Preface: Will 3D printing replace injection molding?Maybe not anytime soon, but 3D printing has a lot of advantages over injection molding, which makes it great for a lot of prototyping and industrial applications. 3D printing is an additive manufacturing (AM) technology that builds parts one layer at a time. It has a lot of unique advantages over injection molding, including faster production times and a distributed supply chain.

In a lot of applications, 3D printing can get you parts faster than injection molding, with accuracy that’s as good as or better than traditional manufacturing, and using more cost-effective and sustainable materials.

That being said, the question of whether 3D printing will replace injection molding has been around since the beginning of additive manufacturing. There’s not a short answer to this question, other than to say that while 3D printing might not completely replace injection molding anytime soon, it has already surpassed these processes in a lot of applications.

Understanding why 3D printing is useful, or even optimal, for manufacturing can help designers make better decisions when they’re developing products and choosing manufacturing processes. In this article, we’ll introduce the conceptual advantages and disadvantages of 3D printing and injection molding, their application areas, and the differences between the two.

3D Printing

What is 3D Printing?

3D printing, also called additive manufacturing, is a process that builds a three-dimensional object by adding material layer by layer. The materials can be plastic, metal, or ceramic. It’s a way to make complex designs quickly and precisely.

How Does the 3D Printing Process Work?

Key Steps in This Process Include:

Digital design: The process starts with a digital 3D model created using computer-aided design (CAD) software. This digital file describes the shape and specifications of the object to be printed.

Model slicing: Using special software to divide a digital model into thin horizontal sections. These layers correspond to slices of the finished product.

Material preparation: Print with the material of your choice – plastic, metal, ceramic or other materials available for printing. Materials are typically delivered as filament, powder, or liquid resin, depending on the type of 3D printer.

Print object: The 3D printer takes the sliced layers of the digital model and starts printing. The printer then prints or joins layer by layer based on instructions for each slice.

Interlayer adhesion: These layers stick together to form a solid object. Whether it’s melting plastic filaments, solidifying liquid resin with UV light, or thermally sintering metal powders with lasers, all types of 3D printing are tasked with bonding layers.

Building the object: As successive layers are added, the object gradually becomes three-dimensional. Keep adding layers until the entire object is complete.

Post-processing (optional): Post-processing work varies depending on the type of 3D printing technology used and the materials used. This may involve trimming supports, sanding, polishing or applying an additional layer of finish to meet specific surface quality standards.

What are the Advantages of 3D Printing?

Rapid prototyping: This is because traditional manufacturing techniques involve slow, time-consuming processes like machining molds or tooling. Designers and engineers can also explore concepts faster through rapid prototyping with 3D printers. This shortens the entire development process.

Customization: The customizable nature of 3D printed objects is useful in many fields. For example, in the medical field, unique implants can be customized to fit individual patients. The technology can accommodate special design needs and can also be used to develop personalized products for consumers.

Reduce material waste: Unlike subtractive processes, which cut material from larger parts into raw chunks, 3D printing pieces the object together piece by piece. The process produces minimal waste, making it a green alternative to other methods that produce more waste, especially if the molded part is complex.

Suitable for small batch production: Manufacturing processes also tend to be automated, which makes them unfeasible for small batch production and requires high installation costs for molds or tooling. Such tools are not economically feasible on a small scale, but 3D printing can produce the required parts at very low volumes or even in one go. This is good for niche markets and customized products.

What are the Limitations of 3D Printing?

Material limitations: However, as the range of printable materials continues to expand, there are still some industries that require materials with certain properties that are difficult to obtain automatically from machines.

Layer resolution limitations: Because 3D printed objects are built one layer at a time, you may see lines of different colors. Higher layer resolution can help with this, but it also increases printing time and cost.

Production speed: While 3D printing is great for rapid prototyping, its speed can be a disadvantage compared to other technologies for practical mass production. Make molded lids. This is more time-efficient for high-volume batch production.

What Industries are Commonly Used in 3D Printing?

Manufacturingand prototyping: 3D printing is great for making prototypes quickly and efficiently. It lets companies try out designs and see if they work before they spend a lot of money making a bunch of them. That saves money and helps them get things done faster.

Aerospace: The aerospace industry uses 3D printing a lot to make lightweight parts that are really complicated. They can also make parts that are lighter and more complicated, like fuel nozzles and things that hold the plane together, so the plane works better.

Healthcare: In healthcare, they use 3D printing to make medical devices and body parts. They can make things that fit a person’s body exactly, so they work better. They can also make models of a person’s body to practice surgery on before they do it for real.

Automotive: In the car business, they use 3D printing to make new car designs and parts for cars. They can also make special parts that are lighter and better, so the car works better. Some companies are even making parts for the engine with 3D printing.

Dentistry: 3D printing has also revolutionized dentistry, allowing the production of high-precision dental restorations (crowns and bridges) and dentures. This also makes it easier to create specific models for dental surgery operations and treatment planning.

Injection molding

What is Injection Molding?

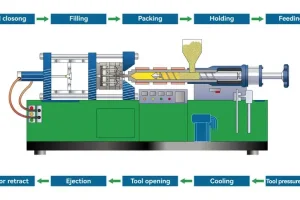

Injection molding is a plastic manufacturing process mainly used to make plastic parts.

In this process, plastic pellets are first heated and melted, then injected into a mold under high pressure, then cooled and solidified in the mold, and finally the mold is opened and the molded plastic product is taken out.

Injection molding has a wide range of applications, including making bottle caps, toys, chairs, and other everyday items. This process is not only suitable for large-scale mass production, but also can make plastic products with complex shapes and diverse functions.

What are the Advantages of Injection Molding?

Super high production efficiency: The injection molding process has made great progress in automation and numerical control, making the whole processing process highly automated and greatly improved efficiency.

The injection molding machine can continuously produce according to the preset procedure without stopping the machine to change the mold, reducing the intervention of workers and human errors, thereby improving production efficiency.

Super high molding precision: The injection molding process uses advanced CNC equipment and high-precision molds to achieve high-precision molding. At the same time, since parameters such as injection time and pressure can be finely controlled, the dimensional accuracy and consistency of the product can be ensured.

Versatile: Injection molding can be used to make a wide range of materials, including thermoplastics, thermosets, rubber, die-casting molds, metal powders, etc. It is highly adaptable and versatile.

Low waste: Injection molding can use a variety of recycled materials for production, reusing discarded plastics, reducing material waste, and reducing environmental pollution.

What are the Disadvantages of the Injection Molding Process?

Expensive equipment and mold costs: Injection molding needs high-precision molds and advanced injection molding machines, which are expensive. So, the equipment and mold costs are high and not suitable for small businesses and individuals.

Strict process requirements: Injection molding has strict requirements on raw materials, molds, environment, and other aspects. If the process is wrong or does not meet the requirements, it can easily cause product quality problems.

Requires a lot of capital and technical support: Injection molding needs professional technicians and highly automated equipment to operate, so companies need to have enough money and technology to support it.

Maintenance Challenges: Both injection molding machines and molds require regular maintenance and inspections. When the equipment and molds are running at high speeds, they are more likely to fail or get damaged. Difficulty in maintenance also means higher maintenance costs.

What Industries are Commonly Used in the Injection Molding Process?

Injection molding is a plastic processing method that is widely used in various fields and can process plastic parts of various types and sizes. Below are some of the main areas where the injection molding process is often used to process plastic parts.

Electronics and electrical appliances: Injection molding is used to manufacture housings, connectors, cables, and other plastic parts for electronic equipment. This includes things like cell phone cases, sockets, wire insulation, and holders for electronic circuit boards.

Automotive and transportation fields: The automotive industry widely uses injection molding processes to manufacture auto parts, such as instrument panels, headlight lenses, interior parts, engine parts, body parts, and various pipes and connections.

Medical device industry: In the medical device industry, injection molding technology is used to make medical devices, medical syringes, infusion bags, medical equipment shells, etc.

Home and household appliances industry: In the home and household appliances industry, the injection molding process is used to make chairs, tables, TV remote controls, electrical appliance shells, faucets, bathroom accessories, etc.

Consumer goods industry: Injection molding is widely used in the production of various consumer goods, such as plastic bottles, toys, shoe soles, tableware, packaging containers, etc.

Aerospace industry: In the aerospace industry, injection molding is used to make components for airplanes and spacecraft, including seats, shells, ducts, and airplane interiors.

What are the Differences Between 3D Printing and Injection Molding?

Production Mode

Injection molding is still the best choice for traditional high-volume, large-scale manufacturing. It can produce standardized products at low cost and on a large scale as long as there are injection molds.

3D printing is better at manufacturing personalized and diversified products. It does not require traditional tools, fixtures, machine tools or any molds. It can directly convert any shape of the computer into a physical model automatically, quickly, directly and relatively accurately. Thanks to the large size of the 3D printer, the more complex and non-solid objects are, the faster they are processed and the cost of raw materials is saved.

In terms of manufacturing costs alone, the cost of injection molding is far lower than that of 3D printing technology. However, for industrial manufacturing, the real cost-saving link of 3D printing lies in modifying the prototype.

Modifying the prototype only requires modifying the CAD model and does not incur any manufacturing costs. One thing to note is that in injection molding, if the prototype is a steel mold, the cost is relatively low, but if aluminum alloy molding tools are used, the cost is much higher.

However, it is worth noting that there are more and more software for injection molding prototyping, so in terms of cost, 3D printing may soon lose its advantage.

Production Quantity

Who is more dominant in terms of production quantity? We all know that speed determines output. Compared with traditional processes, plastic 3D printing speed is still slower. For large-scale manufacturing, injection molding is currently still the best choice.

It should be noted that even large-scale production lines that apply 3D printing technology generally only use this technology to make molds and test products. The core process is not additive manufacturing. From this point of view, injection molding has the upper hand.

Manufacturing Cost

Because of the wide availability of raw materials for injection molding, its large-scale, fast, and standardized production characteristics are also conducive to reducing the cost of a single product. Therefore, in terms of manufacturing costs, the cost of injection molding is much lower than that of 3D printing technology.

However, for industrial manufacturing, the real cost-saving link of 3D printing lies in modifying the prototype. Modifying the prototype only requires modifying the CAD model and does not incur any manufacturing costs.

In injection molding, if the prototype is a steel mold, the modification cost will be relatively low, but if aluminum alloy molding tools are used, the cost will be much higher. This is also the reason why many companies or individuals currently engaged in mold design choose Chuangxiang 3D 3D printers for mold design and printing.

Quality of Manufacturing

Another thing is that 3D printing is limited in the quality of the parts it can make. Traditional manufacturing processes win here. Even though the types of 3D printing materials seem to be expanding, they are still just a drop in the bucket compared to injection molding. So if the 3D printing material is different from the final product, you can only test around the shape, which doesn’t help you at all for physical performance testing.

Another thing is surface finish. Even though the quality of 3D printed parts depends a lot on the performance of the printer, it’s still not even close to polished steel injection molds. The last thing is product durability. 3D printed parts are also a little behind injection molded parts.

Areas of Application

At present, the injection molding process can achieve mass production of products with uniform shapes, so it is very suitable for the mass production of standardized products.

3D printing only needs to input a three-dimensional image through the control terminal, and then it can print raw materials into physical models or even directly manufacture parts or molds, which can effectively shorten the product development cycle. 3D printers for three-dimensional production have been widely used in the fields of makers, architectural design, mold model design, etc.

However, it is worth noting that there are more and more software for injection molding prototyping, so in terms of cost, 3D printing may soon lose its advantage.

Conclusion

In short, 3D printing has many advantages in rapid prototyping, customization, reducing material waste, and being suitable for small batch production. However, it is unlikely to completely replace injection molding in manufacturing. Injection molding still has significant advantages in terms of high production efficiency, high molding precision, strong versatility, and low waste.

Additionally, advances in injection molding technology, such as the integration of digital design tools and automation, continue to increase its efficiency and flexibility. While 3D printing will continue to play a vital role in certain applications and industries, the two manufacturing processes will likely coexist and be used where their respective strengths are most beneficial.