Defects in TPE injection molding can result from issues like improper temperature, moisture content, and machine settings. Identifying and addressing these problems can improve product quality and reduce wastage.

The main causes of defects in TPE injection molding include incorrect processing temperatures, moisture in the material, improper injection speed, and poor mold design. Addressing these factors helps in improving part quality and reducing defects.

Understanding the root causes of TPE defects is key to improving manufacturing processes. Let’s dive deeper into how each of these factors affects the molding outcome and what solutions can be applied to fix them.

Moisture content in TPE causes molding defects.True

Excess moisture in TPE can cause bubbles, voids, or surface imperfections during the injection molding process, leading to defects.

All TPE defects are caused by machine issues.False

While machine settings can contribute to defects, factors like material quality, mold design, and environmental conditions also play a significant role in TPE molding defects.

What is TPE Material?

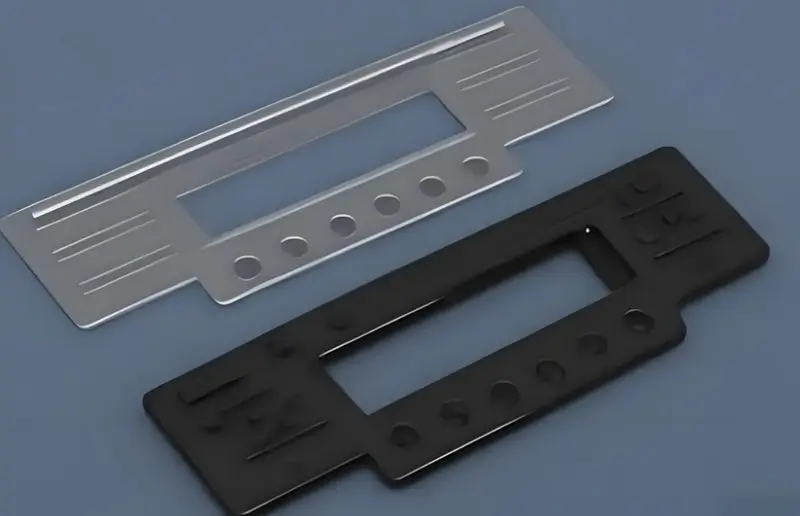

TPE (Thermoplastic Elastomer) is a versatile material combining the properties of rubber and plastic, offering flexibility, durability, and recyclability in various applications.

TPE materials are widely used in automotive, medical, and consumer goods industries. They provide excellent elasticity, chemical resistance, and can be easily molded. TPE is popular for its ability to be recycled and processed like thermoplastics.

Thermoplastic elastomer or TPE is a copolymer or a mixture of polymers that is a soft thermoplastic elastomer rather than a low molecular weight polymers. TPE combines the characteristics or properties of both thermoplastics and elastomers. Therefore, the use of elastomers is usually used for thermosets, while the application of thermoplastic materials ensures a relatively simple manufacturing process.

TPE is a new type of material that possesses the high elasticity, aging and oil resistant characters of cross-linked vulcanized rubber and the easier processing operation and multiple processing technique like ordinary plastic products. It can be made by injection molding, extruding1, blow molding2and others, and it is 100% recyclable after the edge and corner crushing. This means that the processing cycle is eased, cases of producing expensive goods reduced, and the TPE material is considered the latest substitute for rubber, as it maintains environmental and health benefits, comfortable touch and is aesthetic to users to spur product innovation. Therefore, it symbolizes a new synthetic material closer to humanity and possessing a higher quality while at the same time fulfilling international policies regarding protection of the environment.

TPE can be recycled easily.True

TPE's thermoplastic nature allows it to be melted and reformed, making it a more sustainable choice compared to other elastomers.

TPE is the same as rubber.False

While TPE has rubber-like properties, it is a plastic that can be processed using conventional plastic manufacturing methods, unlike traditional rubber.

What are the Common Injection Molding Defects of TPE Materials and Their Solutions?

TPE materials are widely used in injection molding, but defects like warping, air traps, and short shots can impact quality. Understanding and addressing these issues is essential for successful production.

Common TPE injection molding defects include warping, air traps, flash, and short shots. Solutions involve adjusting processing conditions, mold design, and material choices to enhance part quality and consistency.

Material Issues

Moisture Content

-

Cause:In TPE injection molding, high moisture content of the materials used results in formation of such things as bubbles and silver streaks on the surface of the molded product. Moisture turns to a gaseous state at high temperatures cannot be exhausted during injection molding thus forming bubbles and silver streaks.

-

Solution: See to it that the material used is sufficiently dried to avoid problems in injection molding. Usually, drying temperature for TPE materials should be set to the temperature range of 80-100°C, for 2-4 hours. Furthermore, materials should be stored in an area with low humidity to avoid moisture in take in by the structures. The suitable dryer to recommend when dealing with highly hygroscopic TPE materials is the dehumidifying dryer to prevent the moisture level from reaching the dangerous levels.

Impurities

-

Cause: Flaws in original materials particularly its dirt may lead to surface roughness and inconsistencies in color of a finished product. They precipitate out as irregular shaped particles or spots within the material and compromise product looks as well as usability.

-

Solution: Source them from reputable suppliers and embark on tests and analysis to check on the purity and quality of the materials to be used. The filtration, and screening help to remove any contaminants in the water before it is used. Additionally, regularly clean equipment and pipelines to prevent residue from entering materials and maintain a clean processing environment.

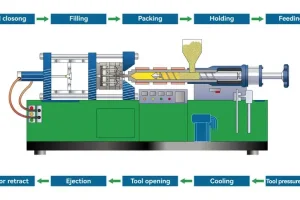

Injection Molding Process Issues

Injection Temperature

-

Cause: TPE material has poor heat resistance. High injection temperatures are responsible for product distortion and dimensional changes on the other hand low injection temperatures lead to surface roughness and internal porosity. High temperatures affect the degradation of material at high temperatures while low temperature affect the fluidity of the material to fill the mold cavity.

-

Solution: Choose the appropriate injection temperature according to the TPE material characteristics and product requirements. Generally, the injection temperature should be kept between 170-230°C. Temperature control must use temperature sensors and automatic temperature control devices to obtain the appropriate temperature so that all foods are heated evenly and the temperature is stable.

Injection Pressure

-

Cause:Low injection pressure can lead to insufficient filling, and high injection pressure can lead to flash and overflow, resulting in some surface depression areas. High pressure can also affect the mold, causing mold damage and causing material waste.

-

Solution: Increase and decrease the injection pressure according to the product structure and mold design to avoid short shots and other related problems. Use an accurate pressure control system for injection pressure to effectively control and achieve stability in real time.

Holding Pressure Time

-

Cause:The in adequate holding pressure time leads to formation of internal voids and also instabilities in dimensions of the product while over holding pressure time often leads to deformations of the product and also causing it to crack. Concisely, if holding time is short, material backflow occurs, but if holding time is long, internal stress also becomes large.

-

Solution: It is therefore possible to establish the holding pressure times as follows; depending on the characteristics of TPE material as well as on requirements that are put into practice with respect to intended products. Usually, holding pressure time should be changed with product thickness and structure so that products could be fully cured and the final dimensions could be maintained.

Cooling Time

-

Cause:Too short cooling time will cause deformation3 and cracking of the product during demolding. Too long cooling time will affect production efficiency. Uneven cooling will cause changes in internal stress and strain, which will in turn affect product performance.

-

Solution: When cooling the mold, the time limit should be reasonably set according to the product thickness and mold structure. Use appropriate cooling systems, such as cooling water channels and fixtures, to ensure uniform cooling distribution of the entire core.

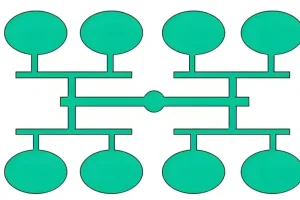

Mold Design Issues

Mold Structure

-

Cause: Defects of mold structure can cause problem such as wrong filling of the product and problem during demolding. Processing structures in particular further raise the material flow resistance and thus change the filling effects.

-

Solution: To make correct decisions in creating the mold, characteristics of the product and injection molding requirements should be taken into account in order to avoid irrationality in the structure of the mold. For runner designs, one should minimize the material flow resistance by following some design aspects such as the creation of uniform filling patterns. Computer aided design (CAD) and computer aided engineering (CAE) can be used for simulation analysis for better selection of mold design.

Mold Temperature

-

Cause: When the mold temperature is too high, parts may stick to each other and take a distorted shape while when it is too low, the surface of the cast is rough and may contain internal voids. Fluctuations in the mold temperature cause variations in the rates of cooling hence influencing product quality.

-

Solution: It is necessary to define the correct mold temperatures according to TPE material properties and expected characteristics of the final product. Normally, the mold temperature can be controlled between 40 to 80 centigrade Precise regulation of the mold temperature is possible by using the mold temperature controllers with a good distribution of temperatures as well.

Venting Design

-

Cause: Vents that are not well designed may result into formation of bubbles ad even burn marks on the final products. Insufficient exhaust generates imperfections on the external layers of the material and consequently surface damage denies the product a suitable appearance or performance.

-

Solution: Any problems with venting can be discussed during the mold design to avoid complications with the air flow and to specify a correct position and type of the vent slot/vent for proper and efficient air discharge. To increase the efficiency of venting and decrease the formation of bubbles and burn marks, vacuum venting devices or micro venting valves should be used.

Equipment Issues

Injection Machine Performance

-

Cause: The performance of the injection molding machine has a great impact on product quality. Instability of injection speed and pressure levels will also cause quality problems. If the injection molding machine is not newly purchased, aging and improper maintenance will also affect the performance of the injection molding machine.

-

Solution: In order to maintain high product stability, it is essential to choose an injection molding machine with stable performance and high precision. The piping system should be kept clean and worn parts should be replaced as soon as possible. All parameters of the injection molding machine can be automatically controlled and adjusted to improve productivity and product quality.

Mold Installation

-

Cause: The following are the drawbacks of improper mold installation; The product size from the mold may be unstable, The mold may be very difficult to demold. Mold parallelism and perpendicularity bore some deviations and this really impacted, the stability of the injection process.

-

Solution: While fixing the mold during the mold installation process, the mold’s parallel and perpendicular orientations must be correct, relying on adequate fixtures. Ensure that installation processes are done professionally using installation tools and equipment to enhance on installation precision.

Equipment Maintenance

-

Cause: If the equipment is not maintained regularly, it will inevitably fail and affect product quality. Injection molding machines and molds will inevitably wear and age after years of use, affecting production efficiency and product quality.

-

Solution: Perform daily maintenance on injection molding machines and molds, such as cleaning the oil circuit, replacing the filter element, oiling the moving parts, etc., to prevent equipment abnormalities and avoid quality problems. Record equipment maintenance, conduct inspections, and evaluate the repair and maintenance status of the equipment.

Warping in TPE injection molding can be minimized with proper cooling rates.True

Controlling the cooling rate evenly across the mold can reduce internal stress, minimizing warping in TPE products.

Flow marks in TPE injection molding are always caused by too high injection speed.False

Flow marks may also be caused by improper mold temperature or poor material viscosity, not just injection speed.

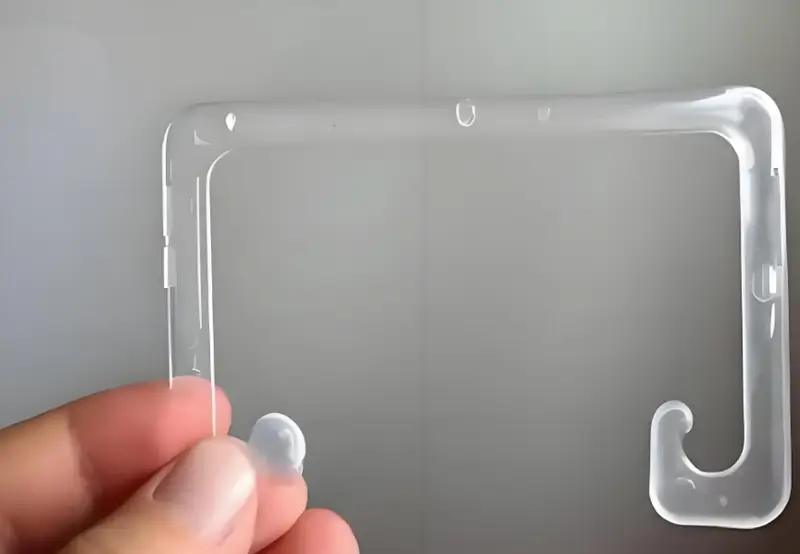

What are the Common Defects of TPE Injection Molding Products and Their Solutions?

TPE injection molding can face defects like short shots, warping, or poor surface finish. Addressing these issues involves adjusting molding parameters and materials to ensure product quality.

Common TPE injection molding defects include short shots, flash, and warping. Solutions involve optimizing temperature, pressure, and mold design to improve consistency and reduce defects, ensuring high-quality results in medical, automotive, and consumer goods production.

Air Bubbles

Cause:

-

High moisture content in materials: This is why, when using TPE materials in injection molding, improper drying is followed by fresh air getting into the material and turning into a gas at high temperature, and creating air bubbles.

-

Excessive injection speed: This limits the rate at which gases can come out in time hence the formation of air bubbles where the injection speeds are high.

- Poor mold ventilation:If the mold is ill designed or the vents are inadequate or blocked, the air cannot escape and this results to the formation of air bubbles.

Solution:

-

Material drying: It is also advisable to always make sure that TPE materials are adequately dried before the process of injection molding is to be carried out. In general, drying temperature should range between 80/100 C, while the drying time is 2-4 hours. Furthermore, store all the store’s material in a place of low humidity so that it does not get absorbed by humid air. If the TPE material is highly hygroscopic, it is recommended to use the dehumidifying dryer for the purpose of drying because high humidity is fatal to the TPE.

-

Adjust the injection speed: Slow down the injection speed4 to allow the gas in the injected material enough time to disperse.

-

Improve mold ventilation: Enhance mold design5 to incorporate more vents or using venting inserts to enhance the Airflow to have a smooth discharge.

Burn Marks

Cause:

-

High injection temperature: The injection temperature exceeds the thermal decomposition temperature of the TPE material, resulting in burn marks.

-

Excessive injection speed: Faster injection speeds raise the level of friction and hence produces heat to burn the materials used.

-

Poor mold venting: Lack of or obstruction of the vents in the mould lead to localised overheating, which creates burn marks.

Solution:

-

Lower injection temperature: Adjust injection temperature to suit TPE material characteristics. Typically, temperatures should be controlled between 170-230°C.

-

Reduce injection speed: Slowing down the rate at which the injection is being made to help in less generation of friction heat.

-

Improve mold venting: Add more vents, or put in vent inserts so that the air can be let out smoothly and localized heating is prevented.

Shrinkage

Cause:

-

Inadequate cooling time: Overheating makes products to keep on shrinking even after they have been demolded due to inadequate cooling.

-

Insufficient injection pressure: Lack of sufficient pressure results to the under filling of the mold through shrinking.

-

Uneven mold temperature: A case of temperature variation gives rise to a variation in the rate of cooling process and hence contraction.

Solution:

-

Increase cooling time: Cooling time should be altered to accommodate the general thickness of the product as well as the structural make-up of the mold.

-

Adjust injection pressure: Press more vigorously as the materials to form the mold to fill it adequately.

-

Uniform mold temperature: Run your molds at a constant temperature and it is recommended to use a mold temperature controller in order to avoid uneven cooling of the molds.

Warping

Cause:

- Uneven cooling: If the cooling time and mold temperature varies then the generation of the internal stresses varies and there will be warping.

-

Uneven injection pressure: Uneven pressure injection distribution leads to the destruction of a consistent flow of material which leads to warping.

-

Poor mold design: Lack of proper mold design results to uniform distribution of material as well as warping.

Solution:

-

Optimize cooling time: Alter the time that takes for the molds to cool since this affects equal cooling and reduced internal stress.

-

Uniform injection pressure: To make injection pressure and material output equal and stable, better implement accurate pressure management systems.

-

Improve mold design: Increase the proper material distribution in the mold and to minimize the warpage condition.

Weld Line

Causes:

-

Poor material flowability: Non-slippery nature of TPE materials results into weld lines especially when the flow of the compound is inadequate.

-

Low injection temperature: If the material does not have good flowability at low temperatures, then weld lines occur.

-

Poor mold venting: Insufficient mold venting also results to poor adhesion of the materials as they do not fully merge together leaving behind weld lines.

Solutions:

-

Improve material flowability: Select TPE materials with a better flowability or modify the formulation of the blend to increase the flowability of materials.

-

Increase injection temperature: Increase the injection temperature to give a right flowability of the material in the injection chamber.

-

Improve mold venting: Bring more vents or use the vent inserts to promote the right rate of air release and to eliminate weld lines.

Flow Marks

Causes:

-

High injection speed: When the injection speed is too high then this leads to uneven flow of material and flow marks result.

-

Uneven injection temperature: Variations in injection temperature can cause inconsistent material flow, leaving flow marks.

-

Rough mold surface: Surface roughness in an uneven manner creates a flow mark during the flow of material on the mold surface.

Solutions:

-

Adjust injection speed: It is recommended that injection speed should be uniform throughout the process to prevent the injection speed from fluctuating.

-

Evenly heat the material: It is also important to heat the material uniformly so that it doesn’t get an exposure to high molding temperature and vice versa.

-

Improve mold surface: Polish the mold surface to reduce roughness and prevent flow marks.

Rough Surface

Causes:

-

Uneven material mixing: If the TPE materials are not well mixed during processing, the surface of the resulting object appears to be quite rough.

-

Low injection temperature: This is because at low injection temperature the material gets into a state of poor flowability state and its surface is very rough.

-

Rough mold surface: A smooth mold surface is not developed properly, and it produces the final product surface to be rough.

Solutions:

-

Evenly mix materials: It is important that during the processing, materials should be mixed well and are also evenly distributed.

-

Increase injection temperature: Increase the temperature of the injection to enhance flowability of the material.

-

Improve mold surface smoothness: Surface finishing6Polish the mold surface for the mold should be done to decrease the surface roughness as well as the roughness of the end product.

Silver Streaks

Causes:

-

High moisture content in materials: Moisture in TPE materials means that during processing it leaves behind silver streaks as a result of this evaporation.

-

High injection speed: Since high injection speed will produce higher shear force on the material, silver streaks will occur.

-

Low mold temperature: Low mold temperatures cause the dough to cool quickly, which can lead to silver streaks.

Solutions:

-

Dry materials: Materials should be adequately dried to keep down the level of moisture that is taken by the injection.

-

Adjust injection speed: Adjust the filling speed according to the resin, resin temperature and mold temperature. Lower injection speed so that there is less of a force on the material that causes it to shear.

-

Increase mold temperature: The appearance of silver streaks can be reduced by adding pure monomer resin, increasing mold temperature, adding injection ports, and increasing resin temperature to slow down the cooling effect on the sand mold.

Adjusting mold temperature can eliminate warping in TPE injection molding.True

Correcting the mold temperature helps maintain uniform cooling, which minimizes the likelihood of warping in TPE parts.

Flash in TPE injection molding is always caused by high pressure.False

Flash can also be caused by issues like overpacking, improper mold alignment, or worn seals, not just high pressure.

Conclusion

In TPE injection molding, it is essential to identify the possible sources of product defects and find the most appropriate remedies to achieve the quality and performance that the final product should have. In order to reduce defects, improve efficiency and ensure consistency, manufacturers can solve material problems, fine-tune injection molding procedures, design molds and maintain the parts that make up the injection molding system of TPE injection molded products.

Further advances in processing technology and better control of quality standards will add more vitality to production and customer satisfaction, thereby promoting the widespread application and innovation of TPE materials in multiple fields.

-

Learn about Extrusion : Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. ↩

-

Learn about Blow molding : Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. ↩

-

Learn about How to Determine Holding Pressure and Holding Time In Injection Molding? Since its inception, the injection molding process has primarily operated in one traditional way — what is known as a cold runner system. ↩

-

Learn about Understanding Injection Speed and Injection Pressure : Typically, the set injection speed refers to the screw’s forward speed. ↩

-

Learn about What is injection mold design? Injection mold design involves the process of producing a mold to a particular specification. ↩

-

Learn about Injection Molding Surface Finishes: From textured to highly cosmetic, there are a number of surface finish options for molded parts Injection ↩