Runnerless injection molding eliminates the need for runners, enhancing material efficiency and reducing waste during the injection molding process.

Runnerless injection molds, also known as hot runner molds, allow molten plastic to flow directly into the cavity, minimizing leftover material. This technology improves cycle times and lowers production costs, making it ideal for high-volume manufacturing.

While this overview highlights the benefits of runnerless injection molds, understanding their specific applications and design considerations can further enhance production efficiency. Explore more to discover how runnerless molds can optimize your manufacturing processes.

Runnerless injection molds reduce waste by eliminating runners.True

By directing molten plastic straight into the mold cavity, runnerless systems minimize excess material, making them more environmentally friendly and cost-effective.

Runnerless injection molds always result in higher quality parts.False

While runnerless molds can improve efficiency and reduce waste, the quality of parts also depends on other factors like material selection, mold design, and processing conditions.

How Does a Runnerless Injection Mold Work?

Runnerless injection molds operate without traditional runners, using hot runner systems to keep plastic melt at optimal temperatures until it reaches the mold cavity. This technology reduces waste, enhances efficiency, and improves part quality, making it widely applicable in industries like automotive, electronics, and medical devices. Key benefits include material savings and faster cycle times.

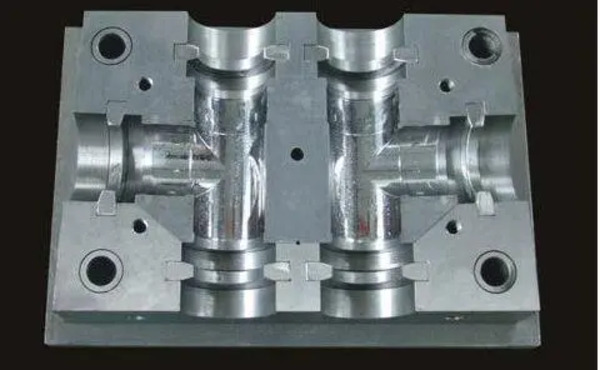

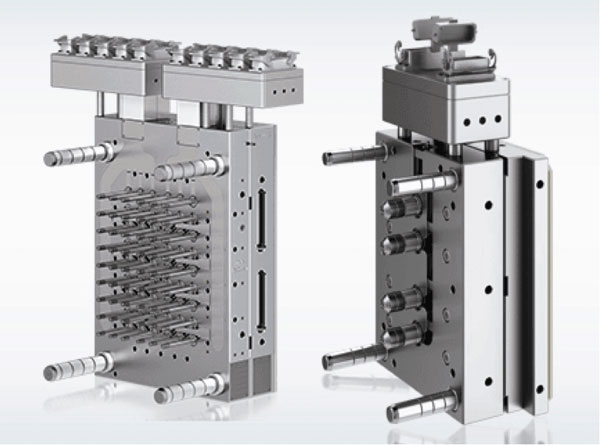

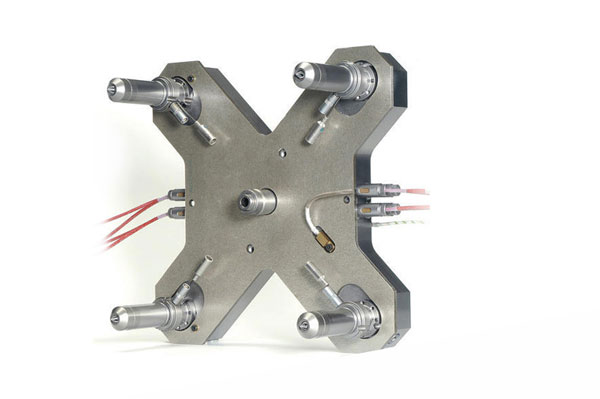

Runnerless Injection Molds’ core is its hot runner system. This system directly injects molten plastic into mold cavities — no need for old-style cold runners. Such systems have heaters, temperature sensors and nozzles. These components do several key jobs: keeping the melt at the right temperature and they can control exactly where the melt flows.

Melt Delivery: The injection molding machine\’s heating barrel is used to heat plastic pellets until they melt; this molten material is then either pushed into a hot runner system by means of an injection screw or plunger.

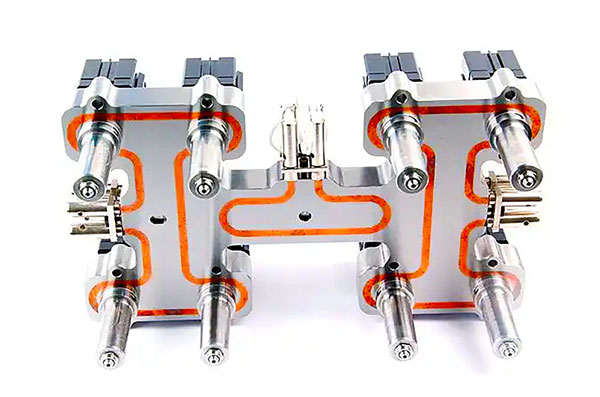

Hot Runner Control: The temperature of the melt is maintained by heaters in the hot runner system so that it does not cool and solidify while flowing. Temperature sensors continually check how much power the heaters need to keep the melt temperature constant—and can make any necessary adjustments then and there.

Precise Injection: The molten material flows through hot runner nozzles1 straight into mold cavities, where it solidifies. Because there are no cold runners, finished parts don’t have extra channels that need to be cut away before they can be shipped out—which means less waste!

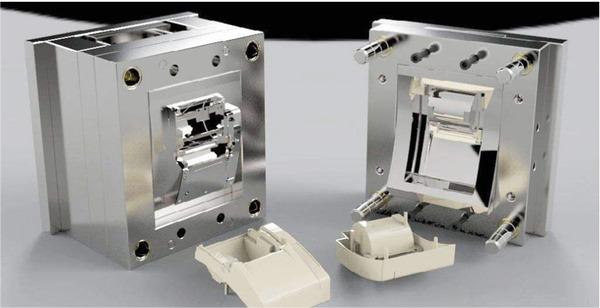

What are the Structural Characteristics of Runnerless Injection Molds?

Runnerless injection molds are characterized by a hot runner system that channels molten plastic directly into each cavity, avoiding the need for traditional runners. This structure reduces waste, enhances precision, and maintains consistent temperatures. Commonly used in automotive, medical, and consumer goods industries, runnerless molds improve cycle times and product quality.

The structure of Runnerless Injection Molds significantly differs from traditional molds, primarily in the following aspects:

Hot Runner System: The central element is the mold’s hot runner system, which comprises nozzles, main runners and sub-runners2. Electric heaters are used to ensure the flow of melt remains constant; temperature control systems then monitor this process with a great deal of accuracy.

Mold Cavity Design: Without the need for cold runners, the cavity design is more compact, allowing for a higher number of cavities and thus improving production efficiency.

Temperature Control System: Runnerless Injection Molds3 require precise temperature control to function optimally. It is important that the temperature control system can both monitor and adjust temperature in real time, so that fluidity of plastic melt – as well as quality in molding – remains consistent throughout use.

Cooling System: Although the injection part of the mold does not require cooling, the rest of the mold still needs an effective cooling system to ensure rapid cooling and forming of the plastic parts.

What are the Advantages of Runnerless Injection Molds?

Runnerless injection molds minimize waste by eliminating the need for runners, which reduces material costs and post-processing requirements. They also improve cycle times and part consistency, making them ideal for applications in automotive, electronics, and medical device production. Key advantages include less material waste, better quality control, and faster production rates.

Compared to traditional injection molds, Runnerless Injection Molds offer many advantages:

Reduced Waste: Because it doesn’t use cold runners4, a hot runner design lowers both material costs and plastic waste.

Increased Production Efficiency: With no runner trimming or waste to handle, cycles shorten and mold use goes up.

Improved Product Quality: Fine temperature control plus hot runners means less uneven cooling and less stress on products—so they’re more consistent and better quality.

Lower Energy Consumption: Heating and cooling systems on hot runner molds are designed to be more efficient than those on competitive molds—using less energy.

Environmental Benefits: Using less energy and producing less waste is good for the planet. In fact these principles fall under something called “green manufacturing.”

What are the Application Areas of Runnerless Injection Molds?

Runnerless injection molds improve efficiency by removing excess plastic runners, reducing waste, and enabling faster cycle times. These molds are widely used in automotive, electronics, and packaging industries. Key advantages include lower material costs, better product consistency, and reduced post-processing time.

Due to their many advantages, Runnerless Injection Molds are widely used in various industries, especially in those requiring efficient and high-quality production.

Automotive Industry: The use of Runnerless Injection Molds is widespread in the manufacture of automotive parts, particularly interior components and functional elements, because these areas need high efficiency and accuracy.

Electronics and Electrical Appliances: Runnerless Injection Molds are used extensively in producing internal elements and casings for electrical goods and gadgets. Such items must be top quality and uniform.

Medical Devices: To meet material and production process requirements, medical devices must adhere to strict standards; Runnerless Injection Molds can produce high-quality, super clean products.

Packaging Industry: Food and beverage packaging requires rapid, mass production. The high efficiency and low cost of Runnerless Injection Molds make them significant in this field.

Consumer Goods: From daily necessities to high-end consumer goods, Runnerless Injection Molds improve production efficiency and product quality, meeting market demands.

How are Runnerless Injection Molds Designed and Manufactured?

Runnerless injection molds, often called hot runner molds, eliminate excess material by keeping the plastic melt within the mold system, enhancing efficiency and reducing waste. This technique is widely used in automotive, electronics, and medical device industries, helping to improve cycle times and reduce scrap. Key benefits include cost savings, material efficiency, and consistent product quality.

The design and manufacturing of Runnerless Injection Molds are complex engineering processes that require consideration of multiple factors, including material selection, hot runner system design, temperature control system configuration, and more.

Material Selection: Mold materials must be strong, wear-resistant and thermally conductive; examples are high-strength steel as well as aluminum alloys.

Hot Runner System Design: When designing this system one must think about how the melted plastic will travel from machine barrel through mold; where along this path heat needs to be controlled precisely so that upon reaching cavities it can create identical parts each time cycle after cycles–and also where those gate points should be located for best results overall.

Temperature Control System Configuration: The configuration of the temperature control system must be precise enough to monitor the temperature in real-time. It should also be able to adjust the heater\’s temperature so that it keeps the melt’s temperature stable as it flows.

Mold Cavity Design: When designing a mold cavity, engineers must think about the plastic part’s geometric shape along with how exact its dimensions need to be; they also consider what kind of surface finish5will best suit their needs. Having a well thought out design for the cavities can improve both quality control during production and overall efficiency.

Manufacturing Process: The manufacturing process of Runnerless Injection Molds includes precision machining, heat treatment, surface treatment, and more. High-precision machining and reasonable process arrangements ensure the mold\’s accuracy and lifespan.

What are the Case Studies of Runnerless Injection Molds in Specific Application Areas?

Runnerless injection molds are applied in industries like automotive, electronics, and medical devices to streamline production and minimize material waste. These molds improve product precision and reduce cycle times by eliminating runners, making them ideal for high-precision, high-volume manufacturing. Key case studies demonstrate success in reducing costs and enhancing product quality in these sectors.

To better understand the practical applications of Runnerless Injection Molds, the following are several case studies:

Automotive Parts Manufacturing

Case Background: An automotive manufacturer needed to make a batch of high-precision dashboard housings with smooth surfaces and short production cycles.

Solution: Using a Runnerless Injection Mold with precise temperature control and hot runner design ensured uniform melt flow and rapid mold filling.

Outcome: Production efficiency increased by 30%, and the defective rate was reduced to less than 1%, significantly saving costs.

Electronic Product Housing Production

Case Background: An electronics manufacturer needed to make a lot of phone housings that were the right size and smooth, and they needed them fast.

Solution: They used a special kind of mold and some other fancy stuff to make sure each housing was the same and really good.

Outcome: They made the phone housings faster, they were all the same, and people liked them.

Medical Device Manufacturing

Case Background: A medical device company needed to make a batch of disposable syringes that were super clean and super fast.

Solution: We used a Runnerless Injection Mold with a high-precision temperature control system and a good cavity design to make sure the syringes were clean and fast.

Outcome: We made the syringes 50% faster, they were super clean, and the doctors loved them.

What is the Future Development Trend of Runnerless Injection Molds?

The future of runnerless injection molds focuses on innovations in energy efficiency, automation, and sustainability. Advanced materials and smart mold technologies are enabling faster cycles, reduced waste, and improved product consistency. Key trends include integration with Industry 4.0 and the use of eco-friendly materials, making runnerless molds essential for modern production lines.

With technological advancements and changing market demands, Runnerless Injection Mold technology is continually evolving and innovating. Future development trends include the following:

Intelligent Manufacturing: By using intelligent technologies in their manufacture, Runnerless Injection Molds can be made smarter which means you\’ll be able to produce them automatically with monitoring in real time for better overall quality as well as efficiency gains. An instance might be integrating Internet of Things (IoT) tech so data can be continuously streamed back for process optimization purposes.

Green Manufacturing: Runnerless Injection Molds will need to become greener as environmental regulations grow stricter, cutting both energy usage and waste generation for sustainable growth. One way to do this is by using more renewable materials and power which has the added bonus of also cutting carbon emissions even further.

New Material Applications: The development and application of new materials will enhance the performance and lifespan of Runnerless Injection Molds to meet more demanding production requirements. For example, using nanocomposite materials can improve the mold\’s wear resistance and thermal conductivity.

Multi-function Integration: To enhance production efficiency and flexibility, forthcoming molds will boast multiple integrated functions. This means that a single mold could perform tasks like shaping parts for an assembly—which it would then also check over before approving for use.

Customized Production: Runnerless Injection Mold technology will be developed to meet market demand and allow cost-effective custom production. Rapid prototyping and modular design will enable fast delivery of personalized products— responding to trends toward individuality and customization with efficient manufacturing solutions.

Conclusion

A runnerless injection mold is an advanced technique in the injection molding process that eliminates the need for runners, which are channels that guide the molten plastic material to the mold cavities. Unlike traditional thermoplastic injection molding6, which often uses a cold runner system, runnerless injection molding, commonly achieved through hot runner systems, maintains the plastic material in a molten state until it reaches the mold. This method is particularly efficient for reducing waste and improving cycle times. Liquid Silicone Rubber (LSR) injection molding differs significantly as it utilizes a runnerless system to feed material directly into the mold cavities, ensuring precision and reducing material consumption. By utilizing these sophisticated techniques, runnerless injection molding enhances productivity and material efficiency in the manufacturing process.

Runnerless injection molds are a kind of advanced injection molding technology. They have many advantages and a wide range of applications. This article explains in detail the working principle, structural characteristics, advantages, application areas, and key technologies of Runnerless Injection Molds. It provides readers with a comprehensive understanding. The future development trend of Runnerless Injection Molds is also pointed out, which provides a direction for the development of the industry. With the continuous development of technology and the change of market demand, Runnerless Injection Mold technology will play an increasingly important role in more fields, and promote the transformation and upgrading of the manufacturing industry.

Runnerless injection molds are great for making things faster and better. They also save money and help the environment. Companies that know how to use runnerless injection molds will do better than other companies. They will grow and make more money. People who make things have used runnerless injection molds in many different ways. They use them to make cars, electronics, and medical stuff. Runnerless injection molds are really good and people like them a lot.

In the future, with the continuous advancement of smart manufacturing, green manufacturing, new material applications, multi-function integration, and customized production, Runnerless Injection Mold technology will have even more room for development. Companies need to continuously improve their technical level and innovation capabilities while actively embracing these new technologies and trends to respond to the rapid changes in the market and growing demand. Through continuous technological research and innovation, Runnerless Injection Mold technology will achieve breakthroughs in more fields, promoting the manufacturing industry towards more efficient, environmentally friendly, and smart directions.

-

Learn about Hot runner nozzles – A variety solutions for modern injection moulding technology: With their large variety of melt-channel diameters, nozzle lengths and gate geometries . ↩

-

Learn about What Are the Roles of Mold Runners and Sub-Runners:A mold runner is a channel in the mold that directs the molten plastic from the injection unit to the mold cavity where the final product will be formed. ↩

-

Learn about What is a Runnerless Injection Mold: Runnerless injection molds allow molten plastic to flow directly into the cavity, minimizing leftover material. ↩

-

Learn about What is the Difference Between Hot Runners vs Cold Runners: Hot runners keep the plastic melt heated within the mold, cold runners cool the plastic in each cycle . ↩

-

Learn about Injection moulding surface finish design guide – DfM : Surface finish can improve the look and feel of a product. ↩

-

Learn about Thermoplastic Injection Molding: Definition, Process & Materials : Thermoplastic injection molding is a transformative process where thermoplastic polymers are melted, injected into a mold, and cooled to form a solid shape. ↩