Choosing the right injection speed is crucial for achieving high-quality injection molded parts and optimizing production efficiency. Selecting the appropriate speed ensures that the material flows properly, fills the mold evenly, and minimizes defects.

The ideal injection speed depends on factors like material type, mold design, and part geometry. Slower injection speeds are used for complex shapes or to prevent defects like air traps, while faster speeds are beneficial for simple parts and larger molds. Adjusting the speed optimizes cycle times and part consistency.

Understanding how injection speed affects the molding process is essential for fine-tuning your operations. Experimenting with speed settings based on part design and material behavior can significantly enhance both quality and productivity.

Slower injection speeds are always better for part quality.False

Slower speeds can prevent defects in complex molds, but faster speeds may be necessary for efficient production and achieving consistency in simpler designs.

The right injection speed improves both part quality and cycle times.True

Optimizing injection speed ensures better material flow, reduces defects, and shortens cycle times for improved efficiency and consistency in production.

What is Injection Speed?

Selecting the right injection speed is critical to achieving optimal part quality and efficient production in injection molding. It impacts cycle time, material flow, and overall process performance.

The ideal injection speed balances fast filling with minimal pressure to avoid defects like warping or short shots. A slower speed is often used for complex parts, while faster speeds are preferred for simple, large parts. Properly adjusting injection speed reduces material waste and enhances part consistency.

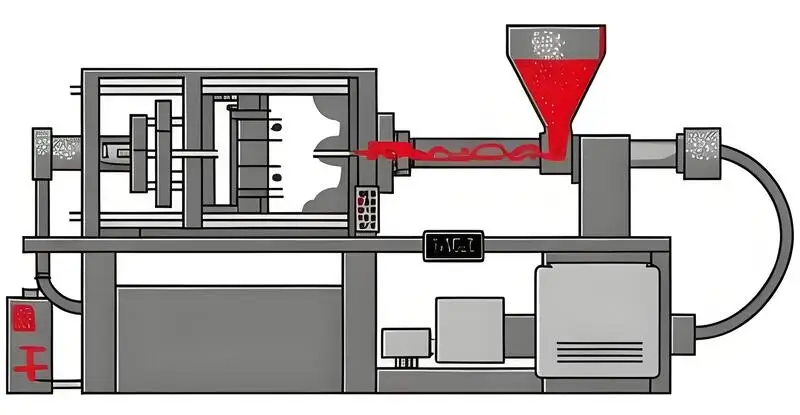

Injection speed is the speed at which the plastic melt is pushed into the mold during the injection process of the injection molding machine.

Injection speed is usually expressed in millimeters per second (mm/s) or centimeters per second (cm/s). The appropriate injection speed not only ensures the uniformity and integrity of the product, but is also directly related to the energy consumption and production cycle of the injection molding machine. At present, it is generally believed in the market that the moderate injection speed is usually between 50 mm/s and 200 mm/s, while special products may require higher speeds.

Faster injection speeds are always better for mold filling.False

While fast injection speeds can reduce cycle time, they may lead to defects like flash or warping if the material fills too quickly. A balanced approach is necessary.

The correct injection speed reduces cycle time and improves part quality.True

The right injection speed ensures smooth material flow, improving part quality and reducing unnecessary cycle time. Proper adjustments are key to preventing defects.

What are the Advantages and Disadvantages of High And Low Injection Speeds?

High and low injection speeds are critical factors in the 사출 성형 공정1, directly affecting cycle time, product quality, and material usage. Understanding the advantages and disadvantages of these speeds is essential for optimizing your production process and improving efficiency.

High injection speeds can reduce cycle times and improve productivity, but may lead to defects like flash or poor fill. Low injection speeds provide better control and reduce defects, though they may increase cycle times. Adjusting the injection speed based on material and part complexity can significantly enhance molding outcomes.

There are Several Advantages to Using High-Speed Injection During the Injection Process

-

Boost production efficiency: The biggest advantage of high-speed injection is its super high production efficiency. Because high-speed injection is much faster than traditional injection, more production tasks can be completed in the same amount of time. For manufacturers who produce in large quantities, this can greatly boost production efficiency and reduce production costs.

-

Make product better:Fast injection makes the plastic melt fill the mold fast, so the melt cools less and the product looks better. Also, fast injection makes the melt get less squeezed and the product gets less squeezed, so the product is better overall.

-

Cut down on waste:Because high-speed injection is fast, it creates less waste during production. This helps cut down on waste and further reduce production costs.

-

Open up new possibilities:The development of high-speed injection technology has made it possible to produce many complex plastic products that are hard to make using traditional injection methods. For example, some thin-walled, high-precision plastic products can only be made with high-speed injection to guarantee product quality and production efficiency.

There are the Following Disadvantages to Using High-Speed Injection During the Injection Process

-

Expensive equipment: High-speed injection has a lot of advantages, but the machines you need to do it are usually expensive. Some small companies might not be able to afford the cost of buying the machines.

-

Need skilled operators: High-speed injection is more complicated, so you need operators who know what they’re doing. They need to have a lot of experience and know what they’re doing to make sure everything goes smoothly.

-

Might wear out the mold: When you do high-speed injection, the plastic rubs against the mold a lot, which can wear it out faster. That means you might have to replace the mold more often.

-

Not for everything:High-speed injection has its advantages, but it’s not always the best choice for certain plastic parts, like thick-walled or large parts. Sometimes, you need to go back to the old way of doing things.

The Advantages of Low-Speed Injection During the Injection Process are as Follows

Preventing 플래시 2on molded parts; Preventing jetting and flow lines3; Preventing burn marks; Preventing air entrapment in the melt; Preventing molecular orientation deformation. The advantages of high-speed injection are also the disadvantages of low-speed injection, and vice versa.

Therefore, combining high speed and low speed during the injection process can take full advantage of their respective strengths and avoid their respective weaknesses, ensuring product quality and process economy. This is what we usually call multi-stage injection technology, which is widely used on modern injection molding machines.

The Disadvantages of Low-Speed Injection During the Injection Process are as Follows

-

The production cycle gets longer: When you inject plastic at a low speed, it takes longer for the plastic to fill the mold. That means the whole molding process takes longer, which slows down production. This is especially true when you’re making a lot of parts.

-

Cooling isn’t even: When you inject plastic slowly, it doesn’t flow as well. That means some parts of the mold take longer to cool than others. Uneven cooling can make the part warp4 or crack, which can make it look bad or not work right.

-

Bubbles: When you inject plastic slowly, air can get trapped in the plastic. The air can’t get out fast enough, so it can make 거품5 or voids in the part. That can make the part look bad and not be as strong, which can make it not work right.

High injection speeds improve cycle time in injection molding.True

High injection speeds reduce the time it takes to inject the material, leading to faster cycle times and increased productivity.

Low injection speeds always result in longer cycle times.False

While low injection speeds can increase cycle time, they can also improve part quality and reduce defects, making them ideal for complex parts or materials requiring more control.

What is the Principle of Injection Speed Selection?

Injection speed selection is a critical factor in the injection molding process that influences both part quality and production efficiency.

Injection speed is the rate at which molten plastic fills the mold cavity. The right speed ensures uniform filling, reduces defects like short shots or warping, and shortens cycle times. It depends on material, part complexity, and mold design, balancing speed with quality.

Because the shape of plastic products is complex, the flow and deformation of the plastic melt through the main channel, branch channel, gate, and each section in the 몰드 캐비티6 during the injection process are extremely complex.

In recent years, through the study of rheology and combined with CAE technology, it is concluded that in order to make the product quality good and the internal stress small, the most important condition is to make the flow field of the melt reasonably uniform, that is, the melt flow front speed remains uniform and stable when it flows through different sections at different times during the injection molding process, that is, the linear speed must remain constant, V = constant.

The products made this way are good quality and don’t have problems like shrinkage and not enough filling. Also, the melt flows evenly in the cavity, so the polymer molecules line up right and the products have a better surface.

Because injection molded products have a complicated shape, the area of the mold cavity that the plastic melt flows through is different in different parts, and the resistance is different too.

So, the flow rate Q=V×S (S is the area of the cross section) is different too, which means the flow rate changes over time. Also, the injection pressure changes over time. To make the process cost-effective, which means to make the injection time and molding cycle shorter, you have to use multi-stage injection to do it. That way, you can make sure the product is good quality and it’s cost-effective.

Faster injection speed always leads to better quality parts.False

Too fast an injection speed can cause defects like flashing or sink marks, while too slow can lead to incomplete filling and longer cycle times. Balancing speed is crucial.

Injection speed should always be high to reduce cycle time.False

The optimal injection speed depends on factors like material, mold design, and part geometry. A balance must be struck to prevent defects and improve efficiency.

What Factors Should be Considered When Choosing a Suitable Injection Speed?

Choosing the right injection speed is crucial for optimizing part quality and reducing defects during the injection molding process.

Injection speed affects part quality, cycle time, and material flow. Factors to consider include material type, part complexity, mold design, and the need for precise control over fill patterns. Choosing the right speed helps reduce defects and improve consistency.

머티리얼 속성

Different plastics have different viscosities and melt flow rates, which directly affect the choice of injection speed. High-viscosity plastics, such as low-density polyethylene, have greater flow resistance during the injection process, so a lower injection speed is required to avoid excessive heat generation, resulting in deformation or shrinkage.

Conversely, some low-viscosity plastics require a higher injection speed to ensure a smooth surface of the plastic part. Materials with good fluidity can use faster injection speeds, while complex molds with high fluidity requirements can prevent material backflow or bubble generation by appropriately reducing the injection speed.

금형 설계

When you’re making a mold with a lot of parts or a mold with a lot of detail, you have to adjust the injection speed to make sure the plastic fills the mold evenly. If you inject the plastic too fast, you can get defects in the mold, like short shots or weld lines.

The size and shape of the flow channels in the mold also affect the injection speed. If you have a mold with big parts, you have to inject the plastic faster to make sure it fills the whole part. If you have a mold with small parts or a mold with a lot of twists and turns in the flow channels, you have to inject the plastic slower so you don’t break the mold or make the plastic solidify too soon.

사출 성형기

The injection speed is directly affected by the parameters of the injection molding machine, such as tonnage, oil pressure, and injection volume. Large injection molding machines have higher pressures and injection volumes, so their injection speeds are faster.

Small injection molding machines may cause cracking or other defects in plastic parts due to too fast injection speeds. Therefore, when selecting an injection molding machine, the appropriate model should be matched according to the plastic properties and mold design.

Right now, there are a lot of different types of injection molding machines being used in the industry, and different types of injection molding machines will also put certain restrictions on the injection speed. All-electric injection molding machines usually have faster response speeds and higher repeatability, while hydraulic injection molding machines can provide greater injection force and higher injection speeds. So, choosing the right type of machine according to your production needs is crucial to achieving the best injection speed.

운영자 기술

The operator’s skill and proficiency have a big impact on injection speed. Good operators can adjust injection speed based on the type of machine and the plastic being used to make sure the injection goes smoothly and the parts come out good.

What is the Reasonable Choice of Injection Speed?

Injection speed plays a key role in determining part quality and cycle time in injection molding. Selecting the right speed ensures optimal flow, reduces defects, and improves efficiency.

The reasonable choice of injection speed depends on material type, part design, and mold temperature. Too fast can cause defects, while too slow can increase cycle time. Proper speed ensures better part quality and efficient production.

Based on the flow of the melt during the injection process, we generally divide the injection speed into five parts:

The first part is the main channel and the branch channel. In principle, high-speed filling is used to shorten the molding cycle, but it must be considered that this high-speed injection should not cause poor surface quality;

The second part is the gate and the product part near the gate. This stage makes corresponding changes for different raw materials and gate forms. Usually a lower injection speed is used, especially for high-viscosity resins such as PC, PMMA, ABS, etc., and side gates (straight gates, such as cabinet transparent sheets, window machine panel door covers and longitudinal blades, etc.) to prevent the occurrence of spray marks and gate fog spots. If the gate adopts a point gate or a lap gate and the raw material is a low-viscosity resin such as PP, PA, PBT, etc., and the surface quality requirements near the gate are not high, high-speed injection can be used;

The third part is the main part of the molded part, which means that the product near the gate is filled to about 70% to 80% of the weight of the molded part. This part is filled at a high speed to shorten the molding cycle, reduce the viscosity change of the melt in the metal mold cavity, improve the gloss of the product surface, and reduce the deformation caused by the reduction of plastic pressure during the final mold filling, improve the weld strength, and improve the appearance of the weld line.

The fourth part is about 85% to 90% full, and it fills up quickly. This part uses medium-speed injection to transition to the next stage of low-speed injection. It also prevents the molded part from being too thick and flashing because the gates are uneven.

The fifth part is the last part to fill the cavity. Use low-speed injection here to prevent flashing and burning marks. It also improves the stability of the part’s size and weight. You can also control and reduce the clamping pressure.

Injection speed affects part quality and cycle time.True

Higher injection speeds can reduce cycle times but may lead to defects such as warping or flash. Balancing speed and material flow ensures quality parts.

Higher injection speed is always better for quality.False

Too high an injection speed may cause defects. An optimal speed, tailored to material and design, is crucial for part quality.

How to Set and Correct the Injection Speed Curve?

Setting and correcting the injection speed curve is crucial to achieving optimal injection molding results, improving part quality, and reducing defects.

The injection speed curve controls the speed of material injection, impacting part fill, surface finish, and cycle time. Proper adjustment ensures efficient filling, minimizes defects, and enhances part consistency.

Knowing the selection principle and reasonable distribution of injection speed, how to accurately set the injection speed curve in actual operation process has become the focus of process personnel.

- Injection speed setting: When setting the injection speed curve, operators should pay attention to two aspects: ⑴ the magnitude of the injection speed; ⑵ the setting of the injection position. The usual practice is to use the zero injection method to set the screw injection position. That is, set the second-stage injection pressure and speed to zero, adjust the injection position, observe the size and shape of the actual injection molded product, compare it with the required position, and then determine.

Then set the second-stage injection pressure, speed, and position, set the third-stage injection pressure and speed to zero, and also compare whether the input position is reasonable, and determine the feed amount by analogy; then adjust the speed, generally from low to high, and try to use high-speed filling without affecting the surface quality of the product to shorten the molding cycle.

- Correction of injection speed:When correcting the injection speed curve, you need to do it in reverse. First, determine the injection speed adjustment, and then review the conversion position of the injection speed change. This is because the injection position is basically in line with our expectations when the injection curve is given, but the change in injection speed will cause deviations in the filling results of the same injection speed conversion position.

When performing multi-stage injection, the injection pressure and injection speed are also interrelated and affect each other. When the filling time is very short, due to the long process, the flow rate (injection speed) of the melt is also higher, so the required injection pressure is also higher.

Also, if you increase the filling time (that is, slow down the injection speed), the polymer will cool for a longer time, so the frozen layer that forms when the polymer hits the cold mold will be thicker. This means that the molten flow layer in the middle will get thinner, the melt will get more viscous, and it will be harder to push it through, so you’ll need a higher injection pressure to fill the mold.

So, when adjusting the injection pressure, the injection pressure should be adjusted slightly higher, so that the flash, lack of material and other defects of the product can be accurately controlled by adjusting the injection speed of each section. This is the idea of the pressure and speed control design of the injection molding machine: the injection pressure is one stage, the injection speed is six stages, and the defects of the product can be overcome by adjusting the injection speed.

- Causes and solutions: Gate flow marks are caused by the flow lines generated by melt injection; the gate injection angle on the mold is aligned with the core to avoid direct injection. In addition, the process is adjusted to slow down the injection speed when the melt flows through the gate. Since the first-stage injection speed is slowed down, the melt solidifies when it encounters the cold mold and the solidification layer is thicker, and the required injection pressure is larger.

Therefore, the second-stage injection speed is increased to reduce the filling time, reduce the injection pressure as much as possible, and prevent the product from shrinking7 . When the cavity is about to be filled, the injection speed is slowed down to prevent the appearance of flash.

- Causes and solutions: Fusion flow marks happen because the melt gets too hot from friction when it goes through the five-point gate, and then it gets cold really fast when it hits the cold mold wall after it’s poured in from the side. When the two streams meet and move forward together, they rub and shear against each other, and that makes the melt break and make fusion flow marks.

On the mold, the side gate straight-in gate is changed to a fan-shaped gate to make the fusion angle bigger, so the two streams start to come together really close to the gate, and try to not have the two streams be different temperatures and cool down.

Also, the process adjustment increases the speed of the first stage, and the injection speed is slowed down when the melt flows through the gate to reduce the shear rate. When the product is filled to 50%, the injection speed is increased to ensure complete filling and maintain low injection pressure to reduce the weld line. When the cavity is about to be filled, the speed is slowed down to reduce the flash and the uneven gloss of the weld line.

Correcting the injection speed curve reduces part defects.True

A well-set curve ensures even material flow, reducing common defects like warping or short shots.

Changing the injection speed curve always improves part quality.False

While adjustments can enhance quality, improper settings may lead to issues like overpacking or material degradation.

결론

Selecting the right injection speed is critical to part quality and production efficiency. Injection speed is affected by materials, molds, machines, and operator skills. High-speed injection can quickly produce high-quality parts, but it is more expensive and prone to wear; low-speed injection avoids problems, but it is slower. Through multi-stage injection, fast production and cost savings can be achieved. Adjusting the injection speed curve can improve part quality and speed up production.

-

Learn about How to Optimize an Injection Molding Process :Injection molding is the process of making semi-finished parts of a certain shape by pressurizing, injecting, cooling, and separating the molten raw materials. ↩

-

사출 성형 공정에서 플래시의 원인과 이를 방지하는 방법에 대해 알아보세요: 사출 성형 플래시는 사출 중 용융된 플라스틱이 금형 밖으로 흘러나와 응고될 때 발생하는 결함입니다. ↩

-

Learn about How to avoid injection molding flow lines: Flow lines or flow marks are a common visual defect in injection molding. ↩

-

Learn about Injection Molding: The Causes of Warpage : it’s clear that varying shrinkage rates can cause warpage . ↩

-

Learn about What are the causes and solutions for air bubbles in injection molded parts : Some bubbles are mainly caused by material degradation. ↩

-

Learn about Mold Core & Mold Cavity: Differences And Design Consideration : The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. ↩

-

Solving the Injection Molding Shrinkage with Effective Ways: Injection molding shrinkage simply refers to how much the polymers will contract during the cooling phase. ↩