Injection molding is a sophisticated manufacturing process that relies on specially-designed molds to create an array of products.

These injection molds shape the molten material as it’s injected, giving each product its unique size and form.

It’s thanks to injection molds that so many high-quality plastic components make their way into our everyday lives!

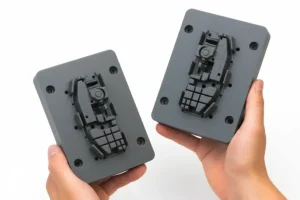

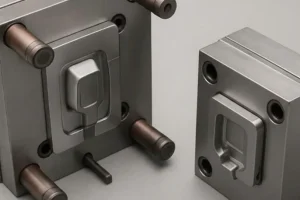

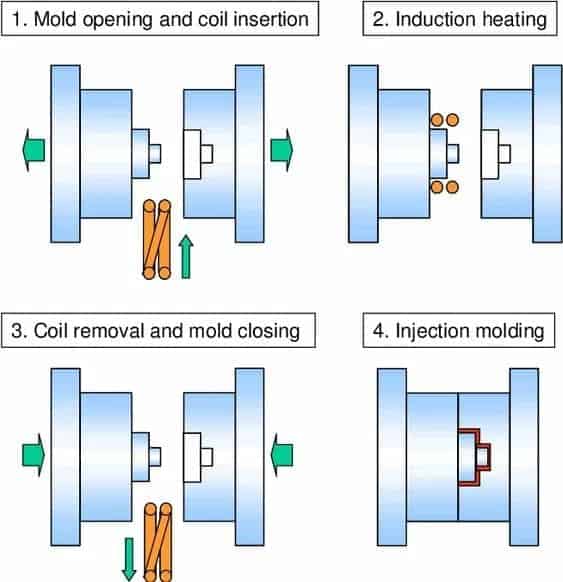

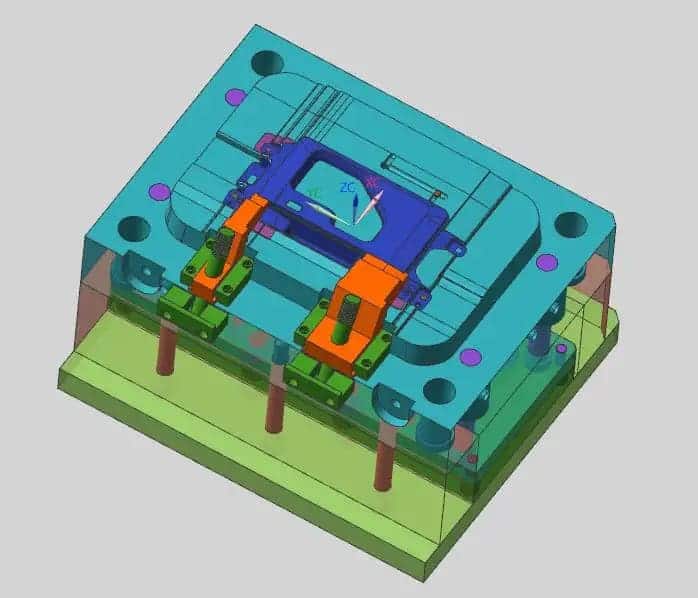

1. Creation of a mold

Creating injection molds involves multiple intricate components, such as a cavity which defines the shape of the finished product.

This is usually constructed using precise techniques like CNC machining and EDM (electrical discharge machining). Moreover, elements including core pins and ejector pins help form and support it in place. Ultimately these pieces are affixed to an advanced plastic injection molding machine – consisting of feed hopper for molten material, heating unit & piston system used to inject it into the actual mold itself.

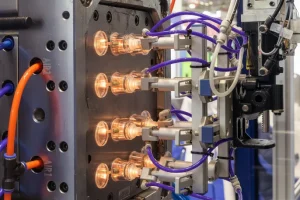

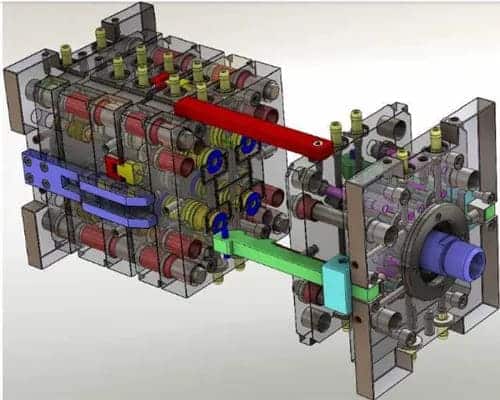

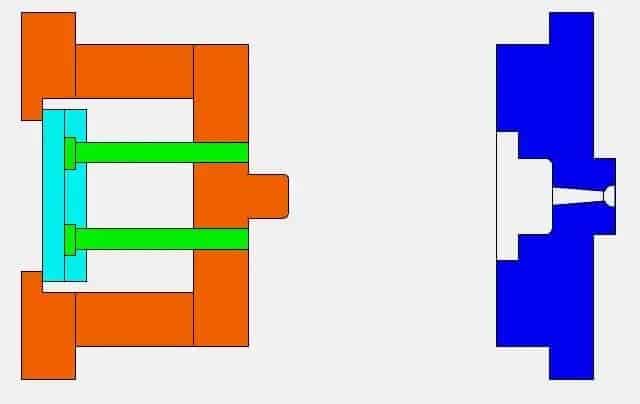

2. Fix the injection mold into the injection molding machine

Precision and accuracy are key when it comes to plastic injection molding. Utilizing advanced machinery with components such as a hopper, heating barrel, reciprocating screw and clamp ensure that the process runs smoothly while producing high-quality results.

3. Heated the molten plastic material

To begin the plastic injection molding process, operators start by loading a precisely measured amount of material into the hopper.

Then, gravity-fed to its destination within the heating barrel – where it is melted and mixed with help from an electric or gas heat source as well as reciprocating screw motion – ensuring uniformity before being injected into the exact injection mold necessary for production.

4. Injection of the plastic material into the mold

By utilizing a powerful hydraulic plunger or screw, melted and mixed plastic is injected into specially-crafted injection molds with extreme force.

This process equips the material to take on detailed shapes as it cools and solidifies – ultimately forming intricate parts that can be utilized in many products.

5. Open the mold and eject the products

The injection molding process begins with plastic being injected into the molds and ends with a perfectly crafted product, created in mere minutes.

As part size and complexity vary, so do cooling times before reliable ejection is possible – leaving you to marvel at how quickly your project progressed from concept to completion!

6. Additional processing

After a part has been crafted with precision using the injection molding process, it may require further enhancement.

Depending on its intended purpose, details such as trimming away any excess material and finishing touches like paint or detailing can bring out its full potential.

Conclusion

Manufacturers across the globe rely on injection molding as a preferred method to rapidly produce intricate parts and products with impressive precision.

Through this process, injection molds are crafted in any desired shape; when molten material is injected into these molds at high temperatures before being cooled and solidified, plastic components of all shapes can be created efficiently for diverse uses.