Injection molding uses various plastic materials, each offering unique properties suited for different applications, from automotive to consumer goods.

The most common plastics for injection molding include ABS, polycarbonate, polypropylene, and nylon. These materials are chosen for their durability, flexibility, and ease of processing in industries like automotive, electronics, and medical devices.

Understanding the properties of these plastics is essential for selecting the right material for your injection molding project. Dive deeper into the benefits and applications of these materials for better production decisions.

ABS is widely used in automotive and consumer goods.True

ABS offers impact resistance and strength, making it a popular choice for parts like dashboards and housings.

Polycarbonate is the most cost-effective plastic for injection molding.False

While polycarbonate offers excellent strength and optical clarity, it tends to be more expensive compared to materials like polypropylene.

What is Nylon Polyamide (PA)?

Nylon (Polyamide) is a strong, versatile plastic commonly used in engineering applications, known for its durability and resistance to wear, heat, and chemicals.

Nylon (Polyamide) is a synthetic polymer used in textiles, automotive parts, and industrial applications. It offers high strength, abrasion resistance, and flexibility, making it ideal for manufacturing gears, bearings, and clothing.

Definition

Nylon is a semi-crystalline polymer and is definitely one of the most popular plastic injection molding materials. It is low cost, high performance, and has a wide range of uses in almost all industries. Nylon is a type of polyamide, although the two terms are often used interchangeably.

There are different types of nylon, the most common of which are nylon 111, nylon 12, nylon 46, and nylon 66.

Properties

Nylon is a great material. It’s tough, it can take the heat, and it’s got some good friction and wear properties. It’s a natural material and it’s also made in a lab.

Nylon has a low friction coefficient, so it’s good for things that rub together a lot. It’s strong and it doesn’t wear out easily. It’s also good with fuels and oils. It can take the heat better than other plastics.

Nylon molding has a lot of good things going for it, but there are some challenges. If you don’t dry it right, it can suck up too much moisture and mess up your parts. It also shrinks when you mold it.

Applications

Nylon is used for a lot of things. It’s used for electrical connectors, medical implants, threaded inserts, mechanical parts like gears and gear components, guitar strings, waterproof and wear-resistant fabrics and ropes, bushings and bearings, and automotive applications where hydrocarbon and heat resistance are critical.

Nylon is a durable material used in high-stress applications.True

Nylon's resistance to wear and heat makes it suitable for applications like automotive parts and industrial machinery.

Nylon is not suitable for high-temperature environments.False

While Nylon has a relatively high melting point, specialized grades of Nylon can withstand higher temperatures, making it suitable for demanding applications.

What is Acrylonitrile Butadiene Styrene (ABS) ?

Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic widely used in various industries due to its strength, durability, and ease of molding.

ABS is a tough, impact-resistant plastic that combines acrylonitrile, butadiene, and styrene. It’s commonly used in automotive, consumer goods, and electronics for its superior strength and processability.

Definition

ABS is a popular thermoplastic polymer used in injection molding2. It’s made up of three monomers: styrene, acrylonitrile, and butadiene. The styrene gives injection molded parts a shiny, visually appealing surface effect, while the butadiene gives them excellent elasticity.

Features

ABS has a low melting point, which makes it easier to mold. It also has a low cost, which is why it’s so popular.

It has good strength and toughness, impact resistance, and chemical resistance to acids, bases, and oils. It is completely opaque and can be molded in a variety of colors. Best of all, it is very cheap compared to other materials on this list. However, it does not perform well in direct sunlight or in humid environments. Avoid those applications.

This engineering plastic is known for its strength and toughness, which means it doesn’t break easily and can take a hit. ABS is also a good insulator and can handle both hot and cold temperatures.

One of the main limitations of ABS is that it doesn’t do well in the weather. It can get messed up if it’s out in the sun or if it gets wet.

Applications

ABS is great for industrial-grade applications, like. It’s also popular for rapid prototyping because of its cost and functionality. ABS is widely used in the manufacturing industry to make plastic injection molded parts such as: kitchen appliances, sports equipment, automotive parts, and high-strength sports equipment, automotive parts, electronics, medical tubing , musical instruments .

ABS is a durable plastic used in various industries.True

ABS offers high impact resistance and strength, making it ideal for automotive, electronics, and consumer goods.

ABS is unsuitable for high-heat applications.False

While ABS has a relatively low melting point compared to some plastics, it can still withstand moderate heat and is often used in parts exposed to low to medium heat environments.

What is Acrylic ?

Acrylic is a versatile, transparent plastic often used in signage, windows, and displays. Known for its clarity and durability, it is a popular alternative to glass in many applications.

Acrylic is a lightweight, shatter-resistant plastic that mimics glass. It’s often used in applications requiring transparency and strength, such as windows, signs, and lenses. Acrylic is easy to fabricate and resistant to UV light.

Definition

Acrylic is a clear plastic that can be used instead of glass. It is strong and doesn’t break easily.

Features

One of the main things about acrylic is that it has glass-like properties – clarity, optical transparency and brightness – but it’s lighter and stronger. So, it’s a great substitute for glass.

Acrylic is dimensionally stable, which is good for large-scale manufacturing of plastic parts. It can also withstand weather conditions like rain and sunshine, so it can be used for outdoor windows and housings.

Like any other material, acrylic has its disadvantages. It can easily stain when it comes into contact with oil or grease.

Applications

Acrylic plastic injection molding has a variety of applications, including: medical devices, windows, industrial equipment, such as masks and other protective glasses. Mobile phone display aquarium screen .

Acrylic is more durable than glass.True

Acrylic is shatter-resistant, making it safer and more durable than glass, which can break easily.

Acrylic is always UV-resistant.False

While acrylic offers good UV resistance, prolonged exposure to UV light can cause it to yellow or degrade over time.

What is Polycarbonate (PC) ?

Polycarbonate (PC) is a durable, high-performance plastic known for its transparency, impact resistance, and thermal stability. It’s used in a wide range of applications, including eyewear, electronics, and automotive parts.

Polycarbonate (PC) is a versatile thermoplastic that combines strength, clarity, and heat resistance. It is commonly used in applications like lenses, protective covers, and automotive components due to its durability and optical properties.

Definition

Polycarbonate is a clear material that’s known for being tough. It comes in different types, like film, antistatic, branched, flame retardant, and abrasion resistant polycarbonate. You can make clear or solid parts with this plastic injection molding material3.

Features

PC is super tough, shatter resistant, and impact resistant. It’s see-through. Plus, it’s got the awesome quality of keeping its mechanical properties and appearance over a wide temperature range. So, it does great in high temperature environments.

It’s got great optical clarity, often better than glass. That’s why it’s a popular material for injection molding helmet visors, machine shields, and goggles.

Polycarbonate has great optical clarity4. Most grades have a light transmittance between 80% and 90%, so it’s a great choice when you need a transparent part.

Another important thing about polycarbonate is that it has good mechanical properties. This engineering plastic is strong, tough, and can take a hit. It can also handle heat. Polycarbonate is used more often than acrylic resins because it can handle heat.

It has great impact toughness and creep resistance, high heat resistance5, good cold resistance, brittle temperature of -100℃, bending and tensile strength comparable to nylon, and high elongation and elastic modulus and great impact strength.

It is colorless and transparent, has good colorability, higher heat resistance than nylon and polyoxymethylene, better creep resistance and electrical insulation, good corrosion resistance and wear resistance.

It has low water absorption, small shrinkage, and good dimensional stability. Stress cracking may occur, and stress concentration (and internal stress) is easy to occur, which requires high molding conditions. It is easy to hydrolyze at high temperature and has poor solubility with other resins. It has poor fluidity, is sensitive to temperature changes, and cools quickly.

Applications

Polycarbonate molding is used for a variety of things, like LED lights, medical devices, playground equipment, display screens, car parts (like sunroofs, headlights, and bulletproof windows), gears, worm gears, racks, cams, bearings, spindles, pulleys, drive chains, nuts, washers, pump impellers, lamp covers, containers, and more. It doesn’t work well with alkalis, ketones, amines, or aromatic hydrocarbons.

Polycarbonate is more impact-resistant than glass.True

Polycarbonate is up to 250 times more impact-resistant than glass, making it an excellent choice for safety glasses and durable covers.

Polycarbonate is always the best choice for transparent materials.False

While polycarbonate is a top choice for transparency and strength, it can scratch more easily than other materials like acrylic.

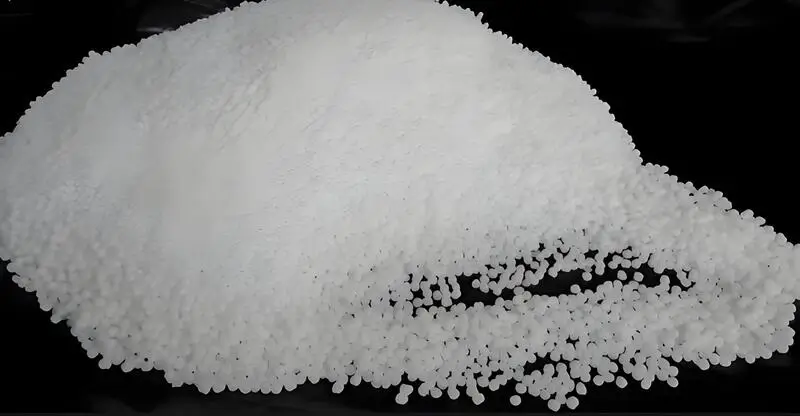

What is Polyethylene (PE) ?

Polyethylene (PE) is one of the most widely used plastics, known for its durability, flexibility, and chemical resistance. It’s commonly found in everyday products like plastic bags, bottles, and containers.

Polyethylene (PE) is a versatile plastic used in packaging, containers, and various consumer goods. It is resistant to chemicals and moisture, making it ideal for numerous applications. There are different types of PE, including LDPE, HDPE, and LLDPE, each with unique properties.

Definition

Polyethylene is still the most commonly used plastics in the world. It is made in different densities, which affects how a particular plastic resin behaves.

Here are the five most common types of polyethylene for injection molding: Ultra-high molecular weight polyethylene (UHMWPE)6, high-density polyethylene (HDPE)7, medium-density polyethylene (MDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE).

Properties

PE grades are usually ductile, have good impact strength and creep resistance (can withstand mechanical loads for a long time without deformation). They are also resistant to chemical reactions.

Polyethylene is usually lightweight, a good insulator, and has good chemical resistance. However, its stiffness, flexibility, and melting point depend on the type of polyethylene. Higher density resins are stiffer, but more brittle. Lower density plastic resins are more flexible, but less stiff.

Applications

Polyethylene is used to make a lot of stuff. You can find it in food containers, plastic bottles, shopping bags, and other throwaway packaging. It’s also used to make pipes for gas, water, and sewer lines. UHMWPE is used to make bulletproof vests and medical devices, like knee and hip implants.

HDPE is stronger and more rigid. So, you can use it to mold things like kettles, bathtubs, and pipes. On the other hand, LDPE is more flexible. It’s a great packaging material and has a multi-billion dollar leading product in the packaging industry (shopping bags, foils, films).

Polyethylene is highly durable and resistant to chemicals.True

Polyethylene's resistance to chemicals and moisture makes it a durable material for a wide range of applications, from packaging to construction.

Polyethylene is only used in packaging.False

Polyethylene is used in a wide range of industries, including medical, automotive, and consumer goods, due to its versatility and range of physical properties.

What is Polyoxymethylene (POM) ?

Polyoxymethylene (POM), also known as acetal, is a high-performance engineering plastic renowned for its strength, stiffness, and low friction. It is widely used in automotive, electronics, and consumer products.

Polyoxymethylene (POM) is a thermoplastic polymer with excellent mechanical properties, such as high tensile strength and low wear and friction. It’s commonly used in precision parts, gears, and automotive components due to its durability and resistance to chemicals.

Definition

Polyoxymethylene (POM)8 is a semi-crystalline, high-performance engineering polymer. It is commonly used in applications that require low friction, high stiffness, and dimensional stability. POM is also known as acetal or polyoxymethylene.

Properties

Polyoxymethylene is usually an opaque white solid with a relatively high melting point. However, it can be dyed to produce different colors. Other material properties that make it popular include high strength, excellent chemical resistance, and wear resistance.

Great overall performance. High tensile strength, impact toughness, rigidity, fatigue strength, creep resistance, good dimensional stability, low water absorption, low friction coefficient, good chemical resistance, performance is not worse than nylon.

POM is famous for being suitable for products that need high precision. It has good dimensional stability because it is stiff and rigid. It also has a low friction coefficient and good lubricity, so it is great for applications where there is a lot of contact. It also performs well at very low temperatures.

Application

Polyoxymethylene is used for a lot of things. It’s used for high-performance engineering parts like gears and gun parts. It’s used for medical equipment like insulin pens and inhalers. It’s used for musical instruments. It’s used for door lock systems in cars. It’s used for fuel sender units and electric windows. It’s used for kitchen knives. It’s used for gears.

It’s used for furniture and ball bearings. It’s used for bearings. It’s used for cams. It’s used for valves. It’s used for pipe nuts. It’s used for pump impellers. It’s used for small parts of the chassis. It’s used for car dashboards. It’s used for carburetors. It’s used for boxes. It’s used for containers. It’s used for rods. It’s used for various copper-substitute parts for sprayers.

POM is a high-strength plastic with low friction.True

POM is known for its excellent mechanical properties, making it ideal for high-performance applications that require durability and minimal wear.

POM is not resistant to all chemicals.False

While POM is resistant to many chemicals, it may degrade in the presence of strong acids or alkaline solutions, limiting its use in some harsh chemical environments.

What is Polypropylene (PP) ?

Polypropylene (PP) is a widely used thermoplastic polymer known for its versatility, lightweight nature, and resistance to chemicals and heat.

Polypropylene (PP) is a durable, lightweight plastic used in packaging, automotive parts, and textiles. It’s resistant to chemicals and fatigue, making it ideal for a wide range of applications. Key benefits include cost-effectiveness and high flexibility.

Definition

Polypropylene (PP) is the second most produced plastic polymer after polyethylene. It’s all around us, especially in our kitchen cabinets in the form of food containers. It’s a low-cost, versatile option, and it’s one of the most common plastic injection molding materials approved for use by the FDA. And it’s easy to get, making it a workhorse material across industries.

Properties

It’s strong, heat-resistant, chemical-resistant, and can be recycled over and over. That makes it easy to work with.

But it has a high coefficient of thermal expansion, which makes it bad for high-temperature applications. It also makes it hard to deal with when you’re injection molding it. After you injection mold it, it also degrades under ultraviolet (UV) light and it becomes flammable.

It’s one of the lightest plastics. Its yield, tensile, compressive strength and hardness are better than low-pressure polyethylene. It has great rigidity, good stress relaxation resistance at high temperature (90°C), good heat resistance, and can be used above 100°C.

It is one of the lightest plastics. Its yield, tensile, compressive strength and hardness are better than those of low-pressure polyethylene. It has outstanding rigidity, good stress relaxation resistance at high temperature (90°C), good heat resistance, and can be used above 100°C.

If there is no external force, it will not deform at 150°C. It is very stable in many media except concentrated sulfuric acid and concentrated nitric acid. Low molecular weight aliphatic hydrocarbons, aromatic hydrocarbons, and chlorinated hydrocarbons have a softening and swelling effect on it.

It doesn\’t absorb water well, has bad high-frequency electrical properties, and is easy to mold. It\’s used for general structural parts, corrosion-resistant chemical equipment, and heated electrical insulation parts, and is used a lot in car interior materials.

The shrinkage of the mold is big, and it is easy to have shrinkage holes, dents, and deformation. When the mold temperature is below 50°C, the plastic parts are not bright, and it is easy to have weld marks and flow marks; when it is above 90°C, it is easy to warp and deform.

Polypropylene is super light and great for things that need to be light. It’s also strong and flexible. It can take a lot of stress without bending. Plus, it’s good with water, chemicals, and heat.

Polypropylene has some material limitations, though. It has poor UV resistance and will degrade with long-term sunlight exposure. Polypropylene also offers fewer color options than other plastic materials.

Applications

Polypropylene products made by injection molding include plastic furniture, children\’s toys, heavy-duty packaging, automotive parts, fibers and fabrics. The automotive industry uses PP with metal additives for fenders, vents, fans, etc. Appliances use PP for dishwasher door liners, dryer vents, washing machine frames and covers, refrigerator door liners, etc.

Daily consumer goods use PP for lawn and garden equipment such as lawn mowers , plastic bags , food packaging , egg cartons , hot food containers , and sprinklers, etc. Food containers, carpets, toys and household appliances also use PP.

Polypropylene is resistant to chemicals and heat.True

Polypropylene’s molecular structure provides resistance to chemical corrosion and high temperatures, making it ideal for demanding environments.

Polypropylene is only used in packaging.False

While PP is widely used in packaging, it also plays a key role in automotive, medical, and textile industries due to its durability and flexibility.

What is Polystyrene (PS) ?

Polystyrene (PS) is a versatile thermoplastic used in a wide range of applications, from packaging to consumer products. It is known for being clear, hard, and easy to mold.

Polystyrene (PS) is a low-cost, rigid plastic material used in packaging, disposable cutlery, and toys. It is available in two forms: solid and foam. Key features include clarity, ease of processing, and low-density properties.

Definition

Polystyrene is a clear, lightweight synthetic polymer that’s moderately strong when it’s not changed. It comes in two main types .

General purpose polystyrene (GPPS) is clear like a gas. It’s not as hard and it’s more brittle than HIPS. High-impact polystyrene (HIPS) is an opaque resin that’s changed with a polybutadiene elastomer to make it better. It makes the material more rigid, stable and strong.

Properties

PS is one of the few brittle injection molding materials. It is particularly lightweight, resistant to moisture and chemical reactions, and is well suited for injection molding due to its uniform heat shrinkage within the mold.

Polystyrene is a cheap plastic with a relatively high melting point. It is dimensionally stable and resistant to moisture and impact. Importantly, polystyrene is radiation resistant, which means it can be sterilized using radiation. The disadvantage is that polystyrene is flammable and has poor UV resistance.

Applications

Polystyrene is used in many different industries and applications. For example, it is used in the medical industry to make medical packaging and diagnostic tools. It is also used in the automotive industry to make car parts.

Polystyrene is used in the consumer goods industry to make things like toys and utensils. It is also used in the manufacturing industry to make things like containers and trays. Polystyrene is used in the electrical industry to make things like transparent containers and insulating films.

Polystyrene is also used in the medical device industry because it does not break down very much when it is exposed to gamma radiation, which is the main way that medical devices are sterilized. So, things like culture dishes and culture kits are made out of polystyrene by injection molding .

Polystyrene is ideal for packaging materials.True

Polystyrene's rigidity and clarity make it an excellent choice for packaging, offering protection while showcasing products in clear, durable containers.

Polystyrene is biodegradable.False

Polystyrene is not biodegradable and can take hundreds of years to break down, contributing to environmental concerns.

What is Thermoplastic Elastomer (TPE) ?

Thermoplastic elastomers (TPE) combine the flexibility of rubber with the processability of plastics, making them ideal for various applications like automotive, consumer goods, and medical devices.

Thermoplastic elastomers (TPE) are flexible, durable materials that can be molded and remolded. Common in automotive, electronics, and medical industries, TPE offers a combination of rubber-like flexibility and the easy processing of thermoplastics.

Definition

TPE is different from other injection molding materials9 because it is a plastic-rubber hybrid. It combines a thermoplastic material and an elastomeric (rubber) material. The resulting material acts like a thermoplastic while also having rubber-like properties. So, TPE is used in applications that need great flexibility. This material is also called thermoplastic rubber (TPR) and can be recycled over and over.

Properties

It combines the advantages of both materials. It is flexible, can be stretched to great lengths, is strong, and is recyclable. Moreover, its main advantage is that it is cheap compared to most rubber alternatives. However, it is not suitable for use at high temperatures because it loses some of its material properties. Moreover, it should not be stretched too much for too long because it tends to creep.

TPE is flexible because it has rubber in it. It goes back to its original shape after you stretch it. It’s also easy to work with when you’re making stuff with it. Besides being flexible, TPE is also really strong when you hit it, it doesn’t get messed up by chemicals, and it doesn’t get messed up by the weather.

However, this type of plastic is more expensive than other plastic injection molding materials. So, designers must carefully consider whether TPE alternatives will produce the same results.

Applications

Thermoplastic elastomers are used in a bunch of different stuff, like: shoes, medical stuff, electronics, things you buy, sports stuff, things that keep stuff from leaking, hoses, shoe parts, things that keep stuff from shaking, things that keep stuff from bumping, etc.

TPE is widely used in automotive manufacturing.True

TPE's flexibility and durability make it ideal for automotive applications, such as seals, gaskets, and interior parts.

TPE is not recyclable.False

TPE is recyclable and can be reprocessed, unlike thermosetting rubbers, making it more eco-friendly in comparison.

What is Thermoplastic Polyurethane (TPU) ?

Thermoplastic Polyurethane (TPU) is a versatile, durable plastic known for its elasticity, resistance to wear, and ease of processing in various applications, from automotive to electronics.

TPU is a highly flexible, durable thermoplastic with excellent abrasion resistance, making it ideal for uses in footwear, automotive parts, medical devices, and electronic components. It combines the benefits of plastics and elastomers.

Definition

TPU is a popular thermoplastic elastomer, often abbreviated as TPU. It is somewhere between rubber and plastic, with superior properties and rubber-like elasticity.

TPU can be divided into three major categories: polyester-based TPU, polyether-based TPU, and polycaprolactone-based TPU.

Characteristics

TPU is another rubber-plastic hybrid with very desirable qualities in its polyurethane component. It is very hard and has very good compressive strength, abrasion resistance, and chemical resistance. Moreover, these properties do not change much at extreme temperatures.

However, it is one of the most challenging materials to be molded. Its hardness and crystallinity often cause problems during molding; you need an expert to handle this injection molding material.

TPU is flexible and has excellent tensile and tear strength. It also has excellent chemical and heat resistance compared to other TPEs. However, it is more expensive than other materials.

Applications

TPU is a great choice for making all kinds of stuff, like: pipes, car parts like wheels, shoes, medical stuff, cases and covers, power tools, wheels, inflatable boats, shoes, and so on.

TPU is flexible and resistant to abrasion.True

TPU's molecular structure allows it to stretch and return to its original form, offering superior abrasion resistance compared to other plastics.

TPU is always more expensive than other plastics.False

While TPU may have a higher cost than some other plastics, its long-term durability and performance often justify the investment, especially in demanding applications.

What is Acrylic (PMMA) ?

Acrylic (PMMA) is a versatile, transparent thermoplastic widely used for its optical clarity and weather-resistant properties. It’s commonly seen as a substitute for glass in various applications.

Acrylic (PMMA) is a transparent, lightweight plastic used in signage, windows, and automotive parts. Known for its clarity and UV resistance, it is often chosen for outdoor applications and displays due to its durability and ease of molding.

Definition

Acrylic, also known as poly (methyl methacrylate), is a thermoplastic material that has good mechanical strength.

Characteristics

It has good transparency, chemical stability and weather resistance, easy dyeing, easy processing, beautiful appearance, light weight, and a clear, transparent appearance. Although it has no ductility, it has good resistance to chipping.

Another thing is, it’s easy to process. After injection molding, acrylic parts are easy to change and finish. It’s got crystal-like transparency, light transmittance of more than 92%, soft light, clear vision, and acrylic colored with dyes has a good color development effect. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

Acrylic sheet is easy to process and can be thermoformed or machined. Transparent acrylic sheet has a light transmittance similar to glass, but the density is only half of glass. Moreover, it is not as fragile as glass, and even if it is damaged, it will not form sharp fragments like glass.

The wear resistance of acrylic sheet is close to that of aluminum, with good stability and resistance to corrosion from various chemicals. Acrylic sheet has good printability and sprayability.

By using appropriate printing and spraying processes, acrylic products can achieve a good surface decoration effect. Flame resistance: It does not spontaneously ignite but is a flammable product and does not have self-extinguishing properties.

Applications

Acrylic is used in many different ways. It can be used in buildings for things like windows, doors, and skylights. It can be used in advertising for things like signs and display racks. It can be used in transportation for things like car windows and train windows.

It can be used in medicine for things like incubators and surgical instruments. It can be used in everyday life for things like bathroom fixtures, crafts, and aquariums. It can be used in industry for things like instrument panels. And it can be used for many other things too.

Acrylic is more durable than glass.True

Acrylic is impact-resistant and shatterproof, making it more durable than glass, which is prone to breaking under stress.

Acrylic is not UV resistant.False

Acrylic offers excellent UV resistance, preventing yellowing and degradation when exposed to sunlight, which is a major advantage over many other plastics.

Conclusion

Injection molding is famous for being used in a lot of different ways. Although some plastic waste is generated , it’s so popular is because there are so many different materials you can use.In addition to the commonly used plastics for injection molding , other materials such as polyethylene terephthalate, polyvinyl chloride, polycarbonate plastic, polyethylene plastic, etc. are also often injection molded.

In this article, we’ve looked at some of the most common types of plastics used in injection molding. We’ve told you what they look like, their advantages and disadvantages, and helped you figure out which plastic is best for you.

-

Exploring nylon 11’s unique properties and applications can provide insights into its suitability for specific industrial uses, enhancing material selection processes. ↩

-

Discover why ABS is a top choice for injection molding, offering cost-effectiveness, strength, and versatility for various applications. ↩

-

Discover the advantages and applications of plastic injection molding materials to enhance your manufacturing processes. ↩

-

Learn how optical clarity in materials like polycarbonate can improve product quality and functionality. ↩

-

Explore the significance of heat resistance in materials for ensuring durability and performance in high-temperature applications. ↩

-

Explore how UHMWPE’s unique properties make it ideal for bulletproof vests and medical devices, enhancing safety and healthcare. ↩

-

Discover why HDPE’s strength and rigidity are preferred for durable products like kettles and pipes, ensuring longevity and reliability. ↩

-

Learn about POM’s exceptional properties that make it indispensable for precision parts in engineering and medical fields. ↩

-

Learn about What are the Commonly Used Injection Molding Materials ? The most commonly used injection molding materials are thermoplastics like ABS, polypropylene, and polycarbonate, thermosets . ↩