Vertical farming is revolutionizing agriculture by enabling crops to be grown in Vertical farming is revolutionizing agriculture by enabling crops to be grown in stacked layers, often in controlled indoor environments. This innovative approach tackles challenges like land scarcity, resource efficiency, and urban food production. At the heart of vertical farming’s success are manufacturing processes such as vacuum forming1 and extrusion, which create critical components like seed trays, structural frames, and irrigation systems. These technologies enhance the physical infrastructure while boosting the sustainability and efficiency of vertical farming systems.

Vacuum forming and extrusion2 are pivotal in vertical farming, producing lightweight, durable components that optimize space, support plant growth, and improve resource use.

Understanding these processes is essential for designing and implementing effective vertical farming solutions. Read on to explore how they work, their applications, and how they compare in this cutting-edge agricultural field.

Vacuum forming and extrusion enhance sustainability in vertical farming.True

These processes use recyclable materials and reduce waste, aligning with the eco-friendly goals of vertical farming.

Extrusion is only used for irrigation pipes in vertical farming.False

While irrigation pipes are a key application, extrusion also produces structural frames and shelves for vertical setups.

What is Vacuum Forming and Extrusion in Vertical Farming?

To grasp their significance, let’s define vacuum forming and extrusion and classify their roles in vertical farming.

Vacuum forming shapes plastic sheets into trays and containers for plant holding, while extrusion creates continuous shapes like pipes and frames for structural support and irrigation in vertical farming systems.

| Process | Definition | Common Materials | Applications in Vertical Farming |

|---|---|---|---|

| Vacuum Forming | A thermoforming process where a heated plastic sheet is shaped over a mold using a vacuum and cooled. | PET, PVC, HDPE | Trays, containers for hydroponic/aeroponic systems |

| Extrusion | A process forcing material through a die to create continuous shapes like pipes or profiles. | PVC, stainless steel | Irrigation pipes, structural frames, racks |

Vacuum Forming in Vertical Farming

Vacuum forming heats a plastic sheet until pliable, then uses a vacuum to mold it over a form, creating components like trays for hydroponic or aeroponic setups. These trays ensure proper drainage and root support, vital for plant health in controlled environments.

Benefits of Vacuum Forming

- Cost-Effective for Small Runs: Lower tooling costs than injection molding, ideal for prototyping or small batches.

- Customization: Easily adapts to different shapes, accommodating diverse crops or farm designs.

- Lightweight and Durable: Parts withstand humid conditions while remaining easy to handle.

Design Checklist for Vacuum Forming

- Ensure proper drainage and aeration in tray designs.

- Match cell size and depth to the plant’s root system.

- Select safe, durable materials suitable for the farm’s environment.

Extrusion in Vertical Farming

Extrusion pushes materials through a die to produce uniform shapes such as irrigation pipes and structural frames. These components deliver water and nutrients efficiently and provide the strength needed to support stacked farming layers.

Benefits of Extrusion

- High Production Speed: Continuous output suits large-scale farms.

- Material Efficiency: Minimal waste enhances sustainability.

- Strength: Provides robust support for multi-tiered growing systems.

Design Checklist for Extrusion

- For pipes: Confirm diameter and length align with irrigation flow and pressure requirements.

- For frames: Verify the profile supports the weight of plants, lighting, and equipment.

- Ensure material compatibility with humidity and temperature conditions.

Comparison Table

| Process | Applications in Vertical Farming | Materials Used | Advantages | Challenges |

|---|---|---|---|---|

| Vacuum Forming | Plant trays, containers | HDPE, PVC, PET | Customizable, cost-effective | Thickness uniformity issues |

| Extrusion | Irrigation pipes, frames | PVC, stainless steel, biodegradable resins | Strong, consistent, scalable | High initial setup costs |

Process Selection Guide

- Choose Vacuum Forming: For hollow, complex shapes like trays or containers.

- Choose Extrusion: For long, uniform components like pipes or beams.

Vacuum forming is ideal for creating custom trays tailored to specific plant types.True

It allows trays with varying cell sizes and depths, optimizing conditions for different crops.

Extrusion is only used for plastic components in vertical farming.False

While plastics are common, extrusion also produces metal components like stainless steel frames for added strength.

What are the Common Materials Used in Vacuum Forming and Extrusion for Vertical Farming?

The materials chosen for vacuum forming and extrusion are critical to creating components that are functional, durable, and safe for vertical farming environments.

Vacuum forming typically uses thermoplastics like PET, HDPE, and PVC, while extrusion employs plastics such as PVC and PE, and occasionally metals, for their durability and compatibility with farming needs.

| Material | Process | Key Properties | Applications in Vertical Farming |

|---|---|---|---|

| Polyethylene Terephthalate (PET)3 | Vacuum Forming | Clarity, strength | Seed trays, planting systems |

| High-Density Polyethylene (HDPE)4 | Vacuum Forming | Durability, moisture resistance | Irrigation components |

| Polyvinyl Chloride (PVC)5 | Extrusion | Rigidity, chemical resistance | Frames, pipes |

| Aluminum | Extrusion | Lightweight, corrosion-resistant | Structural frames |

| Steel | Extrusion | Strength, durability | Heavy-duty supports |

Thermoplastics in Vacuum Forming

Thermoplastics are favored in vacuum forming for their ability to be heated and reshaped. Common options include:

- Polyethylene Terephthalate (PET): PET is a lightweight, recyclable thermoplastic used in vacuum forming to create seed trays. Its clarity and flexibility make it ideal for customizing planting components.

- High-Density Polyethylene (HDPE): HDPE is a versatile material used in both vacuum forming and extrusion. Its durability and moisture resistance suit it for seed trays, irrigation parts, and structural profiles.

- Polyvinyl Chloride (PVC): PVC is widely used in extrusion for pipes and frames due to its corrosion resistance and strength, ensuring longevity in humid vertical farming conditions.

Plastics and Metals in Extrusion

Extrusion accommodates a wider material range, including:

- Plastics: PVC and HDPE provide corrosion resistance and lightweight properties, ideal for frames and pipes.

- Metals: Aluminum and steel offer strength and longevity, used in structural frames and heavy-duty supports.

- Stainless Steel:Extruded stainless steel frames provide unmatched strength and durability, supporting the stacked layers of vertical farms. Its corrosion resistance ensures longevity in humid environments.

These materials are selected for their compatibility with plant growth, resistance to environmental factors, and sustainability, making them foundational to vertical farming success.

HDPE is a preferred material for both vacuum forming and extrusion.True

Its durability and safety for plant contact make it ideal for diverse components in vertical farming.

Metals are the primary materials for extrusion in vertical farming.False

Plastics like PVC and PE are more common due to their cost-effectiveness and corrosion resistance, though metals are used for specific structural needs.

What are the Steps in the Vacuum Forming and Extrusion Processes for Vertical Farming?

These processes are meticulously designed to produce components that meet the precise demands of vertical farming systems.

Vacuum forming heats and shapes plastic sheets into lightweight parts like seed trays, while extrusion forces molten material through a die to create continuous profiles like frames and pipes.

Vacuum Forming Process

- Design Mold: Craft a mold tailored to the component, such as a seed tray with specific cell sizes.

- Select Material: Choose a thermoplastic sheet (e.g., HDPE) for its durability and safety.

- Heat Sheet: Warm the plastic to a pliable state, typically 150-200°C.

- Apply Vacuum: Use vacuum pressure to shape the sheet over the mold.

- Cool and Trim: Cool the formed part and remove excess material.

Extrusion Process

- Design Die: Create a die for the desired profile, like a pipe or frame.

- Prepare Material: Heat plastic pellets or metal ingots to a molten state.

- Force Through Die: Push the material through the die to form a continuous shape.

- Cool and Cut: Cool the extruded profile and cut it to length.

These steps ensure efficient production of high-quality components tailored to vertical farming needs.

Vacuum forming produces parts with consistent thickness.False

Thickness can vary due to stretching over the mold, depending on design and material.

Extrusion is optimized for continuous production.True

Its design allows for uninterrupted creation of long profiles, ideal for pipes and frames.

What are the Key Factors in Vacuum Forming and Extrusion for Vertical Farming?

Several factors determine the effectiveness of these processes in producing reliable vertical farming components.

Key factors include material selection6, temperature control7, and process parameters8, which influence durability, functionality, and cost.

Material Selection

Materials must be heat-formable (for vacuum forming) or extrudable (for extrusion) and safe for plants. Thermoplastics like HDPE and PVC are chosen for their performance and safety.

Temperature Control

Precise heating in vacuum forming ensures pliability without degradation, while in extrusion, it affects material flow and final properties.

Process Parameters

Vacuum pressure (in forming) and extrusion speed (in extrusion) must be fine-tuned to achieve the desired thickness, strength, and shape.

Mold and Die Design

Molds in vacuum forming need draft angles for easy release, while extrusion dies define the shape and consistency of continuous profiles, affecting final quality.

| Factor | Vacuum Forming Impact | Extrusion Impact |

|---|---|---|

| Material Choice | Affects durability, cost | Influences strength, eco-friendliness |

| Design Precision | Mold shapes tray functionality | Die dictates profile uniformity |

| Temperature | Impacts thickness consistency | Affects density and strength |

These factors ensure components meet the rigorous demands of vertical farming environments.

Temperature control is critical for successful vacuum forming.True

Proper heating ensures the plastic forms correctly without losing integrity.

Process parameters have no impact on extrusion outcomes.False

Parameters like speed and pressure directly affect the quality and consistency of extruded profiles.

What are the Applications of Vacuum Forming and Extrusion in Vertical Farming?

These processes support diverse functions in vertical farming, from plant growth to structural stability.

Vacuum forming creates lightweight, customizable components like seed trays and irrigation systems, while extrusion provides durable profiles for structural frames and pipes.

Applications of Vacuum Forming

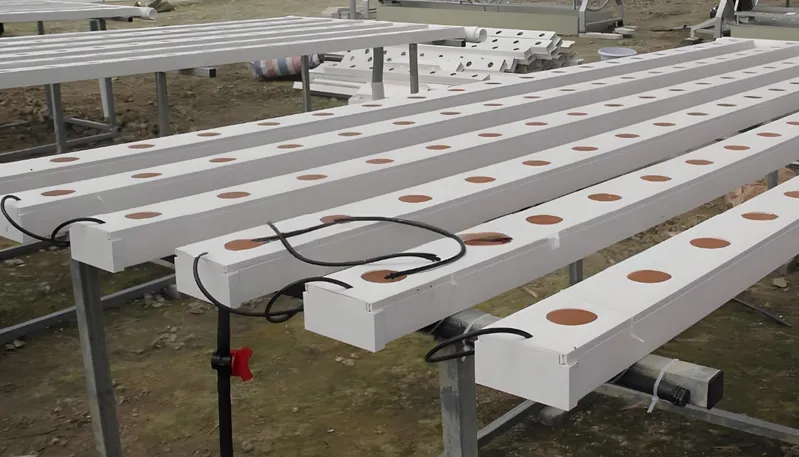

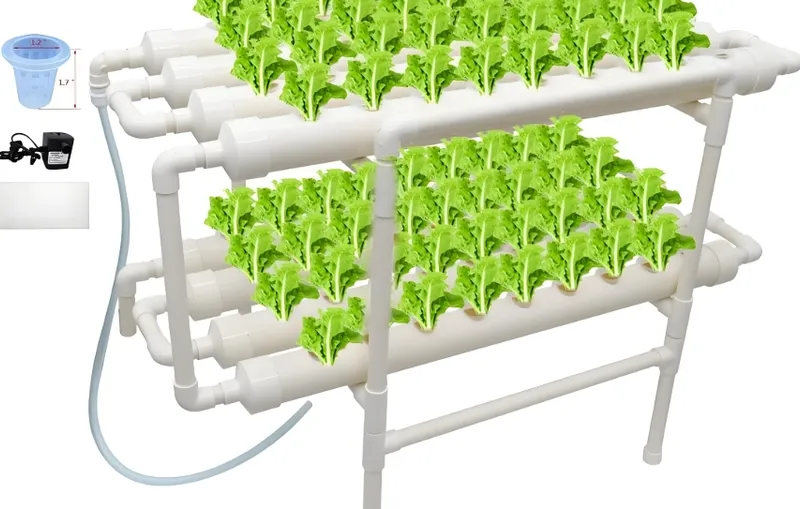

- Seed Trays: Vacuum forming crafts lightweight, customizable seed trays for hydroponic and aeroponic setups, enhancing germination and space use.

- Planting Systems: Hydroponic and aeroponic components for efficient nutrient delivery.

- Irrigation Components: Vacuum forming produces precise water delivery parts, while extrusion creates pipes and channels for efficient irrigation.

Applications of Extrusion

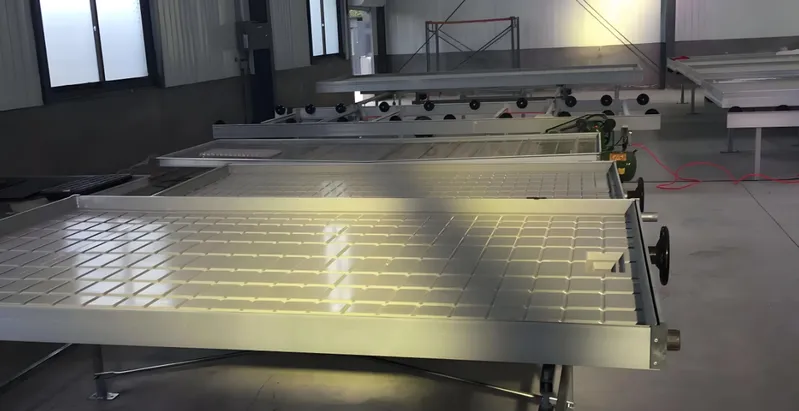

- Structural Frames: Extrusion delivers durable frames and shelves, supporting the multi-layer structure of vertical farms.

- Irrigation Pipes: Pipes for nutrient and water distribution across layers.

- Shelving: Strong, lightweight shelves for plants and equipment.

These applications underscore the versatility of both processes in vertical farming.

Vacuum forming is vital for customizing planting components.True

Its ability to shape complex designs meets diverse planting needs.

Extrusion is limited to structural applications in vertical farming.False

Beyond structures, extrusion also supports irrigation systems with pipes and channels.

What are the roles of vacuum forming and extrusion in vertical farming?

What is the Role of Vacuum Forming in Vertical Farming?

Vacuum forming is a key process in vertical farming, creating custom components that support plant growth in controlled settings.

Vacuum forming produces lightweight, durable trays and containers for plants, ensuring proper drainage and support in hydroponic and aeroponic systems.

| Process | Typical Applications in Vertical Farming | Materials Used |

|---|---|---|

| Vacuum Forming | Plant trays, containers | PET, PVC, HDPE |

| Extrusion | Structural frames, irrigation pipes | PVC, stainless steel |

- Custom Plant Trays: Vacuum forming excels at producing trays tailored to specific plant types, with adjustable cell sizes and depths for optimal growth. These trays are lightweight, durable, and moisture-resistant, making them ideal for hydroponic or aeroponic setups. Companies like DitaiPlastic emphasize its role in sustainable agriculture (Vacuum Forming in Agricultural Applications).

- Material Efficiency:Vacuum forming minimizes material waste, lowering costs and environmental impact. It offers precise control over tray design, ensuring adequate drainage and aeration for plant roots.

Vacuum forming is cost-effective for small to medium production runs.True

The process allows for quick prototyping and customization, making it ideal for vertical farming applications.

Vacuum forming cannot be used for large components in vertical farming.False

While typically used for smaller parts, vacuum forming can be scaled for larger trays with appropriate equipment.

What is the Role of Extrusion in Vertical Farming?

Extrusion is vital in vertical farming, producing structural and functional components that underpin system design and operation.

Extrusion creates continuous shapes like pipes and frames, providing structural integrity and efficient fluid delivery in vertical farming systems.

- Irrigation Pipes9: Extrusion manufactures pipes for irrigation, ensuring consistent water and nutrient delivery. Materials like PVC are favored for their flexibility and corrosion resistance.

- Structural Frames: Extruded profiles, made from metal or plastic, form the backbone of vertical farming racks, supporting stacked plant layers. Stainless steel is often used for its strength and durability.

Extrusion is efficient for producing long, uniform components.True

The process allows for continuous production of pipes and frames, reducing costs at scale.

Extrusion is unsuitable for custom shapes in vertical farming.False

While typically used for uniform profiles, custom dies can be created for unique shapes.

What are the Differences Between Vacuum Forming and Extrusion in Vertical Farming?

The distinctions between these processes guide their use in specific vertical farming applications.

Vacuum forming excels at creating lightweight, complex shapes, while extrusion is ideal for durable, continuous profiles.

Both processes are vital to vertical farming but serve distinct purposes:

- Vacuum Forming: Excels at producing lightweight, custom plastic parts like seed trays, offering cost-effectiveness for high-volume production.

- Extrusion: Ideal for strong, continuous profiles like frames and pipes, providing structural support and durability.

| Aspect | Vacuum Forming | Extrusion |

|---|---|---|

| Material Options | Primarily plastics | Plastics and metals |

| Shape Complexity | High (custom shapes) | Moderate (continuous profiles) |

| Production Volume | High-volume, cost-effective | High-volume, higher initial costs |

| Applications | Seed trays, irrigation parts | Frames, shelves, pipes |

| Process Type | a forming process shaping heated sheets | a shaping process producing continuous profiles |

| Customization | high shape flexibility for unique parts | standardization for long, uniform components |

These differences help determine the best process for each project’s needs.

Vacuum forming is more customizable than extrusion.True

It allows for intricate, tailored shapes, unlike extrusion’s focus on continuous profiles.

Extrusion is less cost-effective than vacuum forming for large runs.False

Extrusion’s continuous nature makes it highly cost-effective for mass production of standard parts.

What Makes Zetar Mold a Top Choice for Vertical Farms?

Zetar Mold, officially Zetar Industry Co., Limited. Capable of producing parts up to 5100g, Zetar Mold holds certifications like ISO9001101, TS16949, and ISO14001, ensuring compliance with international quality standards.With over 16 years of experience, they’ve earned a reputation for producing high-precision, custom plastic parts for a variety of sectors, including agriculture.

For vertical farms, Zetar Mold provides custom-designed plastic components such as growing trays, pots, irrigation systems, and structural parts, all of which are critical for optimizing space, water usage, and crop yield in stacked farming environments.

The partnership between Zetar Mold and America’s leading vertical farm focuses on delivering custom plastic solutions to optimize vertical farming systems. Zetar Mold provides extrusion solutions for vertical farming, creating lightweight, durable plastic components like grow trays, irrigation pipes, and structural supports, enhancing system efficiency.

Zetar Mold has earned its reputation in the vertical farming industry by delivering tailored solutions that meet the unique demands of controlled environment agriculture.

Zetar Mold is favored for its precision, durability, and cost-effective custom plastic components11, essential for optimizing vertical farm operations.

| Aspect | Zetar Mold’s Advantage | Industry Impact |

|---|---|---|

| Precision | Exact component specifications | Consistent growing conditions |

| Durability | Long-lasting materials | Lower maintenance costs |

| Customization | Tailored designs for specific needs | Enhanced operational efficiency |

Precision and Quality

Vertical farms need components that integrate seamlessly into their complex systems. Zetar Mold’s expertise in Plastic extrusion and vacuum forming ensures that parts like growing trays and irrigation fittings meet precise specifications. This accuracy maintains uniform growing conditions, boosting crop yield and quality.

Durability and Reliability

The harsh conditions of vertical farms—constant moisture and temperature fluctuations—demand resilient components. Zetar Mold’s durable products withstand these challenges, minimizing replacements and ensuring long-term performance.

Zetar Mold holds certifications like ISO9001 and ISO14001, reflecting their commitment to quality and environmental standards. For vertical farms focused on sustainability, this assurance of durable, eco-friendly components is a significant draw.

Experience and Reputation

With over 16 years in the industry, Zetar Mold brings a wealth of expertise to the table. Their long-standing reputation for reliability ensures that vertical farms receive consistent, high-quality components critical for uninterrupted operations.

Cost-Effectiveness

Based in China, Zetar Mold offers competitive pricing compared to US-based manufacturers. This cost advantage is crucial for vertical farms, particularly startups or those scaling up, as it allows them to allocate resources efficiently without compromising quality.

Customization for Specific Needs

Each vertical farm has distinct requirements based on its layout, crop types, and automation level. Zetar Mold’s ability to customize solutions optimizes infrastructure, whether for compact designs or automated systems.

Conclusion

Vacuum forming and extrusion are indispensable in vertical farming, providing lightweight, durable, and sustainable components that drive efficiency and innovation. By mastering these processes, farmers and designers can optimize vertical systems for a greener future.

- Explore this link to understand the vacuum forming process and its critical role in creating efficient vertical farming components. ↩

- Learn about extrusion’s significance in vertical farming and how it contributes to sustainable agricultural practices. ↩

- Explore the advantages of PET in vertical farming, including its recyclability and suitability for seed trays, enhancing sustainability. ↩

- Learn how HDPE’s durability and moisture resistance make it essential for irrigation components and structural profiles in vertical farming. ↩

- Discover the role of PVC in creating durable frames and pipes, ensuring longevity in humid environments crucial for vertical farming. ↩

- Exploring this resource will provide insights into optimal materials that enhance durability and safety in vertical farming. ↩

- Understanding temperature control is crucial for ensuring the quality and performance of vertical farming components; this link will deepen your knowledge. ↩

- This resource will help you grasp the essential process parameters that influence the efficiency and effectiveness of vertical farming systems. ↩

- Learn about the manufacturing process of irrigation pipes and their importance in efficient nutrient delivery. ↩

- Understand the importance of ISO9001 certification in ensuring quality and reliability in manufacturing processes. ↩

- Explore how custom plastic components can enhance efficiency and sustainability in vertical farming systems. ↩