Introduction

The construction industry stands as a pillar of modern society, crafting the physical landscapes that define our cities and communities. As urbanization continues to surge and architectural complexities grow, the industry’s reliance on cutting-edge technologies becomes ever more apparent. Amid this dynamic landscape emerges a versatile innovation that has proven to be a game-changer: plastic injection moulding. While commonly associated with consumer goods manufacturing, plastic injection molding’s significance extends far beyond, particularly within the construction sector. In this article, we delve into the symbiotic relationship between the construction industry and plastic injection moulding, uncovering how this transformative process has become critical in shaping the structures that define our world.

II. Understanding Plastic Injection Molding proess

Plastic injection molding, a precision manufacturing technique, has emerged as a cornerstone in various industries due to its remarkable efficiency and adaptability. This section delves into the mechanics of plastic injection molding, shedding light on its fundamental principles and its remarkable versatility across diverse sectors.

Explaining the Plastic Injection Molding Process

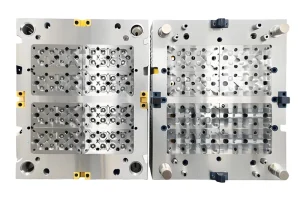

At its core, plastic injection molding is a method of producing intricate plastic parts, and components through the injection of molten plastic into a meticulously crafted mold. The process follows a systematic sequence:

- Clamping: The mold is securely closed, ensuring no leakage during the subsequent stages.

- Injection: Molten plastic, usually in pellet form, is injected into the mold cavity under high pressure. This plastic is often heated to a precise temperature, enabling it to flow smoothly into every intricate detail of the mold.

- Cooling: Once injected, the plastic rapidly cools and solidifies within the mold, taking the desired shape.

- Ejection: The mold is opened, and the newly formed plastic component is ejected, ready for further processing or assembly.

Highlighting Versatility Across Industries

The remarkable adaptability of plastic injection molding is a testament to its transformative potential. It seamlessly navigates various sectors, including but not limited to:

- Automotive Industry: From intricate interior components to robust exterior parts, plastic injection molding contributes to crafting vehicles with precision and durability.

- Medical Sector: Injection-molded medical devices and components meet stringent quality and safety standards, underlining their importance in patient care.

- Construction Industry: Plastic injection molding extends its prowess to construction, enabling the production of custom components, lightweight structures, and architectural elements.

- Consumer Goods: Everyday items like packaging, electronic casings, and household appliances owe their intricate designs and consistent quality to plastic injection molding.

- Electronics: Plastic injection molded parts play a vital role in electronics, offering durability and precision in intricate electronic components.

This remarkable versatility underscores the plastic injection molding process’s ability to adapt, innovate, and elevate industries across the board. From intricate medical devices to robust construction materials, its reach is both expansive and transformative.

III. The Significance of Injection Molding in Construction

The construction sector, a vibrant and essential industry shaping the world around us, relies on a harmonious blend of innovation and efficiency to bring architectural marvels to life. Central to this synergy is the pivotal role that plastic injection molding plays within the construction sector. In this section, we explore the critical significance of plastic injection molding in construction and delve into its ability to address the distinct needs and challenges of this dynamic industry.

The Crucial Role of Plastic Injection Molding

Plastic injection molding stands as a cornerstone technology within the construction landscape, offering a multitude of advantages that propel the industry forward:

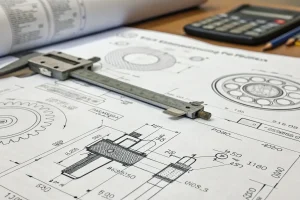

1.Precision Engineering: In an arena where accuracy is everything rigorous quality control paramount, plastic injection molding delivers with unwavering precision. From intricate façade elements to essential connectors and housing components, each detail is meticulously crafted.

2.Material Versatility: The construction realm demands materials with a diverse range of properties, from structural strength to weather resilience. Plastic injection molding rises to the occasion, accommodating an extensive array of thermoplastic materials. This versatility allows construction professionals to select materials tailored to specific project requirements.

3.Customization and Design Flexibility: Architects and designers are empowered to manifest their creative visions with plastic injection molding. Complex geometries, ornate patterns, and visionary designs can be seamlessly translated into tangible construction components.

4.Optimized Weight and Efficiency: Lightweight plastic components not only reduce the burden on structures but also contribute to energy-efficient construction practices. This alignment with sustainability objectives underscores the technology’s relevance in modern construction.

5.Streamlined Production: The swift production cycle of plastic injection molding harmonizes with the rapid pace of the construction sector. This synergy ensures that vital components are fabricated promptly, minimizing project timelines.

Addressing Unique Needs and Challenges

The construction industry presents a distinctive set of demands, a tapestry of challenges that plastic injection molding adeptly navigates:

Diverse Applications: Plastic injection molding spans a broad spectrum of construction needs, from crafting interior fixtures similar construction materials to fashioning exterior elements and intricate architectural details.

Durability Mandate: In an environment characterized by diverse weather conditions and structural stresses, injection-molded plastic components showcase remarkable resilience and extended lifespans.

Design Complexity: Modern architectural marvels often embody intricate and visionary designs. Plastic injection molding’s capacity to faithfully reproduce intricate nuances ensures that even the most elaborate designs can be actualized.

Sustainability Integration: With a growing emphasis on sustainable practices, plastic injection molding aligns seamlessly with construction industry objectives. Minimal waste generation, energy-efficient production, and the use of recyclable plastics underscore the technology’s eco-conscious impact.

Supply Chain Efficiency: Plastic injection molding optimizes the production process, ensuring timely delivery of components that meet precise specifications. This efficiency enhances overall project execution.

By embracing these distinctive needs and surmounting the associated challenges, plastic injection molding empowers the construction industry to achieve new heights of ingenuity, durability, and environmental responsibility. In the intricate dance between technology and construction, plastic injection molding takes center stage, offering a symphony of solutions that shape our built environment for generations to come.

IV. Benefits of Plastic Injection Molding in Construction

A. Precise Component Manufacturing

In the intricate world of construction, precision reigns supreme. Plastic injection molding emerges as a virtuoso performer, orchestrating the production of components with a level of intricacy that defines modern architectural excellence.

The Craftsmanship of Precision

Plastic injection molding choreographs a dance of engineering precision and artistic finesse:

Mold Perfection: The manufacturing process begins with a meticulously designed mold, akin to a sculptor’s masterpiece, bearing the exact contours of the component.

Material Symphony: Selected thermoplastic materials transform into a molten symphony, flowing with graceful fluidity into every recess and groove of the mold.

Solidification Ballet: Cooling is a carefully timed ballet, where the molten material gracefully transforms into a solid, capturing the mold’s details like a freeze-frame of creativity.

Revelation Unveiled: As the mold parts, the component is unveiled – a tangible testament to precision engineering and the magic of plastic injection molding.

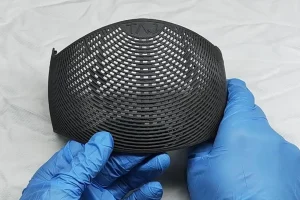

Construction Components Crafted with Precision

Plastic injection molding paints a masterpiece in construction components, each brushstroke of molten plastic contributing to the symphony:

Connectors: These silent heroes of architecture ensure structural cohesion. Precision plastic injection molding offers more births connectors with the finesse required to securely interlock key elements.

Brackets: The unsung champions of load-bearing, brackets owe their precision to plastic injection molding. They stand strong, seamlessly bearing weight in silence.

B. Material Versatility

As the construction industry navigates diverse challenges, material versatility becomes a key protagonist. Plastic injection molding enters the stage, presenting an array of materials fit for the construction canvas.

Materials Tailored to Construction Needs

Plastic injection molding beckons a versatile ensemble of thermoplastic materials:

- High Density Polyethylene (HDPE): A stalwart in construction, HDPE lends its strength and resilience to piping systems, weather-resistant cladding, and insulation materials.

- Acrylonitrile Butadiene Styrene (ABS): ABS takes center stage in intricate designs, carving out intricate patterns and details in window frames, light housings, and customized fixtures.

- Polyethylene Terephthalate (PET): PET graces the construction runway with its recyclable charm, finding its way into insulation materials and sustainable architectural components.

C. Enhanced Efficiency and Reduced Weight

In the delicate ballet of construction, energy efficiency and weight reduction are graceful movements. Plastic injection molding joins this choreography, imparting agility to structures and reducing unnecessary energy transference.

Weightlessness Meets Strength

Plastic injection molding introduces lightweight champions to the construction arena:

- Energy Efficiency: The lightweight nature of injection-molded plastic components translates into reduced energy consumption during transportation and installation, aligning harmoniously with sustainability goals.

- Electricity Transference Minimization: Injection-molded plastic’s innate insulating properties minimize unwarranted electricity transference, contributing to optimized thermal control within structures.

D. Customization and Design Flexibility

Architecture dances to the rhythm of innovation and aesthetics. Plastic injection molding becomes the choreographer of creativity, enabling architects to conjure visions beyond imagination.

Design as Artistry

Plastic injection molding casts a spell of design flexibility, transforming architectural dreams into tangible forms:

- Intricate Patterns: From captivating façade elements to elegantly crafted brackets, injection molding breathes life into intricate patterns and textures.

- Architectural Icons: Unique designs, such as ornate window frames and bespoke fixtures, are sculpted with precision, elevating architectural aesthetics to new heights.

E. Durability and Longevity

In the unforgiving realm of construction, durability and longevity take center stage. Plastic injection molding crafts performers of endurance, ready to withstand the tests of time and environment.

Resilience Under Scrutiny

Injection-molded plastic components stand resilient against the harshest of construction challenges:

- Weather Warriors: Façade elements and exterior components weather storms with grace, thanks to injection molding’s ability to create durable, weather-resistant materials.

- Extended Lifespans: The durability of injection-molded components translates into reduced maintenance and replacement costs, bestowing cost-saving laurels upon construction projects.

F. Streamlined Production and Cost Efficiency

In the grand theater of construction, streamlined production and cost efficiency steal the spotlight. Plastic injection molding dons the mantle of efficiency, delivering performances that resonate with the pulse of the industry.

Precision Production

Plastic injection molding plays a pivotal role in constructing plastic products, a tale of efficiency:

- Injection Molding Machines: These technological maestros conduct a symphony of production, churning out components swiftly and precisely, in perfect harmony with construction’s rapid tempo.

- Economies of Scale: The construction industry reaps the rewards of injection molding’s efficient processes, enjoying the cost-effectiveness born from mass production.

The curtain rises on a stage where precision meets versatility, efficiency dances with sustainability, and innovation embraces durability. Plastic injection molding takes its place as a leading protagonist, shaping the narrative of construction with each precisely crafted component.

V. Hazards and Safety Measures

In the intricate symphony of plastic injection molding, where creativity and engineering converge, there exist potential hazards that warrant careful attention. This section delves into the cautious dance of addressing these hazards and emphasizes the paramount importance of safety measures and responsible handling.

Navigating Hazards in Plastic Injection Molding

- High Temperatures: The heart of plastic injection molding throbs with molten plastic at high temperatures. These elevated temperatures hold the potential to scald or cause burns, demanding vigilant protective measures.

- Chemical Exposure: Some materials utilized in the manufacturing molding process may emit fumes or pose chemical hazards. Adequate ventilation and respiratory protection stand as sentinels guarding against unwarranted exposure.

- Machinery Risks: The very machines orchestrating this manufacturing ballet can present risks. Mechanical entanglement, crush injuries, and other mechanical accidents necessitate prudent precautions.

- Noise and Vibration: The harmonious rhythms of injection molding machine come with a cacophony of noise and vibrations. Proper hearing protection and safety protocols act as a shield against these audible and palpable hazards.

Enshrining Safety Measures

The art of plastic injection molded, while mesmerizing, demands the orchestration of safety measures to safeguard all involved:

- Training and Education: Mastery begins with knowledge. Proper training equips personnel with the expertise to navigate the machinery, materials, and protocols with confidence.

- Personal Protective Equipment (PPE): The armor against hazards, PPE encompasses gloves, safety goggles, face shields, and clothing that shield against potential burns, chemical exposure, and flying debris.

- Ventilation and Respiratory Protection: Adequate ventilation sweeps away fumes and contaminants, while respiratory protection ensures that the air inhaled is free from harmful particles.

- Machine Guards and Lockout/Tagout: Machine guards act as sentinels, and lockout/tagout procedures prevent accidental starts, ensuring that the machines harmonize with safety.

- Emergency Response Plans: The grand performance of safety hinges on well-rehearsed emergency response plans, ensuring swift and effective action in the face of unexpected incidents.

- Ongoing Monitoring: Vigilance is the key. Regular monitoring, inspections, and audits ensure that safety remains an unwavering refrain in the plastic injection molded symphony.

A Harmonious Balance

In the intricate choreography of plastic injection molded, safety waltzes in tandem with creativity and precision. By diligently acknowledging potential hazards and nurturing a culture of safety, the industry cultivates an environment where innovation flourishes and every performer can dance without fear. The stage is set for a harmonious performance where safety takes center stage, protecting the artisans who craft the symphony of plastic injection molded.

Conclusion

In the symphony of modern industry, plastic injection molded has emerged as a virtuoso performer, orchestrating intricate movements across diverse sectors. This journey through the art and science of plastic injection molded has illuminated its pivotal role not only in construction but also in the broader tapestry of industries. As the curtain descends on this exploration, let us revisit the key points that have danced across these pages.

We embarked on a voyage into the heart of construction, a dynamic industry reliant on innovation and precision. Here, plastic injection molded took center stage, revealing its ability to craft precise components with the grace of a master artisan. From connectors that bind structures together to brackets that silently bear loads, plastic injection molded showcased its prowess in transforming architectural visions into tangible reality.

The versatility of plastic injection molding dazzled us as it transcended boundaries, entering domains such as automotive and medical industries. In the automotive sector, it breathed life into intricate interior and exterior components, while in healthcare, it cast a healing spell over intricate medical devices.

However, it is within the construction sector that plastic injection molding performs its most transformative duet. We witnessed the harmonious dance of plastic piping, silently ensuring the seamless flow of utilities, and the majestic emergence of customized architectural features, reflecting the ingenuity of designers and the precision of injection molding.

As the final note resonates, the critical role of plastic injection molding in the construction industry emerges as a crescendo of innovation and potential. Its artistry, harnessed to craft intricate components with precision, aligns seamlessly with the demands of modern architecture. Furthermore, its capacity to produce lightweight, durable, and customizable elements heralds a future of sustainable and efficient construction practices.

With plastic injection molding as a guiding star, the construction industry embarks on a journey toward innovative solutions, reduced environmental impact, and enhanced structural integrity. The stage is set for a symphony of innovation, where plastic injection molding holds the conductor’s baton, leading construction into a harmonious future that balances creativity, efficiency, and sustainability. As the final curtain falls, we are left with the resounding melody of plastic injection molding shaping the very foundations of the world we build.