Injection molding revolutionizes manufacturing, enabling the production of precise and complex plastic parts across various industries.

Injection molds are essential for creating a wide range of products, including automotive components, consumer electronics, and household items. They provide high precision and repeatability, making them ideal for mass production. The process allows for the use of various materials, including thermoplastics and thermosetting plastics, catering to different application needs.

While this summary highlights the versatility of injection molds, understanding the specifics of mold design and material selection is crucial for optimizing production efficiency. Explore further to discover the intricacies of injection molding and how it can benefit your manufacturing processes.

Injection molds are commonly used in automotive manufacturing due to their precision.True

The high precision of injection molds ensures that automotive components meet strict quality and safety standards, making them essential in the industry.

Injection molds are not used in the production of medical devices.False

Injection molds are widely used in the production of medical devices due to their ability to create precise, sterile components efficiently.

What is the Meaning of Injection Mold?

Injection molding is a process that forms parts by injecting molten plastic or other materials into a custom mold cavity, allowing for precise, high-volume production. It is commonly used to create parts for industries such as automotive, electronics, and medical devices. Key advantages include low unit costs, high repeatability, and the ability to produce complex shapes with tight tolerances.

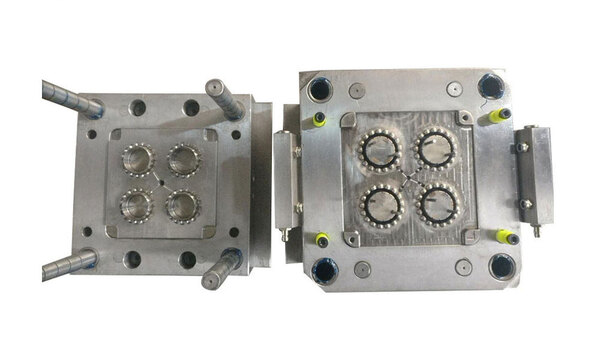

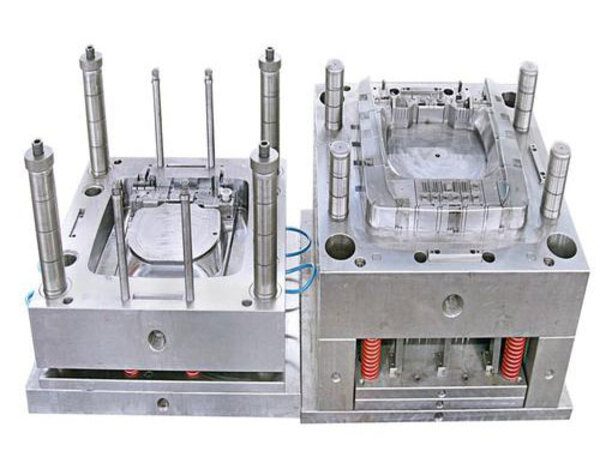

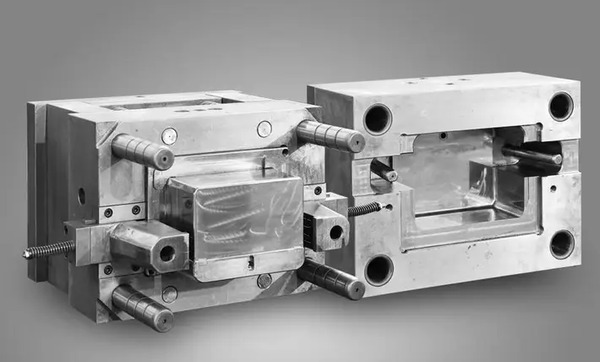

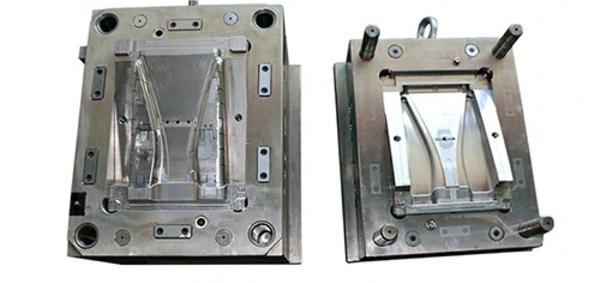

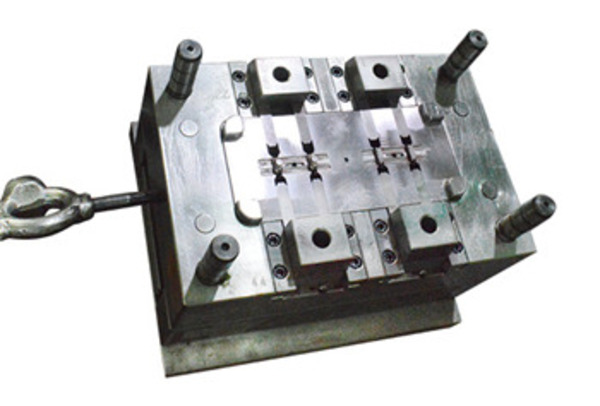

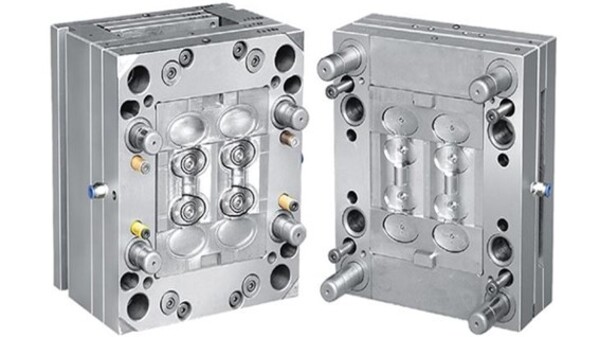

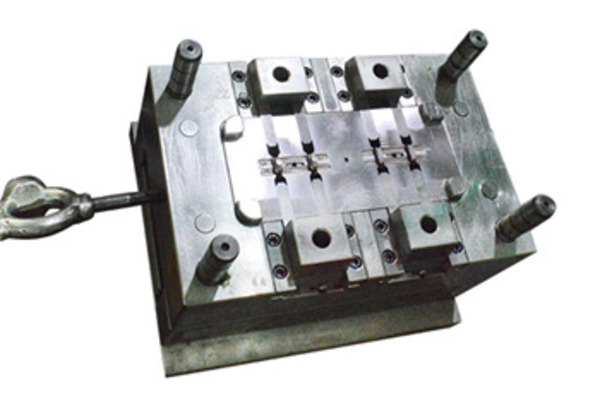

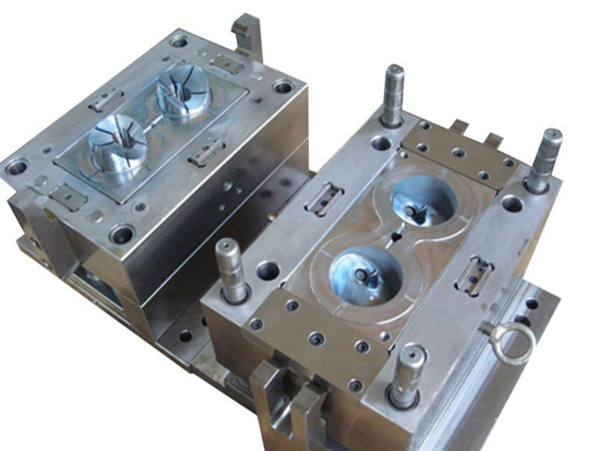

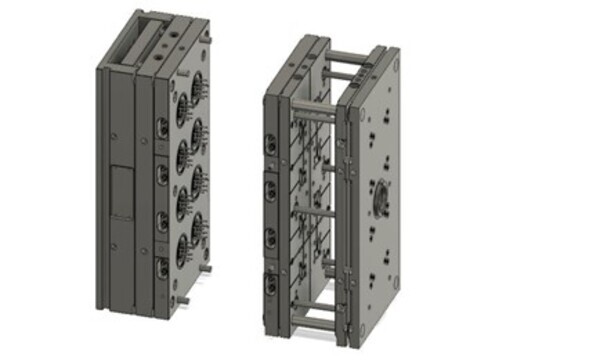

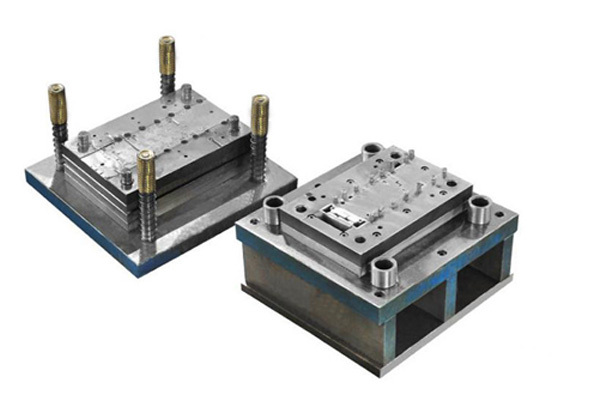

The injection mold has two parts: the movable mold and the fixed mold. The movable mold is on the moving template of the injection molding machine, and the fixed mold is on the fixed template of the injection molding machine.

When you do injection molding, you close the movable mold and the fixed mold to make the pouring system and the cavity. When you open the mold, you separate the movable mold and the fixed mold to take out the plastic product.

How Does an Injection Mold Work?

Injection molding works by injecting molten plastic into a mold cavity under high pressure, allowing it to cool and solidify into the desired shape. Key advantages include rapid production rates, precise part dimensions, and the ability to create complex geometries. It is widely used in industries such as automotive, electronics, and packaging.

The basic idea of injection molding is to take a metal mold (usually steel) and make it into the shape of the product you want. You take plastic, shoot it out of the nozzle of the injection molding machines, and it gets pushed into the mold under high pressure.

Then the plastic cools down and turns into the product you want. Injection molds only work if you have the right temperature and pressure.

To make sure the injection mold works fine, you also need to keep an eye on the mold temperature and pressure1 during the injection process. This way, you can make sure the plastic flows smoothly and doesn’t burn the mold.

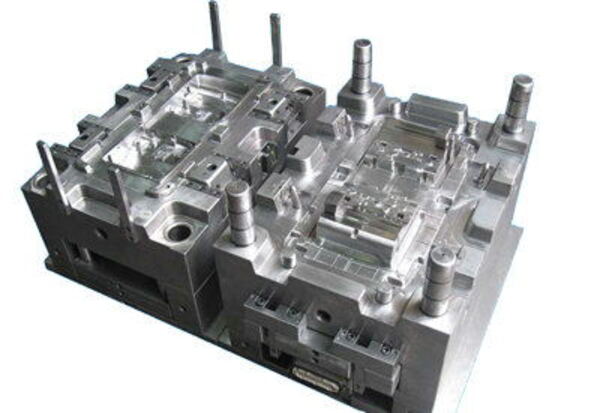

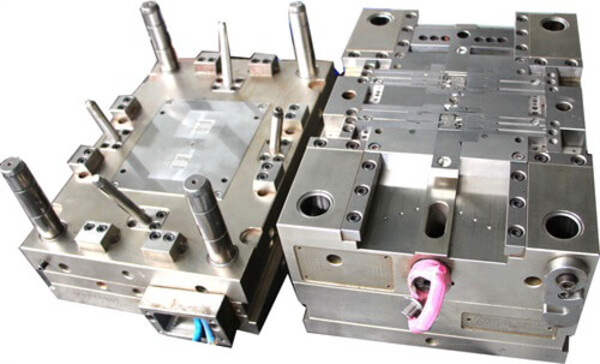

What are the Components of Injection Molds ?

Injection molds consist of several key components, including the mold base, cavity, core, and cooling system. The mold base provides structural support, while the cavity and core shape the part. Cooling systems are critical for maintaining optimal temperatures during the injection process. Properly designed molds enhance efficiency and product consistency, making them essential in automotive, consumer goods, and medical industries.

The injection mold has seven parts: molding parts, pouring system, guide mechanism, ejection device, lateral parting and core pulling mechanism, cooling and heating system, and exhaust system.

Molding Parts

Injection molding parts are the parts that make up the mold cavity. They mainly include: punch, die, core, molding rod, molding ring, and insert parts.

Casting System

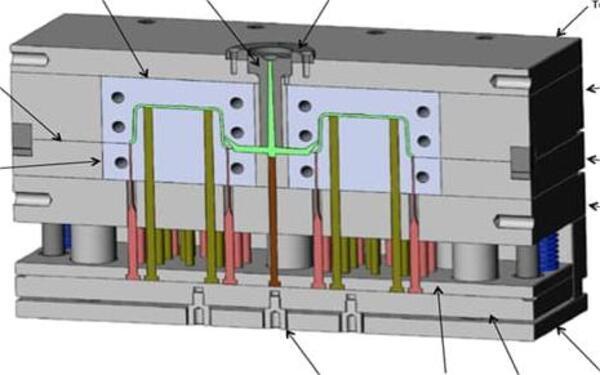

The injection mold pouring system is the plastic flow channel in the mold from the injection molding machine nozzle to the cavity. The ordinary pouring system is made up of the main channel, branch channel, gate, cold material hole, etc.

Guide Mechanism

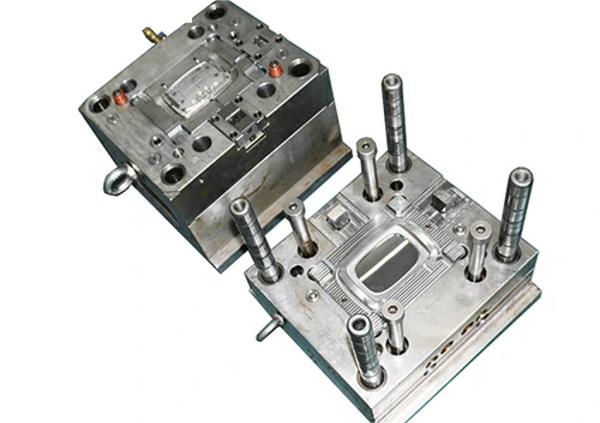

The injection mold guide mechanism has three main functions: positioning, guiding, and bearing side pressure. It ensures that the dynamic and fixed molds are accurately clamped. The mold clamping guide mechanism consists of guide pins, guide sleeves or guide holes (directly opened on the template), positioning cones, etc.

Ejector Device

The ejector device of the injection mold2 is mainly used to eject the workpiece from the mold. It consists of an ejector rod or ejector sleeve or push plate, an ejector plate, an ejector fixing plate, a reset rod, and a pull rod.

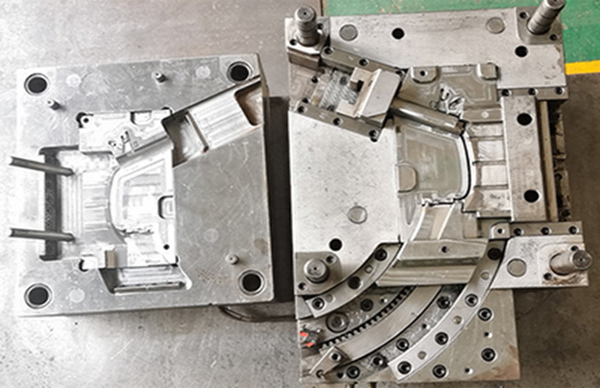

Lateral Parting and Core Pulling Mechanism

The lateral parting and core pulling mechanism of the injection mold is used to disengage the lateral punch or extract the lateral core. It usually includes parts like inclined guide pins, bent pins, inclined guide grooves, wedge blocks, inclined slide blocks, inclined grooves, gear racks, and so on.

Cooling and Heating System

The injection mold cooling and heating system is used to control the temperature of the mold process. It consists of a cooling system (cooling water holes, cooling water tanks, copper pipes) or a heating system.

Exhaust System

The injection mold exhaust system is used to exhaust the gas in the cavity. It is mainly composed of exhaust grooves, fitting clearances, etc.

What are the Types of Injection Molds?

The main types of injection molds include cold runner molds, hot runner molds, and multi-cavity molds. Cold runner molds are cost-effective but may waste material, while hot runner molds reduce waste and improve cycle times. Multi-cavity molds enable the production of multiple parts in a single cycle, increasing efficiency. Choosing the right mold type can significantly affect production costs and part quality.

There are different types of injection molds3 based on different properties. It is important to choose the right type of injection mold for your project. The mold will affect the production speed, overall cost and the quality of the final product.

Different types of molds are classified into four major categories:

Based on Feeding System

The first category we have here is the classification based on the feeding or runner system. The feeding system is a series of channels, including gates, sprues, and runners. The channels direct the molten plastic from the nozzle to the desired part of the cavity. The types of injection molds under this category are:

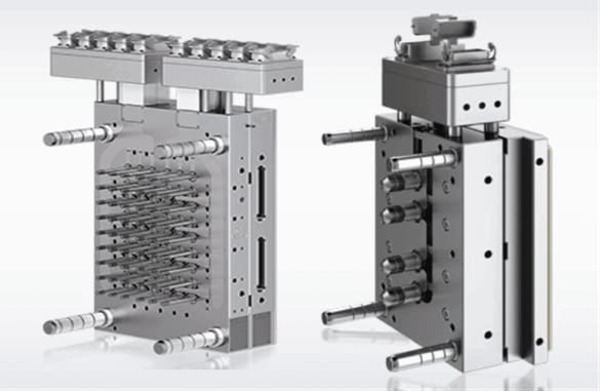

Hot Runner Injection Molds

Hot runner systems use runners that are heated internally or externally by coils or rods. This type of feeding system is enclosed within a fixed manifold plate. They stay permanently in the plate, so they don’t get ejected with the part.

So, the parts come out clean, with no extra plastic waste. That means less waste to deal with and no extra steps to remove or recycle the runners. Plus, you usually don’t have to grind up or do anything else to the parts after they come out of the hot runner mold.

That means you can make parts faster. And when you use a hot runner mold with a lot of cavities, you can make a lot of complicated, delicate parts.

But there are also some disadvantages to using a hot runner system. The system is usually expensive to install and heat. Maintenance is also expensive and requires skilled expertise to oversee the molding process.

Since the runners are hidden, it can be difficult to ensure that they are clean and free of plastic residue from previous production processes. This is often a big issue when dealing with color changes. Lastly, internally heated hot runners can have sticking issues, especially when dealing with heat-sensitive materials.

Cold Runner Injection Molds

Cold runner systems use unheated runners to deliver molten plastic to the injection mold cavity. Unlike hot runner injection molds, cold runner molds are exposed because the operator cuts them into the mold.

You need to make a new runner system for each molding cycle. Depending on the type of plate used, you may be connecting or separating the molded part and the runner system when demolding.

These types of molds are easier to clean and maintain. They also allow for faster and easier material and color changes. Additionally, you can easily swap out molds with iterations due to rapidly changing gate and runner locations.

While internally heated hot runner molds have difficulty handling certain materials, cold runners can handle a wide range of materials.But here’s the thing: mold runner injection molds make a lot of scrap with every cycle. Most manufacturers just throw the runners away.

Some manufacturers find ways to regrind and reprocess the runners for reuse, but that adds time to the manufacturing process. Regrinding the runners also changes their physical properties, which can affect the final product. It might not be the same as the original design.

Insulated Runner Molds

These tools look more like traditional cold runner molds. However, they use cartridge heaters or other forms of heating to form a surrounding layer of molten plastic. Therefore, they form an insulating knockout to create a similar effect to hot runner systems.

Manufacturers often choose this method because it doesn’t require a temperature controller, which makes it cheaper than hot runners. Plus, it’s easy and fast to change materials and colors. But insulated runner molds don’t work for all materials. They usually don’t work for tough engineering-grade plastics.

Based on the Number of Cavities

This category includes three types of injection molds based on the number of parts that can be produced per molding cycle. They are as follows:

Single-Cavity Injection Molds

Single-cavity molds make one part per injection unit. They may be slower to make, but they cost less to tool than other options. Because they’re relatively cheap, they’re often more affordable for small batch production.

Single-cavity molds also give you better control over the molding process. Manufacturers often use multiple single-cavity tools to make sure the process keeps running, even if one mold fails.

Multi-Cavity Injection Molds

A multi-cavity mold is designed to make multiple identical parts in one injection cycle. The initial cost of an injection mold is usually higher than a single-cavity mold.

However, this type of injection mold is better suited for high-volume production. This is because each mold can produce multiple components at the same time. Therefore, production is faster and the cost per part is lower.

Family Injection Molds

Family molds, like multi-cavity molds, have multiple cavities. But they’re best used to make multiple parts in one cycle. For example, you can use one family mold4 to make one right component and one left component iteration. But a simple multi-cavity mold can only make one iteration in one cycle.

While family molds can be expensive, they can often save you money in the long run. This is because one family mold can be used to make a variety of parts. It also saves you a lot of time and operating costs.

However, keep in mind that these types of molds are only good for parts made from the same material and color. If you need parts made from different materials and colors, you’ll need separate molds.Of course, there are also medical devices molds.

Based on Plates

Another important category for classifying mold types in injection molding is the number of plates. As I mentioned earlier in this article, these plates make up the entire mold cavity to ensure you can make enough parts. The types of injection molds under this category are:

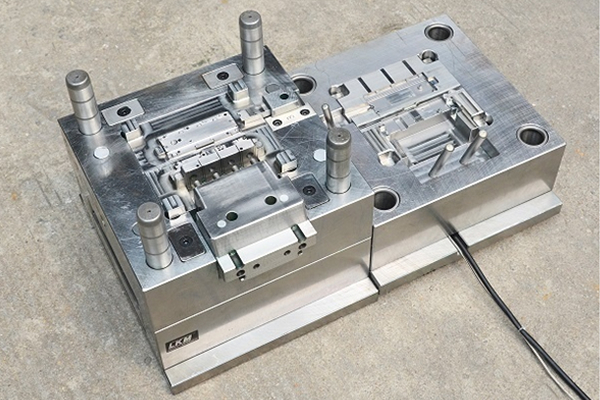

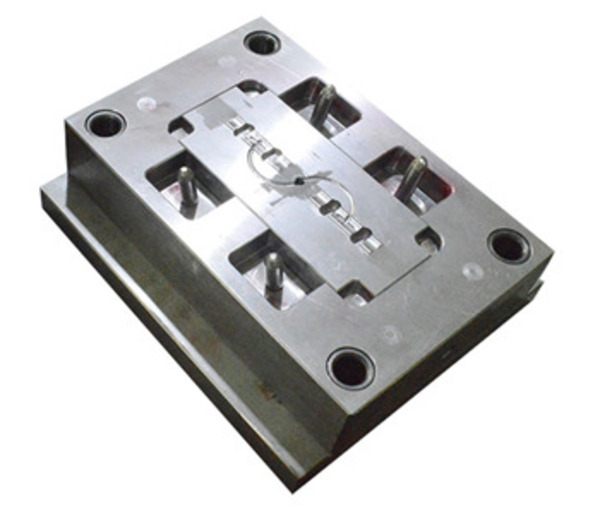

Two-Plate Injection Mold

This is the most common type of mold in this category because of its low mold cost. Two-plate injection molds have a

parting line5where the core plate and cavity plate meet.

In this type of injection mold, the gates, runners, and parting lines must also be aligned. It is compatible with any runner system, but is best used in conjunction with single-cavity molds.

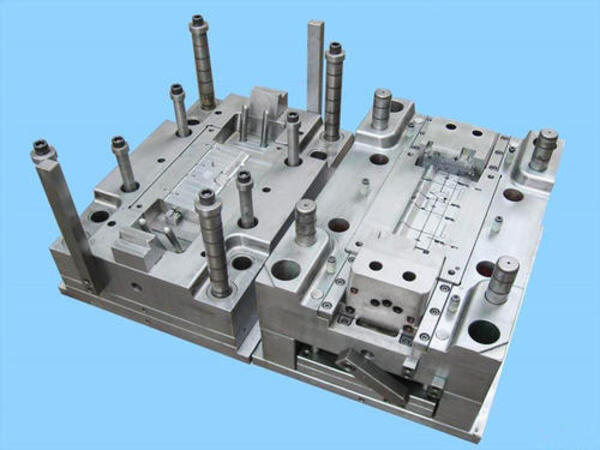

Three-Plate Injection Mold

The mold has an extra plate (stripper plate) that gives it two parting lines. It goes between the cavity and core plates and automatically separates the runner system from the molded part. This makes production faster because you don’t have to separate or recycle the runner system by hand.

However, the extra plate increases the overall tooling cost because the cuts have to be precise to match the other two plates. Note that three-plate molds are only used for cold runner systems to separate the runners. thermoplastic injection molding systems don’t require this type of mold.

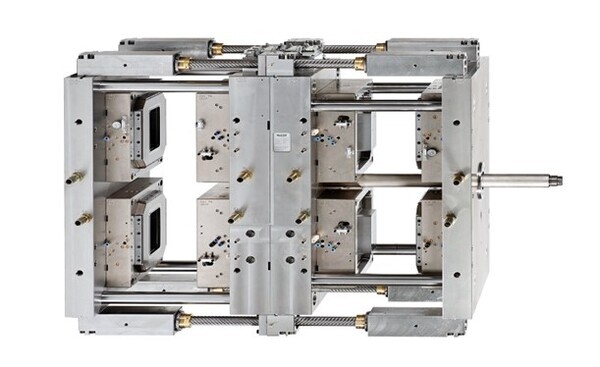

Stack Injection Molds

Stack molds have multiple parallel platens. They can have two, three, or four plates to make the process more efficient. Stack molds use less clamping tonnage per cycle.

They cost more upfront because they take longer to build. But, the smaller clamping tonnage requirement saves money in the long run. The molds can even be designed to hold involves injecting molten material at the same time.

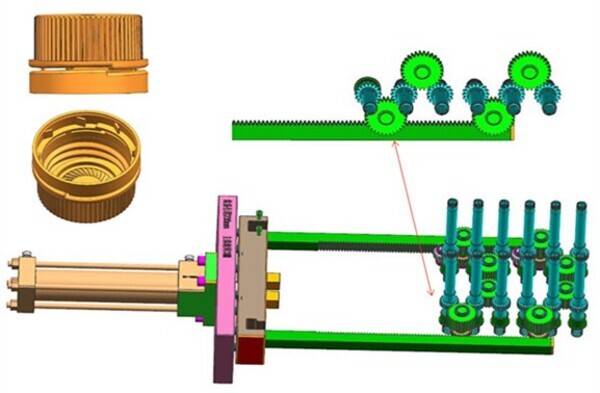

Swing-Based Injection Molds

These are the best molds for making threaded holes within plastic parts. They are automated molds with a drive system that consists of the following:

Rack and pinion,Electric motor,Hydraulic motor

This one-of-a-kind mold makes threaded parts like bottle caps, nuts and bolts, automotive parts, shampoo bottles, and cosmetic packaging by spinning the drive system. These parts are usually hard to get out with a screw-based draft angle.

So, unscrewing the injection mold helps you take it apart without messing up the threads. Undercut injection molding is also important here because it lets you get out damaged complex parts. It runs fast, so you can make a lot of parts in a short time.

What are the Characteristics of Injection Molds?

Injection molds are characterized by their material, design complexity, and durability. They are typically made from steel or aluminum and can be single or multi-cavity. Key features include the ability to produce intricate shapes, excellent surface finish, and consistent dimensional accuracy, making them ideal for mass production.

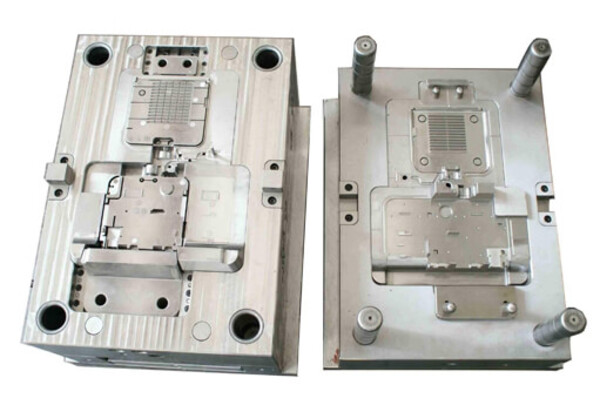

Core and Cavity Present Three-Dimensional Profiles

Plastic parts are hard to process because of their external and internal shapes. These complex three-dimensional surfaces are made by the cavity and core. The inner surface of the blind hole mold in the cavity is especially hard to process.

High Surface Accuracy and Long Service Life

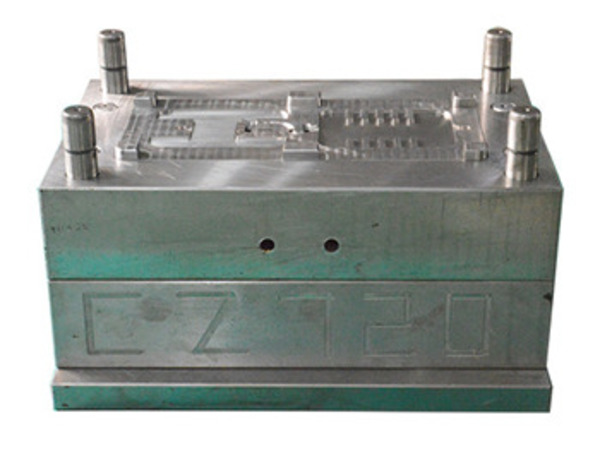

To make high-precision injection molds, you need to improve the processing accuracy and interchangeability of mold parts. Most of them use inlay or full-split structures.

You need to make sure the demolding is even everywhere and choose the best ejection point. The ejection device is important because it affects dimensional accuracy and product deformation. You need long-life injection molds to improve efficiency and reduce costs.

Right now, injection molds usually last more than one million times. To make precision injection molds, you need to make the template thicker, add support columns or conical positioning elements, and use high-rigidity mold frames to keep the mold from deforming when it’s pressed.

Tight Manufacturing Time and Long Process Flow

When it comes to injection molded parts, most of them form complete products with other parts, and in many cases they are completed on other parts, so they are eager to wait for the matching listing of injection molded parts.

Due to the different characteristics of resin materials, the shape or size accuracy of the product is required to be high, so it is necessary to conduct repeated testing and correction after the mold is manufactured, so the development and delivery time is very tight.

Design and Manufacturing in Different Places

Making molds is not the end goal. The user comes up with the final product design. In most cases, mold makers design and make molds based on user requirements, so product design, mold design and making, and product production are done in different places.

Dynamic Combination and Professional Division of Labor

Making molds is a complicated process. The equipment used is all over the place, from regular machines to CNC machines. There are a lot of standard parts that go into making a mold, from the mold base to the ejector. No one company can make all of these parts.

Conclusion

plastic injection molding is a great manufacturing technology that can be used for a lot of different things. But the mold you choose is going to make or break your manufacturing process.

In this article, we’re going to talk about different types of injection molds based on the characteristics of the injection mold, including the feeding system6, mold halves,the number of cavities, and the mold base. This will help you make the best decision when you’re ready to get your project going.

Designing an injection mold is a technology and skill-intensive task that requires expert handling and process control. So, it’s important that you work with a reliable partner that can provide quality injection molding services.

Contact Zetar Mold today to reliably and cost-effectively produce high-quality plastic parts. Our professional injection molding services include moldfabrication, mold design analysis, and plastic part manufacturing.

We can help you create high-quality injection molds to produce durable and reliable plastic molded parts. Our engineering team has the skills and experience to provide the best basics of injection molding solutions.

-

Learn about Hot Troubleshooting Mold Temperature Control : Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part. ↩

-

Learn about Ejector Pins and Their Uses in Injection Molding Process: An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. ↩

-

Learn about Types of Injection Molds: Examining Various Categories and Features: Injection molding is an integral process for creating plastic parts for several applications. ↩

-

Learn about Family Mold : A mold where more than one cavity is cut into the mold to allow for multiple parts made of the same material to be formed in one cycle. ↩

-

Learn about Parting line : A parting line, in industrial casting of molds, is the border line between the two halves of the mold (known as the “core” and the “cavity.”). ↩

-

Learn about Feeding System In Injection Mold : The feeding system (feed system) directs molten plastic from the injection machine’s nozzle into the mold cavity. ↩