Commonly used elastic and thermoplastic plastics for injection molding include self-skinning, flexible, viscoelastic polyurethane foam products and injection molded thermoplastic rubber (TPR), thermoplastic elastomers (TPE), and thermoplastic urethane (TPU). TPU, or thermoplastic polyurethane, is a material that many industries love because it can be melted down and molded again like thermoplastics, but it still has elastic properties. One area where this versatile material really shines is in injection molding; nothing else offers both flexibility and toughness in quite the same way. This article delves into the fundamental properties of TPU, the injection molding process, practical applications, providing comprehensive guidance for industry professionals.

Fundamental Properties of TPU

TPU is a thermoplastic elastomer produced by the reaction of diisocyanates (such as MDI or TDI), polyether or polyester polyols, and chain extenders. It has the following key properties:

Elasticity and Flexibility

TPU is an excellent choice for items that need to be very stretchy because its elasticity is the same over a wide range of temperatures. This material can also cope well in cold conditions, it doesn’t become fragile. The tensile strength and elongation at break of TPU enable it to remain stable under mechanical stress, making it ideal for applications requiring high mechanical performance.

Abrasion Resistance

TPU has superb tear and abrasion resistance. This means it is perfect for making products that need to withstand a lot of wear and tear, like shoe soles or conveyor belts. Its abrasion resistance is not limited to ordinary use environments, TPU can maintain its physical properties even under high-intensity and high-frequency use, thereby extending the product’s lifespan.

Oil and Chemical Resistance

Particularly in settings where resistance to chemicals and oil is crucial, such as the automotive and petroleum industries. TPU can retain its integrity and functionality in harsh environments, making it a reliable choice for demanding applications.

Transparency

Due to the transparency of TPU, it is suitable for those products that need transparent material like phone cases and medical products. TPU has high transparency and high light transmission that in most cases give a clear visibility and still has high physical strength and can be made to withstand tough conditions.

Weather Resistance

With excellent resistance to UV rays and weathering, thermoplastic polyurethane (TPU) is perfect for use outdoors. Even after long periods in the sun, it does not lose its physical properties much, which means TPU-based products such as outdoor gear and building materials last a long time.

TPU in Injection Molding Processes

TPU injection molding process is alike to that of other thermoplastics but demands precise control over processing parameters and conditions because TPU has unique properties. Below is an in-depth guide to how TPU is processed using injection molding techniques:

Raw Material Preparation

TPU raw materials (thermoplastic polyurethane) are commonly in the form of tpu pellets and before injection moulding, extensive drying is often required to get rid of the moisture that might degrade the performance of the produced part. The drying temperature is normally set in the range of 80-110℃ and it takes 2-4 hours to complete the drying process to reduce the level of moisture content which likely to cause some faults as bubbles during injection process. But when the application rate is very high then vacuum drying or desiccant drying may have to be done to remove any moisture that might still be present in the material.

Injection Parameters

1. Temperature Control: TPU of course has its processing temperature range between 180-230℃. As any detail in the TPU will be in proportion to the end product, heat is another factor that may cause deterioration of the TPU’s physical properties. Hence, the control of temperature is very important in the production process, to ensure that the final product is of the right quality. One of the major disadvantage is that, TPU generally has a slightly lower melting temperature compare to many other thermoplastics and therefore requires more refined control of temperature for processing equipments.

2. Injection Speed: To prevent formation of internal stress and bubbles due to very fast injection, medium speed injection should be used. They also confirm that the means of injecting affects the speed of the reaction and the homogeneity of the filling of the mold, which improves the mechanical characteristics of the product. At very high speeds of injecting the material into the mold cavity, air is trapped within the material giving the mold a bubbly appearance.

3. Pressure Control: Both holding pressure and time should be just right in a manner to allow the products to stay dimensionally stable and have an attractive surface. High internal stress level results from too much holding pressure and instead of that if holding time is low then there will be shrinkage plus distortion. Typically, holding time depends mostly on the thickness of the product as well as the complexity of the design on it for the best outcome.

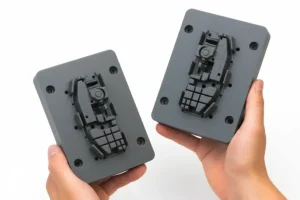

Mold Design

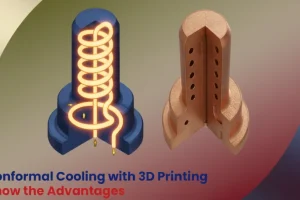

Mold design has a significant influence on the injected TPU molded goods and services. As for flowability of TPU, it is arguably good; however, it should include certain reasonable gate and runner design to avoid poor filling due to the presence of small gates or improper runner design. Besides, the collapsibility feature should be taken into consideration; the draft angle should be set correctly in order not to damage the product at the moment of demolding. Other input parameters include mold surface finish, mold temperature, the former surface finish is important in the prevention of surface defects in the product whereas mold temperature is important since it assists in uniform cooling and thus shortens the cycle time. Key Points to Consider in TPU Injection Mold Design:

1. Shrinkage rate of Molded TPU parts

This distribution depends on molding conditions for instance the hardness of the raw material, thickness of the part, the shape of the part, the temperature of molding and the mold temperature. As for the typical shrinkage range, the two important sources do not indicate a specific value of s typically ranging from 0. 005-0. 020 cm/cm. For example, a 100×10×2mm rectangular bar will thinner at the gate in the length direction, and the shrinkage in flow direction will be 2-3 folds greater when the hardness is 75A rather than 60D. As displayed in the figure one, there are the relation between of TPU hardness and part thickness with shrinkage rate. As illustrated before, for the TPU hardness ranging between 78A and 90A, the shrinkage rate of the part comes down as the thickness increases and when it ranged between 95A and 74D, the shrinkage rate slightly rise as thickness increases.

2. Runners and Cold Slug Well

The primary runner is the passage that communicants the injection molding machine nozzle to the sub-runner or cavities within the mold: this runner expands inwards at an angle of more than 2 degrees in order to ease removal of runner residues. The sub-runner in multi-cavity molds lies connecting the main runner to each cavity and they should equally spaced or balanced in the mold. Cross-section of runners can be round, semi circular, or rectangular and its ideal diameter should be between 6 to 9mm The runner surface should be polished like that of cavity of the mold to let the flow resistance of the material and to enhance the speed of filler mold.

The cold slug well is a recess located at the end of the primary channel and intended to store extra cold material generated between two shots and to prevent it from causing obstruction of the sub-runner or gate. Cold material put into the cavity can also quickly create the inner stress of the product. The cold slug well should ideally be 8-10 mm in diameter and approximately 6 mm deep.

3. Gates and Vents

The gate is identified as the passage for the main runner or the sub-runner to make a connection to the cavity. It typically possesses the cross-sectional area that is less than the runner and is actually the smallest section of the runner system; furthermore, it has to be short in length. The gate can be of any shape like rectangular and circular and dimensions depends on the thickness of the products. For products with thickness < 4mm, diameter = 1mm and for thickness 4-8mm, diameter = 1. For the wall thickness of below 8 mm, the diameter is 1. 4 mm, for thicknesses ranging between 8 mm to 4 mm the diameter is 2 and for thicknesses above 4mm is 2. 0-2. 7 mm The gate position is decided usually in the thickest part of the product that doesn’t make much impact on both the aesthetic value and function, right at the 90 degrees to the wall of mold so as to eliminate shrinkage cavity and swirl mark.

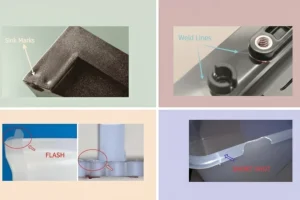

Vents are slot-shaped openings in the mold to release air within the mold cavity because its trapping is likely to cause defects such as voids, poor weld lines, or incomplete filling of the mold, and burning at the produce due to the compression of air that results in the generation of heat and in turn, causes the development of internal stress. Venting can be done at the terminal of melt flow in the cavity or on the parting surface of the mold, generally, they are 0. 15mm depth and 6mm width.

TPU Injection Molding Conditions

The TPU injection molding temperature, pressure, and time parameters at play during TPU molding hold the key to achieving proper plasticization–flowability–and cooling effects. Appearance and performance of any TPU parts made will be directly influenced by these criteria being met correctly. If everything goes as it should during processing, then end products ought all to look more or less the same: a nice even shade between white and beige.

Temperature

The parameters that can be regulated while molding TPU are barrel temperature, nozzle temperature and mold temperature. The first two largely act on the plasticization and flow of TPU, and affect the third on its flow and cooling rate.

1. Barrel Temperature: The selection of barrel temperature is based on the hardness of TPU material Is Getting 6 Higher Hardness mean the TPU has higher melting temperature and at the end of the barrel temperature will also be higher. The range of temperature for processing the barrel in TPU is 177-232 degree Celsius. The temperature distribution is normally raised gradually from the hopper side or the rear end to the nozzle or the front end to enable the tempera- ture of TPU to go up steadily for plasticization.

2. Nozzle Temperature: The nozzle temperature is ordinarily slightly lower than the highest temperature of barrel due to the reasons that there is a phenomenon of drooling when a straight through nozzle is used. However, if the self-locking nozzle is applied to protect drooling, the temperature of the nozzle is possible to be set within the scope of the highest temperature of the barrel.

3. Mold Temperature: The temperature at which the mold is set has a huge impact on the substrate characteristics and surface roughness of TPU parts. This could be affected by aspects like the degree of crystallinity of TPU and the size of the part that is being worked on. Mold temperature is commonly regulated using another cooling medium having a fixed temperature, for instance; water. In addition, apart from increased crystallinity and an initial mold temperature, higher hardness TPU has a different degree of cross-linking. For instance, Texin with hardness 480A suitable mold temperature ranges for it are between 20-30°C, hardness 591A, mold temperature is 30-50°C, while for hardness 355D the suitable mold temperature is between 40-65°C. The typical mold temperature range for TPU part is between 10-60 C. The consequence of low mold temperatures is that part of the melt solidifies before the rest of it and thus creates flow lines and restricts spherulite growth so that the material has low crystallinity. This results into post-molding shrinkage as well as variation in the performance of the part.

Pressure

Pressure or force in injection molding comprises of plasticizing pressure also referred to as back pressure and injection pressure. Cf. On withdrawal of the screw the pressure on top of the melt is the backpressure, controlled by the overflow valve. Higher back pressure increases melt temperature, decreases the plasticizing rate, provides better temperatures in the melt, helps in colorant blending, and helps in the removal of the gases present in the melts but prolongs the molding cycle. It should be noted that TPU back pressure generally varies between 0. 3-4 MPa.

Time

The time it takes to do an injection is called the molding cycle. This includes filling the mold, holding it, cooling it, and other times (like opening the mold, taking the part out, closing the mold, etc.). It affects how much work you get done and how much you use your machine. TPU molding cycles depend on how hard the material is, how thick the part is, and how complicated the part is. Harder materials take less time, thicker parts take more time, and complicated parts take more time. The temperature of the mold also affects the cycle. TPU molding cycles are usually 20-60 seconds.

Post-Treatment of Parts

Because of uneven plasticization in the barrel or different cooling rates in the mold cavity, TPU often has uneven crystallization, orientation, and shrinkage, which leads to internal stress, especially in thick-walled parts or parts with metal inserts. These parts may have reduced mechanical properties, surface silver streaks, or even deformation and cracking during storage and use. These problems can be solved by annealing the parts. The annealing temperature depends on the hardness of the TPU, with higher hardness requiring higher temperatures.

Insert Molding

To meet the strength requirements for assembly and use, TPU parts often need metal inserts. You put the metal inserts in the mold where you want them, then inject the TPU around them to make one piece. TPU parts with inserts can have problems with the TPU not sticking to the metal because the metal and TPU have different thermal properties and shrink at different rates. You can fix this by heating the metal inserts before you put the TPU on them, making the temperature difference smaller when you inject the TPU, cooling the TPU slower around the metal, making the TPU shrink evenly, and not putting too much stress on the TPU around the metal.

Recycling and Reusing Scrap

When TPU is processed, the scrap from the main runners, sub-runners, and defective parts can be recycled and reused. The experiment shows that 100% recycled material without new material blending has only a slight decrease in mechanical properties, which is suitable for use. To maintain the best physical and mechanical properties and injection conditions, the recommended recycling ratio is 25-30%. The recycled material should be the same type and grade as the new material, avoid using contaminated or annealed recycled material, and do not store the recycled material for too long. It is best to pelletize and dry it for immediate use. The recycled material generally has a lower melt viscosity, so the molding conditions need to be adjusted.

Practical Applications of TPU in Various Fields

TPU’s unique properties have led to its widespread application across numerous fields. The following are major application areas and detailed analysis:

Automotive Industry

1. Dashboards and Control Panels: Due to flexibility and abrasion resistance characteristics TPU can be use in automobiles interior parts. TPU dashboards and control panels are comfortable to the touch and can dissipate the impact energy which makes it safe. TPU materials can help sound and shake absorption for giving more comfortable driving experience.

2. Headlamp Seals: The automotive seals found in headlamp assembly must withstand weathers and be able to seal effectively. TPU can be immune to hot and cold weather conditions so that rain water cannot penetrate the headlamp of a vehicle and thus the headlamp does not wear out quickly. The nature of ultraviolet resistance of TPU prevents it from degrading or turning yellow especially when exposed to the sunshine for an extended period.

3. Bumpers: Today TPU is immensely known for its application in automotive industries particularly in the production of bumpers. It has good elasticity in that it can under take and absorb a lot of energy during impacts thus protecting the vehicles. This also increases the durability of the bumper because of its excellent abrasion resistance. TPU protective bumpers are favorable to the car due to the reduction in vulnerability to pedestrians and other cars hence increasing the safety.

Medical Industry

TPU is mostly utilized in medical appliances and items that are utilized once then discarded in medical fields. This makes it to be appropriate for manufacturing of catheters, infusion tubes, surgical gloves among other items that has to be biocompatible and easily sterilized. Here are some specific applications:

1. Medical Catheters: They are highly flexible and biocompatible thus can be used for a long time within the body and yet does not cause any reaction. TPU catheters do not react chemically with fluids entering the catheter or become compromised mechanically in a wide variety of medical circumstances and do not cause patient discomfort.

2. Surgical Gloves: TPU gloves are soft and tough, so while doing surgeries surgeons are very flexible and comfortable and they do minimize the bacterial contamination. TPU gloves are puncture resistant and chemical resistant; thus safer and more reliable during surgeries.

3. Infusion Tubes: TPU does not change its properties under an infusion and does not interact with the reagents, which is very important in the process of infusions units production. TPU infusion tubes used in the current surgical operations does not support the adhesion of blood and drugs hence reducing possibility of formation of infection.

Electronics and Electrical Industry

1. Phone Cases: TPU is mainly the case as it has to be transparent as well as having abilities to hold an impact. TPU cases also provide guarding to the phones from damages such as those that occur from dropping the phone and at the same time give the look and feel of the phone. It is versatile in terms of the color and design as per the requirements and it involves the use of TPU materials.

2. Cable Jackets: Because of TPU’s high abrasion and oil resistance, it is widely used in cable jackets applications. TPU jackets help to accelerate condition changes in difficult climates for cables, therefore, increasing their durability. TPU materials are still flexible when subjected to high or low temperatures making these to be appropriate for use in the industrial sector.

Footwear and Textiles

1. Sports Shoe Soles: Due to the properties of elasticity and strong abrasion resistance, TPU is more suitable for the soles of sports shoes. TPU soles are also light in weight and very strong, which guarantee enough cushioning while doing sport activities and makes shoes very comfortable to wear. It implies that the TPU materials can be produced in different sole structures to conform to the various sports requirments.

2. Functional Textiles: TPU films are used universally with waterproof as well as breathable material that is worn in occasions like outdoor sports and by the military. TPU films are used for waterproof films with breathability, suitable for many severe conditions. TPU material also has the characteristic of waterproof and breatheability even in such environment of high humidity and high stress.

Conclusion

Due to better properties possessed by TPU it is widely used in injection molding industry. Ever evolving technologies and mastering of injection molding and its processing problems, TPU’s fields of application will further widen. In the future the place of TPU in the process of injection molding will become useful, when new technologies and customer’s demand will increase, offering high performance in different fields.

Based on the knowledge of TPU’s basic characteristics, injection molding technology, application and processing, problems and countermeasures, as well as future development and trends, this paper will be beneficial to the wider application of this high-performance material in the injection molding area and create more possibilities for the development of this field. With this article published, these practitioners could be of incorporation and use of TPU as they work to advance injection molding.