Injection molding and 3D printing are the two most popular manufacturing technologies for making plastic parts. They’re also the go-to choices for design, R&D, and manufacturing. The rise of affordable 3D printing technology has given us a powerful tool for rapid prototyping and an alternative to injection molding for manufacturing plastic parts and products. Both injection molding and 3D printing are versatile, effective technologies, but there’s always one method that’s better suited for your project.

There’s a common misconception in the manufacturing world that 3D printing can replace injection molding and be the clear winner in every aspect. But both technologies have their own pros and cons. In this blog post, I’ll give you a quick overview and compare the two technologies to help you make better decisions about your work.

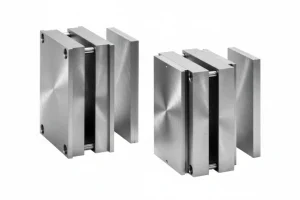

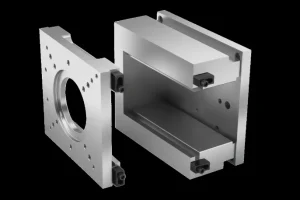

Ⅰ.Injection molding

Injection molding, also known as injection molding, is a molding method that combines injection and molding. The advantages of the injection molding method are fast production speed and high efficiency, the operation can be automated, there are many designs and colors, the shapes can be from simple to complex, and the sizes can be from large to small, and the product dimensions are accurate, the products are easy to replace, and can be made into complex shapes Parts, injection molding is suitable for mass production and complex-shaped products and other molding processing fields.

When the temperature is right, a plastic that’s all melted gets mixed up by a screw, shot into the mold with a lot of pressure, and then it cools down and gets hard and you get a part. This is a good way to make a lot of parts that are hard to make and it’s one of the big ways to make parts.

1. Advantages of Injection Molding

One of the great things about injection molding is that it can produce a lot of parts with great precision and perfect repeatability. When you use plastic injection molding, you have a lot of different materials to choose from. Each material can have thousands of different variations with additives that give them different properties. You can have different weights, costs, flexibilities, just for plasticity, and the possibilities are endless.

Injection molding allows you to make a lot of parts at the same time and make really fine details. It’s really easy to add details to injection molded parts because the process is so repeatable. Injection molding makes it really easy to make parts that are stronger. In fact, you can put fillers in the injection mold.

2. How to Use Injection Molding?

You need big machines to do this kind of manufacturing. These machines have a hopper, an injection plunger, and a heater. Making molds this way is a little expensive, and if you have to make a lot of changes to your product, you have to make a new mold every time, which can be really expensive. Since these molds are usually made out of steel, it’s a little hard to make changes and not good for making your prototype. But if you’re going to make a lot of them, this is a great way to save time and money.

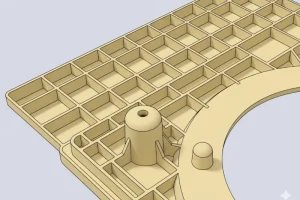

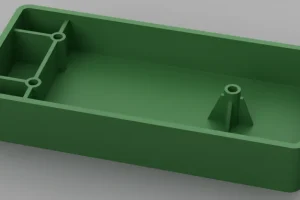

Ⅱ. 3D Printing

3D printing is a type of rapid prototyping technology, also known as additive manufacturing. It is a technology that uses adhesive materials like powdered metal or plastic to build objects through layer-by-layer printing based on digital model files.

1. Advantages of 3D Printing

There are a lot of advantages to using 3D printing, which makes it a true complement to traditional manufacturing techniques. First, 3D printing is great for product iteration. 3D printing has long been considered a rapid prototyping technology. This is no longer the case as it has also become a reliable manufacturing technology. However, quick and easy prototyping remains one of the best advantages this manufacturing technology offers.

When you use 3D printing, you print your project to test it, use 3D printing modeling software to make any changes, and then print again to see if the changes worked. This flexibility will save you time and money, but it will also help you make better products.

Using 3D printing also helps you avoid wasting materials. Compared to traditional CNC machining methods, 3D printing only uses the amount of material needed for the entire project, which reduces waste and lowers production costs. With 3D printing, you can also improve supply chain management and avoid the cost of storing extra inventory.

2. How to use 3D Printing?

Ever since 3D printing came out, there have been dozens of different types of 3D printers to choose from. If you just need to print some 3D printing filament, you can buy a 3D printer like an FDM printer. If you need better materials and better production processes, you can spend more money to buy a more professional industrial-grade 3D printer like an SLS 3D printer. The cost of buying a 3D printer depends on what you need for your project and how much money you have. If you’re developing new products really fast, it’s going to be worth it.

Ⅲ. The Difference between 3D Printing and Injection Molding

When you’re ready to start developing a new project, you need to think about the manufacturing technology you’re going to use. Whether it’s 3D printing or injection molding, you need to understand the differences between the two so you can decide which technology is best for your project. In this article, we’ll compare the production methods, manufacturing costs, application fields, and other aspects to understand all the pros and cons of injection molding and 3D printing.

1. Production Mode

Injection molding is still the best choice for traditional high-volume, large-scale manufacturing because it can produce standardized products at low cost and on a large scale as long as there are injection molds.

The 3D printer is different from the traditional injection molding process. It does not require traditional tools, fixtures, machine tools or any molds. It can directly convert any shape of the computer into a physical model automatically, quickly, directly and relatively accurately. Thanks to the large size of the 3D printer, the more complex and non-solid objects are, the faster the processing speed is and the more raw material costs are saved, so it is more suitable for the manufacturing of personalized and diversified products.

2. Manufacturing Cost

Because there are many raw materials available for injection molding, it can be produced on a large scale, quickly, and in a standardized way, which is also conducive to reducing the cost of a single product. Therefore, in terms of manufacturing costs, the cost of injection molding is much lower than that of 3D printing technology.

However, for industrial manufacturing, the real cost-saving link of 3D printing lies in modifying the prototype. Modifying the prototype only requires modifying the CAD model and does not incur any manufacturing costs.

In injection molding, if the prototype is a steel mold, the modification cost will be relatively low, but if aluminum alloy molding tools are used, the cost will be much higher. This is also the reason why many companies or individuals currently engaged in mold design choose Chuangxiang 3D 3D printers for mold design and printing.

3. Application Areas

Right now, injection molding is the way to go for making a bunch of the same thing. It’s perfect for making a lot of the same thing.

3D printing is when you put a 3D image into the computer and it prints out a real thing. You can even print out a mold or a part. It’s a fast way to make stuff. People use 3D printers to make all kinds of things, like toys, buildings, and molds.

Ⅳ. Factors to Consider When Choosing Injection Molding or 3D Printing

1. Batch Size

The number of parts you need is a big factor in deciding which process to use. Injection molding is great for high-volume production runs (over 1,000 parts per run). For small batches (less than 10 pieces), 3D printing is better and cheaper. For simple 3D printing processes like SLA or SLS, for cheap plastics, single parts or small batches (same and different), 3D printing is definitely a good choice. MJF or SLS are also a good option for medium quantities (10-1000) and are very common.

Conclusion: Injection molding is great for mass production, while for small batches, 3D printing is the way to go.

2. Design Complexity

When you want to make a part with injection molding, you have to make a mold for it. Making a CAD model for injection molding is not easy. There are a lot of things to think about. For example, if you have a right angle in your part, it is hard to get it out of the mold. If you have a delicate area, you have to be very careful with it. But if you want to make a complex part, 3D printing is great. No matter how complex your part is, 3D printing can do it.

So, if you want to make a part, check if you can make it with injection molding. If you can’t, change your part. If you can, use 3D printing.

3. Production Cycle

If you need parts right away, go with 3D printing. Injection molding takes longer because you have to design and build a perfect mold based on design analysis (10-30 days). 3D printing is much faster. You can usually get your parts made in 1-5 days, depending on the material and process requirements.

Conclusion: If you need parts immediately, choose 3D printing.

4. Customization

Once you make a mold for injection molding, it costs a lot of money and time to change it. Injection molding is not good for customizing parts or changing existing designs. What you get from the mold is what you get, and changing it is very hard. 3D printing, on the other hand, is great for customizing, and all you need is a modified or custom CAD file. So, it’s good for prototypes, test pieces.

Conclusion: 3D printing is good for prototyping and customizing.

5. Material Strength

Parts made by injection molding have a single solid layer, which makes them stronger because there are no cracks or weak spots. In 3D printing, parts are made layer by layer, which affects their overall strength. 3D printing can have visible layers or defects in the manufacturing process, which is not usually the case with plastic injection molding.

Conclusion: If material strength is a priority, choose injection molding.

6. Surface Finish

Even though the 3D printed layers are small and close together, you can still see them. This creates a stepped layering pattern on the finished object, no matter how fine the layer detail is. This can cause problems if you want to make objects that rub against other objects, such as machine parts that touch and move. In this case, you have to smooth the object after you print it, which is an extra step.

In contrast, in injection molding, you don’t have to worry about ridges and layers because the material is poured as a single layer and has an almost perfectly smooth surface finish. In addition, injection molded parts can be easily smoothed after they are made.

Conclusion: In terms of good surface finish, injection molding is the first choice.

7. Material Waste

Injection molding is very efficient because it uses exactly the same amount of material for each design. This makes it a very efficient way to mass-produce objects without fear of waste. On the other hand, some 3D printing technologies lose some material when building support structures. Even if the material powder can be reused, it can only be reused a few times, otherwise the material properties will change.

Conclusion: 3D printing creates very little waste, such as support structures, failed prints that have to be removed during post-production, but when using it to produce single units or small batches, the waste is not that important, whereas for large batches, The waste is huge. Therefore, if you want to produce in large quantities, it is better to go for injection molding as no material is wasted.

Ⅴ. Conclusion

Will 3D printing replace injection molding technology? I think a lot of people have their own answer to this question. In the short term, the current 3D printer technology is not yet capable of subverting the economies of scale of injection molding, but for the production of smaller parts, 3D printing has considerable potential. In the long run, due to different processes and different needs, unless 3D printing is faster and cheaper in the future, the two industries will exist at the same time.

When it comes to processing technology, 3D printing builds things up layer by layer. It’s a pain in the ass to do and it’s not very efficient. It’s mostly used for making fancy stuff. Injection molding uses a mold to squirt stuff into shape. It’s faster and easier to do. You can make a lot of stuff at once and it’s cheap.

When it comes to demand, 3D printing technology is more focused on cutting-edge products, like the recently hyped 3D-printed heart. Tel Aviv University in Israel used 3D printing technology to create the world’s first “complete” heart with cells, blood vessels, ventricles, and atria. “This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles, and chambers,” said Professor Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology, Department of Materials Science and Engineering, Center for Nanoscience and Nanotechnology, and Sagol Center for Regenerative Biotechnology, who was the lead researcher for the study. “People have managed to 3D-print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future.” Injection molding technology is focused on various industrial products. Most of the plastic products on the market are made using injection molding machines.

When it comes to deciding between injection molding and 3D printing, it really depends on your specific project. If you’re looking to make a lot of parts, 3D printing is going to be slower than injection molding. If you’re looking to make a lot of parts, injection molding is still the way to go. If you’re looking for quality, parts made with 3D printing don’t have the same physical properties and aren’t going to be as durable as parts made with injection molding. Finally, from a cost perspective, injection molding is going to be cheaper to make.