Automotive injection molds are tools used in the production of vehicle parts through the injection molding process. They create high-precision, durable components for the automotive industry.

Automotive injection molds are specialized molds used to manufacture precise and durable vehicle components. They provide efficient production of parts like bumpers, dashboards, and interior panels, ensuring high-quality standards and cost-efficiency.

To understand how automotive injection molds work and their benefits, it’s essential to explore the various mold types and materials used in automotive manufacturing. Continue reading to discover how they streamline vehicle production.

Automotive injection molds are used for making vehicle parts.True

Automotive injection molds are designed to produce various high-precision vehicle components such as bumpers and dashboard panels.

Automotive injection molds are only used for large-scale production.False

While often used for mass production, automotive injection molds can also be applied in smaller batch runs, depending on the project requirements.

What is Automotive Plastic Injection Molding?

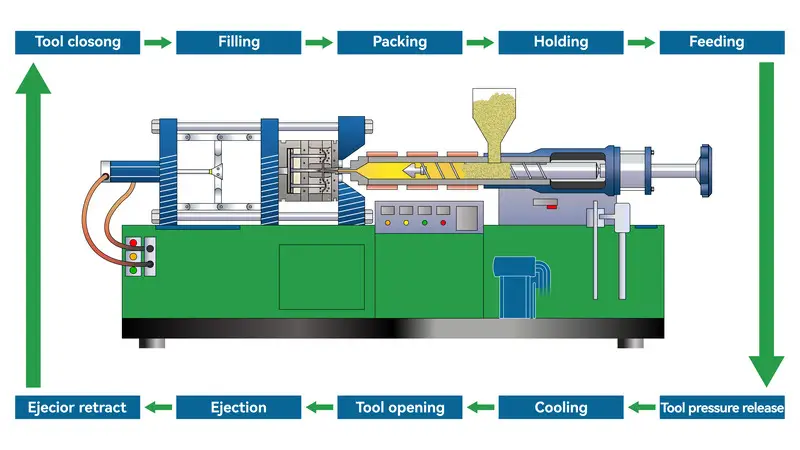

Automotive plastic injection molding is a manufacturing process used to create durable, complex plastic parts for vehicles. It offers precision and cost-effectiveness in automotive production.

Automotive plastic injection molding involves injecting molten plastic into molds to form components like bumpers, dashboards, and trim. This process ensures high precision, durability, and scalability for mass production.

Automotive injection molding refers to the use of injection molding process1 in the automotive industry

Plastic injection molding is used to produce car parts.True

Plastic injection molding is commonly used in automotive manufacturing to create parts like dashboards, bumpers, and trim components due to its precision and efficiency.

Automotive plastic injection molding is only suitable for large-scale production.False

While often used for high-volume production, automotive plastic injection molding can also be effective for smaller batches depending on the design and material used.

What is Automotive Injection Mold?

Automotive injection molding involves creating car parts using molds and molten plastic. It’s essential for producing precise, durable, and high-quality automotive components.

Automotive injection molding shapes car parts by injecting molten plastic into molds under high pressure. It’s widely used to produce various components like dashboards, bumpers, and trim parts, offering efficiency and durability.

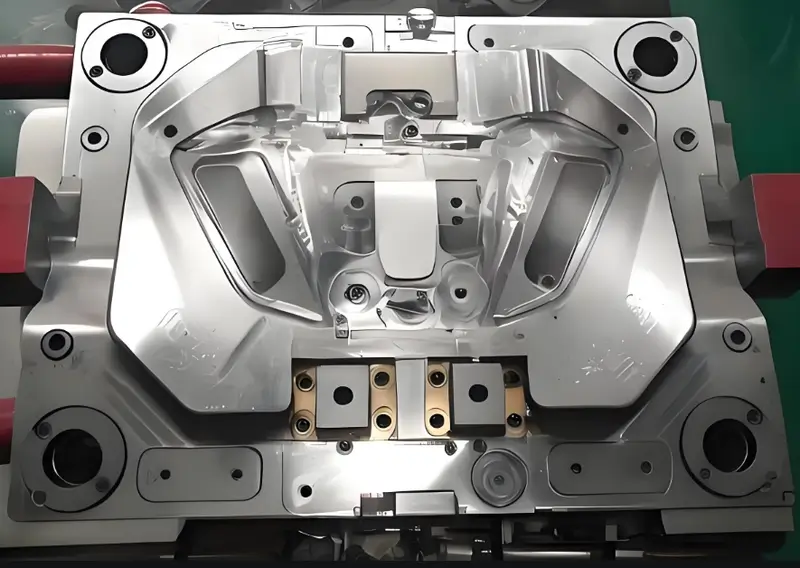

The cover mold is the most important part of the automotive mold. This type of mold is mainly a cold stamping moldity2 . In a broad sense, automotive mold is a general term for molds that make all parts on a car. For example, stamping molds, injection molds, forging molds, casting wax molds, glass molds, etc.

Car molds are molds that make all the parts on a car. Car stamping molds are molds that punch all the stamping parts on a car. Car body stamping molds are molds that punch all the stamping parts on a car body. Car cover stamping die is the die for stamping all the cover parts on the car body.

Automotive injection molding improves part durability and precision.True

Injection molding ensures tight tolerances, making parts durable and fit for the demanding automotive industry.

All car parts can be made using injection molding.False

While injection molding is ideal for many automotive components, it’s not suitable for all parts, especially those requiring metal or highly complex designs.

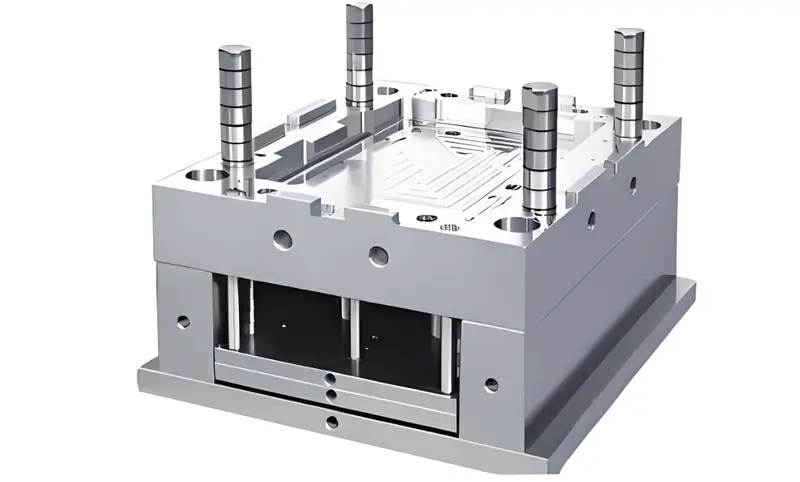

What are the Main Features of Automotive Injection Molds?

Automotive injection molds are key to producing precise, durable parts used in vehicles. These molds ensure high-quality, repeatable results for automotive components.

Automotive injection molds are designed for durability, precision, and efficiency. They are used to create complex, high-performance parts for vehicles, such as bumpers, dashboards, and engine components. Benefits include fast production times and consistent part quality.

High Production Efficiency

The injection mold uses mechanical injection molding3 process, which can quickly and efficiently produce injection molded parts products of various shapes, with high production efficiency and suitable for mass production.

High Precision

The injection mold uses advanced CNC processing technology, so the mold structure is simple, the processing accuracy is high, and the product size produced is accurate. It is suitable for industries with high requirements for product size accuracy.

Low Structural Complexity

The injection mold has a simple structure, is easy to manufacture and maintain, and does not require additional supporting equipment, which can greatly reduce production costs.

Strong Material Plasticity

You can make injection molds with different plastic materials that have different properties. They’re really flexible and can work for all sorts of industries and products.

Long Mold Life

The injection mold is made of high-quality mold steel material with good wear resistance. It is suitable for mass production and has a long mold life, which can significantly reduce manufacturing costs.

- Wear Resistance:When the molten material is deformed in the mold cavity, it moves and slides along the outside of the mold cavity, generating friction between the outside of the mold cavity and the molten material, causing the injection mold to fail due to wear.Hardness is a big deal when it comes to wear resistance. Usually, the harder the injection mold, the less wear and the better the wear resistance. Also, wear resistance has to do with the type, amount, condition, size, and distribution of carbides in the material.

Toughness

Most of the toughness of injection molds is very poor, and some are often subjected to large impact loads, resulting in brittle fracture. In order to avoid sudden fracture of the mold machine, precision metal molds must have high-strength toughness. The toughness of the mold depends on the carbon content, grain size and structure of the material, etc.

- Fatigue Fracture:When the mold is being processed, it is often subjected to long-term stress, which can cause fatigue and breakage. In this case, there is a small amount of energy that can repeatedly attack the fatigue fracture.The fatigue fracture function of the injection mold depends on its strength, toughness, hardness, and the amount of inclusions in the material.

Automotive injection molds improve part accuracy and reduce defects.True

The precise design of automotive injection molds ensures high-quality parts with minimal defects, enhancing vehicle performance and reliability.

Automotive injection molds are only used for exterior parts.False

Automotive injection molds are used for both interior and exterior components, such as dashboards, trim, and under-the-hood parts, contributing to the overall vehicle design.

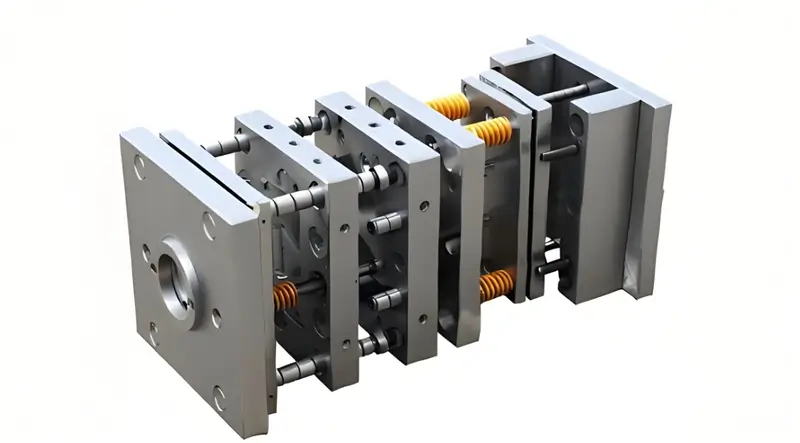

What are the Types of Automotive Injection Molds?

Automotive injection molds come in various types, each tailored to meet the demands of the automotive industry, ensuring precision, durability, and cost-efficiency in production.

Automotive injection molds include cold runner, hot runner, multi-cavity, and family molds. Each type offers distinct benefits, such as improved cycle time, material savings, and better part quality, depending on the design and application.

There are many types of automotive molds, such as injection molds, stamping molds, forging molds, casting molds, etc. Each type of mold corresponds to different types of accessories. Now more and more accessories are starting to use plastic raw materials, and injection molds play a very important role. The classification of automotive plastic molds can be roughly divided into the following types.

There are many ways to classify automotive plastic molds. According to the different methods of plastic parts molding, they can be divided into the following categories:

Injection Mold

Injection mold, also known as injection mold, is a mold used in the molding process. The molding process of this mold is characterized by placing the plastic raw material in the heated barrel of the injection machine. The plastic is melted by heat and, under the push of the screw or plunger of the injection machine, enters the mold cavity through the nozzle and the pouring system of the mold. The plastic is cured and molded in the mold cavity by heat preservation, pressure maintenance, cooling and curing.

Injection molding is a process that uses a heating and pressurizing device to mold plastic parts. It can mold plastic parts with complex shapes, and it has high production efficiency and good quality. So, injection molding is used a lot in the molding of plastic parts. Injection molds account for more than half of plastic molding molds. Injection machines are mainly used for the molding of thermoplastics. In recent years, they have also been used for the molding of thermosetting plastics.

Compression Mold

Compression mold, also known as compression mold or rubber compression mold, is a type of mold used for molding. The molding process of this mold is characterized by adding the plastic raw material directly into the open mold cavity, and then closing the mold. After the plastic is melted under the action of heat and pressure, it fills the cavity with a certain pressure.

Right now, the plastic’s molecular structure is doing a chemical cross-linking reaction and slowly getting hard and set. Compression molds are mostly used for thermosetting plastics4 , and the molded plastic parts are mostly used for the shells of electrical switches and daily necessities.

Transfer Mold

Transfer mold, also known as injection mold or rubber extrusion mold, is a type of mold used in the manufacturing process. The process involves adding plastic raw material to a heated feeding chamber and then applying pressure to the material using a pressure column.

The plastic melts under high temperature and pressure and enters the cavity through the casting system of the mold, and then undergoes chemical cross-linking reaction and gradually solidifies and forms. The transfer molding process is mostly used for thermosetting plastics, and can form plastic parts with relatively complex shapes.

Extrusion Mold

Extrusion mold, also known as extrusion head, can continuously produce plastics with the same cross-sectional shape, such as plastic pipes, rods, sheets, etc. The heating and pressurizing device of the extruder is the same as that of the injection molding machine. The molten plastic will form a continuous molded plastic part through the die head, and the production efficiency is particularly high.

Stamping Die

Stamping die is one of the most commonly used molds in the automobile manufacturing process. It can stamp metal sheets into various shapes of automobile exterior components,These parts include frames, chassis,cylinder head covers, doors, roofs, etc., which take up most of the processes in the whole car manufacturing process. The production cost of stamping dies is relatively low, but special machines and equipment are needed for processing.

Casting Mold

Casting molds are mainly used to melt and cast metals, and are usually used to make car parts like engine parts, transmission parts, wheels, etc. The cost of making casting molds is high, but the process of making castings is relatively simple, and you can make a lot of parts.

Cold runner molds are cost-effective for high-volume production.True

Cold runner molds are ideal for high-volume, low-cost production, though they may lead to more material waste compared to hot runner molds.

Hot runner molds are always better than cold runner molds.False

While hot runner molds reduce material waste and improve part quality, they come with higher initial costs and are better suited for specific production needs.

What are the Design Principles of Automotive Injection Molds?

Automotive injection molds are essential for producing high-quality, durable components. Their design ensures precise fitting and optimal performance in vehicle manufacturing.

Automotive injection molds are designed to meet specific performance standards, ensuring precise and durable parts. Key design principles include optimal material flow, cooling efficiency, and part ejection mechanisms. These factors impact the speed, cost, and quality of production.

Reasonableness Principle

The mold design should meet the actual needs of production, consider the feasibility and economy of production, minimize the cost of making the mold, and maximize production efficiency.

Stability Principle

The mold should be stable during normal production, without any weird stuff like getting bent, so you can make stuff fast.

Principle of Variability

The mold design should be made of plastic, be able to make a lot of different parts, and be able to make different parts at different times.

Automotive injection molds are designed for durability and precision.True

These molds are built to withstand the rigorous demands of high-volume production while ensuring accurate part formation.

Automotive injection molds prioritize cooling efficiency over material flow.False

While cooling efficiency is vital, material flow is equally important for ensuring uniformity and strength of the molded parts.

What is the Material Selection for Automotive Injection Molds?

Choosing the right material for automotive injection molds is key to enhancing performance, durability, and cost-effectiveness in manufacturing.

The ideal material for automotive injection molds depends on factors like strength, heat resistance, and cost. Common choices include steel, aluminum, and specialty alloys, each offering unique benefits for different automotive components.

What Materials are Used for Injection Molds

Stuff like cast iron, steel, aluminum, and magnesium alloys are all used to make car molds.

-

Cast Iron Mold:Cast iron mold is a mold material with high wear resistance and hardness, which is widely used in the automotive manufacturing industry.Cast iron molds are simple to produce, inexpensive, and easy to machine. However, they are not tough and are prone to cracking and damage. As a result, cast iron molds are not widely used for complex automotive mold structures.

-

Steel Mold:Steel molds are the most commonly used material in automotive molds. The material composition of steel molds5 is complex, and it can be adjusted by quenching, carburizing, surface treatment, etc. to make it have good toughness, wear resistance, and hardness.Steel molds are great for making complex molds, but they can be hard to make, take a long time to make, and cost a lot.

-

Aluminum and Magnesium Alloy Molds:Aluminum and magnesium alloy molds are a lightweight mold material with low density and good thermal conductivity. The processing and production cycle of aluminum and magnesium alloy molds is shorter than that of steel molds, and the cost is relatively low.But, because aluminum and magnesium alloys are not as hard as steel, the mold life is relatively short, which is good for some small automotive structural molds or trial molds.

Tips for Accurate Selection of Mold Materials

-

Balance of Strength and Wear Resistance:When designing car molds, the mold has to pass two tests: the injection molding process and the strength requirements of the parts. So when choosing mold materials, you have to balance their strength and wear resistance.Good mold materials are strong and can handle the high pressure and squeezing forces of production, and they also have good wear resistance to fight the friction and wear of plastic resin particles in the mold.

-

Matching Corrosion Resistance with Production Environment:Different automotive parts production environments may involve different chemicals and lubricants that can cause corrosion to mold materials.So, when you’re choosing mold materials, you need to think about the production environment and pick materials that can handle chemicals so your mold will last a long time.

-

Excellent Thermal Stability and Thermal Conductivity:When you’re making car parts with injection molding, you have to heat up the plastic material to just the right temperature and then cool it down fast so it’ll take the shape of the mold.So, the thermal stability and thermal conductivity of mold materials are really important. Good mold materials should be able to handle high temperatures and not get messed up, and they should also be able to move heat around so that the plastic gets heated and cooled evenly in the mold. That way, you can make stuff faster and better.

-

Balance of Processability:When designing car molds, you need to consider whether the material is easy to process. Good mold materials not only have high strength and wear resistance, but also need to be easy to process and shape. Therefore, when selecting materials, you need to balance processability and performance, so that the material is easy to cut and shape, and the performance is stable.When choosing mold materials, it’s important to consider the cost. Different mold materials have different prices.Some high-performance materials may be more expensive, while some conventional materials may be more economical. Therefore, when selecting materials, it is necessary to comprehensively consider the balance between performance and cost to improve production efficiency.

-

Environmental Awareness and Sustainable Development:Nowadays, people care more and more about the environment and sustainable development. When choosing materials for molds, we need to think about whether the materials are sustainable and environmentally friendly. We should choose materials that can reduce the impact on the environment, so that we can meet the requirements of sustainable development.

-

Practical Application and Case Verification:When you’re picking mold materials, you can learn a lot from real-world applications and case studies. If you know how different materials perform under similar production conditions, you’ll have a good idea of what to choose.

-

Continuous Learning and Updating of Cognition:Car making technology is always changing, and new materials are always coming out. Keeping up with learning and updating materials, and understanding the latest mold material technology and trends, will help you better adapt to the ever-changing industry environment.When choosing mold materials, you need to think about a lot of things, like strength, wear resistance, corrosion resistance, thermal stability, thermal conductivity, machinability, cost, and environmental protection. If you choose the right mold material, you can make better parts, improve your production process, and help the car industry keep getting better.

Steel is the best material for all automotive injection molds.False

While steel is commonly used, the choice of material depends on factors such as part complexity, production volume, and mold life. Aluminum is often preferred for lower volumes due to its faster cooling times and lower cost.

Aluminum molds are always cheaper than steel molds.False

Aluminum molds can be cheaper for low-volume production, but steel molds offer better durability and are more cost-effective for high-volume runs, leading to cost savings over time.

What is Automotive Mold Technology?

Automotive mold technology is essential for manufacturing precise, durable components in the automotive industry. It includes various molding techniques that optimize production speed and material usage.

Automotive mold technology involves advanced injection molding processes, such as hot runners and multi-cavity molds, to create high-quality automotive parts. These processes reduce waste, enhance efficiency, and ensure the consistency of molded components.

Mold Design

The first step in making a car mold is to design the mold. When designing a mold, you need to consider the shape, size, material, and process of the parts to ensure the quality and reliability of the final parts. In addition, mold design should include mold structure design, mold parameter calculation, and mold component selection.

Mold manufacturing

-

Material Selection:The mold material is usually high-quality steel to ensure the hardness, toughness, and wear resistance of the mold, and to withstand the complex processing of automotive parts. The choice of mold materials is very important in the mold process.

-

Engraving Processing:Engraving processing is when you engrave the part design onto the mold steel. You need to use high-precision simulation technology to make sure the mold is accurate and precise.

-

CNC Processing:CNC machining is a high-precision machining technology that can complete the machining of complex structural molds in a short time. CNC machining6 can not only ensure the quality of the mold, but also shorten the manufacturing cycle.

-

EDM Processing:EDM processing is short for electric spark discharge machining, which can make odd-shaped parts in high-precision molds. With this technology, mold manufacturers can make complex and high-quality automotive parts.

Mold Trial

Mold trial is a key step in the mold process. It can evaluate the effect of mold design and manufacturing. During the mold trial process, we need to verify whether the manufactured mold can run smoothly and meet the customer\’s requirements.

The mold trial can also help to further fine-tune the parameters and design of the mold in order to enhance the mold’s efficiency and quality.

Subsequent Processing Links

In the following processing steps, the parts need to be processed and treated on the surface to meet the high quality requirements of the automotive industry. Subsequent processing includes heat treatment, assembly, gold plating, polishing and other processes.

Automotive mold technology ensures high-quality parts for vehicles.True

The precision and advanced techniques used in automotive mold technology help produce durable, high-performance vehicle components.

Automotive mold technology is only used in high-end vehicles.False

Automotive mold technology is widely used across all vehicle categories, from economy to luxury models, to ensure consistent quality and efficiency in mass production.

What are the Advantages of Automotive Injection Molds?

Automotive injection molds offer precision, cost-efficiency, and durability in the production of automotive parts, ensuring high-quality components that meet stringent industry standards.

Automotive injection molds enable high precision, low waste, and faster production cycles. Benefits include reduced material costs, improved part consistency, and the ability to manufacture complex shapes for automotive components.

High production efficiency: Automotive injection molds utilize automated production processes, allowing for the rapid production of a large quantity of parts in a short amount of time.

Consistent production quality: The manufacturing technology for automotive injection molds is well-established, the mold structure is sound, and a large quantity of automotive parts with consistent quality can be produced.

Cheap material cost: In the process of making car injection molds, the material usage is low, and the production cost is relatively low.

Various shapes: Car injection molds can be designed and made according to different needs, and can produce car parts of various shapes and sizes.

Automotive injection molds reduce production time.True

By enabling faster cycle times, automotive injection molds improve the overall efficiency of mass production in the automotive industry.

Automotive injection molds are always more expensive than traditional methods.False

While the initial setup cost of automotive injection molds may be higher, their long-term benefits in terms of efficiency and material savings can offset the extra expense.

Conclusion

Automotive injection molds are a must-have tool in the automotive manufacturing process. The quality and performance of the molds are directly related to the quality and production efficiency of the car.

So, it’s important to understand and master the basic knowledge of automotive molds.Zetar Mold provides auto injection molding services.We can perform automotive plastic injection molding.If you need it, please contact Zetar Mold.

-

Learn about What is the plastic injection molding process? Plastic injection molding is a process of precision. ↩

-

Learn about What is a Cold Stamping Mold? Cold stamping is cold-formed using methods similar to those used in metalworking. ↩

-

Learn about Injection moulding : Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould . ↩

-

Learn about What are thermosetting plastics used for?Thermoset plastics permanently retain their new physical and composite shapes when heated. ↩

-

Learn about Mold Steel : Mold steel is a material that is used to manufacture the molds, including cold-punching mould, hot forging die, die-casting mold, and more. ↩

-

Learn about What is CNC Machining: Definition, Process, Purpose & More : CNC machining is a type of automated machining process . ↩