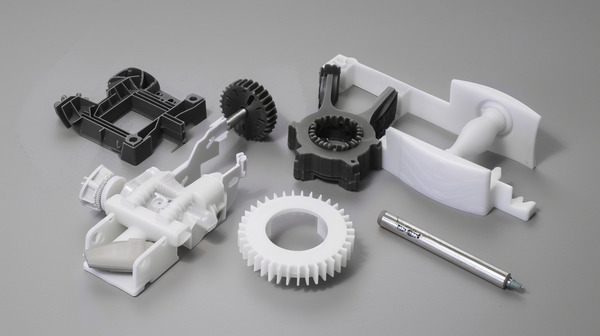

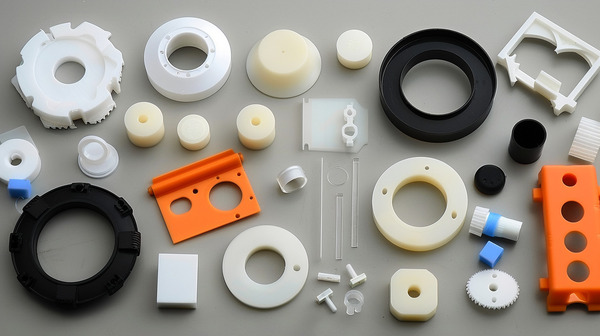

Introduction: injection molding cost are a big deal for plastic product manufacturers who use this process. This article gets into the nitty-gritty of injection molding costs, explaining all the different things that affect how much it costs and how to make it cost less.

What are the Key Factors that Affect Injection Molding Costs?

There are a bunch of things that can make plastic injection molding costs go up or down, and knowing what they are is key to making the money part of your project work out right.

Part Costs

Part Size

Bigger parts need more stuff, which costs more money. They also need bigger machines that use more energy and take longer to make stuff, which makes it harder to make stuff. As parts get bigger, it’s harder to make them right, so you have to use fancier, more expensive ways to make them. Plus, bigger parts make more trash, especially in the little channels that make extra stuff, which costs even more money.

Part Complexity

Fancy designs need fancy molds with more details, which means more money up front. They might also need fancy machines and tighter tolerances, which means more money to run and longer to make.

Fancy plastic parts take longer to make because they need more time to cool and set up, which means you can’t make as many. Plus, the more fancy you get, the more things can go wrong, which means more waste and more time fixing stuff.

Production Volume

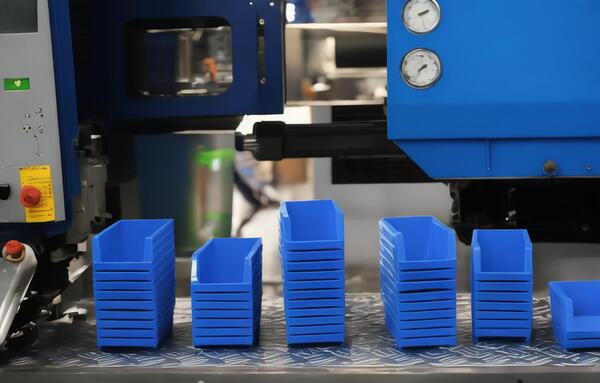

The amount of raw materials needed for injection molding, the complexity of the injection molding machine, and the strength, durability, and other mechanical properties of the injection mold are all affected by production volume. Production volume is divided into three main categories .

Low-Volume Production

This category needs simple same mold , usually made of cheap materials like aluminum or 3D printing materials. It also needs less raw materials and less fancy machines, which means lower overall injection molding costs. But the cost per part is usually higher in low-volume production situations.

Medium and Large Batch Production

You’ll need a tough steel injection mold because it lasts a long time, can handle a variety of materials, and, if possible, a fancy machine. This will make injection molding more expensive. But the high cost is spread out over the parts, so it makes each part cheaper to make. It’s worth noting that the cost per part is higher in high-volume production than in medium-volume production. So, the cost per part is lower.

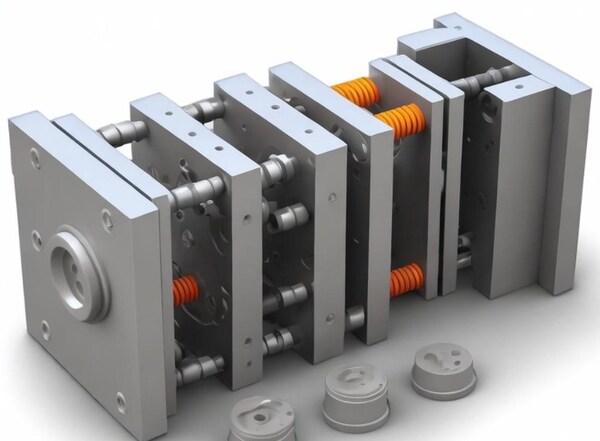

Tooling Costs

The cost of molds in the injection molding process depends on the machining process used to build the mold, the materials used, the complexity of the mold, and the size of the mold cavity.

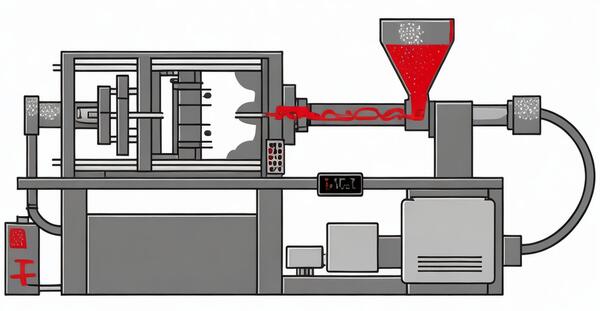

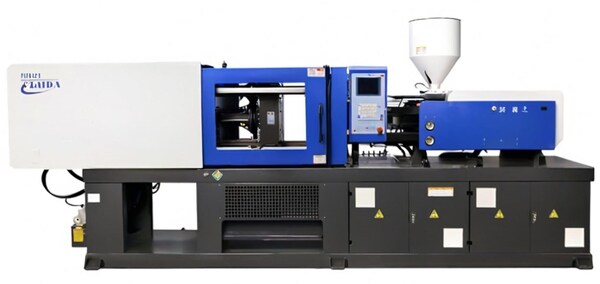

Equipment Cost

The machines used in the molding process are unique. The cost of the machine depends on the size and its complexity (usually measured by the degree of automation), which can range from $10,000 (small) or less for small batch injection molding to $200,000 (large) for large batch injection molding.

Medium-sized molding machines ($50,000 or more) can also be customized for medium-sized molding. In addition, you also need to consider the following types of injection molding machines and their impact on cost .

Hydraulic injection molding machine: Hydraulic molding machines use hydraulic pumps to control the machine during the molding process. They are tough, have consistent injection and ejection, and are cheap to buy. However, they use a lot of energy and are not precise.

Electric Injection Molding Machine: Electric injection molding machines use electric servo motors to control the machine during the molding process. They use less energy, are accurate, have low operating and maintenance upfront costs , and are easy to use. However, they cost a lot to buy and need regular maintenance.

Hybrid Injection Molding Machine: Hybrid injection molding machines are a combination of these two machines. They are characterized by energy saving, high precision, and repeatability. However, due to the use of hydraulic pumps and electric motors, they require a lot of maintenance procedures and the initial investment cost is very high.

Instead of buying the machine, the company outsources the project to an injection molding service provider. So they don’t have to pay the high cost of buying the machine, but they have to pay the service fee of the service provider.

Material Costs

When you choose a specific material, like high-performance plastics, it can cost more. But if you optimize your design and manufacturing process to reduce material waste, you can save a lot of money overall. And while using recyclable materials might cost a little more up front, it sets you up for more sustainable practices and can save you money in the long run.

Labor Costs

Labor costs include a number of costs associated with human operators.

Setup costs include the cost of configuring and setting up the injection molding machine. It takes a lot of time because of the accuracy and technical expertise required for such a process.

Repair costs include replacing faulty parts, tools, and multiple components during the molding process.

Although injection molding machines are automated most of the time, operator costs are important.

Surface finishing

Surface finishing includes processes like annealing, sandblasting, powder coating, etc., where the parts are treated to make them look better or work better. They are separate from the injection molding process itself.

However, many service providers will give you a discount if you use them for injection molding and surface finishing. Also, there are other services, which can be manufacturing processes (like machining and drilling), assembly services (like sonic welding), and decoration (like pad printing), which make the cost of injection molding go up.

Note: Not all parts require surface finishing or other ancillary services. So, make sure you need those services to improve overall production efficiency and reduce material waste.

Part Packaging

The cost of packaging depends on whether it’s consumer packaging (i.e., something you recognize and throw away) or more expensive shipping packaging. Consumer packaging is good for products that are ready to use. But bigger manufacturers can use automated packaging, which can reduce damage and reduce mistakes.

How to Reduce Injection Molding Costs?

There are a few things you can do to save money on injection molding without sacrificing quality. By doing these things, you can make your production more cost-effective and efficient.

Simplify Mold Design

Simplified mold designs help reduce cycle time in the molding process, improve production efficiency, and reduce manufacturing costs. They also minimize material waste by reducing scrap rates and scrap. In addition, simpler molds are easier to maintain, which extends their service life and reduces the frequency and cost of repair and replacement.

To simplify mold design, it is critical to eliminate unnecessary features, optimize part geometry, and consider the use of standardized components. Utilizing CAD and CAM tools can help identify and remove redundant elements, ensuring efficient mold design without compromising product quality.

Reduce Unnecessary Part Features

This approach makes mold design simpler, which saves money because complex molds cost more to production costs. Also, simpler parts use less material usage , which saves money.

Also, simpler designs can make molding cycles shorter, which makes more parts, which saves money on labor and energy. Also, simpler designs make molds easier to maintain. Most importantly, simpler designs usually make parts that are stronger and better quality, which means fewer bad parts.

To cut out the crap, you need to do a thorough design review. You need to look at the part geometry and figure out how to make it work better and easier to make. You might need to get rid of some of the pretty stuff.

You might need to combine a bunch of parts into one part. You might need to change the size of the part to get rid of some extra stuff that doesn’t matter. You need to find the best balance between what the part needs to do and what it costs to make.

Design Optimization

The way you design your product can have a big impact on how much it costs to make with injection molding. If you have a complex design, big parts, or tight tolerances, it’s going to take more time and cost more money to make. That’s why it’s so important to optimize your design to save money.

One of the easiest ways to save money is to simplify your design. If you can get rid of any unnecessary features or combine multiple parts into one, you can make your product easier to make and save money. You can also save money by making your parts smaller and thinner. And if you can use standard parts, you can save money on the mold and make the whole production process cheaper.

Part Inspection Requirements

There are two types of part inspection costs: specialized and standard. Standard inspection is an internal process where trained personnel check for part defects (cosmetic defects or critical defects) and the possible causes are determined by the quality verification team.

Specialized inspection involves inviting professional engineers to inspect the product. Therefore, specialized certifications are more expensive, and sometimes injection service providers charge a fee to provide certification.

Optimizing Material Selection

The kind of stuff you use in injection molding is a big deal when it comes to cost. It’s not just about what you pay up front, but also what you pay over time for things like maintenance and material waste. So, you need to think hard about what you’re using to keep costs down.

There are a lot of different materials you can use in injection molding, like thermoplastics, thermosets, and elastomers. They all have different performance, availability, and cost.

In general, cheap materials are weaker and don’t last as long, while good materials are more expensive. So, you have to find a balance between cost and quality to save money.One way to save money on materials is to use lower-quality materials, like recycled or regrind plastics. These materials are often a fraction of the cost of new materials and can still work fine for some products.

Another way to save money is to look for alternative materials that have similar properties but cost less. For example, instead of using high-quality materials, you can use low-quality plastics that have additives to make them work better.

Eliminate Cosmetic Appearance

In some cases, how a part looks doesn’t matter. Skipping fancy details can make parts faster and easier to make, which can save money. This is especially true for parts that don’t have to look good.

Reuse Molds

Getting the most out of a mold is a smart move in injection molding. By using molds for multiple production runs, you can spread the cost of the mold across more parts, which lowers the cost per part. If you take good care of your molds and maintain them properly, you can make them last longer, which saves you money in the long run.

Choosing Insert Molding

Insert molding is when you put a pre-molded part, or insert, into the mold before you shoot the plastic. This lets you put multiple parts into one shot, so you don’t have to do extra assembly steps. Of course, one step means shorter machine run times and fewer shots and cycles.

Plus, you don’t have to put different parts together that were designed separately, which saves time again. By putting steps together, insert molding saves time and money.

Quality Control

Quality control is super important in manufacturing, especially when it comes to injection molding. If you don’t have good quality control, you’ll end up with bad parts, bad products, and a lot of wasted material, which all costs you money.

So, you need to have a good system in place to make sure you have good quality control . During the injection molding process, the core cavity design of the mold directly affects the dimensional accuracy and production efficiency of the product.

There are a lot of things that can affect quality control. Things like machine calibration, material quality, and human error. If you keep your machines calibrated and maintained, you can help prevent defects and make sure your quality is consistent. If you get good materials, you’ll have less waste and better quality. And if you train your people right, you’ll have better quality control.

Production Efficiency

Efficiency is key to reducing injection molding costs. The more efficiently you can produce your products, the lower your overall costs will be. There are several factors that affect efficiency, such as machine utilization, cycle time, and maintenance downtime.

Proper machine maintenance is crucial to maintaining efficiency. Regular maintenance and calibration of your machines can help prevent downtime and keep your production stable. Using automation and training your employees to operate your machines effectively can also increase efficiency.

Conclusion

Knowing the cost of injection molding can help you optimize your plastic injection molding manufacturing process. By understanding the various factors and components, you can do just that. In this article, we’ll cover everything you need to know about injection molding costs and how to use them.