To minimize the error of mold making.

6) To prevent fluctuations in mold accuracy.

7) To maintain the accuracy of the mold.

1.Proper mold dimensions and tolerances

1) The correlation between the dimensional accuracy of the product and the dimensional accuracy of the mold

Draw the product drawing, consider the mold design, mold making and molding manufacturing process.

First of all, you can seek the mold drawing size from the product drawing size. The actual size of the mold is obtained by making the mold with this mold drawing size. With this mold, we can get the molded product and get the actual size of the product. The problem is how to get the actual size within the tolerance of the drawing.

2) Appropriate shrinkage rate

As mentioned above, even in the same resin with the same pigment, the shrinkage rate varies depending on the molding conditions.

In precision molding, the degree of shrinkage variation should be small, and there should be no difference between the expected shrinkage and the actual shrinkage by half as much as possible.

The actual shrinkage rate is mainly estimated by collating the actual shrinkage rate of similar products in the past, and the actual shrinkage rate is also obtained from the experimental mold, and then corrected and designed to make the production mold.

However, it is almost impossible to estimate the shrinkage rate properly, and it is inevitable that the mold will be corrected after the trial molding. As a result, the size of the concave part will increase and the size of the convex part will decrease.

Therefore, the shrinkage rate should be set to a small value for the concave part and to a large value for the convex part. When the outer diameter of the gear becomes larger, it cannot be meshed, but when it becomes smaller, only the tooth gap becomes larger, so the shrinkage rate should be set to a small value.

2.Preventing fluctuations in molding shrinkage

Precision injection molding is based on the premise that the mold can be made to the desired size.

However, even if the mold size is certain, the actual size of the product varies depending on the actual shrinkage. Therefore, in precision injection molding, shrinkage control is very important. The shrinkage rate is governed by the suitability of the mold design and varies depending on the resin batch, and if the pigment is changed, the shrinkage rate also varies.

The control of shrinkage is difficult because of the different molding machines, the setting of molding conditions, reproducibility, and fluctuations in the action of each molding cycle, which produce fluctuations in the actual shrinkage rate, etc.

1) Main factors affecting shrinkage rate

The mold size can be obtained by adding the shrinkage rate to the product size, so the main factors of shrinkage rate need to be considered in the mold design.

The main factors that affect the shrinkage rate of molding are

(1) Plastic Resin pressure

(2) Plastic material temperature.

(3) Mold temperature.

(4) Gate cross-sectional area.

(5) Injection time.

(6) cooling time.

(7) Wall thickness of the product.

(8) Reinforcing material containing pot.

(9) Directionality.

(10) Injection speed.

These effects vary depending on the variation of resin and molding conditions.

(1) Resin pressure

Resin pressure has a great influence on the shrinkage rate. If the resin pressure is large, the shrinkage rate becomes smaller and the size of the product is larger.

Even in the same mold cavity, the resin pressure varies depending on the shape of the product, so the shrinkage rate varies.

In the case of multi-cavity mold, the resin pressure in each cavity is easy to produce differences, and as a result, the shrinkage rate of each cavity is not the same.

(2) Mold temperature

Whether it is a non-crystalline resin or a crystalline resin, if the mold temperature is high, the shrinkage rate will be larger. Precision molding should maintain the mold temperature at a specific temperature. In the mold design, we must pay attention to the cooling circuit design.

(3) Gate cross-sectional area

Generally speaking, the shrinkage rate changes when the gate cross-sectional area is changed. The shrinkage rate becomes smaller as the gate size becomes larger, which is related to the flowability of the resin.

(4) Wall thickness of the product

The thickness of the product wall also affects the yield. For non-crystalline resins, as the resin has different tendency to affect the shrinkage rate of the wall thickness, the wall thickness is large, the shrinkage rate is also large, and vice versa, the shrinkage rate becomes smaller.

For crystalline resins, it is important to uniform wall thickness. In the case of multi-cavity mold, if there is a difference in the wall thickness of the mold cavity, the shrinkage rate will also be different.

(5) Reinforcing material content

When using glass fiber reinforced resin, the more glass fiber is added, the smaller the shrinkage rate is, the shrinkage rate in the flowing direction is smaller than the transverse shrinkage rate, according to the resin its difference is larger, in order to prevent the twist flying warpage, must consider the gate shape flying fluke mouth position and the number of gates.

(6) Orientation

Although there are large differences in orientation, there is orientation for all resins. The orientation of crystalline resins is particularly large and varies due to wall thickness and molding conditions.

In addition, there is post molding shrinkage that occurs. The main factors affecting post-molding shrinkage are

a. internal stress relief

b. crystallization

c. temperature

d. humidity

2) Measures that can be taken

(1) Flow channel and gate balance

As mentioned above, shrinkage rate varies due to resin pressure. In the case of single-cavity mold with multiple gates and multi-cavity mold, gate balancing is required to fill the mold equally.

The resin flow is related to the flow resistance in the runner, so it is better to take the runner balance before taking the gate balance.

(2) Mould cavity arrangement

In order to make the setting of molding conditions easy, it is necessary to pay attention to the cavity arrangement. Since the molten resin will be tropicalized into the mold, the mold temperature distribution will be concentric circles centered on the gate in the case of general cavity arrangement.

Therefore, when choosing the cavity arrangement of multi-cavity mold, it is easy to take the balance of flow channel and also to take the concentric return arrangement centered on the gate.

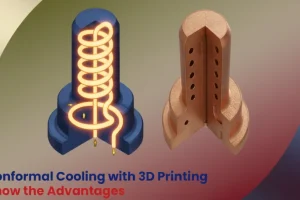

(3) Cooling circuit design for precision injection molding

As mentioned above, the mold temperature has a great influence on the shrinkage rate, at the same time, the temperature difference of each cavity of the multi-cavity mold is difficult to avoid because of different temperature changes in time, so the cooling circuit design needs to be paid attention to.

From the viewpoint of heat exchange efficiency, the flow of coolant should be turbulent, and the cooling circuit should be preferably set up as a series of folded plate type.

In the circuit design, the cavity and the core should bring out different heat, and the thermal resistance also varies depending on the circuit structure, and the inlet water temperature in the cavity and the core produces a large difference.

Therefore, the cooling circuit of precision molding molds is designed separately for cavities and cores, and the temperature control is carried out by separate temperature regulators.

3.Prevention of molding deformation

Molding distortion arises because there is internal stress under uneven shrinkage, so it is necessary to prevent uneven shrinkage.

(1) Number of gates

In the case of a round product with a hole in the center of the gear, a gate must be set in the center. However, when there is a large difference in shrinkage between the flow direction of resin and the vertical direction, there is a disadvantage of oval shape. However, it is necessary to pay sufficient attention to the balance of each gate.

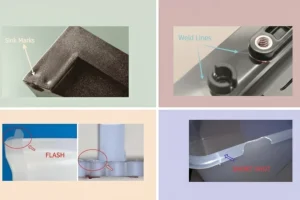

When using side gates, 3-point gates will increase the inner diameter of cylindrical products. In the case where gate marks are not allowed on the exterior and end surfaces, good results can be obtained by using less inner multi-point uniform gates.

(2) Gate shape and position

It is necessary to choose a suitable shape of gate according to the shape of the product. The figure shows the influence of gate shape and position on deformation.

4. Preventing deformation caused by mold release

Precision products are generally small, the product wall thickness is thin, and some of them have many thin tendons. The design of the chess set must be considered so that the products are not deformed and can be properly released.

For resins with low shrinkage, when the molding pressure is high, it is necessary to pay attention to the products that tend to stay in the mold cavity. When molding gears with low shrinkage resins, it is best to design the gear cavity on the ejector side of the mold.

When using ejector pins, attention should be paid to the number of pins without deformation and the position of ejector pressure. In the case of perforated gears, core pins are required on the ejector side of the die plate to facilitate parallel ejection during ejection.

For angular products, it is possible to use a perforated template for ejecting, which prevents deformation.

Generally, the slope of the ejector die is small for precision products. In order to reduce the release force, but need to mirror processing, the grinding direction must be the direction of die pulling. It is necessary to set up easy to grind chunk cores according to the direction of mold extraction.

5. Minimum mold making error

(1) Appropriate mold construction according to the desired processing method

In order to get the size of the product with the required accuracy, it is necessary to have the appropriate mold size, and the mold needs to be machined with extremely high precision and is limited by the finishing machinery.

In order to maintain the accuracy of the mold, it is necessary to have high wear resistance, for which hardening is required. The accuracy of hardened molds can be within 0.01 mm with grinding machines and EDM machines.

When using EDM machine tool tong die processing, it must be noted that the electrode end wear becomes larger. The cavity for gears and the wire EDM machine should be designed as much as possible to be able to go through the structure of processing.

From the point of view of preventing grinding deformation and shortening the processing time, the steel with less quenching deformation should be selected, and the shape should be designed for less quenching deformation. When the shape is complex, the cooling of the haggard fire is not easy to be uniform, and it is easy to produce quenching deformation.

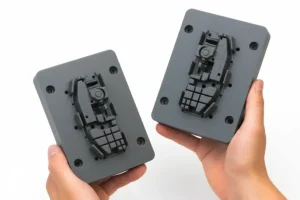

(2) Total split type die

In order to process the quenched parts into higher precision, grinders are used. Therefore, it is necessary to use inserts to form a split type mold. This mold has the following characteristics:

(1) It is able to use the appropriate hardness mold material because the appropriate material can be selected.

(2) It is possible to use mold materials with high corrosion resistance and wear resistance.

(3) It is easy to set the heat treatment condition because it can be heat treated separately.

(4) It is possible to use mold materials with good mirror finish and easy mirror finish operation, so it is possible to improve the mirror finish.

(5) Since it is easy to grind in the drawing direction, it is advantageous to use a mold with a small drawing slope.

(6)Because of hardening, it can extend the mold accuracy keeping time and the mold life is long.

(7)It is easy to set the exhaust at any position, so it is easy to fill the mold.

(8)Easy to grind and process.

(9)It can improve the precision of mold parts, so it may improve the precision of products.

(10)It is possible to make cavities and cores within small tolerances, so the interchangeability of parts is high and maintenance is easy.

(11)High processing efficiency because of grinding processing as the main part.

(12) The number of mold components are large, and the machining accuracy of each part needs to be greatly improved.

(13)Limited to specific machining methods

(14)Adopting complete hardening

(3) Points to note in the design of total split type mold

The accuracy of the relationship and the accuracy of each part must be determined by the inverse operation of the accuracy of the product to be produced.

Because the more the number of divisions, the greater the product error, the more to improve processing accuracy, so the number of divisions to be set at a minimum.

Generally, it is forbidden to set up parting lines on the surface of the product, which is not only disgusting in appearance, but also will become an obstacle in function. If there is a parting line at the place where stress is generated, it often causes damage due to stress concentration.

Because grinding is easy to get uniform size parts, it should be divided into shapes that can be processed with abrasives.

Fragile and breakable parts should be divided into easily replaceable ones, and high wear resistance alloy should be considered.

In addition, easy assembly and disassembly should be considered. Each part of the cavity and core must be assembled with a mechanism that can easily and correctly recover accuracy, and if they are mounted separately on the base, the cavity and core must be concentric. In the case of using mounting pins, the pin holes must be properly ground.

6. Preventing errors in mold accuracy

To ensure the positioning of sliding parts in each cycle, it is necessary to prevent the fluctuation of mold accuracy. In order to maintain the accuracy of the sliding parts, the sliding parts should be haggardly ground. The sliding part of the side core should be positioned and withdrawn, and when the size of the side core is large, the middle part can have a narrow guide slot.

7. Maintenance of mold accuracy

(1) Ensure the center of the cavity and the core are the same

In order to always close the mold correctly, it must be designed so that the two plates can be positioned correctly.

(2) Preventing mold deformation

In order to avoid mold deformation caused by resin pressure on the cavity, the strength of the tooling must be large enough.

Pillars are often added in the middle of the core plate, and high-strength steel is used for the material of the pins, and the pins that are easily bent are located close to the gate, and the resin flow pressure acting on the pins is also reduced.

(3) Prevent aging changes

Mold to quench and temper treatment, if there is residual austenite, will produce aging changes, resulting in changes in mold dimensional accuracy, so then make the temperature of residual austenite decomposition tempering, and children to use cold treatment.

In order to prevent changes due to wear, the hardness needs to be increased, and the use of steel grades with minimal dimensional changes due to hardening and tempering should also be considered.

Compared with tool cutting, grinding is required to minimize the amount of grinding in order to shorten the processing time because of poor processing efficiency. Both the shape of the part to be set to reduce the hardening deformation and the material that can reduce the deformation should be selected.