Russia is a very unique country, it not only has the world’s largest territory and unique geographical advantages across

the Eurasian continent, but also has a unique and extremely profound political culture and social civilization.

This unique political culture not only determines the philosophy of life and social values different from those of other countries, but also directly affects the formulation and implementation of Russia’s foreign strategy, which often makes Russia stand up to the world with a unique look on the international stage.

Russia’s national economy has a solid foundation and huge economic potential. Industry, agriculture and transportation have reached a considerable level of development.

Solid industrial foundation, with machinery, iron and steel, non-ferrous metals, petroleum, natural gas, coal, forest industry and chemical industry as the main, energy, textile, munitions are also very developed.

Are you looking for injection molding suppliers in Russia? We have compiled the top 5 injection molding suppliers list for you to pick as below:

Top 5 Injection Molding Companies in Russia

1. The Nanotechnology Center for Composites

Location: Moscow, Russia

Company type: Manufacturing

Year founded: 1996

The number of employees: 300-399

Main Services: Injection molding, Engineering and Consulting, Lab Test, Production, Certification and Control

NCC Company Profile

NCC is a leading player in the composites market, carrying out a full cycle of development and production of products from polymer composite materials for various industries: design and strength calculations, material development, tooling, painting, prototyping, testing and certification.

NCC LLC provides a full range ofengineering services, including the development of technologies, design work, calculation and modeling, prototyping,tests, production of small series, work on the selection of equipment suppliers and the further implementation of technology in industrial production.

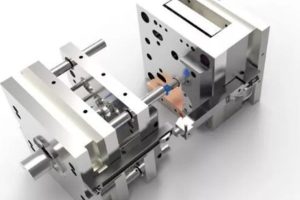

After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker and precision-machined to form the features of the desired part. Injection moulding service is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars.

Advances in 3D printing technology, using photopolymers which do not melt during the manufacturing injection moulding of some lower temperature thermoplastics, can be used for some custom plastic injection moulds.

2. OLDENG

Location: Ekaterinburg city, Russia

Company type: Manufacturing

Year founded: 1997

The number of employees: 200-299

Main Services: Plastics processing(injection molding), Rubbers processing, Gas plasma cutting, Die casting, Maching, Press moulds and press dies, 3D modeling and prototyping

OLDENG Company Profile

OLDENG engineering company has been created with merging big enterprises: PUMORI Corporation Sverdlovsk tools factory (abbreviated in Russian as SIZ) It became the Sverdlovsk Instrument Plant – PUMORI joint venture, or SIZ-PUMORI.

The company has eventually become a pioneer on the market of the professional manufacturers of form-generating tooling: plastics processing(injection molding service) ,press moulds, press dies, chill moulds.

During the first fifteen years of operation, the company has taken a leading position among engineering companies in the fields of press mould machines supply and production of form-generating equipment.

3. BEPLAST

Location: Lipetsk, Russia

Company type: Manufacturing

Year founded: 2000

The number of employees: 200-299

Main Services: Injection molding, pad printing, IML, decorating, component welding; maximum automation and robotic application

BEPLAST Company Profile

BEPLAST is a large Russian plastic injection molding manufacturer. As a part of processing, they make products for various market segments: household items, white goods, electronics, warehousing logistics, and construction. Their own products are food industry items.

They are professionals in plastic injection molding services and secondary operations (printing, gluing, etc.). Processing is B2B OEM manufacturing. They make over 200 plastic products and components for their customers involved in segments of white goods, electronics, construction, fast moving consumer goods, as well as in food industry.

4. Plastic OJSC

Location: Uzlovaya,Russia

Company type: Manufacturing

Year founded: 1983

The number of employees:200-299

Main products: Traditional molding, Injection molding and Extrusion compression molding

Plastic OJSC Company Profile

Plastic, OJSC (located in the town of Uzlovaya, Tula Region) is the number one ABS plastic and EPS producer.The enterprise boasts all necessary facilities for large-scale traditional molding, custom injection molding and extrusion compression molding.

It is also the biggest supplier of polymer material and its products. This line of products includes over 250 molded and injection molded items for VAZ, UAZ, KAMAZ, and GAZ vehicles of various complexity, including reinforced ones,

made from different types of plastic.

Polymer panels (under the Dilur trademark) are used for producing exterior and interior parts for vehicles through vacuum molding. They are also used as cladding material and for making consumer goods, electronics and household appliances.

5. Rosplast

Location: Moscow, Russia

Company type: Manufacturing

Year founded: 1998

The number of employees: 100-199

Main Services: Injection molding, Metalworking

Rosplast Company Profile

The success of the business — it is, above all, quality. Plastic now enjoy great popularity, so custom plastic injection moulds on which they are made, should be ideal. The company “Rosplast” seeks to your products were of high quality, and it prospered.

They have been working since 1998 to gain experience and allow them to safely tackle the most challenging and interesting jobs. The main activity Ltd. “Rosplast”-plastic injection molds service. They perform a complete cycle of works from design to fine-tuning.

They also offer services such as: Injection molding (use modern thermoplastic machines)- Metalworking (for metal centers and turning machines). Their company pays great attention to technical accessories. The volume of production amounted to 120 molds for the year 2008.

This is yet another compelling argument for their customers. They are actively implementing their own design, which allows to significantly reduce production costs, which means do you good price offers. Also “Rosplast” not resorted to the services of third parties, using their own full-cycle production.

If you’re looking for more plastic injection molding manufacturers, Also you can choose a China plastic injection molding supplier : Zetar Mold

Zetar Mold

Location: Shanghai, China

Company type: Manufacturing

Year founded: 2005

The number of employees: 201-300

Main product: Plastic Injection Mold, Plastic Injection Molding Manufacturing

Other products: Injection molding manufacturing, Insert Molding Products, 3D printing and CNC Prototyping

Zetar Company Profile

Zetar is a top-end turnkey China injection molding manufacturing company that helps wholesalers and brand owners fulfill their products.

Zetar has more than 20 English speakers and 7 experienced mold design engineers (some of them can also speak English) with technique and English communication, which could make sure fluent communication and offer feasible design solutions.

Now total Zetar has mold making shop in house, 31 sets injection molding machines range from 60T-1100T. which 6 sets are in dust-free room(M7 Class), assembly room and logo printing room. The largest 1100T injection molding machines could produce product weight up to 5100g.

Zetar definitely also has many certificates: TUV, ISO9001 (quality system certification), TS16949 (certification for auto parts making), ISO14001 (certification for showing not harming the environment during whole manufacturing process).

Conclusion

Finding a trustworthy manufacturer nowadays is not that easy, especially that there are a lot of new manufacturers that have emerged just to keep up with the trend. But hopefully, our list was able to help you find the injection mold supplier that best suits your requirements. It is recommended to do a background check before creating partnerships with manufacturers because they will play a huge part in the success of your business.

If you’re looking for more injection molding suppliers, check out the following articles:

Top 5 Injection Molding Companies in Hungary

Top 5 Injection Molding Companies in Austria

Top 5 Injection Molding Companies in Belgium

Top 5 Injection Molding Companies in Czech Republic