Fully electric injection molding machines use electric motors for all movements, offering high precision, energy efficiency, and minimal maintenance.

Fully electric injection molding machines offer energy savings, faster cycles, and precise control with electric drives, ideal for high-quality parts and minimal environmental impact.

Understanding the benefits and limitations of fully electric injection molding machines can help manufacturers make informed decisions. Learn more about how they optimize production and reduce costs.

Fully electric injection molding machines are more energy-efficient than hydraulic ones.True

Electric machines consume less energy because they only use power when necessary, unlike hydraulic machines that are always running.

Fully electric injection molding machines are always more expensive than hydraulic machines.False

While the initial cost of fully electric machines is higher, their energy savings and reduced maintenance costs can offset the price difference over time.

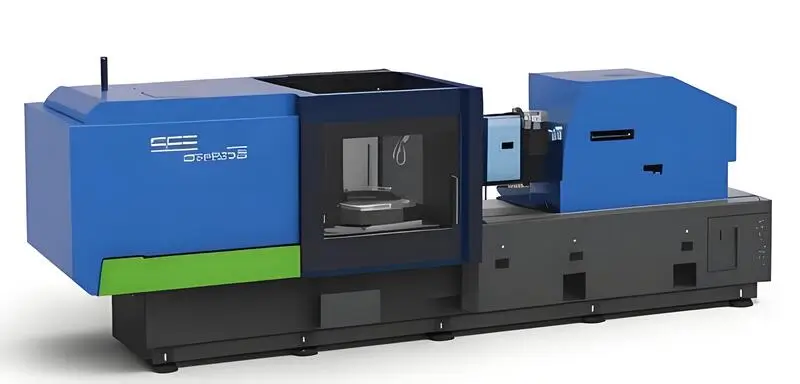

What is the Meaning of Full-Electric Injection Molding Machine?

Full-electric injection molding machines offer enhanced precision and energy efficiency, transforming production capabilities in diverse sectors.

Full-electric injection molding machines, used in electronics and medical industries, offer precise control and energy efficiency with electric servo motors, leading to faster cycles, enhanced accuracy, and lower operational cost.

A full-electric injection molding machine1 (hereinafter referred to as: full-motor) is an injection molding machine that uses AC servo motors2 and is equipped with precision devices such as ball screws to drive various mechanisms.

All mechanisms in the full-motor injection molding device (injection, plasticization, and seat shifting, etc.) and all mechanisms of the clamping device (opening and closing molds, ejection, etc.) are all driven by servo motors, which greatly improves the transmission efficiency, and can realize multiple groups of linkage synchronization functions to achieve high efficiency and energy saving.

Full-electric injection molding machines reduce energy consumption compared to hydraulic systems.True

Electric machines use servo motors that are highly efficient and consume less energy than hydraulic pumps, especially in idle phases.

Full-electric machines are ideal for all types of injection molding applications.False

While they excel in precision and energy efficiency, full-electric machines may not be suitable for high-force applications due to limits in clamping force compared to hydraulic models.

What is the Working Principle of a Full-Motor Injection Molding Machine?

Full-motor injection molding machines enhance precision, speed, and energy efficiency, transforming production capabilities for manufacturers worldwide.

Full-motor injection molding machines, using servo motors, offer precision and energy efficiency, ideal for industries like automotive and electronics. Key benefits include better speed control, repeatability, reduced energy consumption, and enhanced production precision.

Injection Part

The injection part of the all-motor injection molding machine heats and melts the plastic particles, and then injects the molten plastic into the mold through a syringe to form the desired product shape.

In the injection part, the motor controls the high-pressure motor torque through the inverter to inject the molten plastic into the mold through the screw. The speed and pressure of the injection process can be adjusted according to the needs of the product.

Locking Part

The locking part of the all-electric injection molding machine is mainly realized by the hydraulic cylinder. In the locking part, the locking mechanism is activated by controlling the rotation of the locking motor.

At the same time, the hydraulic cylinder locks the mold through high-pressure oil. When the mold is released, the hydraulic cylinder can release the mold from the injection molding machine.

Hydraulic Part

The hydraulic part of the all-motor injection molding machine uses an oil pump frequency conversion control system, which can make the hydraulic system more stable and precise.

When the oil pump of the hydraulic part works, the oil is transmitted through the oil pipe, oil pipe, hydraulic cylinder and other parts, thereby realizing various actions of the injection molding machine.

Electrical Control Part

The injection molding machine’s controller uses a high-performance PLC control system3. It can monitor and adjust many functions, so the injection molding machine can run at its best.

The injection molding machine’s controller uses a high-performance PLC control system. It can monitor and adjust many functions, so the injection molding machine can run at its best.

Full-motor injection molding machines reduce energy consumption.True

These machines use servo motors, which require less energy than traditional hydraulic systems, enhancing overall energy efficiency.

Full-motor injection molding machines are suited for only large-scale production.False

Their versatility allows them to be used effectively for both small and large-scale production, accommodating a range of applications.

What are the Characteristics of the All-Electric Injection Molding Machine?

All-electric injection molding machines offer precise control, energy efficiency, and improved production capabilities, becoming a preferred choice in various sectors.

All-electric injection molding machines offer high precision, lower energy use, and faster cycles, making them ideal for electronics and medical manufacturing due to their clean operation and consistent output.

-

High precision: The all-electric injection molding machine uses a servo drive system, which can achieve super accurate injection molding process control and ensure the product’s dimensions are accurate and consistent.

-

High speed: The electric servo drive system has the characteristics of super fast response and super fast movement, which allows the all-electric injection molding machine to achieve super fast injection and super fast cycle times, and improve production efficiency.

-

Low energy consumption: All-electric injection molding machines don\’t have hydraulic systems like hydraulic injection molding machines do, so they use way less energy and save you money.

-

Easy operation: All-electric injection molding machines have digital control systems with user-friendly interfaces that are easy to use. You can c- Easy operation:hange settings fast and keep an eye on production.

-

Low noise: The electric servo drive system operates quietly, making it more environmentally friendly than hydraulic injection molding machines and meeting the environmental protection requirements of modern factories.

-

Wide range of applications:All-electric injection molding machines are suitable for producing a wide range of plastic products, such as electronic product casings, automotive parts, everyday items, and more.

-

Control: The electric servo drive system can control various parameters of the injection molding process, like injection speed, pressure, temperature, injection unit .etc, and can meet the production requirements of various complex products.

-

Low maintenance cost: Compared with hydraulic pressure injection movement, electric servo drive system has lower maintenance cost, and there is no need to regularly replace hydraulic oil and filter elements, which reduces maintenance cost and maintenance time.

All-electric injection molding machines are more energy-efficient than hydraulic ones.True

All-electric machines consume less energy as they do not require hydraulic pumps, leading to reduced energy costs.

All-electric injection molding machines are cheaper to purchase than hydraulic machines.False

Although all-electric machines have higher initial costs, their efficiency and energy savings result in reduced operating expenses over time.

What are the Advantages of Fully Automatic Injection Molding Machines?

Fully automatic injection molding machines streamline production, improving efficiency and precision in manufacturing processes across industries.

Fully automatic injection molding machines enhance precision, speed, and cost-efficiency. Widely used in automotive, electronics, and packaging industries, they ensure consistent quality and production flexibility.

Reduce Production Costs

All-electric injection molding machines can cut production costs. Because of the electric system’s high efficiency and low energy consumption, all-electric injection molding machines can cut energy consumption and maintenance costs, which cuts production costs.

The electric injection molding machine’s control system is smart, so it can monitor the data and information in the production process in real time. This means it can make real-time adjustments and optimizations to improve production efficiency.

Also, the electric injection molding machine has a faster mold opening speed and a faster injection speed, so it’s got a high advantage in production efficiency. Plus, the maintenance cost and time of electric injection molding machines are relatively low, so they can greatly reduce production costs.

Electric injection molding machines have a major advantage in energy savings. Because the servo motor is driven directly according to the force requirements of each actuator, it not only improves efficiency, but also improves energy utilization.

With an energy utilization rate of over 95%, it can save 25% to 60% energy compared with the full hydraulic injection molding machine, thus reducing production costs.

Because each action of the full electric injection molding machine is controlled by the corresponding servo motor, when a certain production action is performed, other control motors don’t need to run, which saves a lot of power.

The power consumption of a full electric injection molding machine is generally only 1/3 to 1/4 of that of a full hydraulic injection molding machine. Moreover, the full electric injection molding machine does not use hydraulic oil, which eliminates the cooling step of the working oil, thereby greatly reducing the use of cooling water. This can greatly reduce production costs for manufacturers.

Improve Production Efficiency

electric molding machines cover a broader category that includes all-electric and hybrid machines. The all-electric injection molding machine can improve production efficiency under the same production conditions.

Because the electric system has high precision and fast response, the all-electric injection molding machine can achieve higher injection speed and better product quality, thus improving production efficiency.

One of the biggest advantages of all-electric injection molding machines over traditional hydraulic injection molding machines is energy consumption. Hydraulic injection molding machines, on the other hand, need to heat cooling water frequently during operation, which results in a lot of energy waste.

The all-electric injection molding machine uses a completely oil-free hydraulic system, so there is no problem of hydraulic oil leakage when the machine is running. It can not only effectively avoid pollution to the environment, but also reduce energy waste and achieve the goal of improving production efficiency and benefits.

Using servo motors in all-electric injection molding machines enhances system responsiveness, making it responsive, quick, and highly accurate. Each action is driven by an independent motor, enabling the injection molding machine to perform complex actions and multiple processes simultaneously, significantly boosting production efficiency.

Using servo motors makes the system more responsive. For example, the ES series of all-electric injection molding machines have a molding time that’s only 1/3 of a full hydraulic injection molding machine.

Because each actuator on the electric injection molding machine is driven by its own servo motor and isn’t affected by the system, it can do multiple things at once. For example, it can eject at the same time it’s opening the mold and close the mold at the same time it’s plasticizing, which makes it a lot more productive.

High Precision

All-electric injection molding machines are more precise than traditional hydraulic injection molding machines.

All-electric injection molding machines use electric servo control systems, which can achieve precision control at the micron level, with a precision of up to 0.01mm, which is two to three times higher than that of traditional hydraulic injection molding machines. This high-precision control is very important for some precision injection molding parts.

All-electric injection molding machines are faster, more efficient, and more precise. They’re perfect for making high-value products like electronics, appliances, and super-clean medical stuff. They’re especially good at making small parts. They’re just better at making things.

The electric injection molding machine’s control system uses a high-performance CNC system. It can adjust the valve position by monitoring and giving feedback in real time. This guarantees the accuracy and stability of the injection molding process.

Low Noise

The all-electric injection molding machine is very quiet during the injection molding process, which is not the case with traditional hydraulic injection molding machines4. Traditional hydraulic injection molding machines need to control the flow of raw materials by compressing and releasing oil and gas, which causes the hydraulic pump and motor to vibrate and make a lot of noise.

The difference between the all-electric injection molding machine and the all-electric injection molding machine is that it uses an intelligent electronic control system, which greatly reduces the noise of the machine during operation and can effectively improve the quality of the working environment.

Less Pollution to the Environment

When it comes to factory environmental protection, the all-electric injection molding machine also has great advantages. Since the all-electric injection molding machine can not only reduce the emission of polluting gases, but also reduce the noise pollution caused to the environment and improve the working environment of employees, it is favored by many companies.

Compared to traditional hydraulic injection molding machines, all-electric injection molding machines have several advantages: high precision, low energy consumption, low noise, low pollution, and they are being used in more and more applications. Although they are expensive, as they are used in more applications, their value will be recognized by the market.

Electric injection molding machines are different from traditional hydraulic injection molding machines. They use electric direct drive screws and don\’t need hydraulic systems. The way they work is by converting electrical energy into kinetic energy and sending it to the plastic through the screw. The rest of the injection molding process, like cooling and mold opening, is also done with electric energy.

This working method not only consumes less energy, but also reduces the pollution of the hydraulic system to the environment during the production process, which is in line with modern environmental protection concepts.

Also, electric injection molding machines are quiet and produce less exhaust gas emissions. This means that using electric injection molding machines is also good for the environment.

All-electric injection molding machines can reduce environmental pollution5. Because of the low energy consumption and zero emissions of the electric system, all-electric injection molding machines can reduce pollution and impact on the environment, so as to achieve sustainable development.

The all-electric injection molding machine is quiet when it runs, and it doesn’t use any oil, so it won’t leak oil and make a mess.

The Injection Performance is Stable

The dynamic technical parameters6 of the fully hydraulic injection molding machine are affected by the change of hydraulic oil temperature and are prone to fluctuations.

On the other hand, the dynamic technical parameters of the all-electric injection molding machine are hardly affected by external factors. The mold molding parameters stored in the computer always meet the actual molding conditions, so the injection performance is stable. The rapid response of accurate injection molding parameters can only be truly reflected in the servo motor system.

Fully automatic machines reduce labor costs in manufacturing.True

These machines automate most of the molding process, minimizing the need for manual labor and reducing associated costs.

Fully automatic machines are always the most cost-effective solution.False

While they offer many benefits, the high initial investment may not be suitable for small-scale production, where manual or semi-automatic machines could be more cost-effective.

What are the Applications of Fully Electric Injection Molding Machines?

Fully electric injection molding machines offer energy efficiency, precision, and low noise levels, making them suitable for a wide range of industries.

Fully electric injection molding machines boost precision, energy efficiency, and product quality across industries like electronics, automotive, and medical devices. Benefits include reduced energy consumption, lower operational costs, and improved environmental friendliness.

Medical Devices

Fully electric injection molding machines are great for making medical devices like medical syringes and infusion sets. Medical devices need to be made with high precision7, good quality, and no pollution. Fully electric injection molding machines are more precise, stable, and clean, so they are popular in this field.

Electronic Products

With the popularity of electronic products, the manufacturing of electronic products has also received more and more attention. Fully electric injection molding machines can manufacture various electronic product shells and accessories, such as mobile phones, computers, flat-screen TVs, smart homes, etc., and their precision and production efficiency8 are also better than traditional injection molding machines.

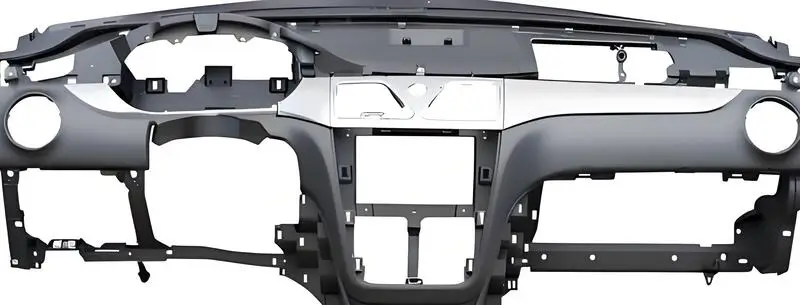

Auto Parts

The level of automation in car manufacturing is getting higher and higher, and the quality requirements for car parts are also getting higher and higher. All-electric injection molding machines have high precision, reliability and stability in the production of car parts, and are especially suitable for the production of car parts with high precision requirements.

Packaging Industry

The packaging industry has high requirements for product appearance. It requires products with high production efficiency and stable quality. All-electric injection molding machines can produce high-quality plastic packaging boxes, bottles, boxes, and other products. It can meet the production needs of this industry.

Fully electric injection molding machines provide superior energy efficiency over hydraulic machines.True

Electric machines use less energy by eliminating the hydraulic system, which consumes more power and requires cooling.

Fully electric injection molding machines can always handle larger tonnage applications.False

While they excel in precision tasks, electric machines might not be ideal for all high-tonnage applications, where hydraulic systems may offer better performance.

How to Maintain an All-Electric Injection Molding Machine?

Proper maintenance of all-electric injection molding machines ensures longevity, efficiency, and optimal performance in production facilities.

Regular maintenance of all-electric injection molding machines involves cleaning, lubrication, and software updates to prevent downtime and ensure consistent quality. Key practices include checking electrical components, calibrating alignment, and monitoring wear on moving parts for flawless operation.

Pay Attention to the Lubrication System

When using an all-electric injection molding machine, you need to use enough grease. The lubricating oil must be kept clean, free of impurities and carbon deposits.

It also needs to ensure sufficient temperature rise to avoid overheating and overcooling, so as to ensure the effect of injection molding and extend the service life of the all-electric injection molding machine. For some precision equipment, you also need to use enough oil.

Check the Safety Protection Device Regularly

Regularly check the safety protection device of the injection molding machine to see if it is normal, so as to prevent the failure to take timely measures to avoid accidents when a failure occurs. At the same time, regularly check the motor, cutter head and other components for failures. If there are any abnormal phenomena, carry out timely maintenance and take necessary measures.

Open the Mold Cover Regularly to Observe and Clean the Residue in the Mold Cavity

Inspect the mold’s cooling system. If the cooling system 9 isn’t working properly, check the cooling system of the all-electric injection molding machine and adjust the system temperature and speed. If there’s a problem, deal with it. If you find that the new machine can’t be used, let the manufacturer know. After you’re done using the machine, park it outside and keep it dry.

Avoid Operating the Machine in the Shutdown State

When you’re running an all-electric injection molding machine, you need to be careful with the buttons. If the machine stops, you need to stop right away. You don’t want to mess up the machine by having an accident. When you turn off the machine, you need to turn off the power. You also need to take out the plastic waste in the machine.

When you’re done, you need to turn off the power and the switch. If you don’t, you’ll mess up the motor and the hydraulics. Then the mold won’t work right. So, don’t run the all-electric injection molding machine when you’re not supposed to.

All-electric injection molding machines require less maintenance than hydraulic ones.True

All-electric machines have fewer mechanical parts, reducing the frequency of maintenance and the risk of hydraulic fluid leaks.

All-electric injection molding machines operate silently.False

While generally quieter than hydraulic machines, all-electric machines still produce noise from motors and mechanical actions, requiring some sound management solutions.

Conclusion

In a nutshell, the all-electric injection molding machine is a big deal in manufacturing. It’s way better than the old hydraulic machines. It’s more precise, more efficient, and more sustainable. By getting rid of the hydraulics and using electric servo motors instead, these machines use less energy, need less maintenance, and give you more control over the molding process.

As companies everywhere try to make more stuff and be more green, they’re going to start using all-electric injection molding machines. That’s going to change the way we make things and make us come up with new ideas and ways to be green.

-

Explore the advantages of full-electric injection molding machines, including efficiency and energy savings, to enhance your production processes. ↩

-

Learn how servo motors enhance precision and efficiency in injection molding, making them essential for modern manufacturing. ↩

-

Discover the role of high-performance PLC control systems in optimizing injection molding operations for better productivity. ↩

-

Understanding traditional hydraulic machines helps appreciate the advancements in all-electric technology and their impact on manufacturing. ↩

-

Learn about the environmental impact of injection molding processes and how modern machines can mitigate pollution. ↩

-

Understanding dynamic technical parameters is essential for optimizing injection molding processes and improving product quality. ↩

-

Discover why high precision is critical in the production of medical devices, ensuring safety and effectiveness in healthcare applications. ↩

-

Learn how production efficiency plays a crucial role in manufacturing, enhancing productivity and reducing costs. ↩

-

Learn about How many types of cooling systems are there for injection molds?The cooling system of injection molds can be divided into air cooling…….. ↩