The parting line of a mold is the line or plane at which the two halves of the mold meet and separate during the injection molding process.

This line is a crucial aspect of mold design, as it determines the final shape and appearance of the molded part.

There are several factors to consider when determining the parting lines of injection molds, including:

1. The shape and size of the molded part

The parting line should be located in a place where it is least visible or noticeable on the finished part.

This may mean placing the line along a natural seam or joint in the part or hiding it behind a rib or other feature.

2. The material of the molded part

Some materials may have different shrinkage rates or flow characteristics, which can affect the location of the parting line.

3. The type of molding process

Different injection molding processes, such as injection molding or blow molding, may require different suggested parting line locations due to the way the material is injected or blown into the mold.

4. The number of cavities in the mold

A multi-cavity mold will typically have a different beveled parting line than a single-cavity mold, as the cavities must be separated to allow the material to flow through the mold.

Several methods can be used to find the optimal vertical parting line for an injection mold, including:

1) Hand sketching

This involves sketching out the shape of the molded part and experimenting with different parting line locations to determine the best fit.

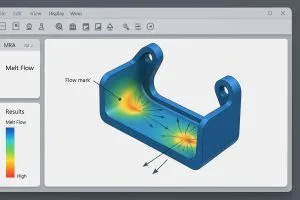

2) Computer-aided design (CAD)

CAD software can be used to create a virtual model of the molded part and simulate the injection molding process to determine the optimal parting line location.

3) Prototyping

Building a physical prototype of the injection molded parts and testing it in a prototype mold can help to identify any issues with the chosen comprehensive parting line location and make adjustments as needed.

Once the curved parting line has been determined, it is important to ensure that it is properly aligned with the mold halves to ensure a smooth and accurate plastic injection molding process.

This may involve adjusting the alignment of the injection mold halves or adding guide pins or other features to help keep them in place.

Conclusion

Overall, finding the optimal plastic parting line for a mold is a crucial aspect of the design process, as it can have a major impact on the final shape and appearance of the molded part.

By considering the shape and material of the part, the injection molding process, and the number of cavities in the mold making, it is possible to determine the best location for the suitable parting line and ensure a successful injection molding process.