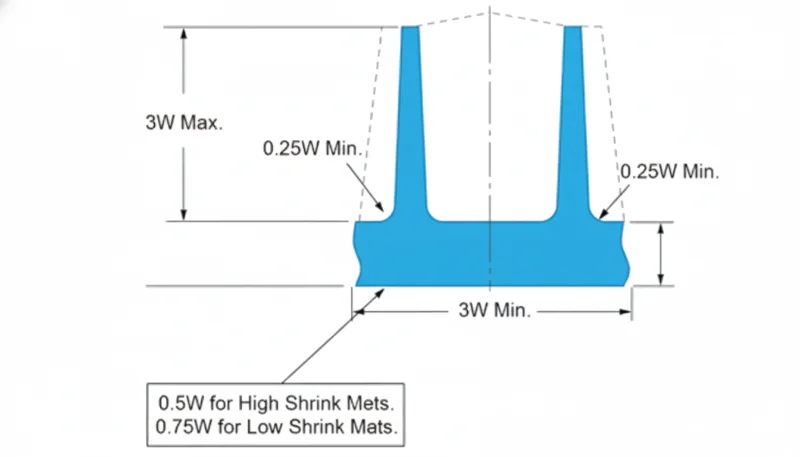

Achieving uniform wall thickness in rib design is critical for preventing cosmetic defects like sink marks and voids while maintaining structural integrity. The “golden rule” is maintaining a rib base thickness of **40% to 60%** of the adjacent nominal wall thickness. Proper implementation requires careful calculation of draft angles (0.5°–1.5°), base radii, and spacing to ensure smooth melt flow and ejection. Adhering to these ratios ensures the part cools evenly, reducing warpage and internal stress.

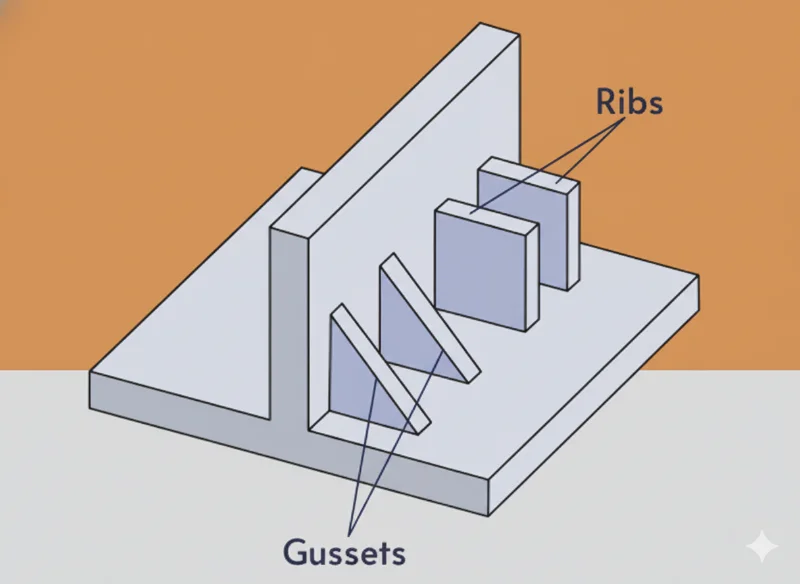

What Are Ribs in Injection Molding?

肋骨 are thin, structural wall-like features extending perpendicular to a part’s nominal wall. They are primarily used to increase the stiffness and strength of a molded component without increasing the overall wall thickness.

という文脈では 射出成形(IM), maintaining "uniform wall thickness" does not mean the rib is as thick as the main wall. Instead, it refers to designing the rib geometry so that the intersection point (where the rib meets the wall) does not create a massive thermal mass. If the mass at the intersection is too large, the material cools unevenly compared to the surrounding wall, resulting in シンクマーク or vacuum voids.

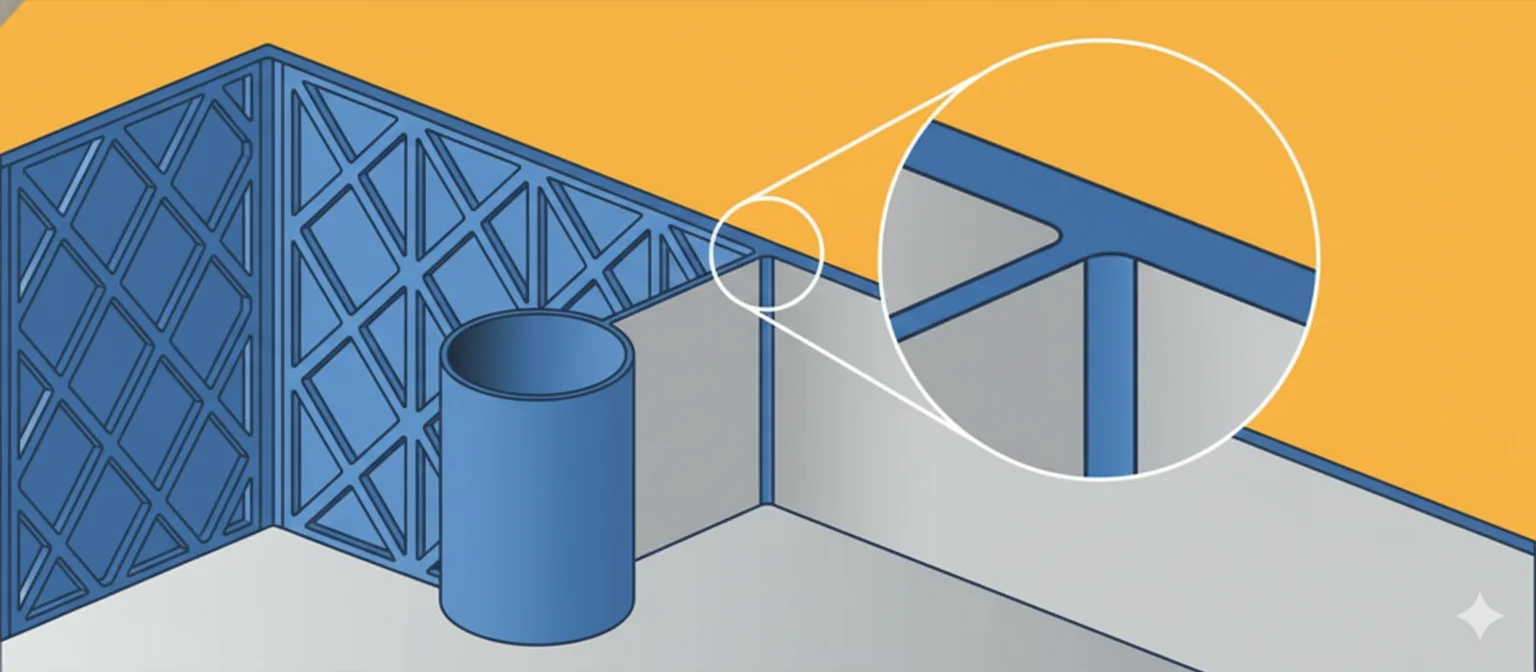

Proper rib design allows engineers to replace heavy, solid sections with lighter, "cored-out" structures, optimizing the strength-to-weight ratio1.

Rib base thickness should be kept between 40% and 60% of the adjacent nominal wall thickness to prevent sink marks.真

This range prevents excessive heat retention at the T-junction, allowing the rib and wall to cool at similar rates, thus maintaining surface aesthetics.

Making ribs the same thickness as the main wall increases part strength without side effects.偽

Matching rib thickness to wall thickness creates a heavy mass area that causes sink marks, voids, and extended cycle times due to uneven cooling.

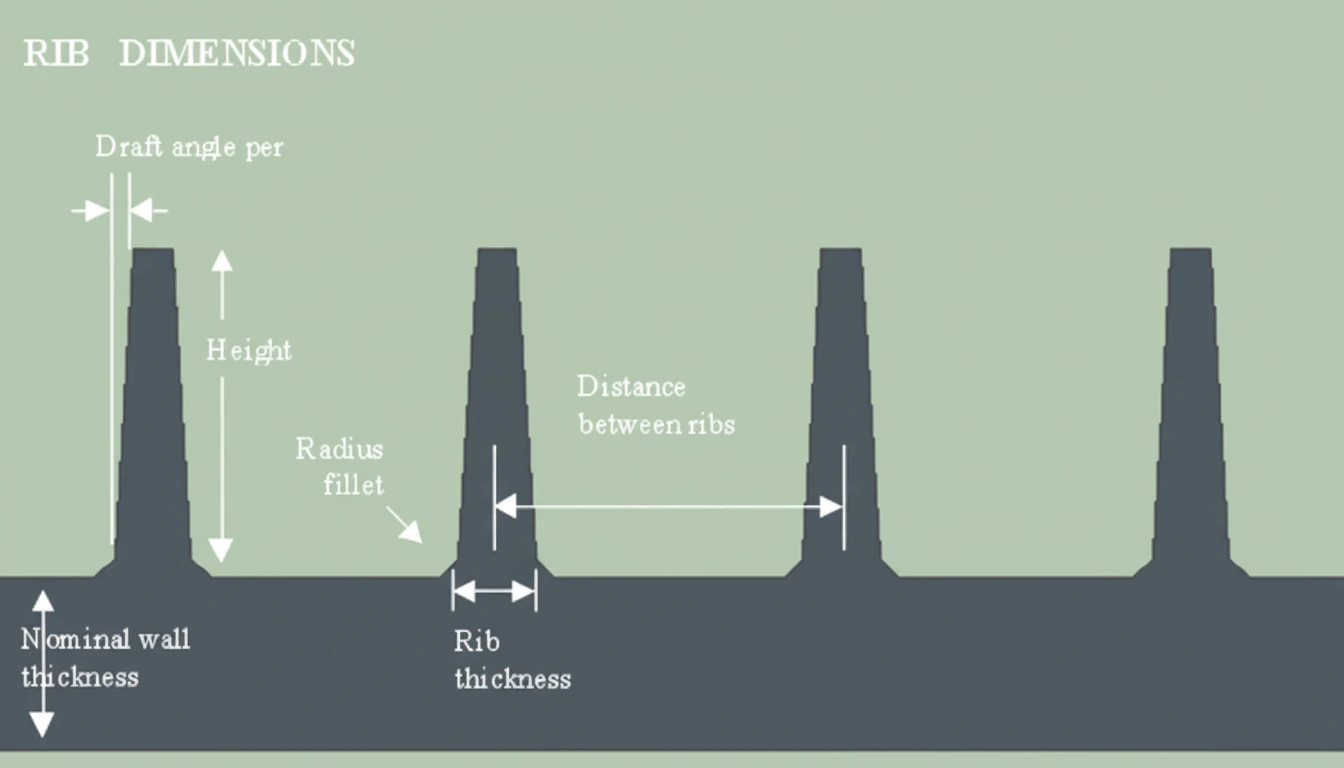

What Are the Key Design Parameters for Ribs?

To achieve effective ribbing without compromising the cosmetic surface or moldability, adherence to specific dimensional parameters is required.

| パラメータ | シンボル | 推奨値/範囲 | Key Note |

|---|---|---|---|

| Nominal Wall Thickness | T | 2.0 mm – 4.0 mm (Typical) | The baseline thickness of the main part geometry. |

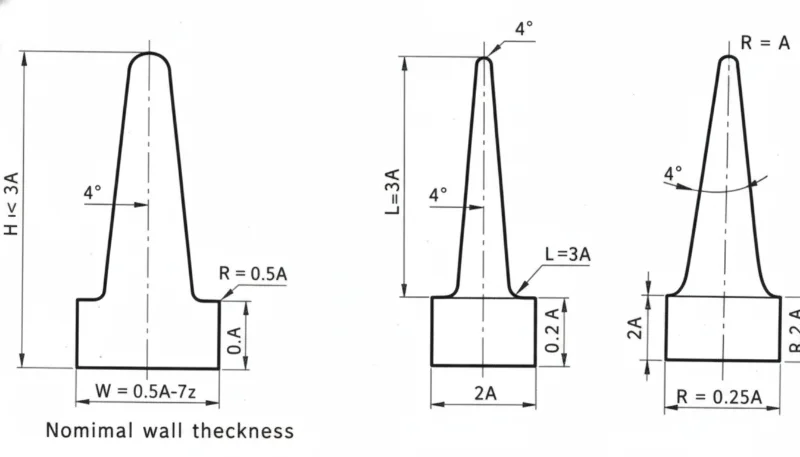

| Rib Base Thickness | t | 40% – 60% of T | < 40% may cause filling issues; > 60% risks sink marks. |

| リブの高さ | H | Max 3.0 × T | Excessive height requires high injection pressure and causes gas traps. |

| ドラフト角度 | θ | 0.5° – 1.5° per side | Essential for part release; reduces rib thickness at the tip. |

| ベース半径 | R | 25% – 50% of T | Reduces stress concentrations; too large creates sinks. |

| リブの間隔 | S | Min 2.0 × T | Distance between parallel ribs to ensure adequate cooling. |

| チップの厚さ | t(先端) | 最小0.75mm | Must be thick enough to vent gas and prevent short shots. |

What Are the Advantages and Disadvantages of Ribbing?

Using ribs to achieve structural goals is generally superior to thickening the entire part, but it introduces specific tooling and processing challenges.

| 特徴 | 説明 | Impact on Molding Process |

|---|---|---|

| メリット | Material Reduction | Reduces the volume of resin used, lowering part cost and weight. |

| Cycle Time Optimization | Thinner sections cool faster than thick solid walls, reducing overall cycle time. | |

| Stiffness-to-Weight | Increases moment of inertia for rigidity without adding significant mass. | |

| デメリット | Sink Mark Risk | Improper thickness ratios (t > 60%T) cause visible depressions on the "A-side" surface. |

| Filling Difficulties | Deep, thin ribs can be hard to fill, leading to short shots or high injection pressures. | |

| Venting Issues | Air traps at the bottom of deep ribs can cause diesel effect (burning)2. |

What Are the Common Application Scenarios?

Ribs are ubiquitous in structural plastic parts across various industries.

- 自動車内装 Dashboard substructures and door panels using アクリロニトリル・ブタジエン・スチレン(ABS) または ポリプロピレン(PP) require ribs for rigidity without heavy weight.

- コンシューマー・エレクトロニクス Housings for laptops and routers use dense rib patterns to protect internal components and manage thermal dissipation.

- Power Tools: Casings made of Glass-Filled Nylon (PA6-GF) utilize cross-ribbing to withstand high impact and torque loads.

- Battery Enclosures: Large enclosures require ribs to prevent warpage over long flat surfaces.

Applying a draft angle of at least 0.5° per side is mandatory for ribs to eject cleanly from the mold.真

Draft angles reduce friction between the steel and plastic during ejection, preventing drag marks and stuck parts.

Polishing the mold steel eliminates the need for draft angles on deep ribs.偽

While polishing helps, it does not eliminate the vacuum forces and friction generated during ejection; draft is still physically required.

Step-by-Step: How to Design Ribs for Uniformity

Follow this workflow to ensure ribs provide strength without violating wall thickness guidelines.

- Determine Nominal Wall (T): Establish the main wall thickness based on the material’s flow properties (e.g., ポリカーボネート(PC) requires thicker walls than ポリエチレン(PE)).

- Calculate Base Thickness (t):

- For cosmetic surfaces (High Gloss): Set $t = 0.4 \times T$.

- For structural/textured surfaces: Set $t = 0.6 \times T$.

- ドラフトアングルを適用する: Add 0.5° to 1.0° draft per side. Note: This will decrease the thickness of the rib as it gets taller.

- Verify Tip Thickness: Check the thickness at the top of the rib. Ensure it is not less than 0.75 mm to allow proper venting and filling.

- Add Base Radii: Add a radius of 0.25 × T at the base to reduce stress concentration. Avoid radii > 0.5 × T to prevent creating a "thick chunk" of plastic at the root.

- Space the Ribs: If multiple ribs are needed, space them at least $2 \times T$ apart. If ribs are too close, the steel tool between them becomes thin and difficult to cool (thermal gate).

- Run Simulation: 用途 Moldflow analysis3 to check for potential sink marks and volumetric shrinkage.

Glass-filled materials shrink less, allowing for slightly thicker ribs (up to 70% of wall thickness) in some cases.真

The fibers in materials like PA66-GF30 resist shrinkage, sometimes allowing a higher rib-to-wall ratio without visible sink marks.

All plastic materials behave the same regarding rib thickness and sink mark susceptibility.偽

Amorphous plastics (like PC, ABS) and semi-crystalline plastics (like POM, PBT) have different shrinkage rates, requiring tailored rib design ratios.

FAQ: Rib Design and Wall Thickness

Q1: Why is the rib thickness ratio limited to 40-60%?

This ratio manages the thermal mass at the intersection of the rib and the wall. If the intersection is too thick, it stays molten longer than the surrounding areas. As it cools and shrinks, it pulls the surface inward, creating a sink mark.

Q2: Can I use ribs on parts with high aesthetic requirements?

Yes, but the design must be conservative. For high-gloss parts (e.g., TV bezels), use a ratio of 40% or lower. Additionally, positioning ribs near corners or styling lines can help mask faint sink marks.

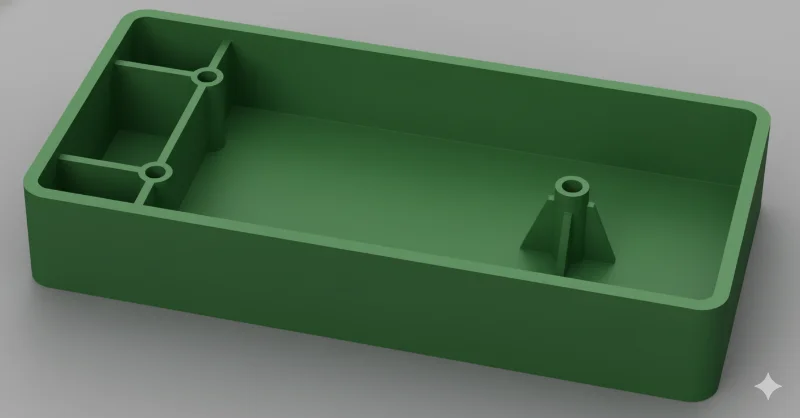

Q3: What is "Coring Out"?

Coring out is the process of removing material from a thick block of plastic to create a shell-like structure reinforced by ribs. This transforms a difficult-to-mold solid block into a part with uniform wall thickness, reducing cycle time and defects.

Q4: How does the draft angle affect the rib height?

Because the draft angle tapers the rib, a tall rib will eventually become too thin at the tip to fill. For example, with a 1° draft, the rib thickness decreases as height increases. This physical constraint limits the practical height of the rib.

Q5: What happens if ribs are spaced too closely together?

If ribs are too close (< 2 × T), the mold steel between them becomes very thin. This thin steel cannot accommodate cooling channels, leading to heat buildup ("hot spots"). This lengthens cycle times and can cause the part to warp.

概要

Achieving uniform wall thickness in rib design is a balancing act between structural requirements and molding physics. By adhering to the 40-60% thickness rule高さは 3x the nominal wall, and applying appropriate ドラフト角度, engineers can design parts that are strong, lightweight, and free of cosmetic defects like sink marks. Ignoring these constraints almost invariably leads to rejection due to surface imperfections or processing inefficiencies.

-

The resource details how rib structures improve stiffness-to-weight ratios and provides specific design guidelines for varying materials. ↩

-

Aprios provides an in-depth look at the causes of sink marks, specifically focusing on the relationship between rib geometry and cooling rates. ↩

-

Autodesk Moldflow is the industry standard for simulating injection molding processes, allowing engineers to predict sink marks and filling patterns before cutting steel. ↩