Plastic injection molding is a highly efficient manufacturing process that offers rapid production, cost savings, and design flexibility, making it a preferred choice for various industries.

The benefits of plastic injection molding include high production speed, reduced material waste, and the ability to create complex geometries. This method is widely used in automotive, consumer products, and medical industries due to its cost-effectiveness and precision. Additional advantages include consistent part quality and the possibility of using multiple materials in a single process.

This overview highlights the key benefits of plastic injection molding, but a deeper understanding of its processes and applications can further enhance your production efficiency. Delve into the specifics to see how injection molding can transform your manufacturing capabilities.

Plastic injection molding offers faster production times compared to other methods.True

The injection molding process allows for rapid cycle times, enabling manufacturers to produce large volumes of parts quickly.

All plastic injection molding processes are environmentally harmful.False

While traditional methods may generate waste, advancements in technology and the use of recycled materials in injection molding can significantly reduce environmental impact.

What is Plastic Molding?

Plastic molding is a manufacturing process that shapes plastic materials into various forms by using molds. It’s widely used in the automotive, electronics, and medical industries due to its versatility, efficiency, and ability to create precise, durable parts. Key advantages include flexibility in design, cost-effectiveness for high volumes, and the ability to create complex shapes.

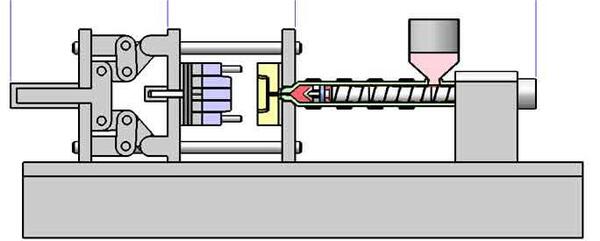

Thermoplastic injection molding1 is a standard process that uses a molding equipment that fills a mold with a polymer melt The injection molding machine allows injection pressure and speed 2, wall thickness,quality control and small errors, so the product is usually ready to ship immediately after production.

Plastic pellets are loaded into a barrel, where they are melted, squeezed and shot into the mold cavity 3. The hot material cools and solidifies in the mold to form a molded part. Injection molding technology means that the ejector finally ejects the part from the mold and the part falls into a bin. Once the run is complete, the parts (or master batch) are immediately boxed and shipped.

What are the Plastic Materials Used for Plastic Molding?

Common plastic materials used in molding include polypropylene, ABS, and polyethylene, each offering unique properties for different applications. Polypropylene is known for its flexibility and chemical resistance, while ABS provides strength and impact resistance. Polyethylene, in its various forms, is widely used due to its durability and cost-effectiveness. Choosing the right material is crucial for achieving optimal performance and quality in the final product.

When it comes to injection molding, we use thermoplastic polymers. These are plastics that can be melted and softened by heating and then solidified by cooling. It’s important to know which type of thermoplastic material to use depending on what you’re making. We use materials like polyethylene, polycarbonate4, nylon, polypropylene, and high-impact polystyrene. Picking the right material for your project can make it work better and cost less.

Polypropylene (PP)

PP, or polypropylene, is a versatile thermoplastic that’s used in injection molding. It’s lightweight, resistant to chemicals, and can withstand a lot of wear and tear. That’s why it’s so popular for making things like packaging, containers, and car parts.

Polystyrene (PS)

Polystyrene (PS) is clear, hard, and cheap. PS is often used in throwaway stuff like packaging, food containers, and throwaway cutlery, and is liked for how easy it is to shape and how cheap it is.

Nylon (PA 6)

Nylon, especially nylon 6 or PA 6, is known for being strong, tough, and resistant to wear. It’s great for making mechanical parts and is used a lot in things like gears, bearings, and other parts that need to be made in large quantities, last a long time, and be made very precisely.

Polycarbonate (PC)

PC, or polycarbonate, is known for being see-through, tough, and able to handle high heat. That’s why it’s used to make things like eyeglass lenses, electronic parts, and clear stuff that doesn’t break in lots of different industries.

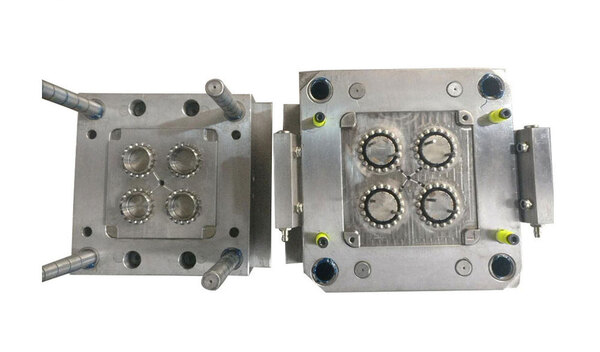

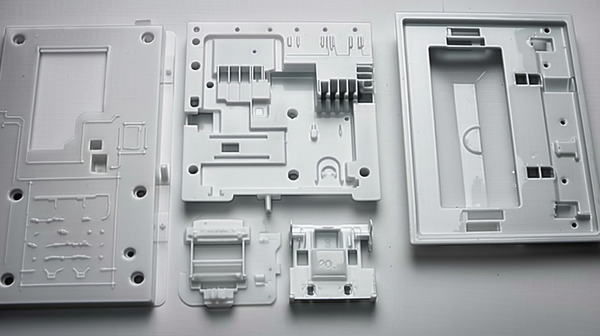

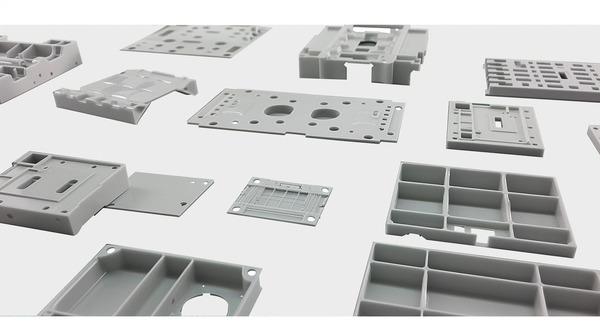

What is Plastic Injection Mold for Plastic Injection Molding ?

They usually have two parts: one part is fixed to the table of the casting machine, and the other part is removable, from which you can take out the finished product.

If the part is big, there will be one cavity for the part. But if the part is small, the mold will have several or even ten or more cavities. This increases the efficiency of the whole process. Depending on the number of cavities, the mold can have different numbers and lengths of runners to distribute the plastic.

What are the Characteristics of Plastic Injection Molding Process?

The plastic injection molding process involves melting plastic pellets and injecting them into a mold to form desired shapes. It offers high efficiency, consistency, and versatility, making it ideal for producing everything from medical devices to automotive components. Key benefits include low scrap rates, fast production times, and excellent dimensional accuracy.

To make sure the injection molding process goes well and the final product is good, you need to get the right stuff happening at each injection molding cycle5

One important thing in the plastic injection molding process is the cycle time. That is, the time the plastic stays in the mold while it cools down under high pressure. It’s usually a few seconds to about twenty seconds. In most cases, this time depends on the type of material and the size and weight of the product.

If you don’t press long enough, the surface of your product will cave in or otherwise get messed up. If you press too long, you won’t get any benefit. If you press too long, you’ll over-seal the material and make it hard to get your product out of the mold.

What are the Advantages of Injection Molding?

Injection molding offers high precision, cost-effectiveness, and scalability, making it ideal for mass production. Key benefits include minimal material waste, fast production cycles, and the ability to produce complex shapes with consistent quality. This process also supports a wide range of materials, further enhancing its versatility in manufacturing.

Injection Molding is Efficient and Fast Manufacturing Processes

One of the big pluses of injection molding is how fast and efficient it is. Once you’ve got the mold made and the injection molding machine set up, you can make a whole bunch of parts in a short amount of time. and less unused or waste plastic , This is great for industries that need a lot of the same thing.

The speed of injection molding is because it’s automated. Robots and automation are a big part of that, because they can do the same thing over and over again, 24/7. This is great for industries like automotive and packaging, where time is money.

Injection Molding is Efficient and Fast

Most injection molded parts have a smooth surface finish6 that is close to the desired final appearance. However, a smooth appearance is not suitable for all applications.

Depending on the physical and chemical properties of the plastic material used, the plastic injection molding manufacturing process creates a surface finish that does not require secondary operations. The process provides flexibility in surface treatments, from matte surfaces and unique textures to engraving.

Versatility of Injection Molding Materials

Injection molding is like a chameleon – it can adapt to a wide variety of materials. From thermoplastics and engineered materials to resins and even silicones, the possibilities are vast. This versatility is another big benefit of injection molding.

Different materials have different properties, and being able to pick the right material for a specific application is important. Whether you need a part with more strength, a specific surface finish, or resistance to certain conditions, injection molding has what you need. It\’s like having a Swiss Army knife in your manufacturing toolkit!

Injection Molding Offers a Variety of Surfaces

Most injection molded parts have a smooth surface finish that is close to the desired final appearance. However, a smooth appearance is not suitable for all applications.

Depending on the physical and chemical properties of the plastic material used, the plastic injection molding manufacturing process creates a surface finish that does not require secondary operations.

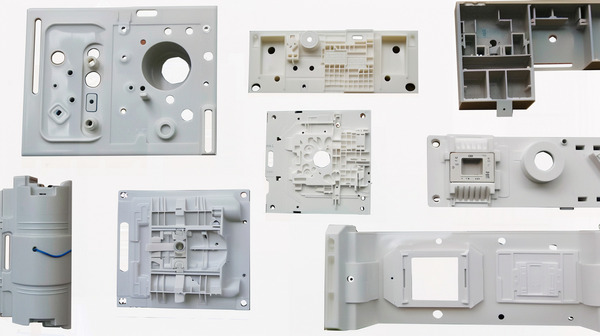

Injection Molding Creates Lightweight Products

OEMs use lightweight plastic injection molded products in many industries, but they are most prevalent in the automotive industry. Using plastic parts helps reduce weight compared to using metal parts. Today, high-strength, lightweight thermoplastics can replace metal parts with little difference in strength or durability, just weight.

Injection Molding Has Consistency Production Process

To make a lot of complicated plastic parts, you need a process that can make the same part over and over again, and make it the same every time. That’s what injection molding does. It uses the same mold to make the same part over and over again.

The injection molding production process helps ensure consistent quality because the same mold is used consistently for each part and is backed by the injection molder\’s continuous improvement practices that incorporate current leading-edge technology.

Injection Molding Creates Precision Products

When you have modern, high-speed injection molds 7equipment that is properly maintained, you can mass produce precision molded plastic parts. This is the best way to make plastic parts like connectors and gears that need to be made with high precision. You can make them with tolerances as close as +/- 0.0002 inches.

Injection Molding Reduces Product Development Time

Injection mold engineers with diverse skill sets can help OEMs achieve shorter product development times. This ensures faster production cycles and brings defect-free parts to market faster, which is a decisive competitive advantage for manufacturers.

Injection Molding Offers Complex Part Designs

Injection molding is great for making complex parts, keeping things consistent, and making a million parts that are all the same. To make a lot of parts and make them right, you need to think about some important stuff.

Designing parts to maximize the efficiencies inherent in high-volume molding is key. With an ideal design, you can make parts that are high quality without sacrificing complexity.

Injection Molding for Greater Strength

Plastics have gotten way stronger and tougher over the years. Nowadays, lightweight thermoplastics can take a beating just as good as metal parts, and sometimes even better.

Plus, there are over 25,000 engineering materials available for complex injection molding applications. You can also make high-performance plastic blends and hybrids to meet specific part requirements and characteristics, like high tensile strength.

Precision and Accuracy in Injection Molding

Injection molding is all about precision and accuracy. It can make parts with complex shapes and tight tolerances. It’s like a master sculptor who can carve out the tiniest details with perfect precision. This is especially important in industries like automotive and medical, where even the smallest deviations can have big consequences.

The precision of injection molding depends on the mold and the controlled injection molding process. The mold is made to the exact shape of the final part, and the molten plastic is injected under high pressure, making sure every corner is filled. The result? Parts that are both precise and beautiful.

The Repeatability Factor in Injection Molding

Another good thing about injection molding is that you can make the same part over and over again. Once you make the mold and set up the machine, you can make the same part again and again. It’s like a machine that just keeps on going and going. It makes the same part every time with very little difference. This is really important in some industries.

If you’re making millions of bottle caps or car parts, you want each one to be almost exactly the same. It’s hard to do that with other kinds of manufacturing, so injection molding is the best way to go.

Cost Benefits of Injection Molding

Let’s talk money, shall we? Injection molding is a cost-effective way to make plastic parts, especially in high volumes. The initial cost to make a mold can be high, but once you have the mold, the cost per part is very low. It’s like buying in bulk – the more you make, the cheaper each part becomes.

Also, because injection molding is an automated process, labor costs and overhead are low. With robotics and automation, the process can run 24/7 with little human intervention. This cost-effectiveness is a big advantage of injection molding, making it a good choice for companies that want to balance quality and cost.

Flexibility in Injection Molding Design

Design flexibility is another feature of injection molding caps. The process can produce parts with complex geometries, undercuts, and intricate shapes that are difficult, if not impossible, to achieve with other manufacturing methods.

What are the Applications of Plastic Injection Molding?

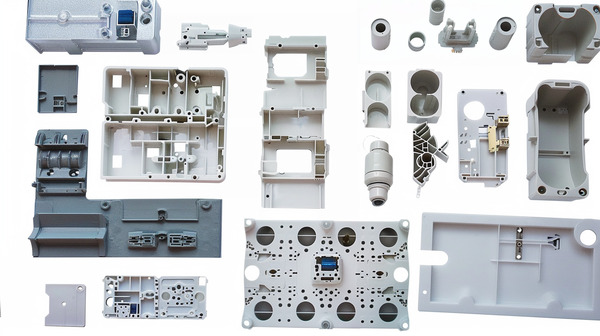

Plastic injection molding is widely used in automotive, electronics, medical devices, and consumer goods manufacturing. It enables high-volume production with precise detailing and minimal waste, making it ideal for creating complex parts quickly and reliably. Key applications include automotive dashboards, medical syringes, and electronic housings.

Plastic parts are everywhere. They’re cheap, strong, chemically stable, wear-resistant, insulating, and thermally conductive. That’s why injection molding is used in so many industries. Here are some examples.

Automotive Industry

They make parts for cars and machines by injecting plastic into molds. The industry uses these plastic parts for a number of reasons. One of the main reasons is that they last a long time. They don’t wear out or break down and they usually last a long time.

Also, plastics are lightweight compared to other materials. This weight helps increase the fuel efficiency of cars because the heavier the car, the more fuel it consumes.

Also, plastic parts can resist UV exposure and corrosion, which makes them ideal for the production of automotive parts like radio controls, cup holders, bumpers, and dashboards.

Medical Industry

The medical industry loves injection molded plastic parts. They need a lot of them, and they need them to be perfect. They also love making a lot of them because most of the plastic stuff they make is disposable, which helps keep diseases and bacteria from spreading because they’re sterile.

Also, stuff made in this industry using injection molding include disposable plastic syringes and IV connectors. Other cool stuff include biocompatible things like prosthetics and dental implants, as well as handles and triggers that can be sterilized. Oh, and common medical-grade plastics include silicone, polypropylene, polyethylene, and ABS.

Electronics

Plastics don’t conduct electricity, but they’re still used in the electronics industry. They use injection molding to make electrical panels and other electronic devices.

Also, the plastics manufacturers use in the electronics industry are usually really good at not conducting electricity and being tough. Injection molding is used to make remote controls, computers, medical instruments, TVs, key fobs, and more.

Agricultural Products

Agriculture still needs injection molded parts. The industry uses plastic injection molding products that are tough and can handle different weather conditions.

Also, injection molded parts have a lot of benefits for the industry. One of the biggest is that they don’t corrode. This is a big deal for farms. Unlike metals, plastics don’t corrode from things like rain. They’re also lightweight, which means they’re tough and they don’t cost a lot to make for agriculture.

Household Products

Most of the consumer products that you find in your home are packaged using injection molding. But why do manufacturers use this process? Because plastic products made using the injection molding process are usually very strong. Another reason is that they can handle different temperatures and weather. They can also be recycled, which helps manufacturers save money on making new products.

Also, injection molding is used to make household plastic products like bottle caps, toilet seats, outdoor furniture, drinkware, barbecue accessories, and more. Injection molding is also used to make long-lasting, colorful, and easy-to-clean household items like children’s toys.

Consumer Goods

The consumer goods industry also uses injection molding to make parts. For example, they make plastic bird feeders and skateboard storage racks that are really strong. Other consumer products made using injection molding include; mobile phone cases, baking trays, game controllers, USB drive housings, etc.

Conclusion

Plastic stuff is used in a lot of industries, like home appliances, medical devices, car parts, and more. That’s why plastic injection molding is a popular technology in a lot of different fields.

Here are some of the injection molding advantages: It’s fast and efficient, It can make a lot of different surfaces, You can use a lot of different materials with it, It makes lightweight stuff, It’s consistent, It can make really precise stuff, It speeds up product development, It can make really complicated parts, It’s strong, It’s precise, It’s repeatable, It’s cheap, You can design a lot of different things with it.

-

Learn about Thermoplastic Injection Molding: Definition, Process & Materials: Thermoplastic injection molding offers a versatile and efficient method for mass-producing plastic parts. ↩

-

Learn about Understanding Injection Speed And Injection Pressure: the set injection speed refers to the screw’s forward speed ….. ↩

-

Learn about Mold Core & Mold Cavity: Differences And Design Consideration: The mold cavity is primarily responsible for forming the product’s internal shape and structure. ↩

-

Learn about Polycarbonate Injection Molding: The Basics: Polycarbonate injection molding refers to the process of injecting melted polycarbonate into a mold at high pressure …… ↩

-

Learn about Injection Molding Cycle: What Are the Stages : The injection molding process consists of specific production cycles that make use of different injection molding components to receive adequate products. ↩

-

Learn about Plastic Injection Molding Surface Finish Options: Making the Right Choice : One of the most significant advantages of injection molding is the natural surface finish of molded parts. ↩

-

Learn about High Speed Injection Molding Machines: Everything You Need to Know : High-speed injection molding machine is a kind of injection molding equipment specially used for rapid production of plastic products. ↩