Introduction: In industry, we need different core and surface properties for many applications. We can’t get that with just one material. So, we layer one material on top of another through secondary molding. But what is secondary molding? Can we use flexible material combinations? How well do these materials integrate?

In this article, we’ll look at the plastic secondary molding process, mold design considerations, and its many applications.

What is S**econdary Molding**?

secondary molding is a fancy way of saying two-shot molding. It’s a process where two or more components are molded one on top of the other.

What are the S**econdary Molding Process Steps?**

secondary molding operations are completed in the following steps .

Material Selection

The most important part is choosing the material. You need to choose a material that meets the physical requirements of the product, both inside and outside.

You need to think about what the product is going to be used for, like if it needs to be comfortable or if it needs to absorb shock, or if it needs to be waterproof or heat resistant. The materials themselves need to be bonded together so they don’t come apart after you mold them.

Mold Design and Setup

The mold design must accommodate the properties and thickness of the two materials, which requires different considerations than a standard mold. Wall thickness should be uniform (no more than 4 mm) and gates need to be placed in the thickest part of the wall. Flow ratio needs to be kept below 150/L.

Like other injection molds, secondary molding is CNC machined and made of durable metals such as steel or aluminum to withstand the pressure and temperature of the injection molding process.

Injection Molding Setup

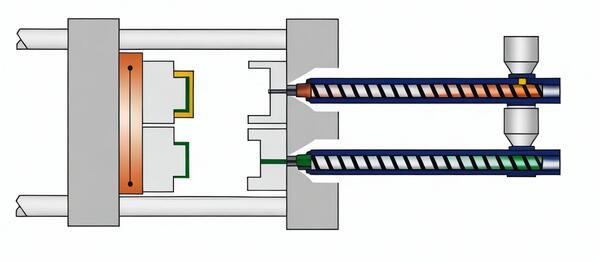

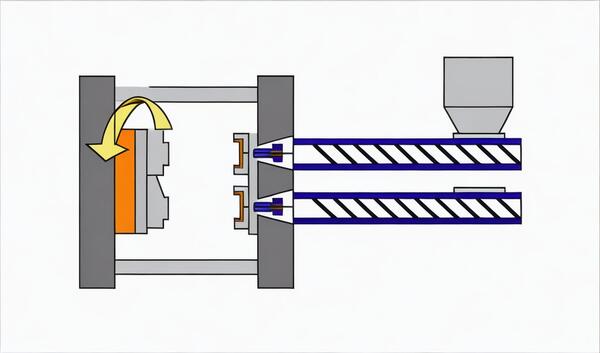

The setup is custom designed based on the materials and their layering sequence. For two-material secondary molding, the setup may use multiple injection units. These units are configured to rotate the mold so that each injector can accurately deposit its respective material.

First, the unit lays down a layer of base material. After it cools, you have a rigid overmolded substrate. Then, another injector adds material on top of it. In some cases, the substrate is made separately in one unit and then the elastomer layer is injected.

Ejection and Inspection

Once the molding process is done, the part is taken out of the mold. We then check the part for any defects like incomplete bonding, air pockets, or surface defects.

Post-Processing

The process gives you a solid part that is a combination of all the materials you put in. But you may need to do some post-processing. For example, you might need to trim off extra material, polish it to make it look nice, or cure it more to make it stronger. The goal is to get the part to look and work the way you want it to.

What are the Common Materials for S**econdary Molding**?

Polycarbonate (PC)

PC is super tough and clear. It’s used for bulletproof windows and protective gear. It’s strong and lasts a long time, and it doesn’t fade. But it scratches easily and gets messed up and turns yellow if it’s out in the sun for a long time.

Polyethylene (PE)

PE has a wide range of applications, from plastic bags to high-strength containers. When it comes to secondary molding, HDPE and LDPE offer a variety of options from rigid structures to flexible parts.

High-density polyethylene is strong, durable, and resistant to chemicals. It’s used to make storage bottles, toys, and anything that needs to be stiff and tough. But it burns easily and doesn’t do well in the sun.

LDPE is softer and more flexible than HDPE, which makes it great for things like squeeze bottles and packaging films. It’s also resistant to acids, alkalis, and vegetable oils, which makes it perfect for food packaging. The main downsides to LDPE are that it doesn’t handle high temperatures well and it’s not very puncture resistant.

Polypropylene (PP)

PP also has excellent chemical resistance and mechanical properties. Common applications include automotive parts, consumer goods, and living hinges, which require repeated flexing. Its chemical resistance makes it a good choice for hygienic applications. However, PP has moderate resistance to UV rays and requires additives to stabilize it in outdoor applications.

Acrylonitrile-Butadiene-Styrene (ABS)

ABS is a tough, versatile thermoplastic used in a wide range of industries. It has excellent impact resistance, good thermal stability, and a smooth surface finish. ABS is easy to mold and paint – a material best suited for aesthetic applications. However, it is not resistant to chemicals.

Thermoplastic Polyurethane (TPU)

TPU is a versatile material that combines the best features of rubber and plastic. It’s durable, flexible, and abrasion-resistant, making it perfect for applications that require a soft touch, like phone cases, seals, and gaskets. It’s also oil resistant and bonds well to plastics like PC and ABS. The only downside is that it’s expensive.

Thermoplastic Elastomers (TPE)

TPEs are a type of copolymers (polymer blends, usually plastic and rubber) that combine the mechanical and thermal properties of thermoplastics with the elasticity of elastomers. They are good for secondary molding applications that need a soft grip, like toothbrush handles, tool handles, and personal care products.

What are Some Secondary Molding Design Tips?

When you make a mold, there are a lot of things to think about. Here are some tips to help you make a good mold .

Understand Material Properties

The main idea of using molding technology is to design a plastic part with the properties you want. So, choose materials based on that. But make sure to think about how they work together and their physical properties, like how hot they get and how much they expand.

Since the two materials are different, the melting temperature and coefficient of expansion may not be similar. Some resins shrink when they settle, which can cause warping. To address this issue, it is recommended to use a core component (substrate) with a higher flexural modulus and melting temperature than the secondary material.

Thickness is also important. Thicker elastomer (TPE) layers provide shock absorption and softness. Conversely, thin layers feel stiffer and are the choice for ribbed structures.

Optimize Part Geometry and Molds

The mold design has to be able to make a lot of parts, so the walls have to be the same thickness, between 1/16 and 1/8 inch. Don’t make the ribs too deep or the corners too sharp, because that makes the plastic too hard to flow.

The corners that are supposed to be sharp should be less than 1/64 inch. Usually, you need to have 1 degree of angle for every inch of depth to get the part out of the mold.

Enhance Bonding

The materials should blend perfectly at the molecular level through chemical bonds. For the best bonding, the contact temperature should be close to the melting point of the material.

If you can’t bond chemically, you can bond mechanically by interlocking. Another option is to texture the substrate so that the resin fills the gaps and sticks.

Design for Manufacturability

When you’re making stuff, you want to make it as simple as possible. You want to make it as easy as possible to make the parts, to make more of them, and to put them together. One way to do that is to make fewer parts so you have fewer steps to put them together.

Another way is to use computers to help you figure out how to make the mold and how to make the parts before you start making them. You can use the computer to figure out where the plastic is going to go and where it’s not going to go. If you don’t have enough plastic in one place, it’s going to be weak.

Another important thing is the material selection. The materials you choose have to not only do the job, but also work well together.

For example, let’s say you’re designing a handle for a power tool. You need something that’s rigid on the inside, but soft and grippy on the outside. You could design it with a hard plastic core made of ABS for strength, and then wrap it in a softer, more comfortable, and slip-resistant material like TPE.

Post-Processing Planning

Get ready to do whatever you need to do to make it look good. You might need to cut it, sand it, or paint it. You might need to do something else to it, like make it UV resistant or fire resistant.

What are the Benefits of S**econdary Molding**?

Manufacturers who need design, grip, and a cool look love what secondary molding does for their products. It’s also cheap and has gotten better over the years, so customers love it. Here’s why you should use secondary molding.

Enhanced Product Durability

secondary molding is when you add another material to protect the main part from getting beat up or messed up by the environment. Like when you have a waterproof camera and they put a rubber seal around the outside to keep the water and dust out.

Improved Aesthetics and Ergonomics

It can make a product more comfortable to use by adding curves and soft handles that fit the way people hold things. For example, kitchen gadgets like blenders have handles that are made with a soft, rubbery material that makes them easier to hold and more comfortable to use.

Material Efficiency

When you combine two materials in one mold, you get one part. When you design each material separately, you use more material and create more waste when you process it.

Functional Integration

Remote controls use secondary molding to integrate soft buttons that are responsive and comfortable to press. Similarly, power tools have a solid plastic grip area that makes it easier to hold and use these tools.

Enhanced Performance

secondary molding is a way to combine different materials to make parts that are better than parts made of one material. For example, they put soft plastic on the inside of dashboard controls to make them feel better and last longer.

What are the Limitations of S**econdary Molding**?

The process is great in many ways, but there are some limitations .

Material Combinability Issues

Not all stuffs are good for sticking. If you stick them together, they won’t stick well. The thing you make will break when you push on it because it’s not stuck together good.

Increased Manufacturing Complexity

secondary molding is a process that requires multiple injections and can involve different materials, which means you need complex tooling designs. This complexity means longer cycle times and specialized machines.

Higher Initial Cost

The process has a higher upfront cost because you need multiple material stocks and specialized secondary molding tools for each material. So, the cost per unit is also higher.

Design Constraints

secondary molding is a bit of a buzzkill when it comes to part design and material selection. Some shapes and materials just don’t get along because they have different melting points and mechanical properties.

What Are S**econdary Molding Applications?**

Manufacturers use secondary molding and insert molding to produce products for a wide range of industries. Below are some examples of products that are often made using one or the other process or a combination of both.

Consumer Products

Look around your house and you’ll probably see a bunch of plastic stuff that’s all one piece and comes in different colors. Chances are, those things were made using secondary molding. This is a really common way to make all kinds of stuff, from bowling balls and kids’ game blocks to storage bins and plastic containers.

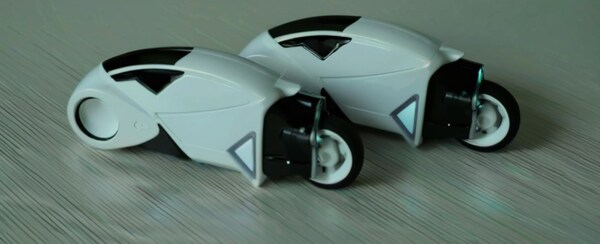

Toothbrushes, cell phone cases, and USB sticks are often made using secondary molding. secondary molding can be used to create a variety of two-tone plastic furniture, such as step stools or lounge chairs. Plastic housings for GPS units and navigation devices often require secondary molding.

Automotive Industry

secondary molding is used to make strong, two-tone interior parts like doors and dashboards, handles, knobs, and various controls.

Appliance Industry

Sometimes, manufacturers put a layer of rubber on wire assemblies to make things like headphones and computer chargers safer. Sometimes they need to put a layer of rubber around more than one wire, and sometimes they need to separate the wires and make them different colors, like blue and red.

Beauty Industry

In this industry, we use secondary molding a lot to make cosmetic packaging look better. You can make custom packaging with different materials and colors. You can make loose powder bottles, makeup brushes, and perfume bottles with secondary molding.

Conclusion

Secondary molding is a multi-step injection molding process that gradually injects different materials to meet specific performance requirements. The process includes material selection, mold design, injection molding settings, and post-processing.

Common materials include polycarbonate, polyethylene, and polypropylene, which are suitable for a variety of applications. The advantages of secondary molding include improved durability and aesthetics, but there are also limitations such as material compatibility and higher initial costs. It is widely used in industries such as consumer goods, automobiles and appliances.