Introduction

Injection molding is an efficient and widely utilized manufacturing method for producing plastic parts. The process entails injecting hot molten plastic material into mold cavities, waiting until it cools and solidifies, then releasing the part from its mold cavity after cooling and solidifying. Injection molding offers many advantages over alternative forms of manufacturing such as injection or blow molding such as high production rates, repeatable precision, and the ability to create complex shapes.

Designing injection molded parts requires prioritizing efficiency and performance. Efficient design ensures optimal material usage, reduced cycle times, and minimized waste; on the other hand, well-designed plastic injection molded parts maximize performance, functionality, and durability.

In this article, we’ll outline key considerations and best practices for designing injection molded parts with maximum efficiency and performance in mind. By adhering to these guidelines, you can improve overall product quality while streamlining production processes.

II. Material Selection for Injection Molding process

Selecting the ideal material is key to successfully injection molding parts. Your material selection affects performance, appearance and manufacturability. When selecting materials for your injection molding project, consider these factors:

Mechanical Properties:

Assess the mechanical requirements for the part, such as strength, flexibility, impact resistance and heat resistance. The material chosen should possess sufficient properties to fulfill these specifications.

Chemical Resistance:

When choosing materials with chemical resistance properties for parts intended to be used in harsh environments like chemicals or oils that come into contact with it, consider how exposed the part will be to substances like solvents or oils and determine its exposure levels accordingly. When making your selection, take note of its environment as well as potential exposure levels from various substances and determine which materials have appropriate chemical resistance properties.

Heat Resistance:

Understand what temperature range the part will experience over its service life and select materials capable of withstanding them without deforming or degradation.

Environmental Considerations:

Be wary of UV radiation, moisture content and outdoor conditions when selecting materials for outdoor environments. Make sure the chosen material can withstand these environmental influences without diminishing its performance.

Collaboration with material suppliers is integral to selecting appropriate materials. Their extensive knowledge and expertise can guide your search for suitable options that suit your requirements, while offering valuable insight into material availability, pricing, potential limitations or considerations during molding processes.

By carefully considering these factors and drawing upon the expertise of material suppliers, you can select an injection molded material with optimal performance, durability and overall success in mind.

III. Design Considerations for Moldability

A. Maintaining Uniform Wall Thickness

One of the key factors in designing injection molded parts is maintaining nominal wall thickness. This ensures consistent material flow during the injection molding design process and helps prevent issues like sink marks, warping, and uneven cooling. By maintaining uniform wall thickness, you can optimize the part’s structural integrity and minimize the risk of defects.

Guidelines for achieving uniform wall thickness:

Design the part with a consistent wall thickness throughout, avoiding sudden changes or variations.

Use ribs or gussets to reinforce areas that require additional strength without significantly increasing the overall wall thickness.

Consider the limitations of the molding machine and mold design when determining the thinnest possible wall thickness.

B. Draft Angles and Easy Part Ejection

Draft angles play a crucial role in moldability and the ease of part ejection. These angles are incorporated on vertical walls to facilitate the removal of the part from the mold. By including draft angles, you reduce friction and minimize the likelihood of the part sticking to the mold, ensuring smooth ejection.

Recommended draft angles for different surfaces:

Aim for a draft angle of 1 to 2 degrees for textured surfaces.

For smooth surfaces, a draft angle of 2 to 5 degrees is generally sufficient.

C. Avoiding Sharp Corners and Stress Concentration

Sharp corners in injection molded part can lead to stress concentration, which can weaken the part and cause issues during the molding process. To enhance the injection molded part’s strength and improve material flow, it is advisable to design rounded corners. Rounded corners distribute stress more evenly and minimize the risk of cracking or failure.

D. Rib Design for Strength and Stiffness

Incorporating ribs into the design of injection molded part can significantly enhance their strength and stiffness without increasing the overall wall thickness. Ribs help distribute stress and improve structural integrity. When designing ribs, consider the following guidelines:

Maintain a rib thickness that is around 50-60% of the adjacent wall thickness.

Ensure proper spacing between ribs to prevent issues like sink marks or flow restrictions.

E. Consistency in Wall Thickness

Consistency in wall thickness is crucial for successful injection molding. It promotes even material flow and cooling, minimizing the risk of defects. To maintain consistent wall thickness, avoid sudden changes or variations within the part design. Consider the limitations of the injection molding machine and mold design when determining the thinnest possible wall thickness.

F. Proper Parting Lines and Ejector Pin Placement

Parting lines and ejector pin placement are vital aspects of mold design. Parting lines define where the mold splits into two halves, and proper placement of ejector pins ensures easy and efficient part removal from the mold.

Consider the following guidelines:

Design parting lines to align with the part’s geometry and minimize the impact on aesthetics.

Strategically place ejector pins to facilitate smooth part ejection without causing damage.

By following these design considerations for moldability, you can optimize the injection molding process, reduce defects, and improve the overall quality and performance of your injection molded part.

IV. Enhancing Quality in Injection Molding process

Ensuring high quality in the injection molding process is crucial for producing parts that meet the desired specifications and performance requirements. Quality control plays a vital role in maintaining consistency, reliability, and customer satisfaction. Here’s why quality control is important and strategies to improve part quality:

1.Importance of Quality Control in the Manufacturing Process:

Quality control in plastic injection molding also involves monitoring and controlling various aspects of the production process to identify and prevent defects. It helps in achieving the following:

Consistency:

Ensuring consistent part dimensions, properties, and performance.

Compliance:

Meeting industry standards, regulations, and customer requirements.

Waste Reduction:

Minimizing material waste, rework, and scrap.

Cost Optimization:

Preventing costly quality-related issues and production delays.

2.Strategies for Improving Part Quality:

To enhance part quality in injection molding, consider the following strategies:

Robust Design:

Start with a well-designed part that considers moldability, material selection, and functional requirements. This helps minimize the risk of defects and optimize the molding process.

Process Optimization:

Optimize process parameters such as temperature, injection speed, and cooling time to achieve consistent and repeatable results. Regularly monitor and adjust process variables to maintain control over the molding process.

Mold Maintenance:

Ensure proper maintenance of the molds to prevent issues like wear, corrosion, or damage that could affect part quality. Clean and inspect molds regularly to identify and address any issues promptly.

Inspection and Testing:

Implement thorough inspection and testing procedures to detect and correct defects early in the production process. This includes dimensional checks, visual inspections, and functional testing.

Statistical Process Control (SPC):

Utilize SPC techniques to monitor process stability, identify trends, and control variation. SPC enables timely intervention to prevent quality deviations and maintain process control.

Training and Skill Development:

Invest in training programs to enhance the knowledge and skills of operators, technicians, and engineers involved in the injection molding process. Proper training ensures adherence to quality standards and promotes a culture of continuous improvement.

Supplier Collaboration:

Maintain a close relationship with material suppliers and other stakeholders to ensure the availability of high-quality materials, resolve issues promptly, and stay updated with the latest advancements in materials and technologies.

By implementing these strategies, you can enhance part quality in injection molding, reduce defects, and achieve consistent, high-quality results throughout the production process.

V. Optimizing Injection Molding Efficiency

Efficiency is a crucial aspect of injection molding as it directly impacts productivity, cost-effectiveness, and overall profitability. By optimizing the injection molding process, you can achieve higher production rates, reduce cycle times, and minimize costs. Here are some process control techniques for efficient production and factors affecting production costs along with ways to minimize them:

Process Control Techniques for Efficient Production: To optimize injection molding efficiency, consider the following techniques:

Scientific Molding:

Implement scientific molding principles to achieve precise control over process variables such as temperature, pressure, and cooling. Scientific molding techniques help in achieving repeatable and consistent results, reducing scrap and rework.

Automation:

Utilize automation technologies, such as robotics and automated systems, to streamline and speed up the production process. Automation reduces human error, improves cycle times, and enhances overall productivity.

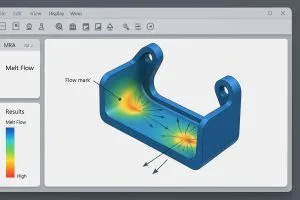

Real-Time Monitoring:

Employ real-time monitoring systems to track process parameters and detect any deviations or abnormalities. Continuous monitoring allows for timely adjustments and proactive intervention, ensuring process stability and minimizing waste.

Lean Manufacturing Principles:

Apply lean manufacturing principles to eliminate waste, reduce non-value-added activities, and optimize process flow. Techniques such as 5S, value stream mapping, and Kaizen can help identify areas for improvement and enhance overall efficiency.

2.Factors Affecting Production Costs and Ways to Minimize Them:

Several factors can influence production costs in injection molding. By addressing these factors, you can minimize costs and enhance profitability. Consider the following:

Material Selection:

Optimize material selection by considering cost-effective alternatives that meet the required specifications. Collaborate with material suppliers to explore options that offer the desired performance while minimizing costs.

Design for Manufacturing:

Design parts with manufacturing in mind. Simplify complex geometries, minimize undercuts, and eliminate unnecessary features. Designing parts that are easier to mold can reduce cycle times and material waste, leading to cost savings.

Efficient Tooling:

Work closely with mold designers and toolmakers to optimize mold design. Opt for efficient runner systems, appropriate gating, and minimize unnecessary complexity. Efficient tooling ensures faster cycle times and reduces maintenance costs.

Production Planning and Scheduling:

Implement effective production planning and scheduling techniques to maximize machine utilization and minimize downtime. By optimizing the production schedule, you can reduce idle time and increase productivity.

Energy Efficiency:

Explore energy-saving measures, such as utilizing energy-efficient machinery, optimizing heating and cooling processes, and implementing smart energy management systems. Energy-efficient practices can lead to significant cost savings in the long run.

Quality Control:

Emphasize quality control measures to minimize the risk of defects and rework. By reducing scrap and rework, you can lower material costs and enhance overall efficiency.

By implementing these process control techniques and addressing cost factors, you can optimize injection molding efficiency, reduce production costs, and increase profitability in the long term.

Conclusion

In conclusion, designing injection molded parts for maximum efficiency and performance is crucial for achieving success in the manufacturing process. By considering key factors and following best practices, you can optimize the design and production of injection molded parts. Here’s a recap of the key considerations:

Material Selection:

Choose materials based on mechanical properties, chemical resistance, heat resistance, and environmental factors. Collaborate with material suppliers for expert guidance.

Design for Moldability:

Maintain uniform wall thickness, incorporate draft angles for easy part ejection, avoid sharp corners, utilize rib design for strength, and ensure consistency in wall thickness.

Quality Control:

Implement quality control measures to maintain consistency, comply with standards, minimize waste, and optimize production costs.

Process Optimization:

Utilize scientific molding techniques, automation, real-time monitoring, and lean manufacturing principles to enhance production efficiency.

Cost Reduction:

Optimize material selection, design for manufacturing, efficient tooling, production planning, energy efficiency, and effective quality control to minimize production costs.

Efficiency and performance are key goals in injection molding. By focusing on these aspects, you can achieve higher productivity, better part quality, and cost savings. With careful consideration of material selection, moldability, quality control, process optimization, and cost reduction strategies, you can design and manufacture injection molded parts that meet or exceed the desired specifications.

Remember, collaboration with material suppliers, mold designers, and other stakeholders is crucial throughout the process. By prioritizing efficiency and performance, you can ensure successful outcomes in your injection molding projects and deliver high-quality, reliable, and cost-effective plastic parts.