An indispensable part of contemporary manufacturing, injection molding machines are heavily relied upon to create a vast array of plastic products. Polycarbonate (PC) is a high-performing engineered thermoplastic which sees widespread use across several sectors, examples range from electronics and automotive components through to medical devices and everyday items like kitchenware. This article will explore whether injection molding machines can produce PC preforms through a comprehensive analysis of injection molding processes, equipment requirements, mold design, material properties, and operating points. By the end of this article, readers will thoroughly understand and resolve this issue.

Characteristics of PC Material

Basic Properties of PC

Polycarbonate (PC) is a transparent thermoplastic with the following key characteristics:

1. High Strength and Rigidity: Polycarbonate materials possess both high impact strength and good rigidity, that means they can take a beating without being warped or stressed out. Because of these properties, PCs are perfect for making things like protective gear (e. g., helmets) as well as structural parts that need to be really tough.

2. Transparency: Polycarbonate (PC) has superb optical properties and transparency, with a light transmittance rate of over 90%. That’s why it’s perfect for use in things like optical lenses, transparent covers, lighting fixtures; anything needing really clear surfaces.

3. Heat Resistance: PC materials’ heat resistance qualities give them the ability to withstand high temperatures without deforming or breaking down. When used in places like automotive headlight lenses or electrical housing units, which can get very hot indeed (upwards of 120°C), this makes polycarbonate a great choice.

4. Dimensional Stability: Due to minimal dimensional changes in high-temperature and humid environments, polycarbonate (PC) materials are great for making precision parts. They won’t shrink much and mess up the dimensions. Its low shrinkage rate and high dimensional stability make it widely used in electronic components and industrial equipment.

5. Electrical Insulation: PC has excellent electrical insulation properties, widely used in the electronics and electrical fields, such as insulating housings, connectors, and switches.

Processing Characteristics of PC

In the injection molding process, PC materials exhibit specific processing characteristics that require special attention, including:

1. High Viscosity: Due to its high viscosity, PC melt does not flow well. This means that when it is being injection molded, necessitating high injection pressure and speed during injection molding to ensure the material fills the mold cavity adequately.

2. Moisture Sensitivity: Polycarbonate (PC) is extremely sensitive to moisture; excessive levels can result in defects like bubbles, silver streaks or reduced performance. As such, strict drying protocols are necessary with these materials prior to their being injection moulded so as not exceed safe moisture content limits.

3. High Processing Temperature: PC should be processed at temperatures between 270 and 320°C. If the temperature isn’t controlled carefully, the material can begin to degrade and take on a yellow hue, both signs of undesirable chain reactions. Therefore, precise temperature control is necessary during processing to avoid overheating or insufficient heating.

4. Mold Temperature Requirements: Mold temperatures of 80-120°C are usually necessary when molding parts with PC, both for quality control and to help minimize stresses as the component cools. Increasing mold temperature can promote more even cooling which may improve strength (reduce stress), appearance and dimensions (form stability).

PC Material Industry Application Examples

Due to its superior properties, PC material is widely used in various industries. Here are some typical application examples:

1. Automotive Industry: PC materials are commonly used in the automotive sector for headlamp covers, instrument panels, interior parts and safety components. Injection molding these materials enables the manufacture of high-precision vehicle parts that improve both performance and aesthetics – including overall quality.

2. Electronics and Appliances: Polycarbonate (PC) is found in a variety of electronics and appliances such as phone cases, computer screens and housing for small kitchen appliances. The reason for this is that PCs are very good electrical insulators as well as being strong mechanically, both qualities which make them perfect materials to use when manufacturing goods like these.

3. Medical Devices: Polycarbonate materials are widely used in medicine as well. Syringes, test tubes, and surgical instruments utilize polycarbonates due to their transparency and biocompatibility, essential qualities for medical equipment manufacturing.

4. Bottle Preforms: The manufacturing process of producing plastic bottles often begins with the creation of bottle preform using injection molding machines. These machines are capable of handling various plastic materials, including plastic resin and molten material, to achieve the optimal material viscosity required for the process. Specifically, the preform mold is essential in shaping the PET preform production, which is a critical step in manufacturing plastics. Understanding whether injection molding machines can effectively produce PC preforms involves assessing their ability to handle the specific characteristics of polycarbonate, ensuring the process yields high-quality plastic bottle preforms ready for further processing into finished plastic bottles.

Basic Principles and Types of Injection Molding Machines

Working Principle of Injection Molding Machines

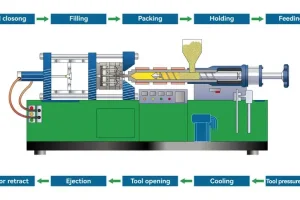

Injection molding machines complete the injection molding process through the following steps:

1. Plasticization: As the heating barrel turns, plastic pellets are melted by the screw which moves within it. They become uniformly molten through this process whereby rotation gradually heats them up.

2. Injection: Molten plastic is swiftly forced into a mold’s cavity as the screw moves forward at speed–high pressure being necessary too. This enables the material to take on the shape of whatever product is being made before cooling down and solidifying later on.

3. Holding Pressure: After the cavity is filled, pressure is applied to compensate for material shrinkage. During the holding phase, continuous pressure compensates for material shrinkage, preventing sink marks and defects.

4. Cooling: The mold is maintained closed for a set time until the plastic solidifies and cools. The length of the cooling time directly affects the dimensional stability and surface quality of the product.

5. Mold Opening and Ejection: The mold opens, and the product is ejected using an ejection mechanism. During ejection, the speed and force must be controlled to prevent deformation or damage to the product.

Main Types of Injection Molding Machines

Based on structure and working principles, injection molding machines can be categorized into several types:

1. Hydraulic Injection Molding Machines: These traditional machines use hydraulic systems to operate the screw and mold movements. They are popular because they have a simple structure and are cheap. Hydraulic machines work for most plastic products but they use more energy than other types — so they can be costly too if you need high precision parts.

2. All-Electric Injection Molding Machines: All-electric injection molding machines, which are driven by servo motors, deliver precision, efficiency and energy savings–but at a premium. Although they carry a higher price tag, these machines are popular in the electronics and medical industries because they excel at making products that demand exacting standards.

3. Hybrid Injection Molding Machines: Combining the benefits of hydraulic and electric machines, hybrid injection molding machines strike a balance between cost and performance. These machines provide both high precision and efficiency; further, they help to lower energy bills and reduce waste. Small wonder that more and more manufacturers are turning to them as a modern, cost-cutting solution for injection molding technology.

Injection Molding Requirements for PC Preforms

Equipment Requirements

Producing PC preforms requires high standards for injection molding machines, including:

1. High-Pressure Injection System: The injection machines must have high-pressure injection abilities because PC material is very viscous. This usually means being able to inject at pressures over 150MPa. Such pressure is necessary to make sure the molten PC material completely fills the mould cavity – which in turn ensures finished products are top quality.

2. Precise Temperature Control System: Injection machines must feature an extremely sensitive temperature control system in order to prevent material damage and yellowing. The system must be able to adjust the heating barrel and mold temperatures with great accuracy to maintain stable processing conditions – essential for dealing with PC’s tendency (in common with many other plastics) towards viscosity variations as its temperature shifts.

3. Efficient Plasticization System: Efficient plasticizing systemInjection machines must have efficient plasticizing systems in order to make sure that PC material is melted uniformly and flows steadily. Quality of melting process and speed of injection are directly influenced by how well this type of equipment works.

4. Effective Drying Equipment: PC materials need thorough drying before injection, with injection machines equipped with effective drying equipment, typically requiring drying temperatures of 120-130°C for 3-4 hours. The drying equipment must monitor and adjust drying parameters in real time to ensure sufficient drying.

Mold Design Requirements

Mold design has a direct impact on the quality of PC preforms, with key requirements including:

1. Reasonable Gating System: Implement the use of hot runner or hot nozzle systems so as to allow for uniform material filling which can help decrease pressure loss too. Injection efficiency stands to benefit from a good gating system as does reducing product defects.

2. Adequate Venting System: Have a venting system in place that works well; if gas remains trapped inside cavities while these are being filled then the result may be blemishes such as bubbles on the surface or silvery streaks. It needs to be designed so air is pushed out effectively from mold spaces during production – if not, quality will suffer.

3. Efficient Cooling System: PC materials cool and solidify slowly, requiring a high-efficiency cooling system to ensure uniform cooling of the product, preventing deformation and internal stress. The design of the cooling system needs to consider the layout of cooling channels and the flow rate of the cooling medium.

4. Surface Treatment: The mold cavity surface needs mirror polishing or hard chrome plating to improve product surface smoothness and prevent sticking. The quality of the surface treatment directly affects the appearance of the product and the service life of the mold.

Injection Molding Process Parameters

The injection molding process parameters for PC preforms significantly affect product quality, requiring careful setting of the following parameters:

1. Injection Temperature: For injection temperature, it is usually kept within the range of 270 to 320°C (adjustments being made depending on the type of mold and thickness of product). Material flow is facilitated at higher temperatures – although if they get too high degradation can result.

2. Mold Temperature: As for mold temperatures, these tend to be around 80 to 120°C. This is important for making sure items have a smooth surface finish and retain their shape; higher temperatures will also lessen any internal stresses products may have (something that can only ever improve its quality).

3. Injection Speed: Choose the right injection speed according to product size and structure: slower speeds can cut internal stress, boost quality – but if it’s too slow, cooling will be uneven. Going too fast may create bubbles or weld lines.

4. Holding Pressure and Time: Select the correct holding pressure and time for the product’s thickness and volume. Normally, pick a holding pressure equivalent to 50-70% of the injection pressure; choose holding times that are double to triple the product thickness. Getting these parameters right helps compensate for material shrinkage – which in turn stops you getting sink marks or finding your components warp.

5. Cooling Time: Adequate cooling time helps fully solidify and stabilize the product, avoiding deformation and warping. Too short cooling time may cause deformation, while too long affects production efficiency.

Practical Operation Steps for Injecting PC Preforms

Material Preparation

1. Raw Material Selection: Pick high-quality PC resin that usually has low volatiles and high flow properties so that product quality is guaranteed. It must be noted that the choice of raw materials will affect both how well the product performs as well its stability during production.

2. Drying Treatment: Regulate drying carefully as moisture affects PC; normally dry at 120-130°C for 3-4 hours, making sure material is <0. 02% moisture. During drying, periodically check the material’s moisture content to ensure drying effectiveness.

Equipment Setup

1. Injection Machine Cleaning: Make sure to clean the screw and barrel of the injection machine well during material switches so that impurities do not affect the performance of PC materials. Use special cleaning tools and agents to guarantee equipment is clean.

2. Mold Installation: Choose correct molds according to product design. Install them securely and accurately – then preheat as needed. For molds to work properly there must also be an exact alignment that does not move when we inject material; this is achieved through careful fixing in place at all times while production takes place (a process known as “fixation”).

3. Parameter Setting: Establish suitable mold temperature, injection temperature, injection pressure, speed of injection, holding pressure and time based on material features and product specifications. It will be necessary to repeatedly adjust these settings to guarantee they are both sensible and stable.

Injection Production

1. Injection and Holding: Carry out the injection and holding process as specified, to guarantee even filling of the mould cavity with material. Compensation for material shrinkage is also achieved through holding. Stability of the process is assured by monitoring parameters in real time throughout injection and holding.

2. Cooling and Ejection: Once the product has cooled and solidified completely, employ ejection mechanism to expel it with caution so as not to cause any deformation or damage. Make sure that ejection takes place at controlled speed and force in order to prevent such problems from occurring.

3. Quality Inspection: Inspect the product for appearance, dimensions, mechanical properties, and other aspects to ensure compliance with design requirements. Use professional inspection equipment and tools to ensure accuracy.

Common Issues and Solutions

Common issues and solutions in the PC preform injection process include:

1. Bubbles and Silver Streaks: If bubbles and silver streaks are appearing (which is often due to lots of moisture or the injection moulding happening too quickly) you’ll need strict drying processes and make sure the injection speed isn’t too high. Check the moisture during drying from time to time to be sure it’s working.

2. Product Deformation and Warping: This may be caused by an unequal temperature in the mold or the fact that it hasn’t cooled for long enough; If so, you’ll need to make your cooling system work better and leave the product in the mold for a bit longer. Cooling system design needs to consider cooling channel layout and medium flow rate.

3. Surface Defects: Surface Imperfections — like rippling and welding lines — usually stem from an injection pressure that’s too unsteady or a mold design that’s flawed. Both issues call for fine-tuning the injection pressure and/or improving the mold’s design. After all, appearances do matter: Poor surface quality may slow sales while product function could also be compromised.

4. Excessive Internal Stress: This can happen if the plastic is injected too fast or it doesn’t have long enough holding pressure. If this is happening we need to slow down the injection speed and increase the holding time. Parts with too much internal stress may be misshapen (not look right) when they are removed from the mould, or even develop small cracks later on whilst you are using them.

Conclusion

After a comprehensive analysis of the plastic material properties of PC, the requirements of the injection molding machine, the design of the mold, the injection molding process, and the operation steps, it can be concluded that the injection molding machine can produce PC preforms, but it must meet certain equipment requirements and process conditions. Reasonable selection and adjustment of the injection molding machine, optimization of the mold design, and strict control of the injection molding process parameters are the key to ensuring the quality of the PC preform. This article aims to provide valuable reference for enterprises and technicians engaged in the production of PC preforms, help solve practical production problems, improve production efficiency, and product quality.