Precision injection molding is a key manufacturing technique for producing high-quality parts with tight tolerances, commonly used in industries such as automotive, electronics, and medical devices.

Precision injection molding produces parts with high accuracy and repeatability, making it ideal for complex designs. This method ensures minimal material waste and quick cycle times, improving production efficiency and product consistency.

To fully grasp the benefits of precision injection molding, it’s important to explore how this method’s design and material choices impact production quality and cost efficiency.

Precision injection molding ensures high accuracy in part production.True

By utilizing advanced technology and careful control of molding conditions, precision injection molding delivers parts with minimal variation in dimensions and quality.

Precision injection molding is only suitable for large production runs.False

While it excels in high-volume manufacturing, precision injection molding can also be cost-effective for medium to small production runs, particularly with specialized or intricate designs.

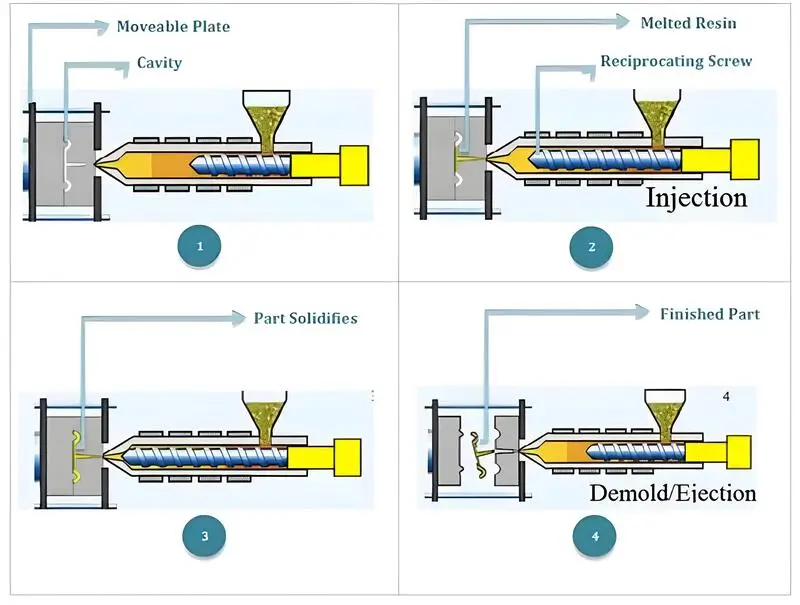

What is the Definition of Precision Injection Molding?

Precision injection molding ensures high-accuracy production of complex parts with tight tolerances. It’s essential in industries where detail and consistency are paramount, such as automotive, aerospace, and medical.

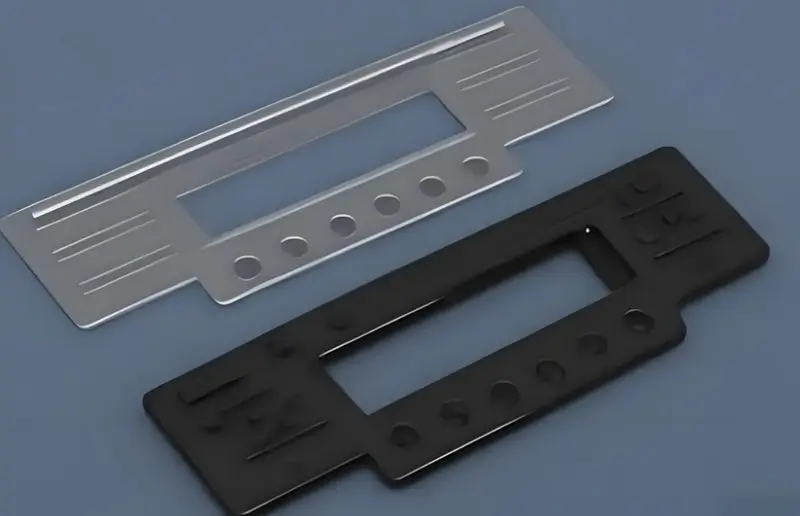

Precision injection molding uses specialized molds and processes to create parts with tight tolerances and high detail. It’s essential for industries requiring accuracy, such as automotive and medical device manufacturing, ensuring part consistency and quality.

Precision injection molding, strictly speaking, refers to a method of injection molding production in which the dimensional accuracy of plastic products produced by injection molding equipment can reach less than 0.01mm, usually between 0.01 and 0.001mm in size.

Precision injection molding is more expensive than standard molding.True

Due to the advanced technology, equipment, and tighter tolerances required, precision molding often has higher upfront costs.

Precision injection molding guarantees flawless parts every time.False

While it significantly improves accuracy, external factors such as material quality, mold design, and machine calibration can still affect the outcome.

What are the Characteristics of Precision Injection Molding Process?

Precision injection molding ensures tight tolerances, intricate designs, and superior surface finishes. It is widely used for high-quality parts in industries like automotive, electronics, and medical devices.

Precision injection molding is known for producing high-accuracy parts with consistent dimensions. The process involves carefully controlled temperature and pressure, reducing defects and improving part strength and surface quality.

High Injection Pressure

Experiments have shown that for different types, shapes, and sizes of plastics, the pressure required for precision injection molding should be 180-250MPa (the injection pressure used for ordinary injection molding is generally 40-200MPa), and in some special cases, higher requirements are required. The highest has reached about 450MPa.

Fast Injection Speed

The size of theinjection speed1 not only affects the productivity of the product, but it can also reduce the dimensional tolerance of the product.

To make injection molded parts more precise, especially for molding complex-shaped products, variable-speed injection has been developed in recent years. This means that the injection speed can change, and how it changes depends on the shape of the part and the plastic\’s performance.

Temperature Control Must be Accurate

Temperature has a big effect on the quality of the product when you’re molding it. It’s one of the three big things you have to get right when you’re doing injection molding.

When you’re doing precision injection molding, you don’t just have to worry about temperature, you have to worry about how accurate you can control the temperature.When you do precision injection molding, if you don\’t control the temperature accurately, the fluidity of the plastic melt and the molding performance and shrinkage of the product will not be stable.

So you can\’t guarantee the accuracy of the product. From this point of view, when you use precision injection molding , whether it\’s the barrel and nozzle, or the injection mold2, you must strictly control their temperature range.

For example, when you do precision injection molding, you use a PID controller for the temperature at the barrel and nozzle, and you control the temperature fluctuation range within 1 degree Celsius.For regular injection molding machines, the temperature at this location can reach 20°C to 300°C.

When doing precision injection molding production, to make sure the product is accurate, besides controlling the temperature of the barrel, nozzle, and mold strictly, you also need to pay attention to the influence of the ambient temperature on the accuracy of the product after demolding.

Precision injection molding offers high accuracy and consistency.True

By controlling factors like pressure and temperature, precision molding ensures minimal defects and consistent part quality, making it ideal for demanding applications.

Precision injection molding is suitable for all types of parts.False

While precision injection molding excels for complex, high-accuracy parts, it may not be the most cost-effective method for simple or low-volume production runs.

What are the Principles of Material Selection for Precision Injection Molding?

Material selection3 for precision injection molding is vital for ensuring product quality, durability, and cost-efficiency. It involves considering factors like material properties, cost, and processing requirements.

Key principles of material selection include evaluating material strength, heat resistance, and chemical compatibility with the molding process. Materials like thermoplastics and thermosets are commonly used, each offering specific advantages for precision parts.

Strong, stable, doesn’t bend, and can be used anywhere. There are four materials that are commonly used:

POM with carbon fiber (CF) or glass fiber (GF) added; this material is strong, doesn’t get tired, can be used outside, doesn’t conduct electricity, doesn’t catch on fire, and comes out of the mold easily when you put slippery stuff in it.

PA and glass fiber reinforced PA66 have the following characteristics: strong impact resistance and wear resistance, good flow performance, and can be molded into products with a wall thickness of 0.4mm. Glass fiber reinforced PA66 has heat resistance (melting point 250℃), but its disadvantage is that it is hygroscopic and generally needs to be humidified after molding.

PBT reinforced polyester has a short molding time. The molding time comparison is as follows:

PBT≤POM≈PA66≤PA6.

Features of PC and GFPC: good wear resistance, improved rigidity after reinforcement, good dimensional stability, weather resistance, flame retardancy and good molding processability.

Material selection affects precision in injection molding.True

The right material ensures high-quality, accurate parts by providing optimal flow, strength, and resistance to wear.

Cost is the only factor in material selection.False

While cost is important, material performance, durability, and processing compatibility are critical factors that influence material choice for precision molding.

What are the Main Influencing Factors of Precision Injection Molding?

Precision injection molding is influenced by various factors such as material properties, mold design, processing conditions, and machine capabilities, all of which affect part accuracy and production efficiency.

Key factors in precision injection molding include material choice, mold design, injection pressure, temperature control, and cycle time. These variables ensure dimensional accuracy and high-quality final products, especially in industries like automotive, electronics, and medical devices.

To make precision plastic products, you need five things: the right material, a good mold, a good plastic injection molding process, good people, and a good machine. Precision plastic parts have to be the right size, the right shape, and have the right surface.

These are called dimensional accuracy, shape and position accuracy, and surface accuracy. They are measured by dimensional tolerance, shape and position tolerance, and surface roughness. Dimensional accuracy is the most important thing for plastic parts. The main things that make parts the wrong size are.

The Shrinkage Characteristics of Molding Materials, Using Plastics with High Dimensional Stability

Plastic shrinkage 4 is one of the inherent properties of plastics. It is very important for the dimensional stability and precision of plastic parts. Plastic shrinkage includes the comprehensive reflection of thermal shrinkage, elastic recovery, plastic deformation, post-shrinkage, and aging shrinkage of plastics.

It is the change in linear shrinkage and volume shrinkage caused by environmental factors during the molding process and use, and is usually expressed by shrinkage characteristic values.

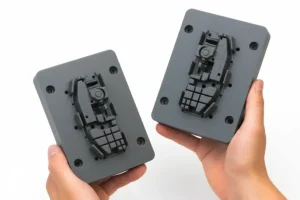

Mold Design and Processing Accuracy

-

Precision Mold Materials:The materials for making cavities and runners must undergo strict heat treatment. Choose alloy steel with high mechanical strength, or high hardness (molded parts must reach about HRC52), good wear resistance and strong corrosion resistance.

-

Machinability and Rigidity:When designing the mold structure, don\’t make too many cavities. Make the bottom plate, support plate, and cavity wall thicker so that the parts don\’t get all bent out of shape when they get hot and squished.

-

Product Demoulding Property:The mold should try to adopt fewer cavities, a small and short runner, and a higher finish than ordinary molds, which is conducive to demolding.

-

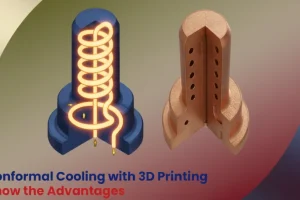

The Accuracy of Plastic Parts:It mainly depends on the accuracy of the mold cavity size, the accuracy of the cavity position, and the accuracy of the parting surface. The judgment criteria are whether the design of the plastic part is easy to process, whether the filling performance of the mold gate is good.whether the mold cooling system can evenly cool the mold, etc. The dimensional tolerance of general precision injection molds should be controlled below 1/3 of the product dimensional tolerance.

The Temperature, Humidity, and Dimensional Creep Amplitude of the Product Use Environment

The product should be able to keep its shape when it’s pushed or when the temperature changes.

Injection Molding Equipment – Replace Conveprecision Injection Moldntional Injection Molding Machines with Precision Injection Molding Machines

Precision precision molding machine are injection machines that have injection closed-loop control. Normally, the injection pressure5 and injection speed of injection molding machines are closed-loop controlled.

The so-called closed-loop control, also called feedback control, means that the output signal of the control system is detected by the detection element in the control system, and then the detection signal is transmitted to the controller.

The controller calculates the detection signal to achieve the output signal consistent with the output signal required by the system, so that the output signal is closer to the expected value and the system output deviation is minimized.

In simple terms, closed-loop control is an automatic adjustment control that gets you closer to what you want. precision injection molding machine have gotten a lot better at making the same thing over and over again because they use closed-loop control for injection.

This has reduced the size differences in the parts and made them more accurate and consistent.To achieve closed-loop control of the injection molding machine, hydraulic injection molding machines must use servo valves to achieve closed-loop control of the hydraulic system pressure and flow.

In addition to using servo valves, ultra-precision injection mold also use servo control boards. The servo control boards work with computer control systems to further improve the repetitive accuracy of the hydraulic system output pressure and flow, and achieve ultra-precision injection molding.

All-electric injection molding machines are way better than hydraulic injection molding machines when it comes to achieving full closed-loop injection control.

The computer motion controller of the all-electric injection molding machine controls and drives the servo motor, and then performs logical operations on the sensor feedback signal through the logic controller to achieve full closed-loop control of the injection molding action including injection, plasticization, mold opening and closing, and ejector action.

The position control can reach 0.01mm, the dimensional accuracy of the workpiece is higher, and the stability and repetitive accuracy of the machine are much higher.

Using Precision Molding Technology

Precision molding is a process that is mainly done on precision injection molding machines. It mainly uses multi-stage injection molding and accurately controls the mold temperature.

Multi-stage injection molding6 means that when the screw pushes the melt into the mold during the injection process, it controls process parameters such as different injection speeds and different injection pressures at different positions.

The multi-stage injection control program can set the multi-stage injection pressure, injection speed, holding pressure, and melting method based on the runner structure, gate form, and injection molded part structure. This helps improve plasticization, product quality, defect rate, and mold/machine life.

The multi-stage injection molding will be set according to the product structure, the location of the defect, and the size of the injection molding machine screw, and it also involves many on-site skills. Due to space limitations, it will be discussed in another article and will not be discussed in detail here.

Material properties significantly affect the accuracy of injection molded parts.True

Material properties such as viscosity, shrinkage, and thermal conductivity influence how well a part conforms to mold specifications.

Faster cycle times always lead to better product precision.False

Shorter cycle times may reduce quality if the part doesn't cool properly or the injection process isn't controlled accurately, highlighting the importance of balanced production parameters.

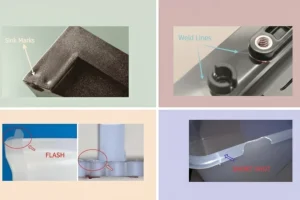

What are the Shrinkage Problems of Precision Injection Molding?

Shrinkage during precision injection molding can affect the quality and dimensional accuracy of molded parts. Addressing this issue is essential to achieving optimal results.

Shrinkage in injection molding occurs when the material cools and contracts. This leads to dimensional inaccuracies and surface defects. Factors such as material choice, mold design, and cooling rates impact shrinkage levels and part consistency

There are four things that make shrinkage happen: thermal shrinkage, phase change shrinkage, orientation shrinkage, and compression shrinkage.

Thermal Shrinkage

Thermal shrinkage is a natural property of molding materials and mold materials. When the mold temperature is high, the temperature of the product is also high, and the actual shrinkage rate will increase. Therefore, the mold temperature of precision injection should not be too high.

Phase Change Shrinkage

Phase change shrinkage happens when polymers crystallize and reduce in volume during the orientation process of crystalline resins. This is called phase change shrinkage. The hotter the mold, the more crystalline the resin, and the more it shrinks.

But, the more crystalline the resin, the denser the product, the less it expands, and the less it shrinks. So, the actual shrinkage is a combination of the two.

Orientation Shrinkage

When the molecules are stretched in the flow direction, they tend to curl up and shrink back when they cool down, causing shrinkage in the direction of orientation. The degree of molecular orientation is related to injection pressure, injection speed, resin temperature, and mold temperature. But the main factor is injection speed.

Compression Shrinkage and Elastic Reset

Plastics can be compressed and stretched. This means that the volume of the plastic changes a lot when you squeeze it. At room temperature, if you squeeze the plastic, it will get smaller, it will get denser, it will not expand as much, and it will shrink a lot less.

The plastic can also stretch back out, which makes the shrinkage less. The shrinkage of the plastic product is affected by the conditions of the molding and the conditions of the operation.

Understanding the causes of shrinkage and how to control it is key to improving your molding process. Dive deeper into strategies that can minimize shrinkage and enhance precision.

Shrinking of molded parts is inevitable during precision injection molding.True

Shrinkage occurs naturally due to material cooling and contraction, which can affect part fit and finish.

Shrinking of molded parts is inevitable during precision injection molding.True

Shrinkage occurs naturally due to material cooling and contraction, which can affect part fit and finish.

What are the Advantages of Precision Injection Molding?

Precision injection molding offers exceptional accuracy and consistency, making it ideal for producing complex, high-quality parts in industries like automotive, medical, and electronics.

Precision injection molding delivers tight tolerances, reducing waste and improving part performance. It’s widely used in producing intricate components with high-quality standards. Benefits include superior accuracy, reduced material waste, and enhanced efficiency.

High Precision and Consistency

Precision injection molding technology is capable of producing plastic products with complex shapes and precise dimensions,high precision metal parts ensuring high consistency and stability. It doesn\’t matter if you\’re making small parts or large components, you can count on the quality and precision of your products.

High Efficiency and Production Speed

Compared to traditional production methods, precision injection molding technology has higher production efficiency and production speed. By using automated equipment and assembly line production, we can greatly improve production efficiency, shorten production cycles, and reduce production costs.

Save Raw Materials and Resources

Precision injection molding technology can help you make the most of your raw materials, cut down on waste and save resources. By controlling the injection molding process and designing your mold just right, you can cut down on waste, save money and meet the demands of sustainable development.

Applicable to a Variety of Materials and Fields

You can use precision injection molding technology to process various plastic material, It is suitable for many fields, such as electronics, automobiles, medical devices, furniture, and so on. Whether you want to make a small batch of customized products or do large-scale mass production, it can meet your needs.

Automated Production and Quality Control

Precision injection molding technology enables fully automated production and quality control, reducing manual operation and human errors. By using sensors and monitoring systems to keep an eye on the injection molding process in real time, parameters can be adjusted promptly to ensure product quality and consistency.

Environmental Protection and Sustainable Development

Precision injection molding technology utilizes thermoplastics as raw materials, which are recyclable and reusable. By recycling raw materials and conserving resources, it can reduce the impact on the environment, which meets the requirements of environmental protection and sustainable development.

Precision injection molding improves part accuracy.True

Precision injection molding allows for tighter tolerances, producing highly accurate and consistent parts that meet demanding specifications.

Precision injection molding is always more expensive than standard molding.False

Although the initial setup cost can be higher, the long-term benefits like reduced waste and fewer defects can offset the additional expense, making it cost-effective for large-scale production.

Conclusion

In general, precision injection molding technology has the advantages of being super precise, super efficient, saving resources, and being used in many fields, making it the best choice for the manufacturing industry.

As science and technology keep advancing and technology keeps improving, precision injection moulding technology will be used more widely in various fields, promoting the development and innovation of the manufacturing industry.

-

Learn about Why is injection speed important? Injection speed is a critical factor when creating a plastic product. ↩

-

Learn about The Eight Types of Injection Molds : In mold types commonly encountered, we find the two-color mold, overmolding, and family mold. ↩

-

Learn about Hot Runner Injection Molding And Its Potential Advantages: Different materials have properties that make them suitable or ineffective for certain injection molding applications, ↩

-

Learn about Plastic Shrinkage: Plastic shrinkage refers to the moisture loss and contraction of concrete before it sets. ↩

-

Learn about Injection Pressure: What Is It, How to Calculate It, and Why It Matters : Injection pressure is a crucial parameter in the process of injection molding. ↩

-

Learn about Multi-material injection molding : Multi-material injection molding (MMM) is the process of molding two or more different materials into one plastic part at one time. ↩