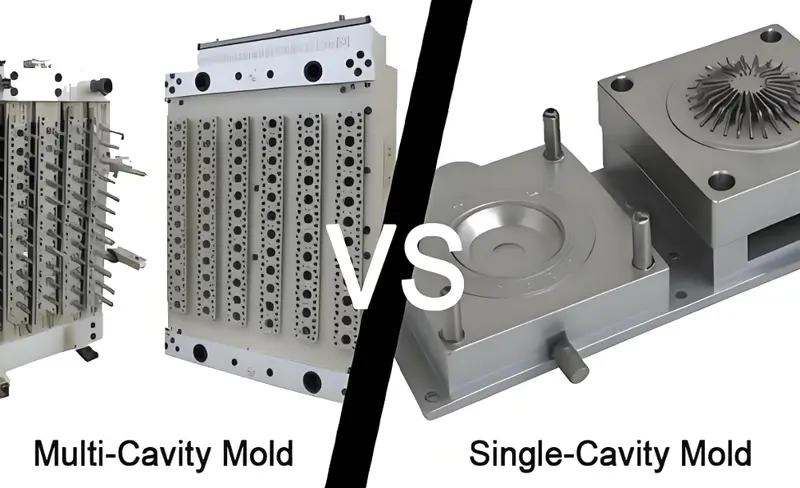

Multi-cavity and single-cavity injection molds are key types in manufacturing, each offering distinct advantages depending on the production scale and part complexity.

Multi-cavity molds produce multiple parts per cycle, improving efficiency and cost-effectiveness for high-volume production. Single-cavity molds are simpler and ideal for low-volume or complex parts.

Understanding when to use each mold type is essential for optimizing production and costs. Dive deeper into the benefits of multi-cavity and single-cavity molds for various manufacturing needs.

Multi-cavity molds reduce cycle times and costs.True

By producing multiple parts per cycle, multi-cavity molds increase production efficiency, reducing unit costs.

Single-cavity molds are always more cost-effective than multi-cavity molds.False

While single-cavity molds are cheaper for small runs, multi-cavity molds become more cost-effective as production volume increases.

What is the Difference Between a Multi-Cavity Injection Mold And a Single-Cavity Injection Mold?

Multi-cavity molds enable mass production by creating multiple parts in a single cycle, while single-cavity molds produce one part at a time. Understanding the difference helps in choosing the right mold for specific production needs.

Multi-cavity molds create several parts per cycle, increasing output and reducing per-part cost. Single-cavity molds produce one part at a time, offering more precision and flexibility for small-batch or complex parts.

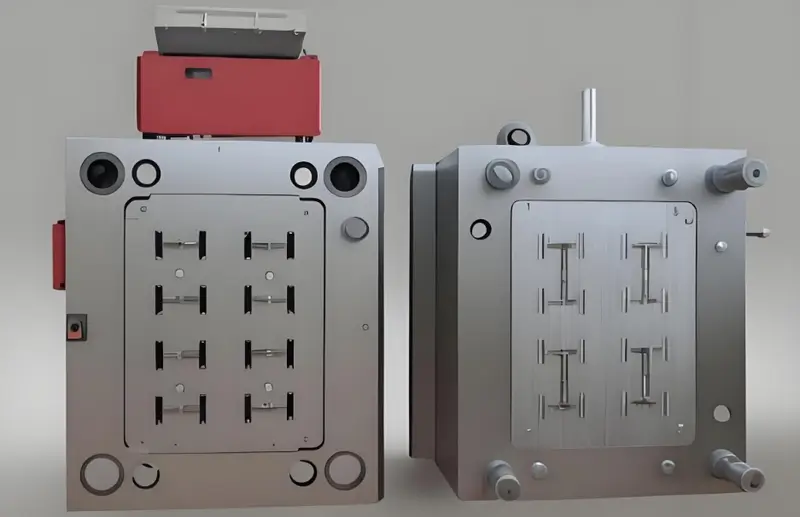

Single-Cavity Injection Molds

Single-cavity injection molds have a single injection molding cavity. During injection molding process, single cavity molds produce only one plastic part.

Characteristics:

-

Simplicity : Since the mold can have only a single cavity, the mold design1, as well as its construction, is easy, which makes this technology suitable for creating complicated structures. Designers only need to focus on the filling, cooling, and demolding of a single cavity, reducing design complexity.

-

Cost : It is cheaper in terms of manufacturing and its maintenance making it ideal for companies that produce in small quantities. Single-cavity molding require comparatively less in the way of material inputs and processing time and therefore the initial outlay is lower.

-

Flexibility : Mold modification and adaptation is simple, this makes it suitable for the multi-variety low volume production. Via this technology, it becomes easy for injection molding suppliers to change molds in order to satisfy the numerous production requirements of the products that are being produced to avoid extended time on the production line.

Multi-Cavity Injection Molds

Multi-cavity injection molds are molds having more than one cavity through which more than one similar or dissimilar plastic products could be produced within a single injection cycle. This according to the number of cavity can be two-cavity, four-cavity, eight-cavity, or even many cavity more.

Characteristics:

-

High Efficiency : Several parts can be manufactured in one shot, thus increasing the rate of production, therefore suitable for use in large quantity production. The use of multi-cavity molding can significantly reduce the time taken to get the products to the market to satisfy the market needs.

-

Complexity : The entire mold comes out more complicated in design as well as in manufacturing because the flow channel needs to designed carefully and there should be a better control on the filling part. Designers have to pay specific attention to the distribution of the plastic within each of the cavities to avoid yielding unequal filling which may lead to generation of some defects.

-

Cost : The initial manufacturing cost is high, but as production volume increases, the unit cost of the product decreases significantly. For large-scale production, the economic benefits of multi-cavity molds are more apparent.

Multi-cavity molds increase production efficiency.True

By creating multiple parts in one cycle, multi-cavity molds reduce overall cycle time and labor costs, making them ideal for high-volume production.

Single-cavity molds are always cheaper than multi-cavity molds.False

While single-cavity molds have a lower initial cost, multi-cavity molds may offer better long-term savings due to their ability to produce more parts per cycle.

What are the Advantages And Disadvantages of Multi-Cavity Injection Molds?

Multi-cavity injection molds improve production efficiency and reduce costs by creating multiple parts in a single cycle. However, they come with challenges like increased mold complexity and maintenance needs.

Multi-cavity molds maximize production by creating several parts at once, reducing cycle time and material costs. However, they require precise mold design and maintenance, which can increase initial costs and complexity.

Advantages

-

Increased Production Efficiency :In this type, several cavities are carved on the mold face whereby in every injection process, a large number of parts are produced. In relation to the mass production it helps to reduce the duration of production to cater for the market needs. For instance if one has an eight cavity mold, the output you get per hour will be eight times as many as the single cavity mold greatly improving the productivity of the production line.

-

Reduced Unit Costs :The multi-cavity molds are relatively expensive in the first instance of manufacturing but the relative production cost of the each part is significantly lower as the number of items produced increases. This cost efficiency is especially notable in large-scale production. When producing large quantities, the distributed costs of materials, labor, and energy decrease, reducing the production cost of each part.

-

Consistency and Quality Control :The design of many cavities in a single mold usually calls for close tolerances2 in the mold and each part made in the cavities must be accurate in every detail. This is very important especially for products that may need to be precise and have standard measurements. For instance, medical devices, and high tech electronic products need to have very high accuracy, and with multi cavity molds, you can achieve consistency in the batch runs.

Disadvantages

- Complex Mold Design :The multi-cavity mold production is comparatively difficult because of the accuracy and uniform filling of flow channels. More often the mold designers requires expertise and experience to guarantee that the mold functions appropriately. This complexity makes design and manufacturing take a longer time and is also expensive.

-

High Initial Cost :Multi cavity molds are initially expensive to manufacture since their design is complex, including design, materials, and high precision requirements in the manufacturing process. For small and medium-sized enterprises, this can be a lot of money. One should define the period for the return of the initial investment; in many cases, due to low production rates, the costs cannot be compensated.

-

Maintenance and Repair Complexity :As for repairs and maintenance of multi-cavity molds, they are relatively complicated and technicians are needed to perform the task. Once the mold issue develops it is capable of hindering the smooth flow of operations of the whole line of production. If the cavity within the mold has some problem, then the production must be stopped for repairment which became a problem, impacting production efficiency.

Multi-cavity molds reduce production costs by creating multiple parts per cycle.True

By producing several parts at once, multi-cavity molds cut down on cycle times and material waste, leading to cost savings in high-volume production.

Multi-cavity molds are always more expensive than single-cavity molds.False

Though multi-cavity molds have higher initial costs due to their complexity, they can be more cost-effective in the long run due to increased production efficiency and lower per-part costs.

What are the Advantages And Disadvantages of Single-Cavity Injection Molds?

Single-cavity injection molds are a popular choice for producing small quantities of parts efficiently. However, they come with both benefits and limitations, making them suitable for specific production needs.

Single-cavity injection molds allow for the production of high-quality parts with lower upfront costs. They are best for small batches but may not be as efficient for mass production due to longer cycle times and higher per-unit costs.

Advantages

-

Simple Mold Design :Compared with multi-cavity molds, the design and manufacturing of single-cavity molds is relatively easy, and there is no need to consider the problem of uniform filling of multiple cavities. Therefore, it is easier to complete the mold design and manufacturing stage. For beginners or small businesses, single-cavity molds are a relatively easy choice.

-

Low Initial Cost :The cost of manufacturing single-cavity models is low because the design and manufacturing of single-cavity molds are not so complicated. Single-cavity molds are reasonable and advantageous for small-batch production or new product trial production. This means that companies can conduct trial production with very little capital to ensure that the product is designed correctly and whether there is demand.

-

High Flexibility :Single cavity molds are simple to replace and can be easily adjust hence are ideal for use in multi variety low quantity production. The production planning of a firm and its supply strategy can easily change depending on the market trends and customer requirements. Single cavity molds are very flexible particularly in areas where manufacturing of standard and non-standard products is involved.

Disadvantages

-

Low Production Efficiency :Single cavity molds are able to manufacture only one part per cycle of injection, therefore the productivity of this method seems to be not very high. In relation to mass production of goods, it does not even meet market requirements; the cycle of manufacturing is also lengthy. In return, more molds and machines might be required to produce the same output, which raises the cost of production considerably.

-

High Unit Costs :Due to low production efficiency, the cost on unit product is relatively high. For mass production, the economy of single cavity molds is very low and not recommended for mass production for a long time. When the production quantity rises, the defects of single cavity molds are exposed gradually.

-

Consistency and Quality Control :Single cavity mold design is comparatively easy, however, several quality and conformity concerns are needed to be reviewed in practice to produce high quality standard parts. This is most especially a challenge especially in cases of multiple production runs and from one batch to another.

Single-cavity molds are ideal for low-volume production.True

Single-cavity molds are designed for producing fewer parts, making them cost-effective for small runs.

Single-cavity molds are always cheaper than multi-cavity molds.False

While single-cavity molds have lower initial costs, multi-cavity molds may be more cost-effective for larger production runs due to their higher efficiency.

What are the Application Areas of Multi-Cavity And Single-Cavity Injection Molds?

Multi-cavity and single-cavity injection molds are essential for producing high-quality parts in various industries, offering cost-effective and efficient solutions for manufacturers.

Multi-cavity molds allow for the simultaneous production of multiple parts, enhancing efficiency and reducing costs. Single-cavity molds, while producing one part at a time, are ideal for high-precision, low-volume production. Applications span automotive, consumer goods, medical devices, and electronics.

Application Fields of Multi-Cavity Injection Molds

-

Mass Production :Multi-cavity molds are suitable for the mass production of plastic parts, such as the car parts, home appliance shells, and auxiliary articles. To sum up, multi-cavity molds that offer high efficiency can solve a set of production issues and can meet the demands of the market in terms of speeding up the production cycle while lowering the unit costs. For example, automobiles incorporate many plastic details, and for the manufacturing process to be fast and the products to be identical in form and design, it is possible to use multi-cavity molds.

-

High-Precision Products :Multi cavity molds have to be precise in their design and must be uniform in design hence they are ideal for products that need precision and uniformity. For instance, cases of medical devices and coverages of electronic products need accuracy and high quality dimensions, which multi-cavity mold is capable of delivering. In these fields, product consistency directly affects the performance and safety of the equipment.

-

Standardized Parts :Multi-cavity molds are ideal for preparing standard parts such as screws and other fasteners. Generally, multi-cavity molds can improve the efficiency of production lines and ensure that each part produced meets the requirements of mass production. Standardized parts usually need to be produced in large quantities, and the size and quality of each part must be strictly consistent to ensure interchangeability during assembly.

Application Fields of Single-Cavity Injection Molds

-

Small-Batch Production :Single cavity molds can be used to start production on a small scale and test new products. New products in the first stage of market entry usually have low market demand, and simple cavity molds can easily adapt to this demand and reduce inventory pressure. For example, startups and small and medium-sized enterprises can use single cavity molds for small batch production, reduce initial investment costs and respond quickly to market demand.

-

Complex Structure Products :Single-cavity molds are suitable for manufacturing parts with more complex final product geometry and internal structures. For single-cavity molds, mold design and manufacture are easier, making the production of complex products easier to complete. Parts with complex structures require a lot of trials and modifications during the design and manufacturing stages, and single-cavity molds are easier to handle at these stages.

-

Multi-Variety Production : Single-cavity molds3are more suitable for multi-variety and small-batch production, such as customized and personalized product production. Enterprises can flexibly adjust production plans according to customer needs, and quickly replace and adjust molds through single-cavity molds to meet customers\’ personalized needs. For example, in the consumer goods market, the trend of highly customized products is becoming increasingly obvious, and single-cavity molds can flexibly respond to these changes.

Multi-cavity molds increase production efficiency.True

Multi-cavity molds produce multiple parts simultaneously, reducing cycle time and increasing throughput.

Single-cavity molds are only suitable for low-volume production.False

Single-cavity molds can also be used for high-precision, low-quantity runs in various industries, including medical and electronics, where quality is prioritized over volume.

What Factors Should be Considered When Choosing Multi-Cavity And Single-Cavity Injection Molds?

Choosing between multi-cavity and single-cavity molds depends on factors such as production volume, part complexity, and cost efficiency. Understanding these variables ensures the right mold type for your project.

Multi-cavity molds improve production efficiency by creating multiple parts per cycle, while single-cavity molds are ideal for lower-volume, high-precision parts. The choice depends on part complexity, mold cost, and production needs.

Production Requirements

When deciding whether to use a multi-cavity injection molding or a single-cavity injection molding, the initial factor that must be considered is production requirements.

If large-volume production is required, multi-cavity molds can be selected to increase the productivity of each part and simultaneously reduce the cost of each part.

If the demand for batches of a specific product or new product variant is relatively low, single-cavity molds can be selected, which requires little initial investment and allows molding changes based on market conditions.

Product Structure

Another factor that determines the choice of mold type is product structure. Single-cavity molds are more suitable for the production of complex products, and their design and manufacturing processes are relatively simple, making it possible to achieve the internal geometric shapes and structural complexity of the product.

For products with high standardization and consistency, multi-cavity molds can provide higher production efficiency and consistency.

Cost-Effectiveness

Cost-effectiveness is a key factor in choosing a mold type4. Although the initial cost of a multi-cavity mold is higher than that of a single-cavity mold, the cost per unit product is relatively low, making it suitable for mass production.

Single-cavity molds have a lower initial manufacturing cost, so they can be used for small-batch production and new product trials. When you need to make a decision on the mold type, you need to evaluate not only the initial cost but also the cost over the entire production cycle.

Quality Control

Another aspect that defines the choice of the type of the mold is quality control. Multi-cavity molds demand accurate and standard mold manufacturing, and therefore match items that need great accuracy and standardization.

About the single cavity mold, the advantage is that it is highly flexible which is ideal for multi variety, small production.

Regarding the kind of mold, there needs to be a comprehensive evaluation based on the quality and, therefore, the uniformity of the product that is produced. For instance, the application of high end electronics manufacturing that requires each part to be made to identical specifications will prefer multi cavity molds.

Market Demand

Another factor that influences the selection of the type of mold is the market demand. If the market demand is high, it is possible to go for multi-cavity molds to improve the productivity and to meet the market demand.

If market demand fluctuates frequently, single cavity molds can be selected so that the response to the changes in the market can be easily made hence allowing firms to change their production strategies frequently.

Multi-cavity molds increase production efficiency.True

By producing multiple parts per cycle, multi-cavity molds significantly reduce cycle time, improving overall efficiency in high-volume production.

Single-cavity molds are always cheaper than multi-cavity molds.False

While single-cavity molds have lower initial costs, multi-cavity molds can offer cost savings in high-volume production by reducing cycle time and material waste.

Conclusion

Multi cavity injection mold and single cavity injection mold both have their own advantages and disadvantages in the plastic injection molding5 process, which needs to select according to the production requirement of the product and its using area.

Multi cavity molds are ideal for high volume, precision and accuracy in the produced items, while single cavity molds are ideal for low volume, specialized structure products and multiple sets of products.

While selecting the type of mold it is important to make a balanced choice between the production necessities, structure of the product, the cost involved and the quality that has to be maintained and the market demand.

Recognizing the distinctions and uses of multi-cavity and single-cavity injection molds will assist companies in making wiser decisions in the Injection Moulding process, increase their efficiency, lower costs, satisfy the market, and ultimately, promote sustainable growth.

-

Learn about What is injection mold design? Edge gates are a common component of injection mold design . ↩

-

Learn about Injection Molding Tolerances: Injection molding tolerances are the accepted deviations from the exact dimensions that parts are supposed to have in the injection molding process. ↩

-

Learn about Single Cavity vs Multi Cavity Mold: What are the Differences : In a single cavity, the mold has only one cavity that produces a single part at a time. ↩

-

Learn about The Eight Types of Injection Molds :In mold types commonly encountered, we find the two-color mold, overmolding, and family mold. ↩

-

Learn about Basics of Plastic Injection Molding : The basics of plastic injection molding process use pressure to inject the melted pellets into the mold. ↩