Proper pressure during injection molding is paramount to creating successful parts with enduring quality.

Insufficient pressing can lead not only to imperfections in the finish, but also a lesser-grade bond between plastic and mold that could result in failure down the line.

Conversely, too much nozzle force risks damaging your equipment as well as accelerating wear on vital components of an injection machine over time.

Injection molding is a process whereby plastic material of varying viscosities, in different shapes and sizes, can be pressure-molded into intricate components or designs.

How much Injection molding requires considerable pressure to ensure a successful outcome, with the amount necessary dependent on several factors.

Plastic type and viscosity can influence this along with the size and shape of the part being molded; the design/construction of injection mold as well as the machine used are also key components that must be taken into consideration.

Moreover, complexity in production increases the importance of adequate force when producing parts from plastic resin – ensuring strong bonds between material & molds is an essential ingredient towards desired results!

The type and viscosity of the plastic material

The injection pressure needed for plastic material can vary greatly depending on the type and viscosity of that particular material.

For instance, an easy-to-flow polyethylene requires lower pressures than a more viscous one such as Polycarbonate – which needs higher applied forces to inject into the injection mold.

Different materials come with different properties requiring small or large amounts of pressure so it’s important keep this in mind when selecting your finishing product!

The size and shape of the part being molded

Injection molding demands varying levels of holding pressure depending on the size and complexity of a part.

As parts get larger and more intricate, greater pressures are necessary to ensure secure bonds between plastic materials and their injection molds. Conversely, smaller simpler components require less pressing power.

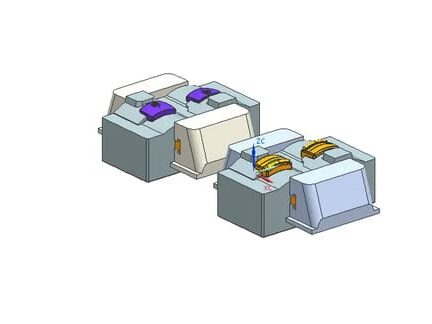

The design and construction of the mold

Injection molding is a precise process that relies on the design and construction of injection molds to achieve desired results.

Complex shapes with delicate features (such as thin walls or deep grooves) necessitate higher injection pressures, while simpler designs can be achieved using less pressure. Understanding these requirements is key to developing successful products through injection molding.

The injection molding machine

Injection molding machines are essential in achieving the right pressure during production.

For instance, a spiral injection machine that boasts a clamping force of 100 tons can employ up to 100 tons of pressure throughout its process – making it crucial to ensure you select an appropriate model for your needs.

The complexity of the part being molded

Depending on the desired result, plastic injection molding pressure can vary widely.

While a simple component made from soft material may require only a few hundred psi of cavity pressure; complex pieces fashioned from stiffer plastics necessitate several thousand psi during the initial phase to achieve accurate forming and superior properties.

Conclusion

Finding the perfect balance of pressure is essential for successful injection molding. Too little can cause defects, while too much could be damaging to both equipment and parts.

Navigating these considerations requires a tailored approach toward each application – selecting an appropriate amount that yields strong, high-quality results every time.