Injection moulding machines are essential for mass-producing plastic parts, offering precise control, speed, and consistency for industries such as automotive and electronics.

Injection moulding machines melt plastic and inject it into molds, enabling efficient mass production of identical parts for industries such as automotive, consumer goods, and electronics.

While the basics of injection moulding machines are straightforward, mastering the nuances of operation and maintenance can greatly enhance production efficiency. Dive deeper to learn how different types of machines can meet your specific manufacturing needs.

Injection moulding machines enable high-volume production of plastic parts.True

These machines create multiple parts in a single cycle, making them ideal for high-volume production settings.

Injection moulding machines cannot produce parts with complex shapes.False

Advanced mould designs and precision controls allow injection moulding machines to create intricate and detailed plastic parts.

What is the Working Principle of an Injection Molding Machine?

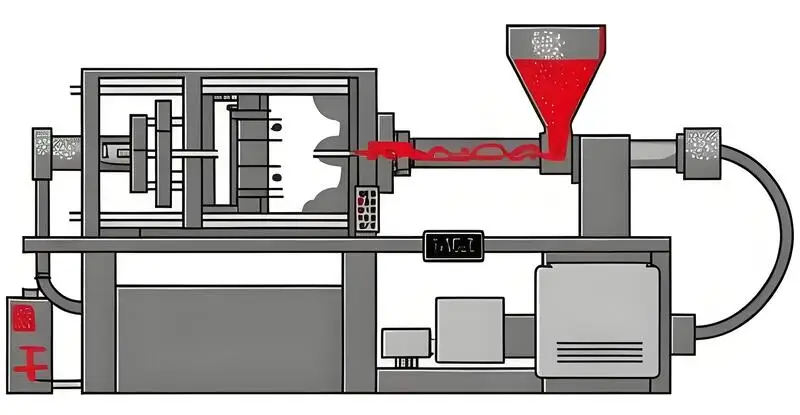

Injection molding machines transform raw plastic materials into finished products by injecting molten plastic into a mold.

Injection molding machines melt plastic pellets and inject them into molds under high pressure, enabling precise dimensional control. This process is essential in manufacturing automotive parts, electronics, and packaging materials.

First, you need to load solid plastic pellets or granules into the hopper of the plastic injection molding machine1. These plastic pellets will be fed into the heating barrel through a conveying system, such as a screw or piston. In the heating barrel, the plastic pellets are heated and gradually melted to form molten plastic.

Next, the molten plastic will be pushed into the nozzle. The nozzle is a part that connects the heating barrel and the mold, and its function is to control the flow of molten plastic. When the plastic enters the nozzle, it goes through a series of pressurization and spiral movements to ensure uniform plastic flow.

Once the molten plastic enters the nozzle, it gets injected into the pre-prepared mold. The mold is designed according to the shape and size of the desired product and usually consists of two half molds. When the two half molds are closed, they form a sealed chamber into which the molten plastic is injected.

Once the plastic is injected into the mold, it starts to cool and harden. The cooling time depends on the type of plastic and how thick the product is. When the plastic is completely cool, the mold opens and the plastic part is taken out. This can be done by hand or by a machine, depending on the type of injection molding machine.

Besides these basic steps, plastic injection molding machines also have different control systems to monitor and control temperature, pressure, and other parameters of the injection molding process. These systems make sure the injection molding process is stable and the product quality is consistent.

Injection molding machines ensure high precision in product manufacturing.True

The high-pressure injection and precise mold design enable accurate replication of product dimensions.

All injection molding machines use hydraulic power.False

While hydraulic systems are common, there are also electric and hybrid injection molding machines, each offering distinct advantages.

What is the Structural Composition of an Injection Molding Machine?

Injection molding machines consist of essential components that orchestrate precision and efficiency in transforming raw materials into complex products.

An injection molding machine consists of a mold, injection unit, and clamping unit. Key components such as the hopper and barrel collaborate to heat and shape materials, supporting diverse plastic part production across industries.

Injection molding machines are typically made up of injection systems, mold clamping system2s, hydraulic transmission system3s, electrical control systems, lubrication systems, heating and cooling systems, safety monitoring systems, and so on.

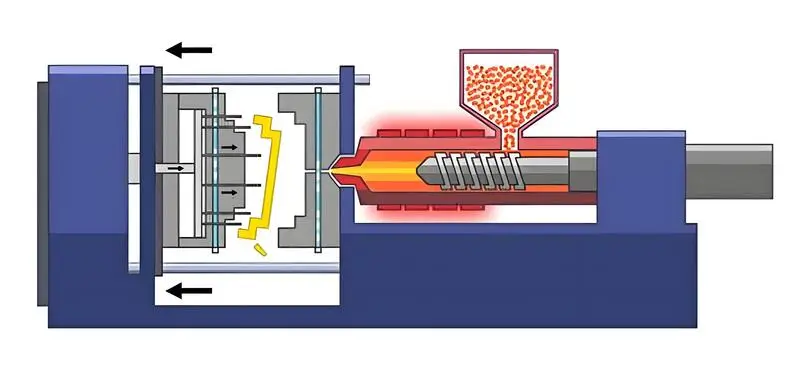

Injection System

The injection system is one of the main components of the injection molding machine4. There are generally three main types: plunger type, screw type, and screw pre-plastic plunger injection type. The screw type is currently the most widely used.

The function of the injection unit is to heat and melt a certain amount of plastic in a specified time in one cycle of the injection molding machine, and then inject the molten plastic into the mold cavity through the screw at a certain pressure and speed. After the injection is completed, the molten material injected into the mold cavity is kept in shape.

Clamping System

The clamping system is responsible for closing, opening, and ejecting the mold. It also provides enough force to keep the mold closed and resist the pressure from the molten plastic entering the cavity. This prevents the mold from opening and causing defects in the product.

Clamping system composition: The clamping system is mainly composed of a clamping device, a mold adjustment mechanism, an ejection mechanism, front and rear fixed templates, a mobile template, a clamping cylinder, and a safety protection mechanism.

Hydraulic System

The hydraulic transmission system is there to give power for all the different things the injection molding machine needs to do, and to make sure that all the different parts of the injection molding machine have the right amount of pressure, speed, temperature, and everything else they need.

It’s made up of a bunch of hydraulic parts and hydraulic helper parts. The oil pump and the motor are what give the injection molding machine its power. Different valves control the oil pressure and flow, so it can do all the different things it needs to do to make the plastic parts.

Electrical Control System

The electrical control system and the hydraulic system work together to meet the needs of the injection molding machine, like pressure, temperature, speed, time, and different program actions.It is mainly made up of electrical appliances, electronic components, instruments, heaters, sensors, etc. There are generally four control modes: manual, semi-automatic, fully automatic, and adjustment.

Heating/Cooling System

The heating system is used to heat the barrel and injection nozzle. The barrel of the injection molding machine generally uses an electric heating ring as a heating device, which is installed on the outside of the barrel and detected in sections with a thermocouple. The heat is conducted through the barrel wall to provide a heat source for the plasticization of the material.

The cooling system5 is mainly used to cool the oil temperature. If the oil temperature is too high, it will cause a lot of faults, so the oil temperature must be controlled. Another place that needs to be cooled is near the discharge port of the material pipe. If it is not cooled, the raw material will melt at the discharge port, resulting in the failure of the raw material to be discharged normally.

Lubrication System

The lubrication system6 is a circuit that provides lubrication conditions for the relative moving parts of the dynamic plate, mold adjustment device, connecting rod hinge, etc. of the injection molding machine, so as to reduce energy consumption and increase the life of parts. Lubrication can be regular manual lubrication or automatic electric lubrication.

The clamping unit in an injection molding machine maintains the mold's position.True

The clamping unit securely holds the mold in place during the injection process, ensuring precise formation of the part.

All injection molding machines use hydraulic systems.False

While many machines use hydraulic systems, electric and hybrid systems are also employed for energy efficiency and precision in modern manufacturing.

What are the Categories of Injection Molding Machines?

Injection molding machines are categorized by their clamping mechanism type and operational capabilities, impacting their applicability across different industries.

Injection molding machines are classified as hydraulic, electric, and hybrid. Hydraulic models offer strong force, electric machines prioritize energy efficiency and precision, and hybrid machines blend both strengths for optimal performance.

Horizontal Injection Molding Machine

The horizontal injection molding machine is a commonly used type. It has the characteristic that the center line of the injection assembly is concentric or consistent with the center line of the clamping assembly and parallel to the installation ground.

Its advantages are low center of gravity, stable operation, convenient mold installation, operation and maintenance, large mold opening, and small space height; but it occupies a large area, and is widely used in large, medium and small machines.

Vertical Injection Molding Machine

The characteristic of this machine is that the clamping device and the injection device are arranged in a straight line and perpendicular to the ground. It has the advantages of small floor space, easy mold assembly and disassembly, easy installation of inserts, relatively uniform plasticization of materials falling from the hopper, easy automation, and easy automatic line management of multiple machines.

But it is not easy for the product to fall automatically after being ejected, and it must be removed by hand, which is not easy to achieve automatic operation.

The vertical injection molding machine sealing machine is suitable for small injection molding machines, generally more for injection molding machines below 60 tons (60 tons refers to the clamping force), and large and medium-sized machines are not suitable.

Angle Injection Molding Machine

The injection direction and mold interface are on the same plane. It is particularly suitable for flat products where gate marks are not allowed to remain in the machining center. It occupies a smaller area than the horizontal injection molding machine, but the inserts placed in the mold are prone to tilt and fall. In addition to this, the comprehensive electric injection molding machines .

Multi-Mode Turntable Injection Molding Machine

It’s a special injection molding machine with multi-station operation. The mold clamping device of the manual packing machine adopts a turntable structure, and the mold rotates around the rotating shaft. This type of injection molding machine fully utilizes the plasticizing ability of the injection device, which can shorten the production cycle and improve the production capacity of the machine.

So, it is especially good for making a lot of stuff that takes a long time to cool and shape or needs more time for the extra stuff you put in it. But because the mold is big and has a lot of parts, the thing that holds it together isn’t very strong, so this kind of machine is used a lot for making things like plastic shoe bottoms.

Electric injection molding machines improve energy efficiency.True

Electric machines utilize servo motors, reducing energy consumption compared to traditional hydraulic systems.

Hybrid injection molding machines are always cheaper than hydraulic machines.False

While hybrids may reduce operational costs, initial purchase prices can be higher due to their advanced components.

What is the Operation Process of an Injection Molding Machine?

Injection molding machines are vital to manufacturing, transforming raw materials into complex shapes efficiently and accurately.

Injection molding melts plastic pellets to form parts via clamping, injection, cooling, and ejection, widely used in automotive, electronics, and consumer products manufacturing.

Raw Material Preparation

Before you start injection molding production, you need to prepare the plastic raw materials you need. According to the requirements of the product, select the appropriate plastic material, weigh it, mix it, and ensure the quality and ratio of the raw materials.

Mold Installation

Put the mold you need on the injection molding machine, adjust it, and lock it in place. Make sure the mold is in the right spot so you don’t make bad parts or break the machine.

Injection Molding Machine Debugging

Before you start making stuff, you need to get your injection molding machine working right. That means you have to mess with the temperature, the pressure, the speed, and all that stuff to make sure the machine is running good and making good parts.

Production Operation

After debugging, you can start the formal injection molding production operation. The operator needs to set the working parameters of the injection molding machine according to the product requirements, such as injection speed, holding time, etc., and monitor key indicators such as temperature and pressure during the production process, and adjust and handle abnormal situations in time.

Equipment Maintenance

When you’re making stuff, you gotta take care of your injection molding machine. You gotta keep it clean, keep it greased, and replace parts when they wear out. That’s how you keep it running and make it last.

Injection molding machines produce minimal waste.True

The process utilizes precision molds and controlled material flow, reducing excess waste during production.

All injection molding machines are equally suitable for any type of material.False

Different machines are designed to handle specific materials, and using the wrong type can affect the quality and efficiency of production.

What are the Operating Steps of an Injection Molding Machine?

Understanding the operating steps of an injection molding machine is essential for achieving optimal production efficiency and high-quality plastic parts.

Injection molding forms parts by clamping, injecting, cooling, and ejecting plastic. Key steps include material preparation, temperature setting, and ejection, ensuring consistent, precise components.

Start-Up Preparation

First, the operator needs to check if all parts of the injection molding machine are normal, such as power supply, hydraulic system, cooling system, etc. After confirming that there is no abnormality, turn on the power switch of the injection molding machine, and preheat and precool it to reach the normal working temperature.

Operation Setting

Once you’ve finished getting your startup ready, you need to set the working parameters of the injection molding machine according to the product requirements. This includes injection speed, holding time, temperature setting, etc. At the same time, you need to adjust and fix the mold according to the requirements of the mold.

Production Operation

Once the setup is done, you can start the formal production operation. You need to keep an eye on the operation of the injection molding machine and adjust the working parameters in time to ensure the quality of the products. Meanwhile, you should also pay attention to safety to avoid accidents.

Shutdown Cleaning

Once the production is done, you need to clean and maintain the injection molding machine. First, turn off the power switch of the injection molding machine and let it cool down. Then, clean all parts of the injection molding machine, including the barrel, mold, etc. Finally, do maintenance and care on the injection molding machine, such as lubricating parts, replacing worn parts, etc.

Proper cooling time determination is crucial in injection molding.True

Adequate cooling time ensures optimal part integrity and prevents defects, impacting the overall quality and consistency of produced parts.

Ejecting is the least critical step in the injection molding process.False

Ejecting is vital for removing the finished parts without causing damage or deformation, ensuring the part quality and efficiency of production.

What are the Working Steps of an Injection Molding Machine?

Injection molding machines streamline production by shaping materials with precision, serving various industries with their efficient mechanisms.

Injection molding is a manufacturing process that melts plastic and injects it into molds to create items like plastic parts, containers, and automotive components.

Melting Stage

The melting stage of an injection molding machine has two main processes: heating and melting, and then injecting. First, you put the dried engineering plastic into the hopper of the injection molding machine.

Then, you heat it up so that the plastic particles melt into a liquid.This process makes sure the plastic gets to a good melting state, and then the injection molding machine shoots the melted plastic into the mold with a lot of pressure to make the part.

In the process of the injection molding machine working, the time it takes to melt the plastic is a big deal, because it decides how good the parts are and how fast you can make them.The melting time is the time it takes for the plastic to be heated, melted, and mixed in the injection molding machine.

In the heating barrel, the plastic particles are heated to a high temperature and gradually melted into a flowing molten glue. The molten glue is pushed into the injection barrel by the screw and then sprayed into the mold cavity through the nozzle, finally forming the desired plastic product.

The time it takes for the plastic to melt has a big effect on how well the injection molding machine works. If it takes too long to melt, the plastic will get too hot, make bubbles, and get messed up. It will look bad and not work right. If it doesn’t take long enough to melt, the plastic might get shot into the mold before it’s melted all the way.

That will make the product look bad and not be strong enough. So, the person running the injection molding machine needs to set the melting time7 right for the kind of plastic and the kind of product. Usually, you set the melting time based on how hot the plastic melts, how thick it is, and other things like that.

Injection Stage

Once the plastic is melted, the cylinder pressure pushes it into the injection chamber. The injection molding machine automatically figures out how much and how fast to inject the melted plastic, and it shoots the melted plastic into the mold cavity to fill up the whole mold cavity.

The injection time and speed can affect the density, size, performance, and smoothness of the inside edge of the plastic part. The injection process is the process of injecting the melted plastic into the mold cavity under a certain injection pressure.

Cooling Stage

Once the injection is done, the mold needs to sit for a while to let the plastic part form. This time is called the cooling time. The only job of the injection molding machine is to make sure the cooling time is right and stays the same so the mold cools down right. How long the cooling time is can also affect how good the plastic parts are.

Mold Opening Stage

The last step of the injection molding machine is mold opening. When the cooling is completed, the mold is opened and disassembled, and the injection molding cycle8 is restarted.This process may require some luck, strength, and skill. But the injection molding machine also brings high-quality molds, excellent and reliable injection molding processes, fast and accurate production speeds, and economic benefits.

Injection molding enhances production speed.True

Injection molding's streamlined process allows for fast production cycles, increasing overall manufacturing output.

Injection molding machines are suitable only for plastic products.False

While primarily used for plastics, injection molding machines can also mold other materials like metals and ceramics, depending on the setup and design.

What are the Application Areas of Injection Molding Machines?

Injection molding machines are pivotal in manufacturing, offering versatility and precision to produce complex parts across diverse industries.

Injection molding machines efficiently produce precise, durable components for automotive, electronics, and consumer products. Key benefits include cost-effectiveness for large runs and consistent creation of complex shapes.

Manufacturing Industry

You can use small injection molding machines to make all kinds of plastic products, like household items, office supplies, toys, electronic accessories, car parts, and more. They’re perfect for small runs or custom orders, and they’re a flexible solution for manufacturers.

Medical Industry

You can use small injection molding machines to make plastic parts for medical equipment and instruments, like syringes, infusion sets, medical equipment housings, etc. It has high precision and stable performance, so the medical industry can get high-quality products.

Using the injection molding machine power saving system can make production more efficient, save energy, and make sure medical equipment is safe and reliable.

Food Packaging Industry

You can use small injection molding machines to make food packaging containers, like plastic bottles, boxes, lids, and so on. It can meet food safety and hygiene requirements and give you custom packaging solutions.

Electronic Industry

You can use small injection molding machines to make electronic product housings and accessories, like phone cases, computer keyboards, TV remotes, and more. They can make complex shapes and do fine work to meet the design needs of electronic products.

Using injection molding machines makes production faster and also meets the high standards for precision and quality that electronic and electrical products need.

Toy Industry

You can use small injection molding machines to make all kinds of plastic toys, like kids’ toys, educational toys, and so on. You can change the way you make them to meet different needs in the market.

Home Decoration Industry

You can use small injection molding machines to make home decorations and supplies, like flower pots, lamps, furniture accessories, etc. It can give you lots of choices for materials and colors, so you can make things that are just right for you.

Automotive Industry

You can use small injection molding machines to make car parts like bumpers, seats, door panels, dashboards, headlight shells, interior trims, and so on. They work really well and make high-quality parts that car companies can trust.

Injection molding machines are only suitable for large-scale production.False

While they are cost-effective for large volumes, advancements in technology have enabled efficient small-batch production as well.

Injection molding provides superior precision and detail in manufactured parts.True

Injection molding allows for the production of highly detailed and precise parts, thanks to the high-pressure molding process.

Conclusion

In a nutshell, plastic injection molding process is a very popular manufacturing process. A plastic processing method in which the plastic is plasticized in the heated barrel of the injection molding machine and then injected into the mold cavity of a closed mold by a plunger or reciprocating screw to form a product.

plastic injection molding machines make plastic stuff by squirting melted plastic into a mold and letting it cool and harden. They work great, so you can make a ton of plastic stuff fast and cheap. As technology gets better, we’ll keep using these machines to make even better plastic stuff for us.

-

Understanding the workings of a plastic injection molding machine can enhance your knowledge of manufacturing processes and improve product design. ↩

-

Exploring the clamping system’s role can provide insights into how product quality is maintained during the injection molding process. ↩

-

Learning about the hydraulic transmission system can help you understand the power dynamics in injection molding, crucial for efficient production. ↩

-

Understanding the injection molding machine is crucial for grasping its components and functions in manufacturing processes. ↩

-

Exploring how cooling systems function can enhance your knowledge of maintaining optimal temperatures in injection molding processes. ↩

-

Learning about lubrication systems can improve machine efficiency and longevity, crucial for any manufacturing operation. ↩

-

Learn how melting time impacts the quality of injection molded products and optimize your production process. ↩

-

Learn about How to Reduce the Injection Molding Cycle Time : The injection molding cycle is a big deal. It affects how much work you get done and how much money you make. ↩