Manufacturing parts through injection molding is the epitome of precision and control. With a variety of products from simple plastic toys to automotive components, pressure plays an integral role in producing these pieces with extreme accuracy.

Comprehending each type of injected pressure is key when designing or utilizing this time-tested process for successful production results.

1. Injection pressure

Injection pressure is a key element of injection molding operations. This important factor impacts the quality and consistency of products produced, so precise control over pressures applied to molten material as it enters molds is essential.

Generated by high-powered hydraulic or electric motors driving plungers or screws in cylinders, average injection pressure on this type of machinery ranges from 10k psi up to 100k psi.

The injection pressure of molten material is a complex measure, and its exact value depends on the type and viscosity of said material as well as factors surrounding the production process such as part size/shape and injection mold complexity. This important metric can be measured in either bars or megapascals (MPa).

2. Clamping pressure

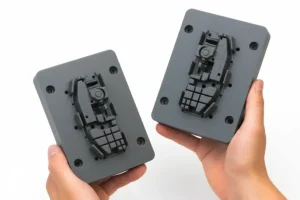

During the injection molding process, clamping pressure plays a crucial role in preventing molten material from leaking out and maintaining the desired shape of the final product.

This pivotal force is typically provided by an injection molding machine’s toggle or hydraulic mechanism – usually measured in tons or kiloNewtons (kN). Without it, precision plastic parts would not be achievable.

3. Back pressure

Back pressure plays a key role in the injection molding process, as it ensures that molten material flows correctly and consistently into the plastic part.

This boundary-pushing force is achieved by adjusting either an injection molding machine’s screw or plunger – measured precisely to produce precise qualities such as surface finish and dimensional accuracy. Through perfect application of back pressure, excellent product properties can be realized for any project!

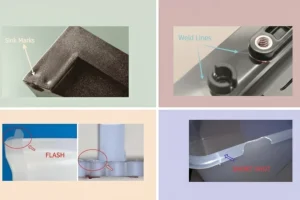

Poorly maintained back injection molding pressure can lead to a wide range of issues, from parts that are too thick and prone to instability all the way through weak filling. To ensure quality control and satisfactory outcomes, precision management is critical in this process.

4. Holding pressure

The injection molding process requires the application of four types of nozzle pressure to ensure form and structure. The fourth type, holding high force is maintained by clamping systems with a pressure ranging from tons to kiloNewtons (kN).

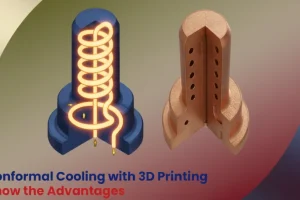

Additionally, other crucial factors like material characteristics, tool design and geometry as well as temperature/humidity are key components for successful outcomes in this intricate manufacturing process.

Conclusion

Injection molding is an intricate process – ensuring high-quality parts and products requires a carefully managed balance of temperature, pressure, and other factors. With the right understanding and control over these elements, successful injection molding operations are made possible.