Custom PP Injection Molding Factory

PP injection molding manufacturing and design guide

Resources for The Complete Guide to PP Injection Molding

What is Polypropylene (PP)?

PP, short for polypropylene, is a kind of thermoplastic polymer. It is made by polymerizing propylene, which has the chemical formula (C3H6)n. It looks like a white waxy thing, and it is transparent and light. The density is only 0.89-0.91g/cm³, so it is one of the lightest plastics. The melting point of PP is 164-170°C, and the softening temperature is about 155°C. The usage temperature range is -30°C to 140°C. It can resist corrosion from acids, bases, salt solutions, and various organic solvents below 80°C, but it will decompose under high temperature and oxidative conditions.

PP is highly moldable, but it shrinks a lot (1% to 2.5%), so thick-walled products are prone to dents, which makes it hard to meet the requirements for some high-precision parts. It has a shiny surface, and it’s non-toxic, odorless, and tasteless. Its molecular weight is about 80,000 to 150,000. It only absorbs 0.01% water in water, so it has good water stability.

What types of PP materials are there?

Polypropylene (PP) is a versatile thermoplastic polymer that can be classified into different types based on its molecular structure, polymerization method, and applications.

1. Homopolymer Polypropylene (PP-H):

Homopolymer polypropylene is made from a single type of propylene monomer. It is rigid and resistant to chemicals. It is used in packaging, automotive parts, electrical appliances, and piping. It is strong and can handle heat.

2. Copolymer Polypropylene (CPP):

Polypropylene copolymers come in two types: random copolymers (PP-R) and block copolymers (PP-B). Random copolymers have ethylene monomers scattered throughout, making them good for food containers and thin-walled products because they’re rigid and can take a hit. Block copolymers have alternating polypropylene and ethylene monomers, so they’re mainly used in automotive parts and other high-impact products because they’re tough and flexible.

3. Impact Copolymer Polypropylene (ICPP):

Impact copolymer polypropylene is a special copolymer with more ethylene content to make it stronger. It is especially good for things that need to be strong when it’s cold, like suitcases and protective cases. It is very tough and works well in the cold.

4. Expanded Polypropylene (EPP):

Expanded polypropylene (EPP) is a super low-density closed-cell foam material that’s used in automotive parts, packaging, and consumer goods. It’s got a high strength-to-weight ratio, and it’s got excellent impact resistance and thermal insulation. That’s why it’s used in all kinds of different things.

5. Polypropylene Terpolymer:

Polypropylene terpolymer consists of propylene segments linked with ethylene and butylene monomers, suitable for sealing films and applications requiring high transparency. These copolymers are more transparent and flexible than homopolymers and are used in a variety of packaging applications.

6. Bio-based Polypropylene:

Bio-based polypropylene is made from renewable raw materials with different levels of bio-based content (30%-100%). It can be used for many things just like regular PP, but it’s better for the environment. People are starting to use it more and more.

There are also PP types with additives and filled PP, where the former enhances specific properties through additives, and the latter increases rigidity and reduces costs through fillers, suitable for various industries and products with special requirements. Polypropylene fibers (PPF) are also widely used in textiles and interior decoration due to their softness and wrinkle resistance. These different types of PP materials play an important role in industrial and consumer markets based on specific needs and performance requirements.

What are the characteristics of PP?

Polypropylene (PP) is a thermoplastic polymer that is used in a wide range of applications because it performs well. Here are the main characteristics of PP materials:

1. Physical Properties:

① Density: Polypropylene (PP) materials have a density range of 0.90 to 0.92 g/cm³, which makes it one of the lightest options among all plastics. This makes PP perfect for products that need a lightweight design, like packaging materials and automotive parts.

② Melting Point: The melting point of PP ranges from 164 to 170°C, and the specific melting point may vary due to its crystalline structure and different additives. It starts to get soft around 155°C, good for thermoforming processes.

③ Water Absorption Rate: PP has a super low water absorption rate of only 0.01%, which means it barely absorbs water. This makes it great for humid environments and applications where you need it to resist moisture.

2. Chemical Properties:

① Chemical Resistance: PP has good resistance to various chemicals (including acids, bases, and solvents), making it widely used in chemical storage and processing equipment. However, under high temperatures or strong oxidative conditions, PP may degrade, so be careful where you use it.

② Heat Resistance: The temperature range for using PP is from -30°C to 140°C, and it can handle temperatures up to 120°C for short periods, so it’s good for stuff that needs to be heat resistant, like home appliances and industrial equipment.

3. Mechanical Properties:

① Strength and Rigidity: Polypropylene is stronger and stiffer than LDPE, but it gets brittle in cold temperatures, which can cause it to break. Also, PP doesn’t wear well and can get old.

② Surface Gloss: PP products have good surface gloss, suitable for applications requiring visual appeal. However, thick-walled products are prone to dents, and dimensional accuracy is relatively low.

4. Processing Properties:

① Moldability: PP has great moldability, suitable for various molding processes like injection molding, extrusion, and blow molding. However, its larger shrinkage rate (1%-2.5%) may lead to shrinkage holes and dents during the cooling process, requiring reasonable design.

② Flowability: PP has good flowability, so it can flow fast at high temperatures, but it cools fast, so you have to control the mold temperature and the molding temperature really well when you’re molding it to make sure you get good parts.

5. Environmental Properties:

Recyclability: Polypropylene materials have good recyclability and can be reused, having a minimal impact on the environment. This aligns with modern society’s requirements for sustainable development and environmental protection, widely used in packaging, automotive, and medical fields.

6. Other Properties:

① Electrical Insulation: PP is an amazing electrical insulating material, used in electronic and electrical products, protecting components from electrical currents.

② UV Resistance: PP has limited resistance to UV radiation, and long exposure to sunlight can cause it to age. To extend its life outdoors, you need to add UV stabilizers.

③ Impact Resistance: Although it originally has weak impact resistance, you can make it a lot stronger by modifying it. That makes it good for things that need to be able to take a hit.

What are the properties of PP?

Polypropylene (PP) is a widely used thermoplastic polymer characterized by its versatility and range of properties. Here are the main parameters of PP materials:

| Property | Metric | English |

|---|---|---|

| Density | 0.880 - 2.40 g/cc | 0.0318 - 0.0867 lb/in³ |

| Water Absorption | 0.000 - 0.800 % | 0.000 - 0.800 % |

| Particle Size | 300 - 1000 µm | 300 - 1000 µm |

| Melt Flow | 0.200 - 1800 g/10 min | 0.200 - 1800 g/10 min |

| Hardness, Rockwell R | 20.0 - 118 | 20.0 - 118 |

| Hardness, Shore D | 30.0 - 83.0 | 30.0 - 83.0 |

| Tensile Strength, Ultimate | 9.00 - 80.0 MPa | 1310 - 11600 psi |

| Tensile Strength, Yield | 4.00 - 369 MPa | 580 - 53500 psi |

| Surface Resistance | 10.0 - 1.00e+15 ohm | 10.0 - 1.00e+15 ohm |

| Static Decay | 0.0100 - 2.00 sec | 0.0100 - 2.00 sec |

| Dielectric Constant | 2.20 - 2.38 | 2.20 - 2.38 |

| Dielectric Strength | 19.7 - 140 kV/mm | 500 - 3560 kV/in |

| Dissipation Factor | 0.0000700 - 0.00300 | 0.0000700 - 0.00300 |

| Arc Resistance | 88.0 - 136 sec | 88.0 - 136 sec |

| Comparative Tracking Index | 550 - 600 V | 550 - 600 V |

| Tribocharge | 10.0 V | 10.0 V |

| Melting Point | 61.0 - 220 ℃ | 142 - 428 ℉ |

| Crystallization Temperature | 110 - 115 ℃ | 230 - 239 ℉ |

| Maximum Service Temperature, Air | 65.0 - 125 ℃ | 149 - 257 ℉ |

| Heat Distortion Temperature | 85.0 - 115 ℃ | 185 - 239 ℉ |

| Minimum Service Temperature, Air | -30.0 ℃ | -22.0 ℉ |

| Brittleness Temperature | -20.0 ℃ | -4.00 ℉ |

| Gloss | 30.0 - 160 % | 30.0 - 160 % |

| Transmission, Visible | 0.500 - 99.0 % | 0.500 - 99.0 % |

| Processing Temperature | 87.8 - 274 ℃ | 190 - 525 ℉ |

| Nozzle Temperature | 190 - 270 ℃ | 374 - 518 ℉ |

| Melt Temperature | 40.0 - 320 ℃ | 104 - 608 ℉ |

| Head Temperature | 200 - 230 ℃ | 392 - 446 ℉ |

| Mold Temperature | 4.00 - 91.0 ℃ | 39.2 - 196 ℉ |

| Drying Temperature | 65.6 - 105 ℃ | 150 - 221 ℉ |

| Moisture Content | 0.0200 - 1.00 % | 0.0200 - 1.00 % |

| Injection Pressure | 2.76 - 103 MPa | 400 - 15000 psi |

| Cure Time | 0.0250 - 0.0417 min | 0.000417 - 0.000694 hour |

Can PP materials be injection molded?

You can totally injection mold polypropylene (PP) materials. It’s a popular way to make PP parts and products. PP has great processing properties, so it’s good for lots of injection-molded products, especially in industries like cars, stuff people buy, and medical stuff.

Injection Molding Characteristics of Polypropylene Plastics:

① Good Melt Flow Properties: It has a low melting point and low viscosity, so it’s easy to melt and flow.

② Rapid Cooling and Solidification: It has good thermal conductivity, so parts cool quickly, which speeds up production.

③ Low Shrinkage Rate: It shrinks very little as it cools, so it stays the same size and doesn’t warp.

④ Chemical Resistance: It’s resistant to chemicals and solvents, so it’s good for places where there are a lot of chemicals.

⑤ Good Electrical Insulation: Blocks electrical currents, perfect for electronic and electrical applications.

⑥ High Mechanical Strength: Can handle physical loads, used a lot in cars and household appliances.

What are the key considerations for PP Injection Molding?

Polypropylene (PP) is a widely used thermoplastic for injection molding, known for its great durability and cost-effectiveness. There are several important factors to consider when it comes to injection molding PP to ensure high-quality parts. Here are the main things to think about when it comes to PP injection molding:

1. Material Handling:

① Material Properties: Pure PP is semi-transparent ivory white and can be dyed in many colors. It’s common to use color masterbatches for coloring, but you can also use color powders on certain injection molding machines. If you’re making outdoor products, you need to add UV stabilizers and carbon black fillers to make them more weather resistant.

② Recycled Material Usage: The proportion of recycled materials should not exceed 15%, as this may lead to reduced strength and discoloration. Generally, no special drying treatment is required before PP injection, but maintaining humidity below 0.2% is an important measure to prevent defects.

2. Injection Machine Selection:

Equipment Requirements: Injection machines for high-crystallinity materials need to have higher injection pressure and multi-stage control functions. The clamping force is generally determined at 3800t/m², with injection volume between 20%-85%.

3. Mold and Gate Design:

① Mold Temperature: Keep it between 50-90°C; for products with high precision requirements, the temperature should be higher. The core temperature should be at least 5°C lower than the cavity temperature.

② Runner and Gate: The runner diameter should be 4-7mm, with a pin gate length of 1-1.5mm, and the diameter can be as small as 0.7mm. Good venting is essential to avoid shrink marks.

③ Gate Design: The gate’s position and design are important for filling and minimizing warpage.

4. Melt Temperature:

Temperature Control: The melting point of PP is 160-175°C, and the injection processing temperature should be set not to exceed 275°C, with the optimal melting segment temperature at 240°C.

5. Injection Speed and Pressure:

① Injection Speed: High-speed injection is good for reducing internal stress and deformation, but for certain grades of PP and molds, low-speed injection may be required.

② Holding Pressure: Use high injection pressure and holding pressure (about 80% of the injection pressure) of 1500-1800 bar to ensure conversion to holding pressure at 95% stroke.

6. Cooling System:

Effective Cooling: Cooling time and cooling system design are crucial for maintaining part integrity and dimensional accuracy. Improper cooling may lead to warpage and deformation.

7. Post-Molding Operations and Quality Control:

① Hot Water Soaking: To prevent shrinkage deformation caused by post-crystallization, products generally need to undergo hot water soak treatment.

② Operator Training and Quality Control: Train operators to make sure they do the same thing every time and check parts to check for part defects to reduce scrap rates.

Resources for The Complete Guide PP Injection Molding Manufacturing

Design guidelines for PP Injection Molding

When you’re designing for polypropylene (PP) injection molding, you need to keep a few things in mind to make sure your part performs well and is easy to make. Here are some key things to think about:

1. Wall Thickness: Keep wall thickness the same, with a recommended range of 0.5-1.5 mm (0.02-0.06 inches). For movable hinges, the wall thickness should be 0.5-1 mm to balance flexibility and durability.

2. Draft Angle: The minimum draft angle should be 1-2 degrees, and for every additional inch of depth, it is recommended to increase by about 1 degree to ensure smooth part ejection.

3. Ribs and Bosses: Minimum thickness should be 0.5 mm, and don’t use thin ribs to reduce the risk of cracking.

4. Corners and Edges: Make sure to round off sharp corners and edges. For inner corners, use a radius that’s at least 50% of the wall thickness. For outer corners, use a radius that’s about 150% of the wall thickness. This will help reduce stress concentration.

5. Holes and Cavities: Make sure the holes and cavities are at least 0.5 mm wide. That way, you can fill them up without a problem and avoid any dents.

6. Surface Finish: Make sure the surface finish is smooth, with a Ra of 0.5-1.5 microns. That way, it’ll look good and work good.

7. Gate Location: Design gates to reduce warpage and ensure uniform filling. Typically, put them in areas with minimal stress concentration.

8. Ejector System: Make sure the design lets parts pop out easy, maybe using ejector pins or slides.

9. Mold Design: Optimize for PP injection, including cooling channels and venting systems to ensure optimal filling and ejection.

10. Runner and Gate Design: Make sure your runner sizes and gate types are optimized to ensure you get the best fill possible.

Summary Table:

| Parameter | Recommended Value |

|---|---|

| Wall Thickness | 1mm - 4mm |

| Living Hinge Thickness | 0.5mm - 1mm |

| Draft Angle | 1° - 2° |

| Internal Corner Radius | ≥ 50% of wall thickness |

| External Corner Radius | ≥ 150% of wall thickness |

| Injection Pressure | Up to 1500 bars |

| Mold Temperature | 40°C - 80°C |

| Moisture Content | < 0.2% |

How to Perform PP Injection Molding: A Step-by-Step Guide

Polypropylene (PP) injection molding is a widely used plastic part manufacturing process. The following is a step-by-step guide for the PP injection molding processing guide:

1. Raw Material Preparation:

① Select Suitable Polypropylene Raw Materials: When choosing raw materials, you need to consider the different properties of polypropylene (PP), such as impact resistance, chemical resistance, and UV stability. Pure PP is usually semi-transparent ivory white and can be dyed different colors to meet different product appearance requirements. Also, for outdoor products, you can add UV stabilizers and carbon black fillers to enhance weather resistance.

② Pre-treatment: Dry and screen the chosen polypropylene pellets to remove any impurities and moisture. This is important to make sure the raw materials are pure and consistent, which will help improve the quality of the final product when you inject it into a mold.

2. Mold Design and Manufacturing:

When designing the mold, you need to be precise, based on the shape and function of the final product. Make sure the mold structure is reasonable and has good venting, so you don’t get defects like bubbles when you inject the plastic. When you make the mold, make sure there are no scratches, burrs, or other surface defects. Put a release agent inside the mold so the finished product doesn’t stick.

3. Mold Installation:

Put the mold on the injection molding machine and make sure it’s tight. When you put it on, make sure it’s lined up right so the plastic goes in smooth.

4. Plastic Melting:

Put the pre-prepared polypropylene pellets into the hopper of the injection molding machine. The pellets are heated to a molten state in the barrel by the heating system. The melt temperature is usually set between 180-220°C (356-428°F). This temperature range allows polypropylene to melt completely without degradation, so it flows well.

5. Injection:

When the plastic gets hot enough, the injection screw pushes it into the mold cavity really hard, with the injection pressure usually between 50-100 bar (725-1450 psi). The injection time is controlled between 1-5 seconds to make sure the plastic fills the mold fast and even.

6. Holding Pressure:

Keep applying holding pressure (usually 10-50 bar) while the molten plastic cools and solidifies. This is important to prevent defects like dents and bubbles in the finished product and to make sure the mold stays filled.

7. Cooling and Shaping:

The cooling time for the finished product in the mold usually takes 10-30 seconds, depending on the thickness of the product and the design of the mold. The cooling stage is important because it helps the plastic solidify into the shape you want, so it’s the right size and looks good.

8. Mold Opening and Ejection:

Once the finished product has cooled to the set temperature, open the mold and use an appropriate ejection system (e.g., ejector pins or slides) to remove the finished product from the mold. Be careful not to damage the finished product during this process.

9. Post-Processing:

Perform secondary operations on the final product, such as trimming, deburring, and quality control. Depending on the requirements, the final product can be buffed, painted, or otherwise treated to improve its appearance and functionality. These treatments not only make the final product look better, but also make it more durable and usable.

10. Inspection and Packaging:

At this stage, you need to check the finished product to see if it meets the requirements. You can use a bunch of different tests to do this. You want to see if the thickness is right, if it’s strong enough, and if it does all the other things it’s supposed to do. If it passes all the tests, you can put it in a box and send it to the customer.

11. Monitoring and Adjustment:

When you’re doing injection molding, you need to keep an eye on a few things. You want to watch the temperature of the melted plastic, the pressure of the injection, and how long it takes to cool. If you see something that needs to be changed, you can do it right away. That way, you can make sure that the parts you’re making are the best they can be.

Recommended Machine Settings:

| Parameter | Recommended Value | Notes |

|---|---|---|

| Plastic Injection Pressure | Up to 1500 bars | Ensures proper filling and shape retention |

| Melting Point | 200°C – 275°C | Optimal flow without degradation |

| Mold Temperature | 40°C – 80°C | Improves surface finish |

| Moisture Content | Below 0.2% | Prevents defects |

| Shrinkage Rate | 1% – 2.5% | Important for part design |

What are the advantages of PP Injection Molding?

PP injection molding is a manufacturing process that’s used in many industries, like automotive, consumer goods, medical devices, and packaging. It’s popular because it has a lot of advantages. Here are the main ones:

1. Lightweight and High Strength:

PP materials have a density of only 0.90-0.91 g/cm³, which makes it one of the lightest plastics around. This lightweight feature allows manufacturers to make more parts with the same amount of raw materials, which improves production efficiency and lowers transportation and handling costs. This is especially important in industries that need lightweight designs (like car manufacturing), which helps improve fuel efficiency a lot.

2. Excellent Insulation Properties:

PP has excellent electrical insulation properties, which makes it ideal for electrical components and devices. Its insulation properties ensure safety in high-voltage and complex electrical environments, reducing the risk of electrical failures. This makes PP an important material in the electrical industry and electronic product manufacturing.

3. Low Water Absorption Rate:

PP materials have a water absorption rate of only 0.01%, which means that products made from it can maintain stable performance in humid environments. This low moisture absorption is important for products that need to be highly moisture resistant (like building materials and some industrial parts), so they can be reliable and durable in different climates.

4. High Heat Distortion Temperature:

PP has a high heat distortion temperature, which means it keeps its shape in high-temperature environments. This makes it great for things that need to resist heat, like kitchenware, car parts, and stuff in your house that gets hot and needs to keep its shape.

5. Non-toxic and Odorless:

PP materials are non-toxic, odorless, and tasteless, making them perfect for food packaging and medical devices. PP meets international regulatory standards (like FDA and EU regulations), so it’s safe to use with food and drugs, which makes people trust it more.

6. Excellent Flowability:

When you’re making stuff with injection molding, PP is good because it flows really well. That means you can make complicated shapes and tiny details without a problem. It flows so well that it fills up the mold fast, which means you don’t have to worry about air bubbles or other problems that can mess up your stuff. That’s why PP is good for making high-quality stuff.

7. Cost-Effective:

PP is a cheap plastic. It’s especially cheap when you make a lot of it. Once you make the mold, the cost per part goes way down. That’s why PP injection molding is great for people who want to make a lot of stuff and not spend a lot of money.

8. Design Flexibility:

Injection molding is a process that allows you to make complicated shapes and tight tolerances in your product design. The design flexibility of PP allows you to make complicated shapes that are hard to make with other manufacturing methods. This lets you make the personalized and innovative designs that people want.

9. Durability and Impact Resistance:

PP materials have great impact resistance and fatigue resistance, able to withstand repeated physical stress without breaking or failing. This makes them very popular in consumer goods that require long-term use (such as sports equipment and household appliances), as these products often need to maintain stable performance in high-stress environments.

10. Chemical Resistance:

PP can withstand a bunch of different chemicals, like acids, bases, and solvents, which makes it good for places that deal with stuff that can burn you. This chemical resistance is why PP is used a lot in the chemical, pharmaceutical, and other industries that deal with that kind of stuff, so you know the things you’re making are safe and won’t change.

11. Low Waste Production:

Compared to traditional manufacturing methods, the waste generated during the PP injection molding process is relatively low. Excess materials (such as runners and sprues) can be reprocessed and reused, which helps to reduce resource waste and align with sustainable development principles.

12. UV Stability:

PP has excellent UV resistance, which makes it perfect for outdoor applications. It can maintain its performance even when it’s exposed to sunlight. This is why PP is the best material for outdoor furniture, agricultural films, and other products that are exposed to the elements.

13. Easy to Color and Finish:

PP materials can be dyed and post-processed to meet different design needs. This coloring capability allows manufacturers to quickly respond to market changes and provide personalized and customized products for customers.

14. Recyclability:

PP is a recyclable material that meets environmental protection requirements, adapting to current concerns about sustainability and resource recycling. Its recyclability not only helps reduce waste but also lowers overall production costs.

15. Wide Range of Applications:

PP is used in many industries, including packaging, automotive, medical devices, and consumer goods. This versatility allows PP materials to meet the needs of different fields, ensuring their competitiveness in the market.

What are the disadvantages of PP Injection Molding?

While PP injection molding is a popular and widely used manufacturing process, it has some significant drawbacks that you should consider before using it. Here are some of the main disadvantages of PP injection molding:

1. High Shrinkage Rate

PP materials have a shrinkage rate of 1% to 2.5%. This means they shrink when you make them in an injection mold. This can mess up the size of the part, especially if it’s thick and has a lot of plastic in it. It can make dents in the part.

2. Low Dimensional Accuracy:

Because of shrinkage, products made from PP may have trouble meeting high precision requirements. This can lead to inaccuracies in the final product dimensions and increase production costs.

3. Flowability Issues:

PP has poor flowability, meaning you need to use higher injection pressure and temperature to make sure the material fills the mold completely, otherwise you might not fill it enough or it might flow back. This affects the quality of the product and may also slow down production.

4. Surface Gloss and Appearance:

PP has a nice shiny surface, but it doesn’t flow well enough. So, the surface of the product will have silver-white streaks or voids where the mold wasn’t filled all the way. That will mess up the way it looks.

5. Low Impact Resistance:

PP has low impact resistance, so it’s not good for applications that might get hit hard and fast. That means it’s not good for some things.

6. Limited Chemical Resistance:

PP has limited resistance to irritating chemicals and corrosive substances, which may make it unsuitable for products that come into contact with these materials.

7. High-Temperature Limitations:

Polypropylene (PP) has a low melting point and can degrade or become brittle in high-temperature environments, which limits its use in some high-temperature applications.

8. Poor Adhesion Properties:

PP’s molecular structure makes it not stick well to other materials or coatings, which limits its use in some applications that need things to stick together.

9. Limited Color Choices:

The color consistency of PP is pretty bad, and you might not have a lot of colors to choose from, so it might not look great in the end.

10. Mold Challenges:

Making molds for PP injection molding can be complicated and costly, which can drive up the upfront investment in production.

Common issues and solutions in PP Injection Molding

The following is a summary of common issues and their solutions in polypropylene (PP) injection molding:

1. Warping:

Description: When you do injection molding, the parts can warp because the injection pressure and cooling aren’t even.

Cause: The mold design is wrong, the process isn’t set up right, or the cooling isn’t even.

Solution: Fix the mold design, adjust the temperature, pressure, and cooling time to make sure the cooling is even.

2. Short Shots:

Description: The mold isn’t filled up all the way, so there are holes in the part.

Cause: The injection machine doesn’t have enough power, the runner and gate in the mold are too small.

Solution: Increase the injection pressure, move the injection point, or use a material that flows better. Also, make the runner and gate bigger.

3. Bubbles:

Description: When you inject plastic, air gets in and makes bubbles.

Cause: The plastic is too hot and the mold doesn’t have enough holes.

Solution: Make the injection process better, make the plastic go faster and harder, make more holes in the mold, and dry the plastic before you use it.

4. Surface Pores:

Description: Small holes on the surface of molded parts.

Cause: Runner and gate are too small, plastic part has too thick walls.

Solution: Make the runner and gate bigger, adjust the molding temperature and injection pressure, and make the walls thinner.

5. Flashing:

Description: There’s too much material coming out of the mold.

Cause: The mold isn’t clamping hard enough, the mold is old and busted, or the mold is designed wrong.

Solution: Clamp the mold harder, fix the mold, or make the mold colder or shoot it with less pressure.

6. Weld Lines:

Description: Visible lines at the meeting point of two flow fronts, affecting part strength.

Cause: Melt temperature too low or injection speed too slow.

Solution: Increase melt and mold temperatures, optimize gate location, and increase injection speed as needed.

7. Sticking to the Mold:

Description: The plastic part doesn't come out of the mold smoothly.

Cause: The mold surface is not smooth enough, and the mold temperature is not controlled properly.

Solution: Make the mold surface smoother, adjust the mold temperature, and make the ejection area bigger.

8. Shrinkage Deformation:

Description: Molded parts shrink when they cool.

Cause: Not enough hold pressure, not enough injection pressure, or the mold is too hot.

Solution: Hold longer, shoot harder, and cool the mold down.

9. Vacuum Holes:

Description: Voids in molded parts, usually hidden from view.

Cause: Not enough holding pressure, mold temperature and injection pressure don’t match.

Solution: Increase holding pressure time, increase mold temperature, and decrease barrel temperature.

What are the applications of PP Injection Molding?

Polypropylene (PP) is a widely used thermoplastic that has a significant presence in various industries due to its excellent durability, lightweight characteristics, and cost-effectiveness. Below are the main areas where PP injection molding is used, showing its extensive applications across different industries:

1. Packaging Industry:

PP is now widely used in food packaging, pharmaceutical packaging, and daily necessities packaging because it is light, resistant to chemicals, and wear-resistant. PP film has good transparency and heat resistance, and can effectively resist moisture and chemical erosion, so it is an ideal choice for making food containers (such as take-out boxes and storage containers) and various packaging materials. With its excellent protection performance, PP can extend the shelf life of products, ensuring the safety and freshness of food and medicine.

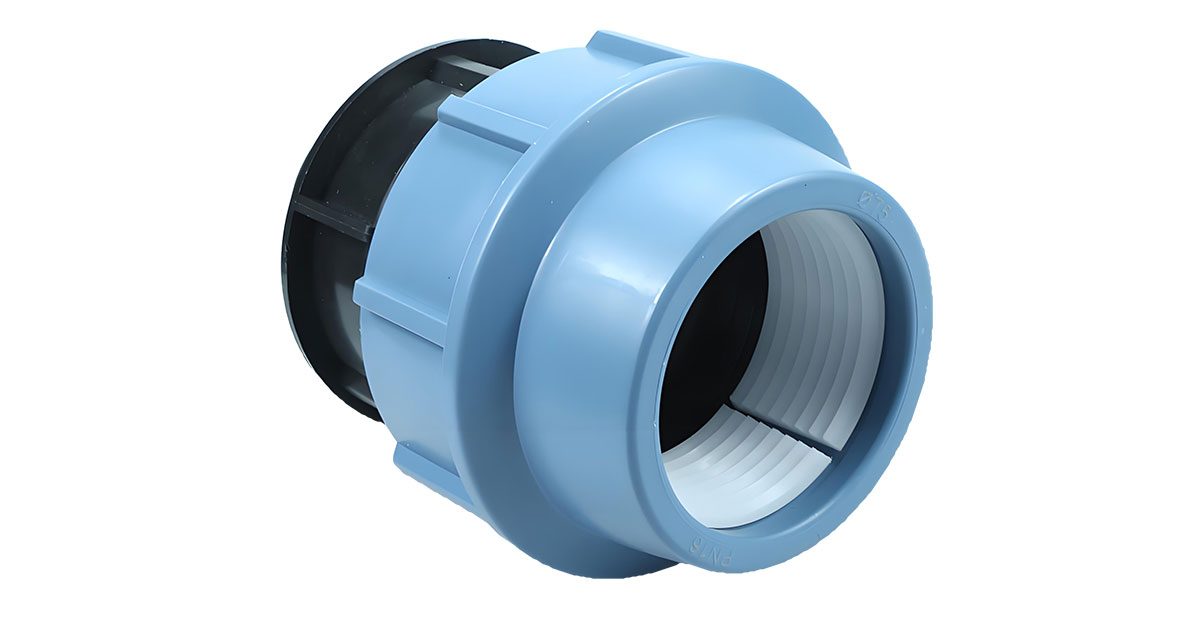

2. Construction Industry:

In the construction field, the use of PP sheets is getting more and more popular, which is commonly used for exterior walls, interior walls, ceilings, and flooring decorations. Its aesthetic, durability, and easy-to-clean features make it suitable for various architectural styles. In addition, PP is used to produce pipes, insulation materials, and flooring materials, which have excellent chemical corrosion resistance and UV resistance, so it is very suitable for outdoor use. These characteristics not only extend the life of the building but also effectively reduce maintenance costs.

3. Automotive Industry:

PP is used a lot in making car parts like dashboards, rearview mirror housings, bumpers, and body parts. Because it’s light and can take a hit, it can make cars weigh less and use less gas. Also, because it’s tough and doesn’t rust, it can be used in places where cars get beat up, making them safer and last longer. It can also be made into all kinds of shapes, so cars can look cooler and work better.

4. Electronics and Electrical Industry:

In the electronics and electrical industry, PP is widely used to make cable sheaths, sockets, switches, and other components. Its good insulation properties ensure the stable operation of electronic devices, reducing the risk of electrical short circuits and overheating. Due to the heat resistance and chemical stability of PP, it is particularly important in the manufacturing of household appliances, ensuring the safety of devices in high-temperature and humid environments.

5. Medical Device Industry:

PP is an important material in the medical device field because it’s biocompatible and non-toxic. It’s used in medical syringes, test tubes, infusion tubes, and surgical instruments. These products often touch the human body. PP is non-toxic, odorless, and corrosion-resistant. It’s highly recognized in the medical industry because it meets strict hygiene standards and keeps patients safe.

6. Furniture and Daily Necessities:

PP materials are also widely used in furniture and daily necessities, such as storage boxes, laundry baskets, and garden furniture. Its durability, waterproof properties, and easy-to-clean features make it an ideal choice for making everyday items. These furniture not only look good, but also have a long service life, meeting the dual needs of modern consumers for practicality and aesthetics.

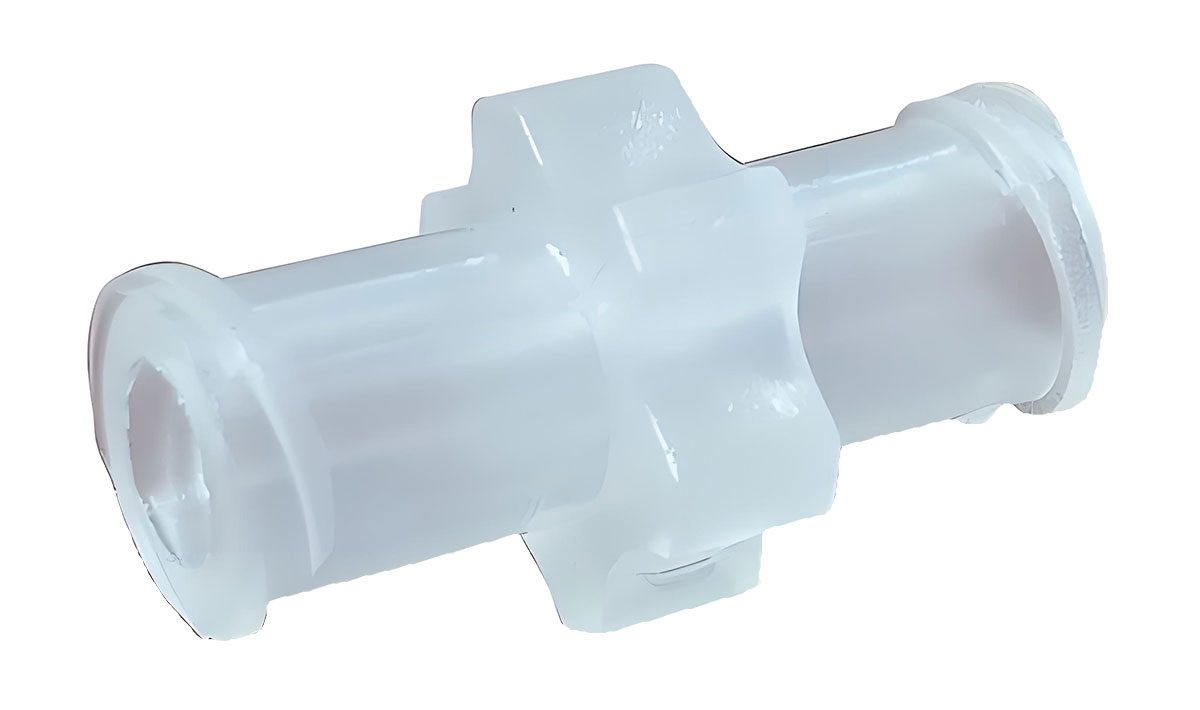

7. Industrial Parts:

PP is also important in industry, where it is used to make gears, bearings, seals, and other industrial parts. Its high strength and resistance to chemicals make it useful in many tough environments. In particular, in the chemical and machinery manufacturing industries, PP’s resistance to corrosion can make equipment last longer and reduce maintenance costs.

How Can Manufacturers Effectively Reduce Costs in Injection Molded Part Production?

Key Takeaways – Material selection and wall thickness optimization are the primary drivers for reducing piece-part costs. – Investing in higher-quality tooling (Class 101/102) can lower long-term unit costs through

Family Molds vs. MUD Systems: Which Strategy Best Manages Multi-Part Injection Molding Projects?

Key Takeaways – Family molds produce multiple different parts in one shot, but a single compromised process window affects all cavities simultaneously. – MUD (Master Unit Die) systems use interchangeable

What is a High-Speed Injection Molding Machine?

Key Takeaways – A high-speed injection molding machine is defined by injection speed4s of 300–600 mm/s and clamp speeds exceeding 500 mm/s, compared to 100–200 mm/s for standard machines—enabling cycle

Optimization Solutions Provided For Free

- Provide Design Feedback and Optimization Solutions

- Optimize Structure and Reduce Mold Costs

- Talk Directly With Engineers One-On-One