Reaction Injection Molding (RIM) is a manufacturing process that mixes liquid components to create large, lightweight, and complex parts, curing them in a mold for industries like automotive1 and medical, offering cost-effectiveness and design flexibility.

Understanding Reaction Injection Molding (RIM) is essential for industries seeking efficient production of durable, intricate components. This blog post explores RIM’s fundamentals, applications, technical details, practical tools, and related technologies, providing a comprehensive guide for decision-makers and professionals.

RIM is cost-effective for low to medium production volumes.True

Lower tooling costs with aluminum molds make RIM economical for smaller runs compared to high-cost steel molds in other processes.

RIM can only produce simple shapes.False

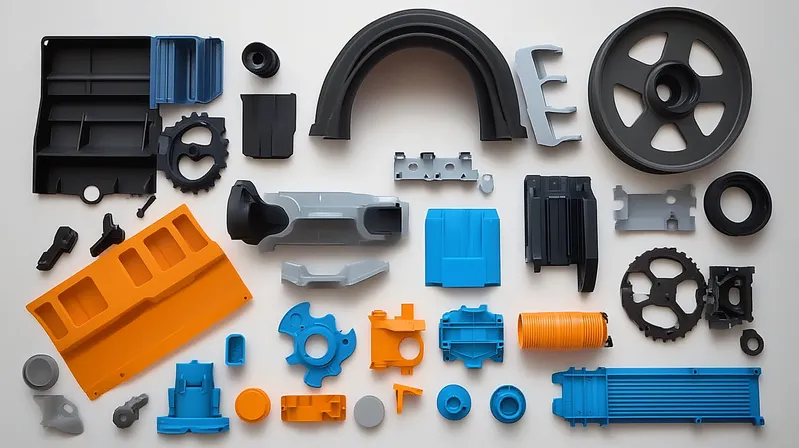

RIM excels at creating complex geometries due to the low viscosity of its liquid materials, enabling intricate designs.

What are the Basics of Reaction Injection Molding?

RIM is a specialized process that delivers unique advantages in manufacturing, particularly for parts requiring strength and complexity.

Reaction Injection Molding2 involves mixing two or more liquid thermosetting polymers3 that react and cure within a mold, forming solid, lightweight parts for diverse applications.

Clear Definitions

-

Full Technical Name: Reaction Injection Molding

-

Common Aliases: RIM, Liquid Injection Molding

-

Core Principles: Two or more liquid components, typically thermosetting polymers, are mixed, injected into a mold at low pressure, and cured through a chemical reaction to form a solid part.

Classification

-

Process Perspective: A subset of injection molding tailored for thermosets, using low-pressure injection4 and curing reactions.

-

Materials Perspective: Primarily employs thermosetting polymers such as polyurethane, polyureas, and polyisocyanurates.

-

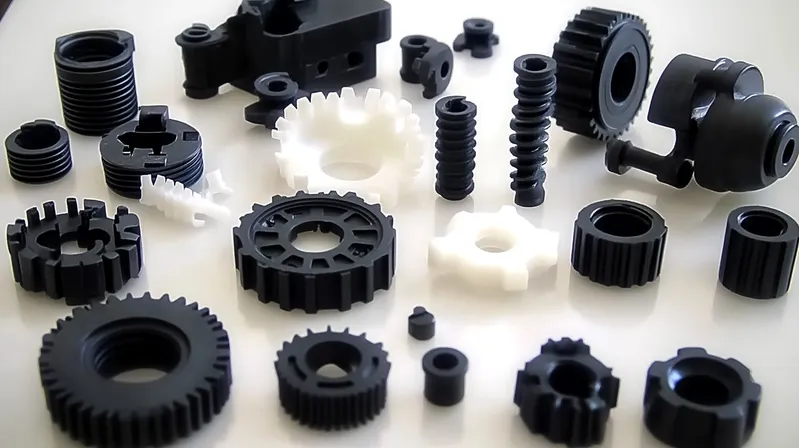

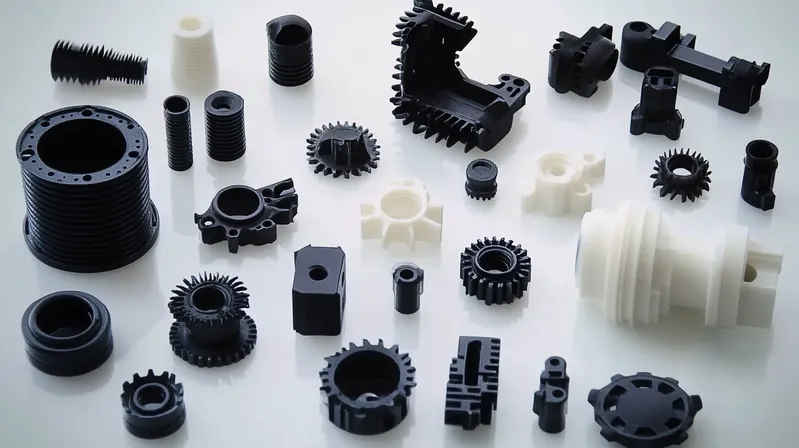

Applications Perspective: Common in automotive (e.g., bumpers), medical devices (e.g., trays), furniture, and industrial components.

What are the Applications of Reaction Injection Molding?

RIM’s versatility makes it a go-to choice for various industries needing lightweight yet robust parts.

RIM5 is widely used in automotive, medical, and industrial sectors for producing large, complex parts with excellent material properties and cost efficiencies.

Typical Application Scenarios

-

Automotive: Bumpers, fenders, air spoilers.

-

Medical Devices: Swivel trays, equipment covers.

-

Household Appliances: Heat-resistant casings.

Pros and Cons Comparison

| Aspect | RIM | Traditional Injection Molding |

|---|---|---|

| Material | Thermosets | Thermoplastics |

| Pressure | Low (~100 psi) | High |

| Tooling Cost | Lower (aluminum molds) | Higher (steel molds) |

| Part Size | Large, complex | Smaller, precise |

| Production Volume | Low to medium (100-20,000 parts) | High |

RIM is ideal for large, complex parts.True

Its low-pressure process and liquid materials allow for intricate designs and bigger components.

RIM is suitable for high-volume production.False

RIM is optimized for low to medium runs due to its process and tooling economics.

What are the Steps in the Reaction Injection Molding Process?

RIM’s workflow is a precise sequence that ensures quality and efficiency in part production.

The RIM process mixes liquid components, injects them into a mold at low pressure, and cures them into solid parts, ideal for lightweight, complex designs.

Process Full Workflow Breakdown

-

Material Preparation: Liquid components (e.g., polyol and isocyanate) are stored separately.

-

Mixing: Components are combined in a high-pressure mixing head.

-

Injection: The mixture is injected into a mold at low pressure (~100 psi).

-

Curing: The chemical reaction occurs, curing the material into a solid within the mold.

-

Demolding: The solidified part is removed after curing.

-

Post-processing: Trimming, painting, or finishing as needed.

Key Parameters

-

Mixing Ratio: Determines reaction speed and part properties.

-

Temperature: Influences curing time and quality.

-

Pressure: Low injection pressure ensures proper mold filling without excessive force.

Material Compatibility

-

Polyurethane: Offers flexibility or rigidity based on formulation.

-

Polyureas: Provides chemical and wear resistance.

-

Polyisocyanurates: Enhances thermal insulation.

Material choice impacts RIM outcomes.True

Different thermosets like polyurethane or polyureas tailor the part’s properties to specific needs.

What Practical Tools Enhance RIM Design and Selection?

Practical tools help professionals optimize RIM for specific projects and decision-making.

RIM design checklists and process selection guides assist in creating effective parts and choosing the right manufacturing method.

Design Checklist

-

Part Size: Ideal for large, complex components.

-

Wall Thickness: 1.2mm to 3mm for optimal strength and curing.

-

Draft Angles: 1.5-2 degrees for easy demolding.

-

Material Selection: Match properties (e.g., flexibility, heat resistance) to application.

Process Selection Decision-Making

- Production Volume: Best for low to medium runs (100-20,000 parts).

-

Part Complexity: High, due to fluid material properties.

-

Material Properties: Requires thermoset-specific characteristics.

How Does RIM Connect to Other Technologies?

RIM fits into a broader manufacturing ecosystem, complementing and contrasting with related processes.

RIM integrates with upstream material preparation and downstream finishing, while differing from technologies like traditional injection molding.

Related Technology Navigation

-

Traditional Injection Molding: Uses thermoplastics for high-volume, precise parts.

-

Compression Molding: Suited for larger, simpler thermoset parts.

-

Rotational Molding: Produces hollow thermoplastic parts.

-

Additive Manufacturing: Ideal for prototyping before RIM production.

Comparison Table

| Technology | Material Type | Pressure/Temperature | Typical Use Case |

|---|---|---|---|

| RIM | Thermosets | Low pressure, ~100 psi | Large, complex parts |

| Traditional Injection Molding | Thermoplastics | High pressure, high temp | Small, precise parts |

| Compression Molding | Thermosets | Moderate, heated mold | Larger, simpler parts |

| Rotational Molding | Thermoplastics | Low, heated rotation | Hollow parts |

RIM complements additive manufacturing.True

Prototypes from 3D printing can be tested before scaling to RIM production.

Conclusion

Reaction Injection Molding (RIM) is a powerful process for crafting large, lightweight, and complex parts, especially in automotive, medical, and industrial applications. Its use of thermosetting polymers, low-pressure injection, and cost-effective tooling makes it a standout choice for low to medium production volumes. By understanding its workflow, material options, and practical tools, manufacturers can leverage RIM to meet specific design and performance needs.

-

Discover how RIM is revolutionizing the automotive sector with lightweight and durable components. ↩

-

Explore this link to gain a deeper understanding of RIM, its processes, and its diverse applications across industries. ↩

-

Learn about thermosetting polymers, their properties, and why they are crucial in manufacturing processes like RIM. ↩

-

Discover the significance of low-pressure injection in molding and how it affects product quality and efficiency. ↩

-

Explore the benefits of RIM in manufacturing to understand its impact on various industries and applications. ↩