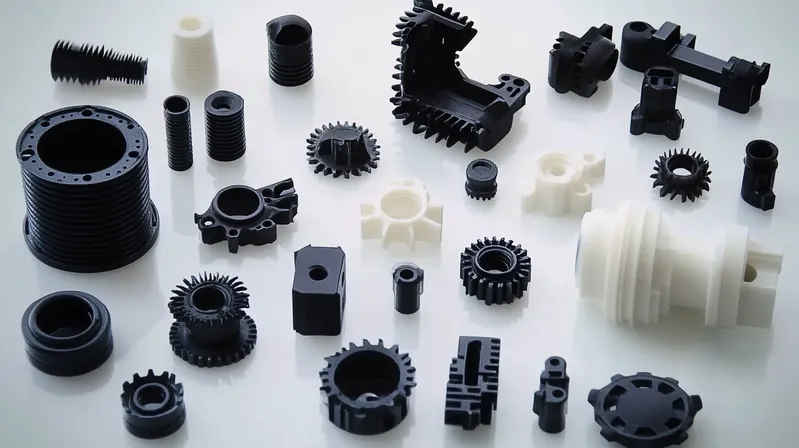

The integration of 3D Printing—technically known as Additive Manufacturing (AM)—into the Injection Molding (IM) workflow is transforming tooling strategies. Rather than replacing injection molding, AM acts as a force multiplier through **Rapid Tooling** and **Conformal Cooling**. By utilizing technologies like Direct Metal Laser Sintering (DMLS) for metal inserts and Stereolithography (SLA) for polymer molds, manufacturers can reduce lead times by 90% for prototypes, optimize cycle times through advanced cooling geometries, and bridge the gap between design and high-volume production.

Core Concepts: Rapid Tooling and Conformal Cooling

The synergy between these two manufacturing pillars primarily occurs in the fabrication of the mold itself, known as soft tooling or bridge tooling.

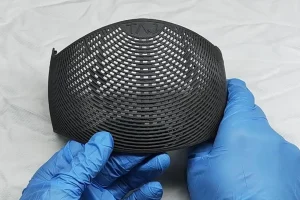

1. Polymer-Based Rapid Tooling

This involves using high-temperature photopolymers (e.g., Digital ABS) to print mold cavities and cores. These molds are inserted into standard metal mold bases (Master Unit Die or MUD frames).

- Purpose: Functional prototyping, low-volume runs (10–100 shots), and design validation.

- Technology: Stereolithography (SLA) or PolyJet.

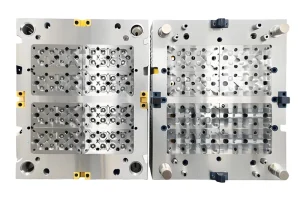

2. Metal-Based Additive Manufacturing (Conformal Cooling)

This involves printing mold inserts using metal powders (Maraging Steel, Stainless Steel). Unlike traditional drilling, which is limited to straight lines, AM allows for cooling channels that curve and conform to the part’s geometry.

- Purpose: Cycle time reduction (up to 40%), warpage minimization, and high-volume production durability.

- Technology: Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM).

Conformal cooling channels created via 3D printing can reduce injection molding cycle times by 20% to 40%.True

Conformed channels follow the part geometry precisely, removing heat more efficiently than straight drilled lines, drastically reducing cooling time.

3D printed polymer molds are suitable replacements for P20 steel molds in high-volume production runs.False

Polymer molds have low thermal conductivity and structural integrity compared to steel; they are strictly for low-volume prototyping (10-100 shots) or bridge tooling.

Technical Parameters: Traditional vs. Additive Tooling

The following table compares standard tool steel against common additive manufacturing solutions used in injection molding integration.

| Parameter | P20 Tool Steel (Traditional) | Maraging Steel (DMLS Printed) | Digital ABS (PolyJet Printed) | High-Temp Resin (SLA Printed) |

|---|---|---|---|---|

| Primary Use | High-volume production | Conformal cooling inserts | Low-volume prototypes | Detailed prototypes |

| Shot Life (approx.) | 100,000+ | 1,000,000+ (hardened) | 10 – 100 | 10 – 50 |

| Thermal Conductivity | ~29 W/m·K | ~15–20 W/m·K | ~0.2 W/m·K (Insulator) | ~0.2 W/m·K |

| Lead Time | 4 – 8 weeks | 1 – 2 weeks | 1 – 2 days | 1 – 2 days |

| Max Melt Temp | >300°C | >300°C | <250°C | <230°C |

| Tolerances | ±0.01 mm | ±0.05 mm (post-machined) | ±0.1 mm | ±0.1 mm |

Note: The DMLS process1 typically requires post-process machining to achieve mating surface tolerances suitable for flash-free molding.

Advantages and Disadvantages

Integrating 3D printing into the injection molding workflow offers strategic benefits but introduces specific physical limitations.

Advantages

- Speed to Market: Polymer molds can be printed and mounted in a press within 24 hours, allowing for same-week functional testing using the actual production material (e.g., Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS)).

- Complex Geometries: DMLS allows for internal lattice structures and curved cooling channels that are impossible to machine with CNC.

- Cost Reduction for Prototypes: Eliminates the cost of cutting aluminum or steel for designs that may change, saving thousands in initial development.

- Design Iteration: Enables "Fail Fast" methodologies; engineers can test multiple mold iterations simultaneously.

Disadvantages

- Heat Dissipation (Polymer Molds): Printed plastics are thermal insulators. Cycle times must be significantly extended to allow the mold to cool between shots to prevent deformation.

- Pressure Limitations: Polymer molds cannot withstand high injection pressures (typically capped at 500–800 bar) or high clamping forces.

- Surface Finish: Layer lines from 3D printing may transfer to the molded part unless the mold is manually polished or vapor smoothed.

- Material Compatibility: High-temperature engineering thermoplastics like Polyetheretherketone (PEEK) or glass-filled nylons are generally incompatible with polymer printed molds due to abrasion and heat.

Application Scenarios

1. Bridge Production

When steel tools are delayed, manufacturers use PolyJet molds2 to run 50–100 units for marketing samples, UL testing, or assembly line validation.

2. Conformal Cooling for Cycle Optimization

For parts with deep cores or complex curves (e.g., bottle caps, automotive connectors), DMLS inserts are used to place cooling water strictly equidistant from the mold wall. This eliminates "hot spots" and reduces differential shrinkage.

3. Insert Molding Validation

Testing overmolding or insert molding processes by printing a quick mold to verify the fit of metal inserts before committing to a hard tool.

Hybrid tooling involves using a standard metal mold base (MUD frame) with interchangeable 3D printed core and cavity inserts.True

This method combines the mechanical strength of a metal frame with the speed and low cost of printed inserts for rapid prototyping.

3D printed molds require higher injection pressures and faster injection speeds to fill the cavity.False

Printed molds are weaker than steel; injection pressure and speed must be reduced to prevent cracking the mold or flashing the part.

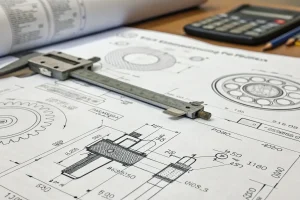

Stepwise Process: Implementing Printed Molds

To successfully integrate printed tooling, process parameters must be adjusted from standard scientific molding norms.

- Design for Additive Manufacturing (DfAM):

- Add 2–3 degrees of draft angle (more than standard steel molds) to facilitate ejection, as printed surfaces have higher friction.

- Thicken mold walls to withstand clamping force.

- Material Selection:

- Select a printing resin with high Heat Deflection Temperature (HDT) and high stiffness (Flexural Modulus).

- Ensure the injection material has a melt temperature compatible with the printed mold’s thermal limits.

- Post-Processing:

- Sand and polish the cavity surfaces to remove layer lines.

- Machine the back of the insert to ensure flatness for proper seating in the mold base.

- Process Setup:

- Clamping Force: Set to the minimum required to seal (prevent crushing the mold).

- Injection Speed: Reduce speed to minimize shear heat.

- Hold Pressure: Reduce significantly to lower stress on the cavity.

- Cooling Time: Increase cooling time by 2x–5x compared to steel molds to dissipate heat from the insulating tool.

- Ejection: Use hand-loaded inserts or large surface area ejector pins to avoid punching through the soft mold material.

FAQ: 3D Printing in Injection Molding

Q: Can 3D printed molds produce parts with tight tolerances?

A: Generally, no. While SLA printing3 is accurate, the mold deformation under heat and pressure usually limits part tolerances to ±0.1mm or greater. Precision critical features should be machined post-molding.

Q: How many parts can I get from a 3D printed mold?

A: It depends on the material.

- Plastic Printed Molds: 10 to 100 shots.

- Metal (DMLS) Molds: Thousands to millions (similar to traditional steel if properly heat-treated).

Q: Can I mold glass-filled nylon in a printed mold?

A: It is not recommended for polymer printed molds. The abrasive glass fibers will scour the soft mold surface, destroying details within a few shots. Metal printed molds handle glass fibers excellently.

Q: Is 3D printing cheaper than CNC machining aluminum molds?

A: For very small geometries or complex details, yes. However, for simple shapes, CNC machining aluminum (QC-10) is often comparable in cost and offers significantly better durability and thermal performance.

Q: What is the "Hybrid Mold" approach?

A: This refers to using a standard steel Master Unit Die (MUD) frame and only printing the core and cavity inserts. This minimizes resin usage and provides the necessary mechanical support for the printed parts during clamping.

Summary

The future of injection molding is not the replacement of the process by 3D printing, but the hybridization of the two. By leveraging 3D printing for Rapid Tooling, manufacturers can drastically cut development cycles and prototyping costs. Simultaneously, Conformal Cooling via metal AM unlocks efficiency gains in high-volume production that were previously physically impossible. Successful integration requires a distinct adjustment of processing parameters—specifically lower pressures and longer cooling times for polymer molds—and a clear understanding of the trade-offs between speed, durability, and precision.

-

EOS DMLS Technology: Direct Metal Laser Sintering creates metal mold inserts with mechanical properties comparable to wrought steel, enabling conformal cooling. ↩

-

Stratasys PolyJet Solutions: PolyJet Injection Molding utilizes digital materials to print smooth, detailed molds capable of withstanding injection molding pressures for short runs. ↩

-

Formlabs Rapid Tooling: Guide to Rapid Tooling outlines the specific design guidelines and material limitations for using SLA resin printers in injection molding workflows. ↩