Injection molds1 are precision tools essential for manufacturing plastic parts, forming the backbone of industries like automotive, medical, and consumer goods. These molds, crafted from metals such as steel or aluminum, are created through a meticulous process that transforms raw materials into highly functional devices capable of producing consistent, high-quality parts.

Injection molds are made by designing with CAD software2, selecting materials like steel or aluminum, machining with CNC or EDM, heat-treating steel molds, assembling components, and testing to ensure precision in producing plastic parts for automotive, medical, and consumer applications.

Understanding how injection molds are made is vital for professionals in manufacturing and product design. This article explores the process in detail, from conceptual foundations to technical workflows, practical tools, and real-world applications.

Injection molds are critical for mass-producing precision plastic parts.True

Their ability to shape molten plastic into complex, accurate forms makes them indispensable for high-volume production.

What Is an Injection Mold?

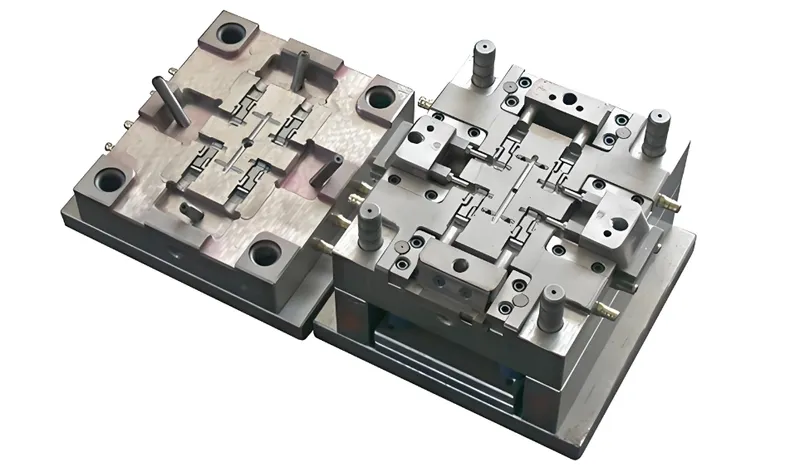

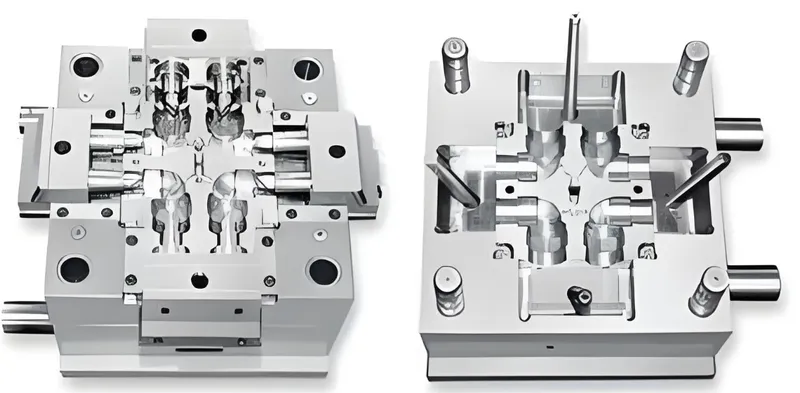

An injection mold, often referred to as a mold tool, is a precision-engineered device used in the injection molding process to create plastic parts. It consists of two main components: the cavity, where molten plastic is injected, and the core, which shapes the interior of the part as the plastic cools and solidifies. These molds are typically made from durable metals like steel or aluminum, selected based on production volume, cost, and durability needs.

Injection molds, made from steel or aluminum, shape molten plastic into precise parts via a cavity and core system, tailored to production volume and application requirements.

Key Characteristics

-

Materials: Steel (e.g., P20, H13) for high-volume durability; aluminum for cost-effective prototyping.

-

Design: Incorporates features like cooling channels, ejector pins, and gates for efficient molding.

-

Applications: Used in industries requiring precision, such as automotive (bumpers), medical (syringes), and consumer goods (casings).

Steel molds are always better than aluminum molds.False

While steel offers greater durability for high-volume runs, aluminum is more cost-effective and faster to machine for prototyping or low-volume production.

What Are the Steps in Making an Injection Mold?

The process of creating an injection mold is a blend of engineering precision and craftsmanship. Below is a step-by-step breakdown of how these vital tools are manufactured.

Injection molds are crafted through a multi-step process: designing with CAD, selecting materials, machining with CNC or EDM, heat-treating steel molds, assembling, and testing for accuracy and functionality.

1. Designing the Mold

Engineers use Computer-Aided Design (CAD) software to create a detailed mold design. This step defines the part geometry, including wall thickness, draft angles, and gate locations, while incorporating cooling channels and ejection mechanisms to optimize performance.

2. Material Selection

The mold material is chosen based on production needs:

-

Steel: Durable and ideal for high-volume production (e.g., 100,000+ cycles).

-

Aluminum: Cost-effective and faster to machine, suited for prototyping or low-volume runs (e.g., <10,000 cycles).

3. Machining the Mold

The mold is shaped using advanced machining techniques:

-

CNC Machining3: High-precision milling for standard geometries.

-

Electrical Discharge Machining (EDM)4: Used for intricate details or hardened steel, ensuring tight tolerances.

4. Heat Treatment (Steel Molds)

Steel molds undergo heat treatment to enhance hardness and wear resistance. This involves heating to specific temperatures (e.g., 800–1000°C) and controlled cooling, critical for longevity in high-volume production.

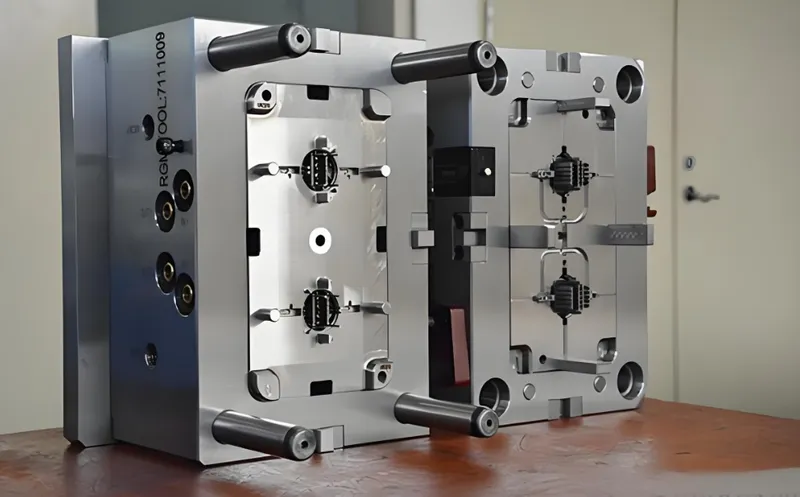

5. Assembly

Mold components—cavities, cores, cooling channels, and ejector pins—are assembled with precision to ensure alignment and functionality.

6. Testing and Validation

Trial injections are conducted to test the mold, identifying defects like flash or incomplete fills. Adjustments are made to perfect the mold before full production.

| Step | Key Tools/Techniques | Critical Parameters |

|---|---|---|

| Design | CAD Software | Draft angles, gate placement |

| Material Selection | Steel vs. Aluminum | Production volume, cost |

| Machining | CNC, EDM | Tolerances, surface finish |

| Heat Treatment5 | Furnace | Temperature, duration |

| Assembly | Manual/automated | Alignment, fit |

| Testing | Injection trials | Part quality, defect rate |

CNC machining is sufficient for all injection mold designs.False

While CNC offers precision, EDM is often required for complex geometries or hardened steel that CNC cannot effectively handle.

What Factors Influence Injection Mold Manufacturing?

Several factors determine the quality, cost, and efficiency of injection mold production.

Injection mold manufacturing6 hinges on material choice, machining methods, and design complexity, impacting durability, cost, and production speed.

1. Material Choice

-

Steel: Withstands high temperatures (200–400°C) and pressures, ideal for long-term use.

-

Aluminum: Easier to machine and less expensive but less durable under prolonged stress.

2. Machining Method

-

EDM: Slower but essential for intricate features or hardened materials.

3. Design Complexity

Complex parts require multi-cavity molds or additional features like side actions, increasing manufacturing time and cost.

Aluminum molds are always cheaper to produce than steel molds.False

While aluminum has lower material and machining costs, complex designs or high-volume needs may offset savings compared to steel.

What Are the Applications of Injection Molds?

Injection molds are versatile tools with widespread use across industries.

Injection molds are used in automotive, medical, and consumer goods industries to produce precise, high-volume plastic parts8 like bumpers, syringes, and casings.

Automotive Industry

Molds create components like dashboards, bumpers, and interior panels, requiring durability and precision for safety and aesthetics.

Medical Industry

Used for sterile, high-precision parts like syringe bodies and device housings, where tolerances are critical.

Consumer Goods

Produces items like electronic casings and toys, balancing cost, complexity, and surface finish.

Injection molds are only suitable for large-scale production.False

While ideal for high volumes, molds can be cost-effective for prototyping when using aluminum or simplified designs.

How Do Injection Molds Compare to Other Technologies?

Injection molding stands out among manufacturing methods but has distinct differences.

Injection molding9 excels in high-volume plastic part production compared to 3D printing or die casting, offering precision and scalability but higher upfront costs.

| Technology | Material | Precision | Volume Suitability | Cost (Upfront) |

|---|---|---|---|---|

| Injection Molding | Plastics | High | High | High |

| 3D Printing | Plastics/Metals | Medium | Low | Low |

| Die Casting | Metals | High | High | High |

-

Vs. 3D Printing: Injection molding offers faster production for large runs but lacks the flexibility of 3D printing for rapid prototyping.

-

Vs. Die Casting: Injection molding focuses on plastics, while die casting is for metals, each serving different material needs.

Injection molding is more efficient than 3D printing for all applications.False

3D printing is faster and cheaper for small batches or prototypes, while injection molding shines in mass production.

Practical Tools for Injection Mold Design

To aid in mold creation, here are actionable tools for designers and engineers.

Design Checklist

-

Ensure uniform wall thickness for even cooling.

-

Include draft angles (1–2°) for easy part ejection.

-

Design cooling channels to reduce cycle time.

-

Select material based on production volume and budget.

Decision-Making Guide

-

High Precision/Complex Shapes: Use CNC or EDM.

-

Prototyping: Opt for aluminum molds or 3D-printed inserts.

-

High Volume: Choose steel with heat treatment.

Conclusion

Injection molds are the cornerstone of modern plastic manufacturing, enabling the production of precise, high-quality parts at scale. The process—spanning CAD design, material selection, machining, heat treatment, assembly, and testing—requires a balance of technical expertise and practical decision-making. Whether using steel for durability or aluminum for cost savings, understanding how injection molds are made empowers professionals to optimize production for their specific needs.

-

Explore this link to gain a deeper understanding of injection molds and their critical role in various industries. ↩

-

Learn how CAD software enhances mold design efficiency and precision, crucial for successful manufacturing processes. ↩

-

Discover the significance of CNC machining in creating high-precision molds, essential for quality manufacturing. ↩

-

Explore this link to understand how EDM works and its significance in precision machining, especially for intricate designs. ↩

-

Learn about heat treatment techniques that enhance mold durability and performance, crucial for high-volume production. ↩

-

Understanding the key factors in injection mold manufacturing can enhance your production efficiency and cost-effectiveness. ↩

-

Exploring CNC machining advantages can help you optimize your injection mold production process for better precision and speed. ↩

-

Learn about the production process of high-volume plastic parts to see how efficiency and precision are achieved in manufacturing. ↩

-

Explore the advantages of injection molding to understand its unique benefits in high-volume production and precision. ↩