What is clamping force in injection molding?

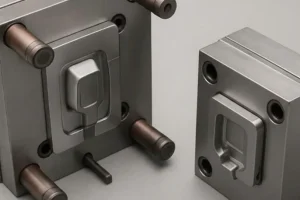

Clamping force is the force applied to the mold by the injection molding machine to keep the mold closed during the injection and curing process.

It is critical to ensure that the clamping force calculation is sufficient to prevent the mold from opening and allowing the plastic to leak out.

How important calculate the clamping force in injection molding?

Calculating the clamping force in injection molding is an important step in the design and optimization of the injection molding process.

Also is an important step in the design of a mold and selecting the injection molding machine.

It is a key parameter that affects the success of the molding process and must be carefully calculated and controlled to produce high-quality parts with consistent dimensional accuracy.

What factors can affect the clamping force required in injection molding?

Several factors can affect the clamping force required in injection molding, including:

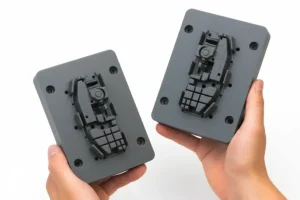

1. The size and complexity of the part being molded.

2. The material being used.

3. The injection molding machine itself.

In general, larger and more complex parts require higher clamping forces to prevent the mold from opening and leaking.

Similarly, harder and stiffer materials require higher clamping unit forces than softer and more flexible materials.

The size and complexity of the part being molded

The most important of these factors is the size and complexity of the part being molded. Larger and more complex parts require more required clamping force to hold the mold closed and prevent warpage or distortion during the injection molding process.

The material being used

Another factor that influences the maximum clamping force is the type of plastic material being used.

Harder and stiffer materials, such as polycarbonate or polyphenylene oxide, require more too big clamping force to prevent the mold from opening under the cavity pressure inside of the injection molding process.

Softer and more flexible materials, such as polyethylene or polypropylene, require less clamping force.

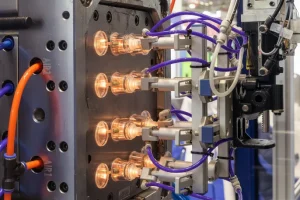

The injection molding machine itself

The injection molding machine itself also plays a role in determining the clamping force required.

Different types of injection molding machines have different clamping forces, which determine the maximum force that can be applied to the mold.

For example, a machine with a clamping force of 100 tons can apply a maximum injection pressure of 100 tons to the mold.

In general, larger and more powerful injection molding machines have higher clamping forces than smaller and less powerful machines.

How to calculate the clamping force in injection molding?

1. Open the 3D drawing of the product with ProE or UG software to determine the direction of product release.

2. Next, calculate the projected area. For simple products, we can directly measure the projected area. Here we measure the projected area as 52794.8 square millimeters.

3. For complex products, we can enter the sketch, draw a plane similar to the product, and then stretch it into a solid.

4. Then we measure the projected area of the stretched entity, and the measured projected area here is 55625.6 square millimeters.

5. Next, let’s determine the number of cavities, where the number of cavities is 2.

6. Next, let’s calculate the minimum clamping force of the mold.

The minimum clamping force of the injection mold is F=S (inch square) X 2.50 (simplification factor, considering the projected area of the runner).

Here S=52794.8/25.4/25.4*2=164 inches square, F=164*2.5=410 Ton.

7. The minimum clamping force is not equal to the design clamping force.

Generally, the design clamping force is a little larger than the minimum clamping force.

Design clamping force = minimum clamping force/0.9=410/0.9=456Ton.