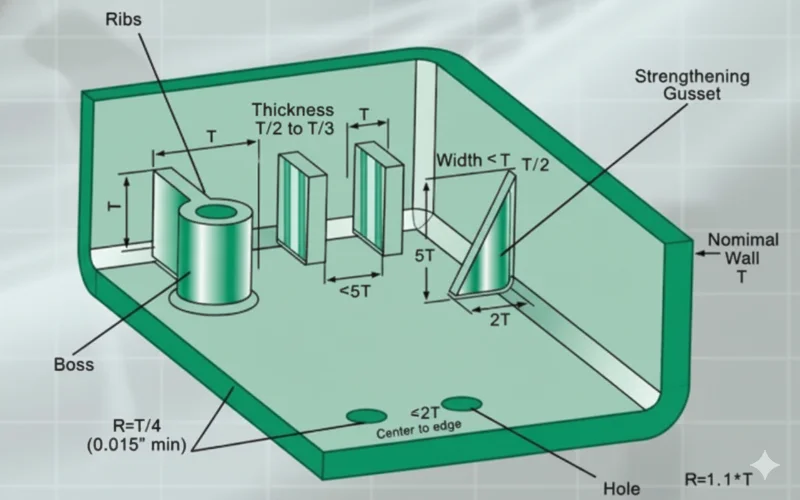

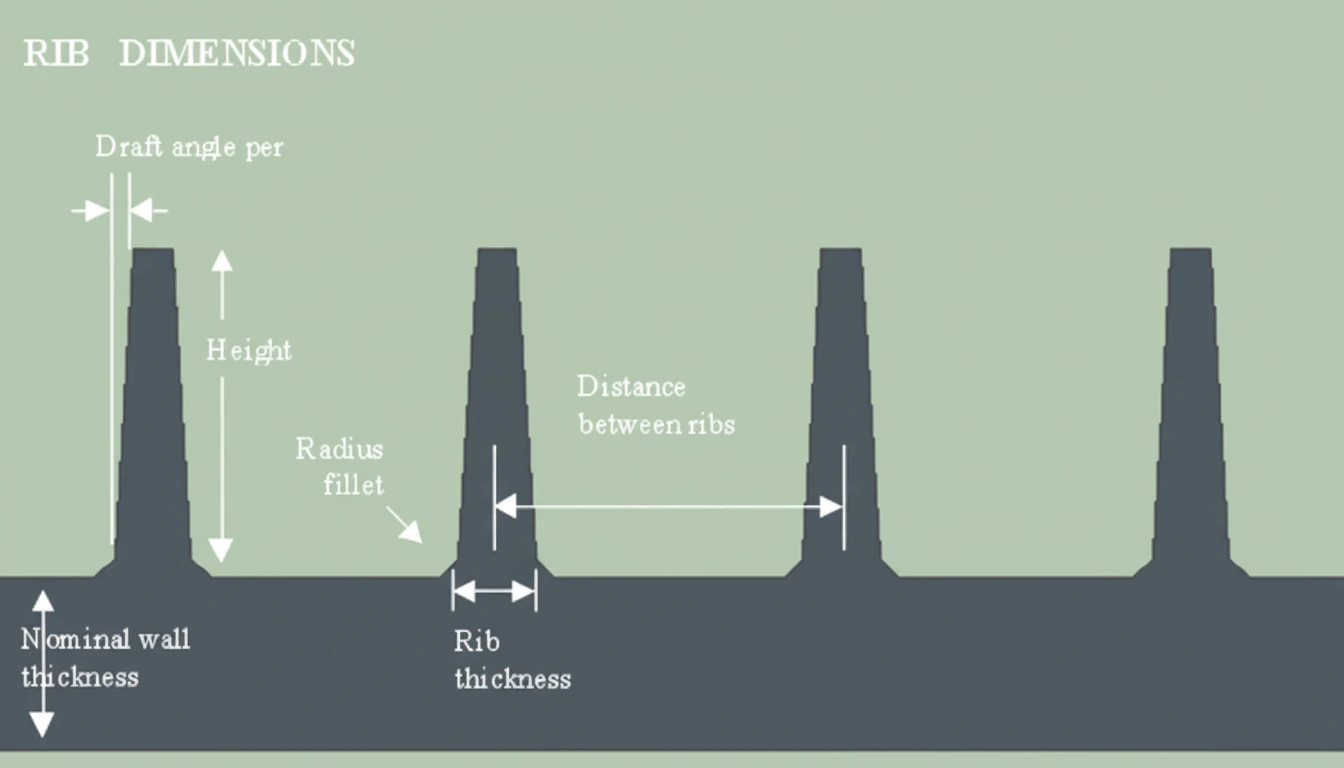

Optimizing rib design involves balancing structural rigidity with manufacturability. Ribs increase the **moment of inertia** of a part, enhancing stiffness without significantly increasing wall thickness or cycle time. The “Golden Rule” is maintaining a rib thickness of **50% to 70%** of the nominal wall thickness to prevent sink marks. Proper draft angles (0.5° to 1.5°) and base radii are essential for ejection and stress reduction.

Definition

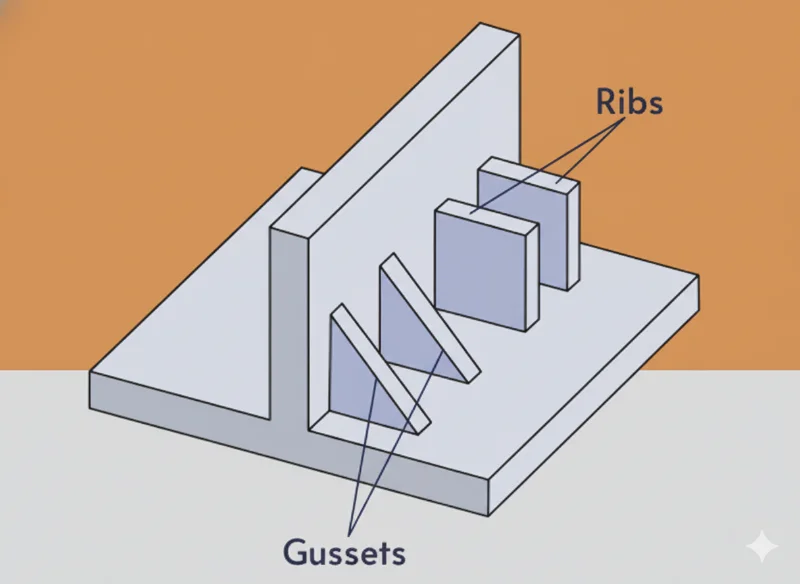

Ribs are thin, wall-like features extending perpendicularly from the nominal wall of a plastic part. They are primarily used to improve the bending stiffness and strength of a component without increasing the overall wall thickness.

In Injection Molding, relying on ribs rather than thick walls is crucial because thick walls result in extended cooling times, higher material costs, and defects like voids or warpage. Ribs also act as flow leaders, aiding the flow of molten plastic, such as Polypropylene (PP)1 or Acrylonitrile Butadiene Styrene (ABS)2, into difficult-to-fill areas of the mold.

Thick ribs provide the highest structural integrity with no downsides.False

Thick ribs generally lead to sink marks on the cosmetic surface and internal voids due to differential cooling rates.

Rib thickness should generally be 50% to 70% of the nominal wall thickness.True

This ratio balances structural stiffness while minimizing the risk of sink marks on the opposite surface.

Key Design Parameters for Ribs

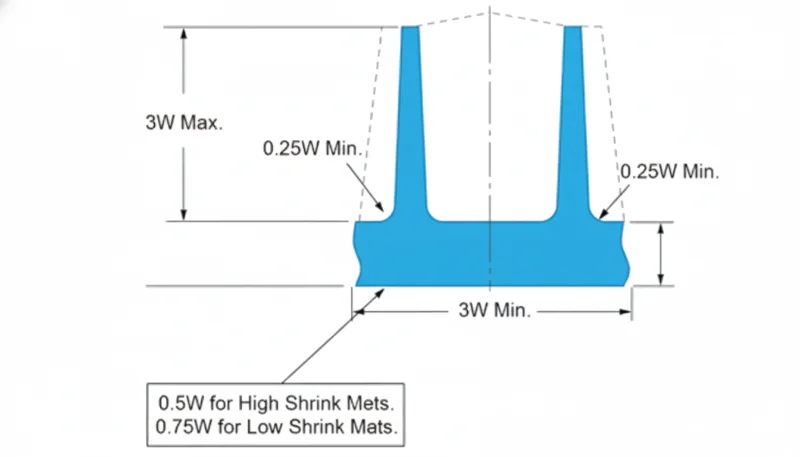

The following parameters utilize standard industry guidelines (e.g., DFM guidelines, SPI standards).

| Parameter | Symbol | Recommended Range | Unit | Key Notes |

|---|---|---|---|---|

| Base Thickness | w | 40% – 70% of t | mm | t = Nominal Wall Thickness. 40% for high-gloss; up to 70% for structural/textured parts. |

| Rib Height | h | ≤ 3 × t | mm | Excessive height complicates venting and ejection; can cause buckling. |

| Draft Angle | α | 0.5° – 1.5° | deg | Required for ejection. Texture requires additional draft (1° per 0.025mm depth). |

| Base Radius | R | 25% – 50% of t | mm | Prevents stress concentration. Too large R creates thick sections (sink risk). |

| Rib Spacing | S | ≥ 2 × t | mm | Distance between ribs. Too close causes "steel safe" issues and thermal hotspots. |

| Tip Thickness | t(tip) | ≥ 0.75 | mm | Minimum thickness at the top of the rib to ensure the mold fills correctly. |

Advantages vs. Disadvantages

| Feature | Advantages | Disadvantages |

|---|---|---|

| Strength-to-Weight | Significantly increases stiffness and load-bearing capacity with minimal weight addition. | Improper design leads to cosmetic defects like sink marks3 on the visible side (A-side). |

| Cycle Time | Allows for faster cooling compared to increasing the entire wall thickness. | Deep ribs can trap gas (diesel effect) or cause difficulty in ejection (drag marks). |

| Material Flow | Acts as internal runners (flow leaders) to help fill thin sections or distant corners. | Complex ribbing increases tooling costs (EDM work required). |

| Warpage Control | Reduces warping by breaking up large flat surfaces and redistributing stress. | Sharp corners at rib bases become stress concentrators, leading to failure under impact. |

Making a rib taller is always the best way to increase part stiffness.False

Excessively tall ribs are prone to buckling under load and require deep, difficult-to-vent mold cavities.

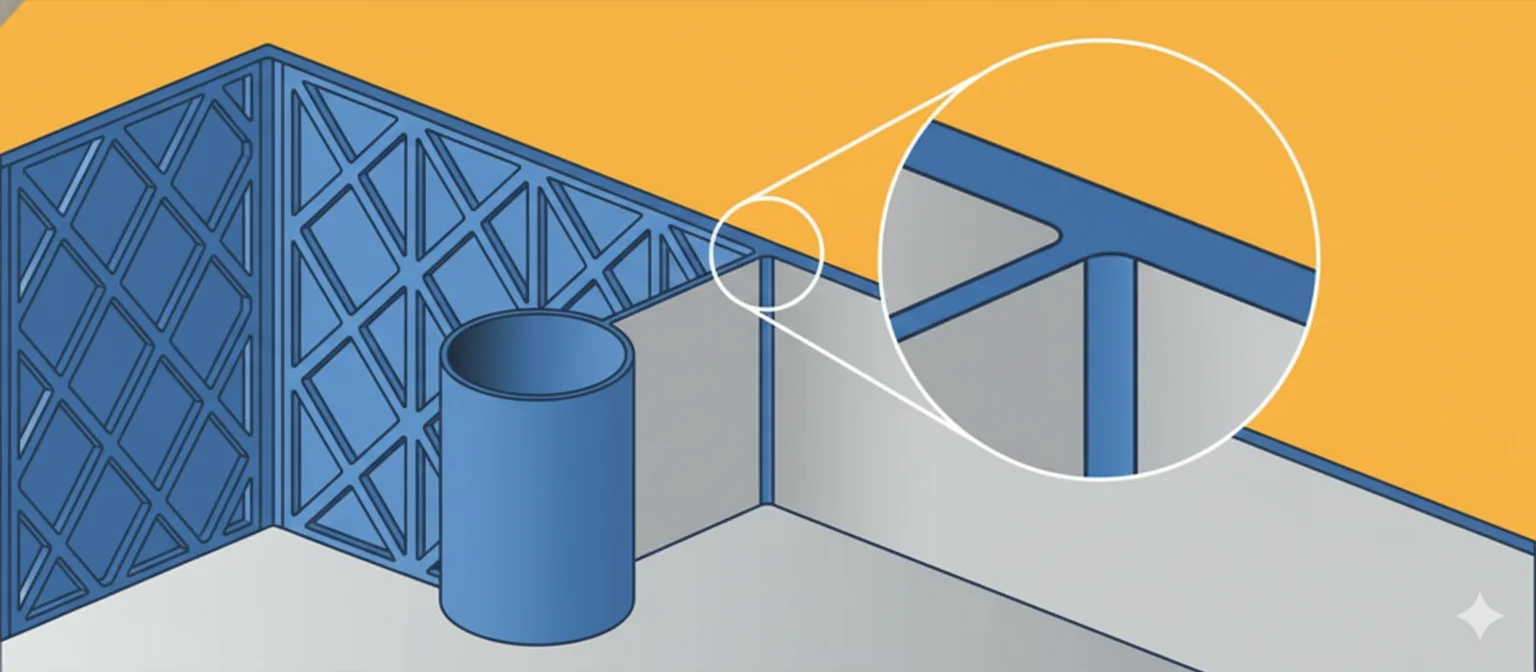

Adding multiple shorter ribs is often structurally superior to one very tall rib.True

Multiple ribs distribute the load more effectively and maintain easier moldability compared to deep, narrow features.

Application Scenarios

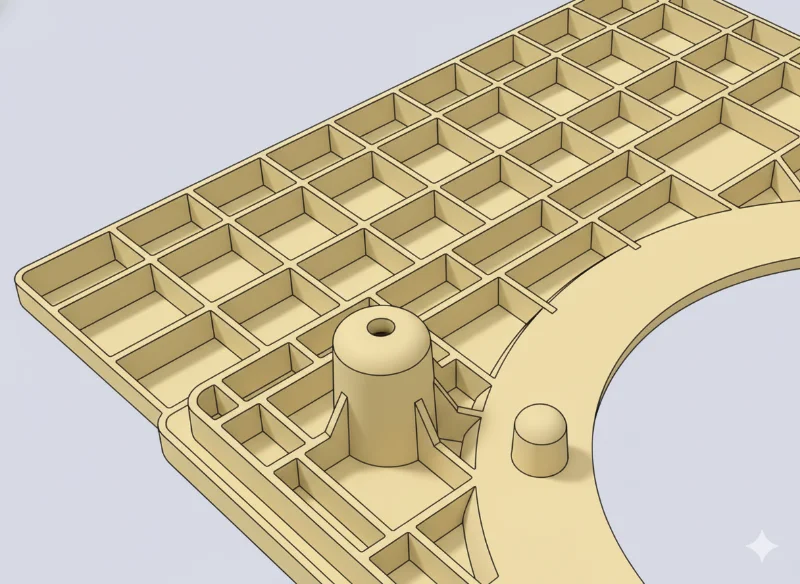

- Automotive Interiors: Dashboard substrates and door panels often use honeycomb rib patterns to reduce weight while maintaining crash safety standards.

- Consumer Electronics: Housings for laptops or phones use micro-ribs to support internal PCBs and prevent crushing without adding bulk.

- Structural Components: Power tool casings made from Glass-Fiber Reinforced Polymer (GFRP)4 utilize cross-ribbing to withstand high torque and drop impact.

- Container Lids: Thin-walled packaging uses radial ribs to prevent bowing or warping during stacking.

Stepwise Process Recommendations

To achieve an optimized rib design, follow this workflow:

- Establish Nominal Wall (t): Determine the base wall thickness required for the part’s general function.

- Calculate Rib Base Thickness:

- For Amorphous materials (e.g., Polycarbonate (PC), ABS): Set rib thickness to ~60-70% of t.

- For Semi-crystalline materials (e.g., Polypropylene (PP), Polyethylene (PE)): Set rib thickness to ~40-50% of t due to higher shrinkage rates.

- Define Height Limits: Ensure rib height (h) does not exceed 3 × t. If more stiffness is needed, add more ribs rather than increasing height.

- Apply Draft Angles: Add a minimum of 0.5° draft per side. For taller ribs (>50mm), increase draft to 1.0°–1.5° to prevent vacuum lock during ejection.

- Design the Root Radius: Add a fillet radius of 0.25 × t at the base. Example: If wall is 4mm, radius should be 1mm. This reduces notch sensitivity.

- Verify Spacing: Ensure space between ribs is at least 2 × t. This ensures the mold steel between the ribs is robust enough to dissipate heat and not fatigue.

- Simulation: Use mold flow analysis software to check for volumetric shrinkage and potential air traps at the rib tips.

Gussets are a form of rib used for edge support.True

Gussets are triangular ribs used to support sidewalls or bosses, following the same thickness rules to avoid sink.

Ribs can be placed arbitrarily without considering mold cooling.False

Ribs placed too closely create thermal hotspots in the mold steel, leading to longer cycle times and warpage.

FAQ

Q1: What is the most critical rule for rib design to prevent cosmetic defects?

The rib base thickness must generally be between 50% and 70% of the nominal wall thickness. Exceeding this ratio increases the mass of material at the intersection, causing differential cooling that results in visible sink marks5 on the opposite surface.

Q2: How does material selection affect rib design?

High-shrinkage materials (semi-crystalline plastics like PA66 or PP) are more prone to sink marks and warpage. For these materials, ribs should be thinner (closer to 40-50% of the nominal wall) compared to low-shrinkage amorphous materials (like PC or ABS).

Q3: Can ribs replace solid wall thickness for strength?

Yes. Using ribs to increase the moment of inertia is mechanically more efficient than thickening the entire wall. It saves material, reduces part weight, and significantly lowers the cooling time required for the molding cycle.

Q4: What happens if the draft angle on a rib is too small?

Insufficient draft leads to ejection difficulties. The part may stick to the stationary (A-side) or moving (B-side) mold half, or "drag marks" (scuffing) may appear on the rib surface. In severe cases, the rib may shear off or crack during ejection.

Q5: Why is the root radius important?

Sharp corners at the base of a rib act as stress concentrators. Under impact or cyclic loading, cracks will initiate at these sharp corners. A radius distributes the stress flow; however, it must not be too large, or it will create a thick section that causes sink marks.

Summary

Optimizing rib design is a critical skill in injection molding that directly impacts part cost, aesthetics, and performance. By adhering to the standard ratio of rib thickness to nominal wall (40-70%), limiting height to 3x wall thickness, and ensuring adequate draft and radii, engineers can maximize structural stability while avoiding common defects like sink marks and warpage.

-

Polypropylene (PP) Properties: Provides a comprehensive overview of PP characteristics, essential for determining shrinkage rates and rib dimensioning in semi-crystalline applications. ↩

-

ABS Material Guide: Details the properties of Acrylonitrile Butadiene Styrene, a common amorphous material where rib design ratios differ slightly from semi-crystalline plastics. ↩

-

Sink Mark Prevention: Explains the physics behind sink marks, a primary defect caused by improper rib-to-wall thickness ratios. ↩

-

GFRP Structural Applications: detailed scientific context on how fiber reinforcement interacts with rib structures to enhance mechanical properties. ↩

-

Design Tips for Ribs: Offers practical design guidelines specifically focused on minimizing cosmetic defects while maintaining structural integrity. ↩