モールドフロー解析は、射出成形プロセスをシミュレートして潜在的な欠陥を予測し、部品設計を最適化することで、生産効率と品質を向上させます。

金型流動解析は、エンジニアが製造前にエアトラップやウェルドラインなどの問題を検出し、設計を強化し、欠陥を減らし、製造コストを削減するのに役立ちます。

金型流動解析を理解することは、設計を改良し、不良のない生産を確保するために不可欠です。このシミュレーションツールがどのように製造効率を向上させるのか、さらに深く掘り下げてみましょう。

金型流動解析は、エアトラップやウェルドラインのような欠陥を防ぎます。真

溶融プラスチックの流れをシミュレートすることで、金型流動解析は欠陥を予測し、エアトラップやウェルドラインのような問題を防ぐために部品設計を最適化するのに役立ちます。

モールドフロー解析は複雑な部品にのみ有効です。偽

モールドフロー解析は、単純な部品にも複雑な部品にも適用でき、品質を向上させ、製造不良を減らすことができるため、さまざまな設計に役立ちます。

金型流動解析の具体的なステップとプロセスとは?

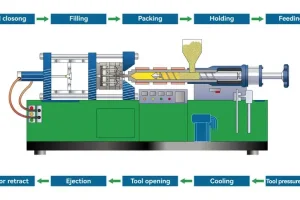

モールドフロー解析は、射出成形中に溶融プラスチックがどのように流れるかを評価するもので、潜在的な欠陥を予測し、より良い性能のために設計を最適化するのに役立ちます。

金型流動解析は射出成形プロセスをシミュレートし、エアトラップやウェルドラインのような問題を検出し、設計、サイクルタイム、材料使用量を向上させ、より高品質な部品と生産コストの削減を実現します。

準備しっかりとした土台作り

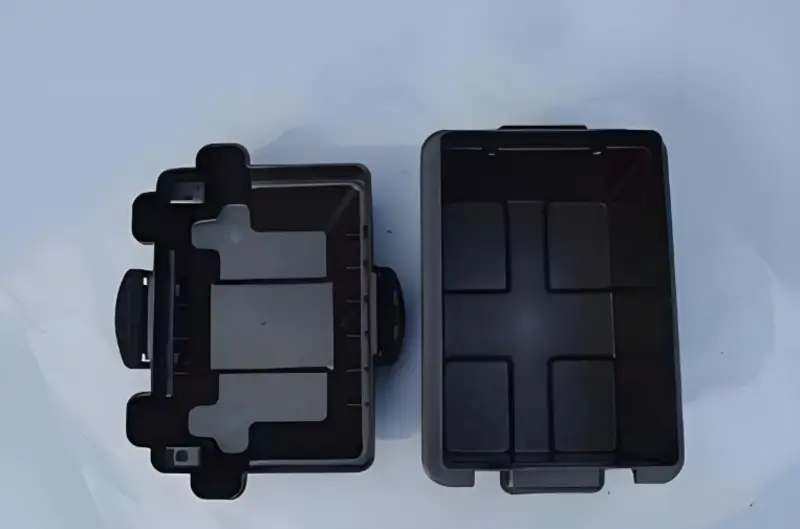

金型流動解析を行う前に、なぜそれを行うのかを知り、必要なものを集める必要があります。つまり、3Dモデル、金型構造、その他もろもろです。それがシミュレーションの世界の「レンガとモルタル」であり、正しいものでなければなりません。

例えば、新しい携帯電話のケーシングを設計する場合、ケーシングの詳細な3Dモデルと金型の予備的な構造計画を提供し、流動解析ソフトウェアが金型内の溶融物の流動を正確にシミュレーションできるようにする必要があります。

メッシュ作成:シミュレーション世界の骨格を作る

メッシュ作成は 金型流動解析1.シミュレーションの精度と効率を決定する。高品質の 有限要素メッシュ2 は、シミュレーションの世界で立派な「骨格」を作るようなものだ。

このプロセスでは、メッシュがモデルの幾何学的特徴を正確に反映できるように、モデルの複雑さ、解析精度、計算リソースを考慮する必要がありますが、複雑すぎて計算時間が長くなることはありません。

例えば 射出成形プロセス3 車のバンパーの場合、シミュレーション結果の精度と信頼性を確保するために、バンパーの複雑な形状とサイズに応じてメッシュの密度と種類を合理的に分割する必要があります。

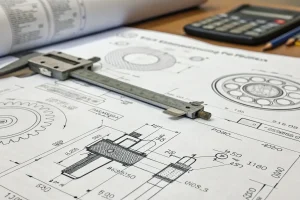

パラメータ設定:シミュレーション世界のルールを定義する

金型流動解析では、パラメータの設定も重要な作業である。シミュレーションの世界における様々な物理的、化学的プロセスのルールを定義します。これには、プラスチックの密度、粘度、熱伝導率などの材料パラメータや、射出速度、射出圧力、保圧時間などの射出パラメータが含まれます。シミュレーションの世界で正しい「物理法則」が設定されているように、これらのパラメーターの精度は解析結果の信頼性に直接影響します。

例えば、新しいプラスチックボトルを設計する場合、プラスチック材料と射出パラメーターを正確に設定する必要があります。そうすれば、射出成形プロセスでプラスチックボトルがどのように変形し、どこに応力がかかるかをシミュレーション結果で実際に示すことができます。

シミュレーション分析:シミュレーションの世界を動かす

金型流動解析ソフトは金型流動解析の核心です。シミュレーションの世界を「ライブ」アップさせるようなもので、金型流動、冷却、硬化過程のプラスチック溶融物が生き生きと表示されます。ユーザーが設定した境界条件とパラメータに従って、ソフトウェアは流体力学、熱力学、状態方程式からなる連立一次方程式を解き、詳細なシミュレーション結果を生成します。

例えば、携帯電話のケーシングの射出成形プロセスをシミュレートする場合、ソフトウェアはメルトフローレート、圧力分布、金型内の温度変化などの重要なパラメータを計算し、その後の評価と最適化のための科学的根拠を提供する。

モールドフロー分析は、成形プロセスにおける潜在的な欠陥を特定するのに役立ちます。真

金型流動解析は、実際の成形条件をシミュレートし、エアポケット、ショートショット、流動のアンバランスなどの欠陥を突き止め、より効率的な設計を保証します。

金型流動解析が必要なのは、大規模生産の場合だけである。偽

金型流動解析は、試作段階と量産段階の両方で有益であり、あらゆるプロジェクト段階において設計を最適化し、試行錯誤のコストを削減するのに役立ちます。

金型流動解析の役割と利点とは?

金型流動解析は、溶融プラスチックが金型内でどのように流動するかをシミュレーション・解析することで、射出成形プロセスを最適化し、より良い設計と生産効率を実現します。

モールドフロー解析は、材料の流れや潜在的な欠陥を予測し、金型設計を最適化することで、部品の品質を向上させ、サイクルタイムを短縮し、無駄を最小限に抑え、費用対効果の高い製造を実現します。

射出成形品の不良率を減らす

適切な射出圧力、速度、温度、その他のプロセスパラメーターを決定するのに役立ちます。さまざまなパラメータ設定下で充填効果をシミュレーションし、最適な充填と製品品質を保証するパラメータの組み合わせを選択します。これにより、生産効率と製品の安定性が向上します。また、射出成形品の不良率を低減します。

モールドフロー解析は、欠陥の数を減らし、射出成形部品の表面仕上げと寸法精度を改善することで、より良い部品を作るのに役立ちます。これは、射出成形プロセスにおける温度、圧力、メルトフローレート、その他のパラメーターの微調整と最適化を支援することによって実現します。

近年、一部の関連加工・製造企業は CAE関連技術4 金型流動解析により、関連プラスチック製品の統合設計プロセスを実現し、システム全体の最終製品の品質を大幅に向上させた。

金型流動解析は成形部品の変形と欠陥を予測し、金型のデバッグと成形工程の調整を導き、製品の品質と歩留まり率を向上させることができる。金型流動解析は金型構造の強度と剛性を分析し、金型構造と加工技術を最適化し、生産効率と製品品質を向上させることができる。

コスト削減と生産効率の向上

モールドフロー分析は、金型やプラスチック射出方法を調整することで、廃棄物を減らし、材料費を節約し、不良部品の数を減らすのに役立ちます。

モールドフロー解析は、射出成形プロセスのプロセスパラメータと製品品質を迅速かつ正確に予測し、製品開発サイクルと市場投入までの時間を短縮します。これにより、生産効率が向上します。

旧来の射出成形金型設計は金型設計者の経験に依存していたが、金型流動解析ソフトは経験的判断に取って代わり、得られるデータは安定的で信頼性が高く、製造リスクとコストを低減する。

モールドフロー分析は、射出成形プロセスのどこに問題があるかを見つけ出し、最適なプロセスパラメーターを見つけ、生産効率と生産能力を向上させるのに役立ちます。金型流動解析は、金型を作る前に何が問題かを見つけるのに役立ちます。これにより、より多くの部品をより早く作ることができます。

ソフトウェア自体は使いやすく、パラメータ情報のシミュレーションと分析機能は強力で、反応が速く、一定の範囲内で全体的な作業効率を向上させることができます。金型流動解析はコンピュータシミュレーションにより、塑性流動状態と変形を迅速に予測でき、実験コストと時間を節約できる。

自動化された高品質のランナーメッシュ構造

ランナーメッシュを手作業で作ることは、複雑な橋をミニチュアで作るようなものだと考えてください。自動化された高品質のランナー・メッシュは、あなたのためにすべてを行う「ブリッジ・ビルダー」を持つようなものです。このテクノロジーは、高解像度の6面体メッシュを自動生成し、直線ランナーの接合部を正確に接続するためのさまざまなノードタイプを提供するため、オリジナルのランナー形状を忠実に表現することができます。これにより、時間を節約し、シミュレーション精度を大幅に向上させることができます。

射出成形プロセスを例にとろう。ランナーの設計は、溶融物の流量と圧力分布に直接関係しています。自動メッシング技術は、これらの重要なパラメータの正確なシミュレーションを保証し、ランナー設計の最適化を強力にサポートします。

比類なきメッシュ技術

ノンマッチング・メッシュ・テクノロジーは、製品とインサートのメッシュ・インターフェイスは連続的でなければならず、番号に対応していなければならないという従来の制約を破る「翻訳機」のようなものである。たとえ製品とインサートのメッシュノードが一致していなくても、 非マッチング・メッシュ・テクノロジー5 それでもなお、正確なシミュレーション解析を実施し、シミュレーション結果の正しい分布と接続部品の変形予測を行うことができる。

この技術的ブレークスルーにより、金型ベースメッシュの処理効率と解析精度が大幅に向上した。電子製品のインサートの射出成形を例にとると、インサートとプラスチック部品の界面は複雑で不規則であることが多く、非整合メッシュ技術は、シミュレーション結果の精度と信頼性を確保するために、この課題に容易に対処することができます。

多重特殊プロセスのシミュレーションと解析

金型流動解析は、標準的な射出成形工程のシミュレーションや解析にとどまりません。金型流動解析は「何でも屋」のようなもので、常にそのスキルを拡大しています。今日、金型流動解析は、射出圧縮成形、圧縮成形、金属粉末射出成形のような幅広い特殊工程をカバーしています。

自動車の軽量化と低燃費の要求が高まるにつれ、金型流動解析は、ガスアシスト射出成形、水アシスト射出成形、微細発泡成形などの高度な成形技術をシミュレーション予測の範囲に含め、印象的な検証データと使用経験を達成してきた。

これらの技術の使用により、金型流動解析は複雑な成形工程を容易に扱うことができるようになり、製品設計と製造革新の余地が広がった。

特定の課題に特化した分析機能

の製造におけるインクの流出やシワの変形といった特定の問題に関して言えば、そのような問題はない。 インモールド加飾射出成形6金型流動解析ソフトウェアは、「あらゆる不従順に対応する」能力を備えています。専用の解析機能を提供し、インモールドトリムシミュレーションの前処理でフィルム境界オプションをサポートし、トリムメッシュ層の処理をより速く、より簡単に、より正確にします。

一方、新しい「スクラブ・インデックス」によって、製品設計者はスクラブがどの程度必要かを確認できるため、毎回同じ品質のインモールド・トリムパーツを得ることができます。この機能は、金型内装飾部品をより良く、より速くするだけでなく、設計者が何をすべきかを判断するためのより良い方法を提供します。

金型設計の最適化

金型を作る前に、射出成形加工業者は金型流動解析を使って潜在的な問題を予測することができる。

例えば、エアーの閉じ込め、ショートショット、融着痕など、起こりうる欠陥を予測し、金型のゲート位置、ランナーシステム、排気構造などを最適化・調整することで、実際の生産後期に金型の補修を繰り返すことを避け、コストと時間を節約することができる。

金型流動解析は、金型内のプラスチックの流動状態を予測し、デッドコーナー、デッドフロー、ショートフローの可能性のある問題を発見し、金型の構造設計と最適化を導くことができます。

モールドフロー解析は部品の品質を向上させます。真

モールドフロー解析は、設計上の欠陥を特定し、材料フローを最適化することで、均一な部品品質と欠陥の低減を実現します。

金型流動解析は複雑な金型設計にのみ有効です。偽

モールドフロー解析は、単純な金型にも複雑な金型にも有効で、あらゆる設計における全体的な効率、品質、費用対効果の向上に役立ちます。

射出成形工場におけるモールドフロー解析の応用例とは?

金型流動解析は射出成形工場において非常に重要であり、設計を最適化し、様々な産業の生産効率を向上させます。

金型流動解析は射出成形をシミュレートして材料の流動と冷却を予測し、金型設計を強化し、自動車、電子機器、医療機器製造における欠陥を最小限に抑えて効率と品質を向上させます。

複雑な成形品の加工

モールドフロー分析は、射出成形工場が複雑な射出成形品を加工するのに役立ちます。例えば、複雑な製品が生産され、射出成形プロセスのパラメータを調整する必要がある場合、モールドフロー解析を使用して最適な射出成形プロセスパラメータを取得し、製品が要件を満たすように処理できるようにすることができます。

製品の表面仕上げの改善

モールドフロー解析は、金型を設計する際にゲートやベントの位置、ランナーの形状や長さを最適化するために使用することができ、その結果、製品の表面仕上げを改善し、製品表面の欠陥や不完全性を減らすことができます。

製品製造コストの削減

金型流動解析は、次のような最適化に使用できます。 射出成形プロセスパラメータ7 と金型構造により、製品の製造コストを削減する。

例えば、ある製品の生産において、元の各金型は100個の製品を生産することができるが、最適化のための金型流動分析によって、各金型は120個の製品を生産することができ、製品の生産コストを削減することができる。

金型流動解析は射出成形の不良低減に役立ちます。真

材料の流れをシミュレートすることで、金型流動解析は、エアトラップ、ウェルドライン、材料の不均一性などの欠陥を特定し、防止するのに役立ちます。

モールドフロー分析により、100%の無欠陥生産が保証されます。偽

モールドフロー解析は不良を大幅に減らすが、材料の品質や機械の設定など他の要因も関係するため、完全に不良のない生産を保証するものではない。

モデル・フロー分析の未来は?

モデルフロー解析は急速に進化しており、設計精度を高め、様々な産業の射出成形プロセスを最適化しています。将来的には、より高度なシミュレーションと自動化との統合が期待されています。

モデルフロー解析の将来は、シミュレーションの精度とスピードを向上させ、生産効率を高め、コストを削減するために、AIと機械学習の統合を重視する。

知性と精度:さらなる高みへ

AIと機械学習技術の絶え間ない発展により、金型流動解析はインテリジェンスと精度の新時代を切り開くだろう。

これらの技術を金型流動解析ソフトウェアに組み込むことで、重要なパラメーターを自動的に特定・最適化し、解析の精度と効率を向上させることができる。これは、金型流動解析ソフトウェアに「インテリジェントな目」を設置するようなもので、プラスチック成形プロセスの微妙な変化まで、より正確に観察できるようになる。

統合と融合:シームレスなリンクの構築

将来的には、金型流動解析は他のCAD/CAEソフトウェアとより密接に統合されるでしょう。これにより、設計、解析、最適化のプロセスがよりスムーズかつ効率的になり、手戻りやデータ変換ミスが減少する。これは、シームレスな「設計-解析-最適化」のエコシステムを構築するようなもので、設計者はこのエコシステムの中を自由に行き来し、設計から生産までのすべてのステップを簡単に完了することができます。

クラウドコンピューティングとビッグデータ:無限の可能性

クラウド・コンピューティングの発展と ビッグデータ技術8 は、金型流動解析のためのかつてないコンピューティングリソースとデータストレージ容量を提供する。そして クラウド・コンピューティング9企業はいつでもどこでも金型流動解析ソフトウェアとデータにアクセスでき、遠隔コラボレーションとリソース共有を実現できる。

同時に、ビッグデータ技術は、企業がモールドフロー分析によって生成された膨大な量のデータを採掘・分析し、より深い洞察と製品設計・製造の意思決定支援を提供するのに役立つだろう。モールドフロー解析に関しては、より高く、より遠くへ飛べるように、私たちはそれに一対の「翼」を加えた。

新素材とプロセス:広がる応用の境界

新素材や新工程が続々と登場するにつれ、金型流動解析はますます発展していくでしょう。例えば、繊維複合材料の圧縮成形プロセス解析、ガスアシスト射出成形、水アシスト射出成形、その他の先端成形技術シミュレーション予測のために、金型流動解析はますます大きな役割を果たすでしょう。

このような新しい材料やプロセスの適用は、金型流動解析に新たな課題と機会をもたらすだろう。同時に、金型流動解析技術の継続的な革新と発展も促進されるでしょう。

モールドフロー解析は、コンピュータを使ったシミュレーション技術で、プラスチック製品の設計や製造に超重要なものだ。最終的な形状、サイズ、応力分布、その他製品に関する重要なことを予測できる、超精密な「預言者」のようなものです。金型やプラスチック部品の設計に大いに役立ちます。

技術が進歩し、アプリケーションが拡大し続けるにつれて、金型流動解析は将来、より大きな役割を果たし、企業にさらなる価値を生み出すだろう。

モデルフロー解析は、設計時間を大幅に短縮します。真

高度なシミュレーションは、より迅速な反復を可能にし、設計上の欠陥の迅速な特定につながり、製品開発に費やす全体的な時間を短縮します。

モデルフロー解析は、物理的なプロトタイプの必要性を排除します。偽

シミュレーションはプロトタイプの繰り返しを減らすことはできるが、実環境での製品性能を保証するための物理的試験の必要性を完全に代替するものではない。

結論

金型流動解析は、金型内でのプラスチック溶融物の流動、冷却、硬化過程をシミュレートし、金型設計を最適化するために使用されるコンピューター・シミュレーション技術である。 射出成形プロセス 10 と金型設計。

このプロセスには、事前準備、メッシュ分割、パラメータ設定、シミュレーション解析、結果の最適化が含まれ、効果的に欠陥を減らし、製品品質を向上させることができます。生産コストの削減、効率の向上、ガスアシスト射出成形やインモールド加飾成形などの様々な特殊工程のサポートなどのメリットがあります。

また、自動ランナーメッシュと非マッチングメッシュ技術により、解析精度が向上し、複雑な射出成形品の加工最適化に広く利用されている。

-

金型流動解析を理解することは、製造工程を最適化し、製品の品質を確保するために非常に重要です。詳しくはこちらをご覧ください。 ↩

-

有限要素メッシュの品質はシミュレーション結果に直接影響します。より良い結果を得るための効果的なメッシュの作成方法をご覧ください。 ↩

-

射出成形における重要なパラメータを知ることで、製品設計と製造効率を高めることができます。このリソースをご覧ください。 ↩

-

CAE技術が金型流動解析にどのような革命をもたらし、プラスチック製品の設計プロセスを向上させているかをご覧ください。 ↩

-

複雑な金型設計における正確なシミュレーションと解析のための非マッチングメッシュ技術の利点についてご覧ください。 ↩

-

金型内加飾射出成形を探求することで、製品の美観と機能性を高める革新的な技術が見えてきます。 ↩

-

射出成形プロセスパラメーターの最適化は、コスト削減と製品品質向上の鍵です。 ↩

-

ビッグデータ技術は、製品設計と製造に貴重な洞察を提供し、金型流動解析における意思決定を強化します。その利点について詳しく知る。 ↩

-

クラウドコンピューティングは、金型流動解析ツールへのアクセスに革命をもたらし、リモートでのコラボレーションと効率化を可能にします。そのインパクトをご覧ください。 ↩

-

射出成形プロセスを最適化するには?射出成形は、溶融した原料を加圧、射出、冷却、分離することにより、一定の形状の半完成品を作るプロセスです。 ↩