If you’re in the market for a new molding process, you’ve probably heard of reaction injection molding. This process is becoming more and more popular due to its many benefits. In this blog post, we will discuss what reaction injection molding is and some of its key benefits.

What is Reactive Injection Molding(RIM Process)?

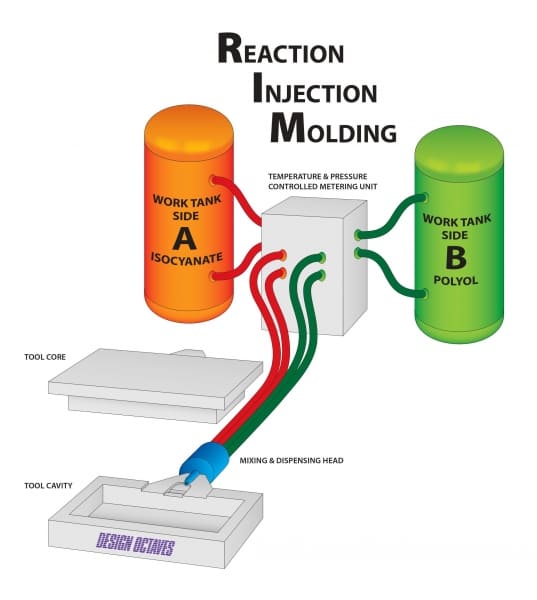

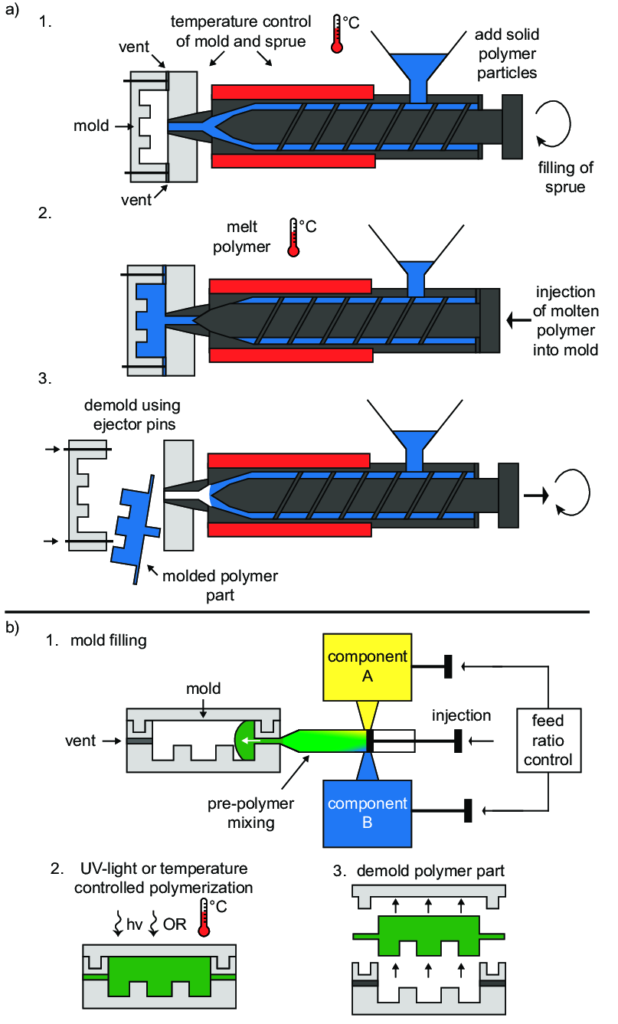

Reaction Injection Molding (RIM) is a process in which two-component materials with high chemical activity and low relative molecular mass are mixed by impact and injected into a closed mold at room temperature and low pressure to complete the chemical reactions of polymerization, cross-linking, and curing and form products.

According to the new technology forum industry about reaction injection molding share: this new process combining polymerization reaction and injection molding has the characteristics of high efficiency of material mixing, good fluidity, flexible raw materials formulation, short production cycle, and low cost, which is suitable for the production of large thick-walled products, so it has received attention from all over the world.

Origin and Development of Reaction Injection Molding

At the same time, to broaden the application area of RIM technology, especially in the automotive industry, the process also introduced fiber reinforcement technology.

RIM was first used only for polyurethane materials, but with the advancement of the process technology, RIM can also be applied to the processing of a variety of materials (such as epoxy resin, nylon, polyurea, and polycyclopentadiene, etc.). A subset of RIM is structural reaction injection molding, which uses fiber meshes for the reinforcing agent.

The RIM process for rubber and metal molding is a hot topic of current research.

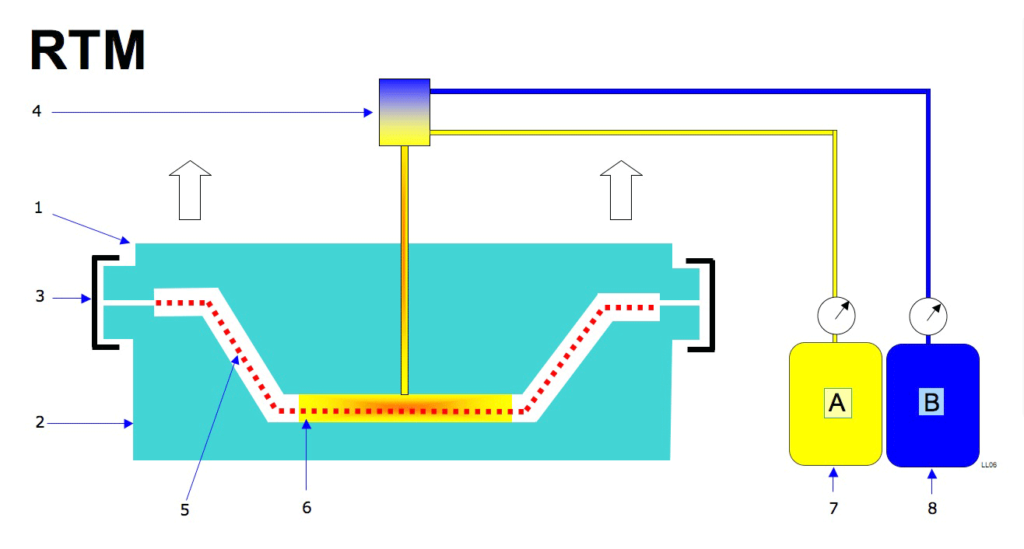

At the same time, to broaden the application area of RIM, improve the rigidity and strength of RIM products, and make them structural foam products, RIM technology has been further developed, and the Reinforced Reaction Injection Molding (RRIM) and Structural Reaction Injection Molding (SRIM) technologies, which are specifically used for the molding of reinforced products, have emerged.

RRIM and SRIM molding process principles are the same as RIM, the difference mainly lies in the preparation of fiber-reinforced composite products.

Applications of Reaction Injection Molding

Currently, typical RIM products are large products such as automotive bumpers, fenders, body panels, rigid foam automotive panels, truck cargo boxes, truck center doors, and rear door assemblies.

They have better product quality, faster production speed, and require less secondary processing than SMC products.

RIM molding process

Process

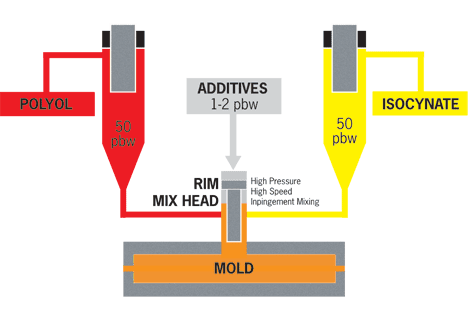

RIM process is monomer or prepolymer in a liquid state through the metering pump with a certain ratio into the mixing head for mixing.

The reaction injection molding process utilizes low-viscosity liquid polymers. These polymers expand and thicken through a variety of chemical reactions. After the polymers have been injected into the heated mold they eventually harden.

After the mixture is injected into the mold, the rapid reaction and cross-linking curing in the mold after demolding is RIM products.

This process can be simplified as follows: storage → metering → mixing → mold filling → curing → ejecting → post-processing.

Process Control

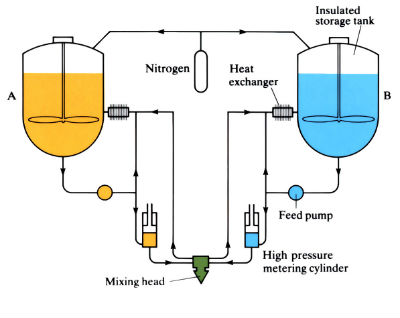

(1) Storage: The RIM process used in the two-component liquid is usually stored at a certain temperature in two separate storage containers, storage containers are generally pressure vessels.

When not forming, the stock liquid is usually at a low pressure of 0.2~0.3 MPa and circulates continuously in the storage vessel, heat exchanger, and mixing head. For polyurethane, the raw liquid temperature is usually 20~40℃, and the temperature control accuracy is ±1℃.

(2) Metering: The metering of the two-component raw liquid is generally done by the hydraulic system, which is composed of pumps, valves, and auxiliary parts (piping system to control the liquid material and oil circuit system to control the work of the distribution cylinder).

When injecting, it is also necessary to go through the high and low-pressure conversion device to convert the pressure to the pressure required for injection. The raw liquid is measured and output by a hydraulic quantitative pump(no need high pressure industrial pumps), requiring a metering accuracy of at least ±1.5%, preferably controlled at ±1%.

(3) Mixing: In the RIM product molding, the quality of the product depends largely on the mixing quality of the mixing head, and the production capacity depends entirely on the mixing quality of the multi stream mix head.

Generally adopted pressure of 10.34 ~ 20.68MPa, in this pressure range to obtain a better mixing effect.

(4) Mold filling: The reaction injection material filling is characterized by the high velocity of the material flow. For this reason, the viscosity of the original liquid should not be too high, for example, the viscosity of the polyurethane mixture is about 0.1 Pa.s when filling the mold.

When the material system and the mold are determined, there are only 2 important process parameters, i.e. mold filling time and raw material temperature. The initial temperature of polyurethane material shall not exceed 90℃, and the average flow rate in the cavity shall generally not exceed 0.5m/s.

(5) Curing: polyurethane two-component mixture has high reactivity after injecting into the mold cavity, and can be cured and shaped in a very short period.

However, due to the poor thermal conductivity of plastic, a large amount of reaction heat cannot be dissipated in time, so the internal temperature of the molded material is much higher than the surface temperature, resulting in the curing of the molded material from the inside out.

To prevent the temperature inside the cavity from being too high (not higher than the thermal decomposition temperature of the resin), the heat transfer function of the mold should be given full play to distribute heat.

The curing time inside the reaction injection mold is mainly determined by the formulation of the molded material and the size of the product. In addition, heat treatment is required after the reaction injection product is removed from the mold.

Heat treatment has two functions: one is to supplement the curing, and the other is to bake after painting to form a solid protective or decorative film on the surface of the product.

RIM molds and products design

Mold Design

(1) Pouring system: The pouring system, also known as the “injection system”, consists of gates, runners, and venting holes. In RIM mold design, the shape and height of the gate depending on the wall thickness and cavity flow of the molded parts.

For large capacity molds, a straight bar gate is usually preferred, while for small capacity molds, a fan gate is preferred.

The main runner should be located directly on the mold, but care should be taken to locate the runner so that the material enters the cavity from the lowest part of the cross-section of the product.

The venting hole should be located at the end of the material flow so that the air can be driven out of the cavity during the injection.

(2) Mold temperature control system: Here is only the RIM metal mold as an example to explain. The mold temperature control method is usually to bury a sleeve in the mold and pass water to heat or cool it.

The thickness of the metal mold should be 50mm, and the spacing of the casing should be different depending on the processing resin.

Usually, the mold temperature of polyurethane RIM is 40~80℃, and the mold temperature control accuracy is ±4℃, preferably ±1℃. The casing spacing is 80~100mm, and the distance between the cooling hole and the mold cavity wall should be 9.5mm.

(3) Parting surface: there is a general requirement for the location of the parting surface, that is, the location of the parting surface is located slightly below the contour of the processed part, so that the material is expanding and filling the cavity will be the residual air in the cavity to the outside of the mold.

Product Design

(1) Product thickness: the same as conventional injected products, in the design of the varying wall thicknesses of RIM products, should also avoid wall thickness too thick or too thin.

Take polyurethane foam RIM products as an example, the conventional wall thickness should be controlled at 6.35~12.7mm, when the wall thickness is greater than 12.7mm or less than 3.17mm, then appropriate remedial measures should be taken.

(2) Reinforcement: The purpose of using reinforcement is to improve the rigidity and hardness characteristics of the product. Thin and long reinforcement should be used, avoiding the use of thick and short reinforcement.

The setting of reinforcement should be along with the material flow, so as not to affect the gas emission during the material flow.

(3) Release slope: RIM product release slope should be selected 2 °, too large or too small are not conducive to product release.

(4) Rounded corners: RIM products of the internal corner radius shall not be less than 3.175mm, the external corner radius shall not be less than 1.578mm.

(5) Bump: The bump should adopt a 2° demoulding slope and be arranged along the periphery of the part of the inner rib. If the design height of the bump exceeds 6.57mm, it must be supplemented by a brace plate.

The position of the positioning threads and self-tapping threads must be accurately determined when forming in the introduction hole. The size of the boss and the introduction hole have a great influence on the release strength and should be taken into account.

The difference between reaction molding and injection molding

The reaction molding processes differ from standard injection molding in one important way; the material used in the molding process requires a curing stage while the material is still in the mold.

The molding material used in reaction injection molding has a special advantage over the material used in traditional injection molding for this process. On the other hand, reaction injection molding requires more time and expensive molding materials.

In most cases, the liquid formulation is fed into a reservoir, where it is heated and then mixed, and then placed into a prefabricated cavity called a mold, where it cools and hardens.

The mold is manufactured using a separate process and is usually removable, allowing multiple parts to be made on one traditional injection molding machine. The hardened object is removed and placed in an area where it is hardened and further hardened.