The switchover position in injection molding is crucial for optimizing production efficiency and part quality during the injection process.

The switchover position refers to the specific point in the injection cycle where the machine transitions from filling the mold to packing the material. This adjustment helps maintain consistent pressure and ensures proper filling of complex mold cavities. A well-set switchover position improves part accuracy and reduces defects, leading to better overall production results.

Understanding the switchover position is essential for molders aiming to enhance production quality. Explore more to grasp how adjustments to this setting can significantly impact your injection molding outcomes.

A correctly set switchover position reduces part defects.True

Setting the switchover position accurately helps maintain consistent pressure, which minimizes defects and ensures high-quality parts.

A poorly set switchover position can increase cycle time.False

While an incorrect switchover position may lead to defects, it does not inherently increase cycle time; instead, it can lead to inefficiencies elsewhere.

What is Injection Molding?

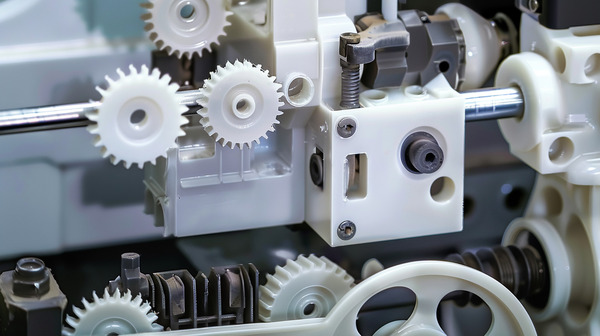

Injection molding is a manufacturing process where plastic or other materials are melted and injected into a mold to create parts. It is efficient for mass production, offering high precision, repeatability, and low cost per part. Common applications include automotive parts, medical devices, and consumer products. Key benefits include fast production cycles, complex shapes, and minimal material waste.

A complex manufacturing process called injection molding is used to make a variety of plastic products. To begin, molten plastic is injected into a mold cavity; it then cools and solidifies into the final shape. There are several key steps in this procedure:

Clamping: The two halves of the mold are closed and clamped together to withstand the injection pressure.

Injection: Molten plastic is injected into the mold cavity at high pressure.

Cooling: The plastic inside the mold cools and solidifies, forming the shape of the mold cavity.

Ejection: The mold opens, and the solidified part is ejected.

Precise control of each stage is crucial for producing high-quality parts. During the injection stage, one of the most critical parameters is the switchover position1.

What is Switchover Position in Injection Molding?

The switchover position helps control the molding process by determining when the injection pressure switches to holding pressure, stabilizing the part and minimizing defects. Proper adjustment of this position ensures uniform material distribution, reduces sink marks, and improves cycle times.

In plastic injection molding, the switchover position is when the control system transitions from velocity control to pressure control( holding pressure2). This shift is crucial because it decides how the molten plastic behaves as it fills mold cavities and packs them which directly affects both quality factors (like appearance) as well as whether each part will be same as all others made before or after it. There a few ways the molding machine can know when to make this switch. This can be done by screw position (most common), pressure limit, time, or cavity pressure.

The switchover position refers to a precise moment in the injection molding cycle when the process shifts gears from its initial phase (injection process) and moves into another phase called holding pressure. During the injection phase, molten plastic is injected into the mold cavity under high pressure. Once the cavity is filled, the process switches to the packing phase, where additional pressure is applied to ensure the material fully fills the mold, compensating for any shrinkage that may occur as the plastic cools.

What is the Importance of Switching Positions?

The switchover position affects several key aspects of the injection molding process:

Product Quality

For successful switchover between phases, make sure the mold cavity fills correctly (completely filled). Transition only when it’s ready for packing; otherwise you risk defects like voids, uneven wall thickness 3or incomplete parts because material flow hasn’t finished. But don’t wait too long either—as pressure builds up there is a risk of cosmetic problems such as warping due to excessive flashing while still in mold.

Dimensional Stability

Effective management of the transfer position is key to preserving the molded parts\’ dimensional precision; a crucial factor to bear in mind when producing components that call for close tolerances.

Material Efficiency

Getting the switchover position right can cut down on waste material. If the plastic is injected and packed correctly there will be less surplus – so each cycle makes better use of resources and there is an overall efficiency saving.

Cycle Time

Shorter cycle times and increased productivity are two more pay-offs from getting the switchover right all the time. Fewer defects also mean quality control and sorting out mistakes take up less production effort-hours.

What are the Factors That Affect the Switching Position?

The switching position is primarily affected by factors such as material properties, temperature, pressure, and mechanical design. These elements determine how components transition from one state to another, influencing both speed and accuracy. Correctly managing these factors ensures optimal system performance and minimizes downtime.

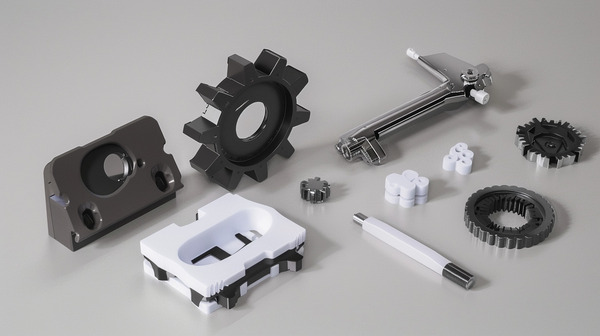

Determining the optimal switchover position in injection molding involves considering several factors:

Material Properties: The flow characteristics of different plastic materials vary, which affects how the injection and packing phases go as well as how quickly the mold fills. If a material has high viscosity it might need a different switchover point than one with lower viscosity.

Part Geometry: An intricate design may require changing when you switch from filling to packing so that no areas wind up with sink marks4or empty spaces (also known as voids).

Mold Design: The complexity and geometry of the mold also influence the switchover position. Intricate molds with complex features may need more precise control of the transition point to ensure complete filling and packing.

Machine Specifications: Things such as pressure, speed and temperature settings will also play a role in determining the best possible point for making transitions between processes; tweaking these factors just right is essential if you want top-notch goods at the end!

Process Conditions: Other factors needing consideration when deciding at what stage switching ought to happen include how hot both the melted material and mold itself are along with plus how fast injections are taking place.

How to Determine the Switching Position?

The switching position is typically determined by the alignment of components within a system, which could be based on mechanical, electrical, or sensor-based triggers. In electrical circuits, the switching position is defined by the state of the switch, either open or closed. Proper positioning ensures the correct functioning of the system and prevents faults or inefficiency.

Determining the optimal switchover position involves a combination of empirical testing and scientific analysis. Here are some common methods:

Empirical Testing: A set of trials is performed at various switch-over points and the ensuing part defects and quality metrics are analyzed. Though it takes time, this technique imparts practical knowledge from an actual production setting.

Scientific Molding: Data and principles from polymer science are used in this method to forecast the best switch-over point. Process control can be so fine-tuned with techniques like cavity pressure sensors and software simulations that they come close to exact prediction.

Process Monitoring: Today’s injection molders have advanced sensors and control systems fitted as standard. These continuously monitor variables such as flow rate, pressure and temperature in real time. The information can be used to alter (dynamically change) the switch-over point so as to achieve best results.

How to Optimize the Switching Position?

Optimizing the switching position ensures accurate transitions between machine modes, reducing downtime and improving production speed. It helps achieve more consistent results, especially in high-precision operations such as injection molding. Key strategies include analyzing machine feedback, adjusting timing settings, and considering environmental factors such as temperature and pressure.

Optimizing the switchover position requires a systematic approach to balance various process parameters and achieve consistent, high-quality parts. Here are some steps to optimize the switchover position:

Material Characterization: Understand the rheological properties of the plastic material, such as viscosity and flow behavior, to determine the initial switchover position.

Mold Flow Analysis: Use computer programs to predict the best time to switch based on mold design and part shape.

Process Trials: Carry out a range of tests using various switch positions and examine defects in parts – for example, those that are too short, have flashes of material attached or sunken areas. During these trial runs, watch closely how different switch settings perform and be prepared to make changes on-the-spot. Also keep an eye on the overall quality of moulded items coming out checking specifically for problems such as inaccuracies in dimensions or other visible defects.

Data Analysis: Use statistical techniques alongside tools like control charts so you can make sense out of all this information gathered during experiments then work what is best switchover setting from there.

Continuous Monitoring: Implement real-time monitoring systems to track process variables and dynamically adjust the switchover position during production.

Conduct Process Analysis: Start by examining how your current injection molding works. You can do this systematically using sensors and monitoring equipment that track fill speed, pressure, and temperature over the entire cycle. Data on these variables will help you understand both material properties and how the mold functions – key factors for identifying an optimal switchover position.

Use Simulation Software: Try Software SimulationInjection molding simulation software is a useful tool worth trying out when looking to optimize switchover points. Such programs enable users to see what might happen with different settings or materials; they also make it possible to predict behavior from molds under various conditions. This can save time and resources compared to a physical trial-and-error approach.

Implement Closed-Loop Control: Consider using closed-loop control systems that automatically adjust the switchover position based on real-time data. These systems can enhance consistency and precision, ensuring optimal performance throughout the production process.

Collaborate with Material Suppliers: Work closely with your material suppliers to understand the specific properties of the plastics you are using. They may be able to provide recommendations for optimizing the switchover position based on their knowledge and experience.

What are the Case Studies?

Case studies are in-depth analyses of real-world examples that demonstrate how a particular solution or strategy was implemented. They typically highlight the problem, approach, results, and lessons learned. Commonly used in business, healthcare, and education, case studies serve as powerful tools for decision-making and knowledge sharing.

Automotive Parts: An automotive parts maker had trouble with accurately shaping and smoothing out complex plastic parts. But after examining how things worked during production changes – using computer-generated models of molten plastic flows plus some real-life tests – things got better. In fact, by working this way the company made big strides in improving overall product quality: less shrinkage and no warping meant fewer rejects when it came to meeting tough criteria for each part.

Medical Devices: An organization producing medical instruments was having problems with defective plastic parts because the material was not filling them consistently. By using sensors to keep track of things as they happened and making sure the equipment changed position at just the right moment, the company found it could control how these parts were made. As a result, there were fewer faults per batch—and less waste overall. In fact, once production stabilized after this change, unit costs went down too.

Consumer Electronics Housings: Flow lines5 and warping were observed in housings from a consumer electronics company. By analyzing mold flow in detail and making adjustments to switchover position, these flaws were reduced significantly. An optimized switchover position enabled even filling and packing — so parts look good upon close inspection, resist damage better as well.

What are the Challenges of Optimizing Switching locations?

Optimizing switching locations helps improve operational efficiency by reducing delays and improving resource allocation. However, challenges include accurately predicting the optimal locations, dealing with machine downtime, and minimizing material waste during switching. Key difficulties also lie in balancing cost, speed, and quality during the optimization process.

While optimizing the switchover position offers many benefits, there are also challenges:

Complexity: Because material properties, part geometry, and process conditions all interact with one another, working out exactly where the switchover point is can be difficult.

Time-Consuming: Testing things out and using trial and error takes a long time and it can also cost a lot of money.

Dynamic Changes: If the material being processed alters because a new batch has been used or as environmental conditions change there are continuous adjustments which need to be made — this doesn’t happen by itself.

Technical Limitations: Although some injection moulding machines do have clever monitoring systems that allow for greater control, not all machinery does.

What are the Future Trends and Innovations?

Advancements in injection molding are ongoing. New technologies and methods are constantly being developed to improve both part quality and process control. When it comes to optimizing the switch-over point, there are several trends we can expect to see more of in coming years:

Advanced Sensors: To have better control of the switch point, we need advanced sensors to watch cavity pressure6, temperature, and flow rate in real time – and develop more sophisticated ones than are now available.

Artificial Intelligence and Machine Learning: If injection molding machine could learn from experience, they might use it to predict switchover points more accurately. One way this could happen would be by employing artificial intelligence (AI) techniques along with historical data on how past jobs went—plus information on what’s happening right now.

Integration with Industry 4.0: Leveraging Industry 4.0 technologies to create interconnected and intelligent injection molding systems can automatically optimize the switchover position, improving overall manufacturing efficiency.

Enhanced CAE Tools: Tomorrow’s computers will let us know today what tomorrow brings. By making computer modeling programs better (and better still), engineers can simulate different conditions before starting manufacturing processes … therefore reducing the number tests needed later on down line just checking quality controls etcetera.

Smart Materials: Using smart materials capable of feedback on their processing conditions can better control the injection molding process, including the switchover position.

What Practical Advice do Manufacturers Have?

Practical advice from manufacturers includes optimizing supply chain management, investing in employee training, and regularly maintaining machinery. Manufacturers emphasize the importance of quality control and lean production practices to reduce waste, lower costs, and boost output. Additionally, staying up-to-date with technological advancements plays a key role in maintaining competitiveness.

For manufacturers looking to optimize the switchover position, here are some practical recommendations:

Invest in Training: Make sure your team understands both the practical and theoretical aspects of injection molding – it can be really helpful when you’re trying to optimize things like switchover positions if they know why the process works as it does.

Leverage Technology: Consider investing in high-tech machinery for injection molding which comes with its own control systems and monitors that provide up-to-the-minute information; having access to data at all times will make adjusting switchover points much easier.

Regular Maintenance: Maintain your molds and machines regularly to ensure optimal operation, which is crucial for consistent switchover positions.

Collaborate with Material Suppliers: It’s worth getting to know more about plastics from suppliers – such knowledge could enable better decisions around what switchover point is needed.

Document and Analyze: Record every single detail that goes along with how processes have gone; afterwards, study information for trends showing areas where improvements may still be made – including fine-tuning when machines switch over.

Conclusion

Switch position in injection molding is a big deal. It affects part quality, consistency, cycle time, and material efficiency. To get it right, you need to think about material properties, part geometry, mold design, machine specs, and process conditions. By doing some testing, using scientific molding techniques, and keeping an eye on the process, you can get the switch position right and make good parts. As technology gets better, we’ll be able to control switch position even better, and that’ll make injection molding even more awesome.

While optimizing the switchover position can be a challenge, it has the potential to greatly improve the efficiency and quality of your injection molding operations. By continuously innovating and taking a systematic approach to process control, you can achieve higher precision, reduce defects, and increase overall productivity. Whether you’re new to injection molding or looking to improve your current processes, taking the time to optimize your switchover position can provide significant benefits to your production operations. Start by conducting a thorough analysis, using simulation tools, and considering closed-loop control systems to ensure you achieve the best results.

-

Learn about What Is Switchover Position in Injection Molding: The switchover position, also known as the V/P switchover point, is a crucial transition point in the injection molding process. ↩

-

Learn about Holding Pressure in Injection Moulding: What is it and How to Set it: The setting of hold pressure is aimed to prevent resin backflow . ↩

-

Learn about Why is Uniform Wall Thickness Important : Uniform wall thickness means that all the walls of a part are of the same thickness. ↩

-

Learn about Injection Molding Defects: Sink Marks : Sink marks are formed essentially due to high volumetric shrinkage. ↩

-

Learn about How to avoid injection molding flow lines : flow lines generally occur when molten material flows unevenly . ↩

-

Learn about Cavity pressure : Cavity pressure is a key indicator of the quality of the molded parts produced. ↩