Injection molding machines are essential equipment in the automotive industry for manufacturing plastic parts. These machines have revolutionized production processes, making them more efficient and cost-effective.

Introduction

Injection molding is a very common plastic manufacturing method. It works as follows: First, the plastic is heated until it becomes molten. The liquid plastic is then pushed into the mold under high pressure. After cooling in the mold, the material hardens again. The machine that does this job is called an injection molding machine, and they are often used in industry to make various products from plastics, especially in the automotive industry. In terms of the production of automotive parts, the demand for injection molded parts has been increasing. The main factors contributing to this growth include the characteristics of automotive injection molding parts such as light weight, rust resistance and easy molding, and because they can significantly reduce the weight of the whole vehicle and improve fuel efficiency. This article explores the application of injection molding machines in the production of automotive plastic parts, including its advantages, process flow, equipment selection, quality control and future trends.

Basic Principles and Construction of Injection Molding Machines

Working Principle of Injection Molding Machines

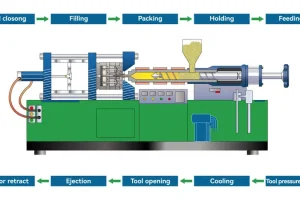

Injection molding machines complete the injection molding process through several steps:

1. Plastic Melting: Polymeric or plastic granules (often in the form of pellets or powder) are placed in the feeding chamber, then through a heating system the granules are melted.

2. Injection: High pressure melt is forced into the mold cavity with the help of a screw or a plunger.

3. Packing and Cooling: High pressure is maintained to ensure the plastic fills the entire mold cavity, while a cooling system cools the mold to solidify the plastic.

4. Mold Opening and Product Ejection: The mold opens, and the molded plastic product is ejected.

Main Components of Injection Molding Machines

Injection molding machines consist of the following main parts:

1. Injection Unit: Encompasses the hopper, heater, screw or plunger, etc. used to melt the plastic and to inject the same.

2. Clamping Unit: Primarily employed for opening and closing of the mold and usually consists of fixed and moving dies as well as clamping means.

3. Hydraulic System: Supports motion for something like clamping, injecting, packing, and ejecting.

4. Control System: Operates and supervises a number of aspects of the injection molding machine using computer or control keypad.

Injection Molding Process Flow

Mold Design and Manufacturing

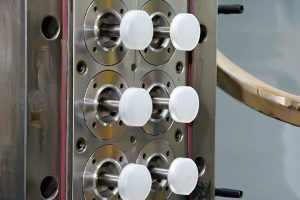

Designing the mold is an essential part of injection molding and has a direct effect on how good the final product will be. When designing a mold, engineers think about things like:

1. Product Design: Based on the design requirements of automotive plastic components, the mold structure and dimensions are determined.

2. Material Selection: Suitable mold materials, typically steel or aluminum alloys, are chosen to ensure durability and precision.

3. Machining Precision: High machining precision is required for molds, typically achieved using CNC machines.

Plastic Injection Molding Process

These are the steps involved in injection molding:

1. Material Preparation: Dry plastic material so that its moisture content falls within acceptable levels.

2. Heating and Melting: Add plastic granules to machine hopper, use heating system melt them down.

3. Injection Molding: Molten plastic is injected into the mold cavity using a screw or plunger.

4. Packing and Cooling: Injection cooled liquid plastic through entire cavity for uniformity at high pressures while cooling both product and mold itself.

5. Mold Opening and Part Removal: The mold opens, and the molded plastic product is ejected.

Quality Control

During injection molding, it is important to have quality control. Some common methods for controlling quality are:

1. Mold Temperature Control: This controls how hot or cold the mold is so that products made from plastic will be the right size and shape with a good surface finish.

2. Injection Parameter Control: Regulating things like pressure or speed at which material is forced into mold; how long each “shot” lasts (among other factors) all help maintain control over quality levels.

3. Inspection Equipment: Using various devices there are checks aplenty one can perform on molded parts including dimensional checks, seeing whether surfaces look rough/defective plus testing things like strength and flexibility.

Application of Injection Molding Machines in Automotive Manufacturing

Types of Automotive Plastic Components

In automotive manufacturing, there is a wide variety of plastic components, including:

1. Interior Components: Interior Components like dashboards, center consoles and door panels must look good, feel good to the touch, be strong enough to withstand wear and tear, and stand up to heat. Plastics make it possible to give them complex shapes and different finishes, enhancing interior aesthetics.

2. Exterior Components: Examples include bumpers, grilles and headlight covers. These parts need to withstand knocks well as harsh weather conditions. Exterior components not only need to be visually appealing but also functional, such as improving aerodynamics and protecting the vehicle body.

3. Functional Components: Fuel tanks, radiator tanks, air conditioning ducts, and more fall into this category. To function effectively, these parts need to be strong, corrosion-resistant, and heat-resistant. Injection molding is up to the job. Indeed, not only can it meet all necessary safety standards for automotive use – producing lightweight items too boot.

4. Structural Components: Items like the frames of vehicles and components of their chassis. Both must be very strong and rigid. Plastic structural components are often used in combination with metal components to reduce weight while ensuring strength.

Advantages of Injection Molding Process in Automotive Manufacturing

The injection molding process offers several advantages in automotive manufacturing:

1. High Production Efficiency: Injection molding has short cycles for molding which makes it perfect for mass production needs in automotive manufacturing—it can quickly produce what you need. When compared with old-style methods that used metals only or mostly there is also an added bonus: increases capacity.

2. Excellent Product Quality: Injection molded products possess precise dimensions and smooth finishes. By fine-tuning mold production and control parameters, we can create high-quality surfaces on even the most intricate plastic parts structures.

3. Strong Design Flexibility: Diverse shapes and intricate structures of plastic parts can be created by altering molds to meet a range of automotive design needs. By taking advantage of plastics properties, designers can use innovation to improve both the look and functionality of vehicles.

4. High Material Utilization: Injection molding produces very little waste material which helps cut down on costs and environmental pollution. Additionally, any scrap materials can be recycled, aligning with environmental and sustainable development requirements.

Successful Cases of Injection Molding Machines in Automotive Industry

Production of Automotive Interior Components

Nowadays, car insides need to look good and work well. Injection molding can make this happen, it’s how lots of high-quality interior car parts like dashboards, center consoles and door panels are produced. Here are a few things made this way:

1. Dashboards: Injection molding gives dashboards a sleek look, robustness and resistance to heat – plus integration that cuts parts and steps, making the production line move faster. Mercedes-Benz uses this technology for the dashboards on some of its most luxurious cars, helping interiors convey quality and style. It also means these dashboards can have curves and textures put on them as they are made, improving both aesthetics and functionality like touch-screen use.

2. Center Consoles: An essential part of any vehicle, center consoles not only need to look good but also must function well too. This is why many car makers rely on injection molding to create these complex controls that can do everything from opening armrest compartments to displaying radio information. Take Tesla as an example: using this technique they produce multi-functional integrated units for their electric cars which improve user experience compared with traditional designs. The injection molding process for center consoles allows for the combination of various materials, such as hard plastics and soft touch materials, ensuring structural strength while enhancing touch and aesthetics.

3. Door Panels: Door panels need to look good and be durable and mechanically strong. With injection molding, door panels can have all these qualities in one piece, making car assembly quicker and more efficient. Toyota uses this process for many models, which don’t just look better when they’re done but take less time to make overall.That’s because each panel made via injection molding can do lots of things at once: hold a speaker at the same time as a storage compartment and the controls for windows and mirrors (plus other functions).

4. Seat Components: Injection molding can be utilized to create multiple components for vehicle seats, think seat adjustment handles, backrests, seat frames, all of which need to be durable, strong and somewhat comfortable with a hint of flexibility too.This manufacturing process also allows for surface treatments in a range of textures and colors, complex shapes are possible as well. For example, some BMW models use injection molded seat frames, ensuring seat strength while reducing weight and enhancing vehicle fuel economy.

5. Armrests and Storage Boxes: Armrests and storage boxes found in cars are made using the process of injection molding. These parts need to be strong, look good and feel nice to the touch. Injection molding delivers all this because it can create things with complex designs that are one piece, so there is less putting together to do, making them tougher as well as better-looking than would otherwise be possible. For example, Audi’s armrests and storage boxes use injection molding technology, enhancing the overall interior feel and user experience.

Production of Automotive Exterior Parts

Automotive exterior parts must meet strict standards for both aesthetics and durability. For example, bumpers, headlamp housings, grilles. All parts that Injection molding technology can make beautifully and tough enough for car makers’ needs. Here are some cases in point:

1. Bumpers: Bumpers serve as external protection devices for vehicles, requiring good impact resistance. One way of making them both strong and light is through a process called injection molding. BMW has been using this technology for many years on over 3 million cars so far, it helps make their vehicles safer as well as better-looking. This process allows for complex design shapes and the use of composite materials like polypropylene and reinforced fiberglass, improving impact resistance while reducing weight.

2. Headlamp Housings: Good transparency and weather resistance are necessary features of headlamp housings. These attributes can be achieved through injection molding, a technique commonly employed in the manufacture of headlight casings for Audi vehicles. As well as being weather-resistant and transparent, this process offers design advantages such as the ability to produce uniform light distribution with precise optical qualities; it also enables different colours and surface treatments – thereby further enhancing not only their functionality but also overall look when fitted onto cars’ front ends.

3. Grilles: Grilles play a crucial role in enhancing the look and resilience of a car’s front end. Injection molding is perfect for making them because it can create intricate shapes while also providing a high-quality finish. High-end Lexus vehicles illustrate this best: their grilles not only help make the cars look good; they also set them apart from other models. Indeed, designers can use the process to establish multi-level patterns with fine grid work that adds even more individuality, something which helps boost brand recognition along with overall appearance values.

4. Wheel Arch Covers: Wheel arch covers are another part that needs to look good and stand up to wear. Injection molding can make these with both high quality and lots of style, for example by adding chrome plating, electroplating or painting the surface. This is why some car makers like Ford use it to give an attractive finish to models as well as making them last longer; in fact they believe has helped improve appearance while also increasing longevity of things such as wheel arch covers on their vehicles overall.

5. Door Handles: A combination of strength, durability and tactile qualities is crucial for door handles. Injection moulding can be used to meet these criteria and produce high-quality products. One of the main benefits of the process is that it enables the manufacture of components with integrated design features: this means fewer joints are required, which can both improve reliability and make the product more aesthetically pleasing. Nissan fits injection-moulded door handles to some of its models, improving both the appearance and user experience.

6. Mirror Housings: Mirror housings need to be weatherproof and strong enough to withstand impacts. Injection moulding can be used to make mirror housings of excellent quality – even if they have complicated designs – and give them finishes such as paint or chrome effect plating so cars look better overall. For example, Volvo uses injection-molded mirror housings in some models, improving appearance, durability, and safety.

7. Sunroof Frames: In order to be both strong and long-lasting, sunroof frames need to be made just right. Injection molding is up to the job. This process can create high-quality frames with complex shapes if necessary, and they will have the exact dimensions needed for a perfect fit. For example, some Hyundai models use injection-molded sunroof frames, enhancing overall sunroof performance and vehicle luxury.

Production of Automotive Functional Components

Automotive functional components include items like fuel tanks, radiator reservoirs, and air conditioning ducts, which require high mechanical strength, corrosion resistance, and heat resistance. Examples include:

1. Fuel Tanks: Fuel tanks require good corrosion resistance and mechanical strength. Injection molding can produce high-quality tanks meeting these requirements. For instance, Volkswagen uses injection-molded fuel tanks in some models, enhancing durability and fuel efficiency.

2. Radiator Reservoirs: Cooling System TanksCooling system tanks must possess strong heat resistance along with excellent thermal conductivity. One way to manufacture tanks like these is through injection molding. Chevrolet takes advantage of this technology by using it to make radiator reservoirs for some models, helping ensure the parts are durable and work efficiently at removing heat from the engine bay.

3. Air Conditioning Ducts: Air conditioning ducts require good pressure resistance and corrosion resistance. Ducts made via injection molding can fulfill both criteria exceptionally well. For instance, Toyota uses injection-molded air conditioning ducts in some models, enhancing air conditioning system performance and durability.

Production of Automotive Structural Components

Automotive structural components include items like body frames and chassis components, requiring high mechanical strength and rigidity. Examples include:

1. Body Frames: To meet the high strength and good impact resistance needed for body frames, injection molding is used. Ford, for instance, employs this process with certain models, helping make its cars safer while also boosting overall robustness.

2. Chassis Components: It’s important for frame components to be able to resist wear and tear and be mechanically strong. Injection molding technique is a great way of making components like these that are high quality. BMW fits some models with injection-molded frame parts because they meet these criteria exactly.

Production of Other Automotive Components

Apart from the main interior, exterior, functional, and structural components, injection molding is widely used for various other automotive parts production, such as:

1. Battery Boxes: Battery boxes for EVs require excellent thermal insulation performance and high strength. Injection molding enables efficient manufacturing processes as well as complex internal structure designs that help guarantee stable performance and safety of batteries.

2. Engine Hood Liners: Engine hood liners require good heat resistance and resistance to chemical corrosion. Injection molding can produce lightweight, high-strength liner components, protecting the engine and improving overall vehicle performance.

3. Air Deflectors: To perform well, air deflectors need both high temperature resistance and an effective aerodynamic design. Injection molding enables complex shape designs and optimized airflow effects, enhancing vehicle fuel economy and driving stability.

4. Roof Racks: Roof racks need to be lightweight, strong and corrosion-resistant. Injection moulding can create racks that meet these requirements well. This improves vehicle usefulness and appearance.

5. Interior Detail Parts: Interior parts such as air vents for AC units, door handles and buttons for dashboards need to feel good to the touch and be tough. Injection moulding allows for the production of complex shapes and the use of different plastic materials at the same time. This makes interiors nicer overall, and adds to quality perceptions among users too.

Conclusion

It is very important to use injection molding machines to manufacture plastic injection molding automotive parts. These machines are essential in the field of automotive manufacturing because they can work quickly, produce high-quality products, and can be designed to do many different things. With the development of science and technology and changes in market demand, injection molding machines will continue to develop in the direction of intelligence, energy saving and environmental protection, multi-function, high speed and high efficiency, bringing more innovations and breakthroughs to the automotive manufacturing industry.

As the injection molding process and equipment are continuously optimized by automakers, they will be able to produce higher quality and more diverse automotive plastic injection molding parts than ever before. This is very important. In the future development, injection molding machines will play an increasingly important role in automobile manufacturing and become an important force to promote innovation and progress in the automotive industry.