Choosing between steel and aluminum molds is essential for optimizing production efficiency, cost, and quality. Both materials have distinct advantages and applications in injection molding.

Steel molds offer superior durability, making them ideal for high-volume production, while aluminum molds are cost-effective and best suited for lower-volume runs. The right choice depends on production needs and cost considerations.

While the material choice significantly impacts mold performance, understanding the differences in durability, cost, and lead time is crucial. Dive deeper to determine which mold material aligns with your production goals.

Steel molds are more durable than aluminum molds.True

Steel molds can withstand higher wear and tear, making them suitable for high-volume production runs.

Aluminum molds are always cheaper than steel molds.False

Aluminum molds may be cheaper initially, but steel molds offer better cost-efficiency in high-volume production due to their extended lifespan.

What are the Things to Note Before Choosing an Aluminum Mold or a Steel Mold?

Choosing between steel and aluminum molds is essential for optimizing production efficiency, cost, and quality. Both materials have distinct advantages and applications in injection molding.

Steel molds offer superior durability, making them ideal for high-volume production, while aluminum molds are cost-effective and best suited for lower-volume runs. The right choice depends on production needs and cost considerations.

Do you know what happens if you use the wrong molds? You get bad parts, slow cycle times, low production, high costs, and maybe even a failed project. But you can avoid all that if you consider these things when you choose aluminum injection molds1 and steel injection molds2.

Tool Life and Maintenance

Steel and its alloys are stronger, harder, more resistant to wear and fatigue, and more thermally stable than aluminum. That’s why steel molds last longer. So, you need to decide if you need a mold that lasts.

Second, both types of molds require maintenance over time to keep making the same product. Some typical maintenance activities include cleaning, greasing, checking how often you use the mold, and checking for wear.

Product Quantity and Production Scale

Here’s another thing to think about before you decide on steel injection molds or aluminum injection molds. Steel is great for high-volume production because it lasts a long time and can handle high temperatures all day long. You can make millions of parts with it and they’ll all be the same and perfect.

But if you’re doing low-volume production or you’re just making a prototype, you should use aluminum molds.

Cost Analysis

When you compare the price of steel to the price of aluminum in the context of injection molding , aluminum molds are cheaper. Steel molds can cost twice or more than aluminum molds of the same size and specifications.

While steel molds require a higher upfront investment, they pay off in the long run. Plus, when you’re doing mass production, steel is the way to go because it has a lower unit cost. On the other hand, if you’re doing a few thousand runs for prototyping, aluminum is the way to go because it’s cost-effective.

Material Properties

Steel and aluminum have different physical, mechanical, and chemical properties. So, they behave differently during the injection molding process. Aluminum is soft and ductile, but it has excellent thermal conductivity. On the other hand, steel is a strong and highly wear-resistant material with relatively low electrical conductivity.

Compatibility of Advanced Resins

The type of stuff you’re molding will also affect your decision of steel versus aluminum injection molds. For example, aluminum molds can’t process some abrasives and high-melting thermoplastic polymers like PEEK, glass-filled nylon, and PSU. But steel molds can make parts from almost any advanced resin. So it’s important to evaluate the properties of the molding material3.

Steel molds are more durable than aluminum molds.True

Steel molds can withstand higher wear and tear, making them suitable for high-volume production runs.

Aluminum molds are always cheaper than steel molds.False

Aluminum molds may be cheaper initially, but steel molds offer better cost-efficiency in high-volume production due to their extended lifespan.

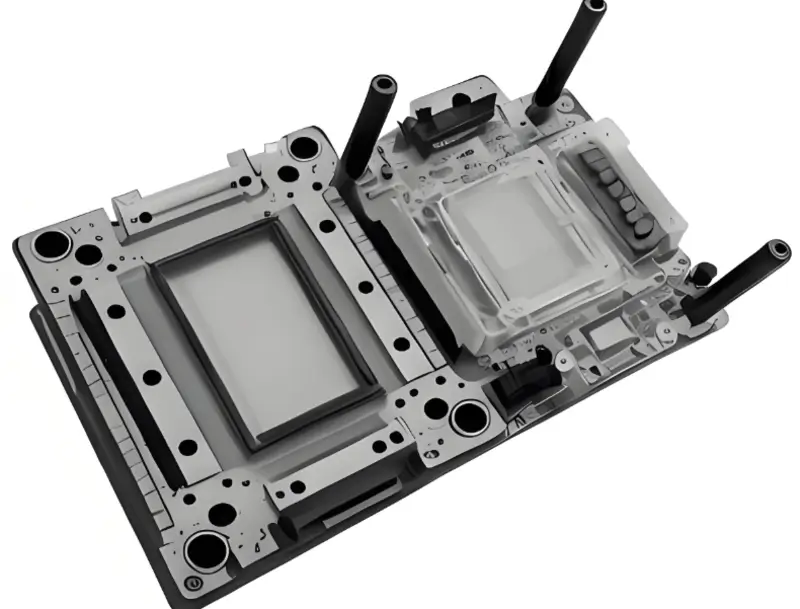

What are the Advantages of an Aluminum Mold?

Aluminum molds offer enhanced production efficiency with faster cooling times, making them ideal for prototyping and short-run manufacturing.

Aluminum molds provide quicker machining, faster cycle times, and excellent heat dissipation, which contribute to cost-effective prototyping and reduced manufacturing lead times in various industries.

Easy to Modify and Repair

Steel molds can be very difficult and expensive to repair if they get damaged or deformed because they are so hard. In that case, you usually have to get a new mold. Aluminum molds are easier to repair and because they are a softer material, they are easier to modify if you make a mistake in production.

Aluminum is great because it machines really well, you can run it faster, you can cycle it faster, you can make engineering changes easier, you can hold tighter tolerances, and you can have consistent processes, which all reduce your costs. Now, anything you can do in a traditional P20 mold, you can do it in an aluminum mold.

Processing Speed 5-10 Times Faster

Aluminum is great to work with. It makes small chips, has fewer burrs, and you can feed it into a CNC machine really fast. You can machine it and EDM it five to ten times faster than steel tooling. You can finish and polish it faster, so you can build molds faster.You can build molds 20% to 50% faster.

The aluminum mold cavities conduct heat and cool down almost five times faster than P-20 tool steel. Faster cooling usually means you can make parts faster and reduce the cycle time. You can also mold parts without machining cooling channels, which saves time making the mold.

Aluminum molds are much better than steel molds because they cool down faster. They can heat up and cool down up to 7 times faster than steel molds. Cooling time is a big part of how long it takes to make a plastic part. So, if you use an aluminum mold at the right time, you can make parts a lot faster.

20-30% Reduction in Production Costs

Aluminum molds are usually one-third the weight of steel molds, which makes them easy to handle. Aluminum is easy to machine, so it’s easier to make aluminum molds and there is less tool wear. Aluminum molds have simplified cooling systems and mold designs, which makes them more productive. All of these things reduce the cost of making parts.

Aluminum molds can be a better cost advantage4 when used in the right application because of the reduced scrap rates of parts. For shorter runs, the lower upfront cost of aluminum molds can reduce the overall cost per part.

Aluminum molds are good for small batches. As I mentioned earlier, aluminum molds can give you more value for small batch production because of the lower upfront cost of aluminum molds.

When it comes to the cost of making a mold, aluminum is cheaper than steel. Now, the total value and return on investment of aluminum molds and steel molds will vary greatly depending on how you use the mold (like how long you expect it to last). But, all things being equal, the upfront cost of aluminum will be less than steel.

Improve the Ddimensional Stability of Parts

Aluminum alloy injection molds can dissipate heat evenly, which means the mold temperature stays stable. This makes the mold more dimensionally stable, so it doesn’t warp or deform. That means less waste when you make stuff.

Aluminum is great at getting rid of heat, which means the mold can heat up and cool down faster and more evenly. That’s good because it means fewer bad parts and less scrap.

Design Modification is More Flexible

Injection aluminum molds are a great way to speed up product launch because they’re more flexible and easier to process than steel molds. That means you can make design changes or modifications without a lot of trouble or added cost. So, if you need to make a lot of changes or you’re not sure what the final design will be, aluminum molds are a good choice.

Aluminum molds are molds that are formed by injecting aluminum alloy into the mold cavity through a high-pressure injection molding machine according to the set shape and size, and cooling and condensing under high pressure.

During the entire injection molding process, aluminum molds have good thermal conductivity and heat dissipation, which can quickly cool the aluminum alloy, thereby improving the manufacturing efficiency of the mold.

Aluminum molds reduce cooling times in injection molding.True

Aluminum's superior thermal conductivity leads to quicker cooling times, increasing production speed.

Aluminum molds are suitable for every type of production run.False

Aluminum molds are best suited for prototyping and short runs due to their lower durability compared to steel molds.

What are the Disadvantages of an Aluminum Mold?

Aluminum molds offer certain benefits, but they also present several disadvantages, such as lower durability and limited suitability for high-volume production runs.

Aluminum molds are less durable than steel molds, limiting their use in high-volume production. They are more prone to wear and may warp under high heat or pressure, making them less suitable for producing complex or high-precision parts.

Compared to steel molds, the service life is relatively short, not durable enough, prone to wear, deformation, and other problems, and need to be replaced frequently. These molds are not suitable for some advanced high-melting point resins such as PEEK and PSU.

The life is too short, only ten thousand cycles. The softness of aluminum makes the mold more prone to wear. For example, scratches will form even with regular maintenance.

Aluminum molds decrease production costs for low-volume runs.True

Aluminum molds have lower initial costs compared to steel, making them suitable for prototype and low-volume production where high durability is not required.

Aluminum molds are suitable for high-pressure applications.False

Aluminum molds lack the strength to withstand high pressures, which can lead to warping or deformation during the molding process.

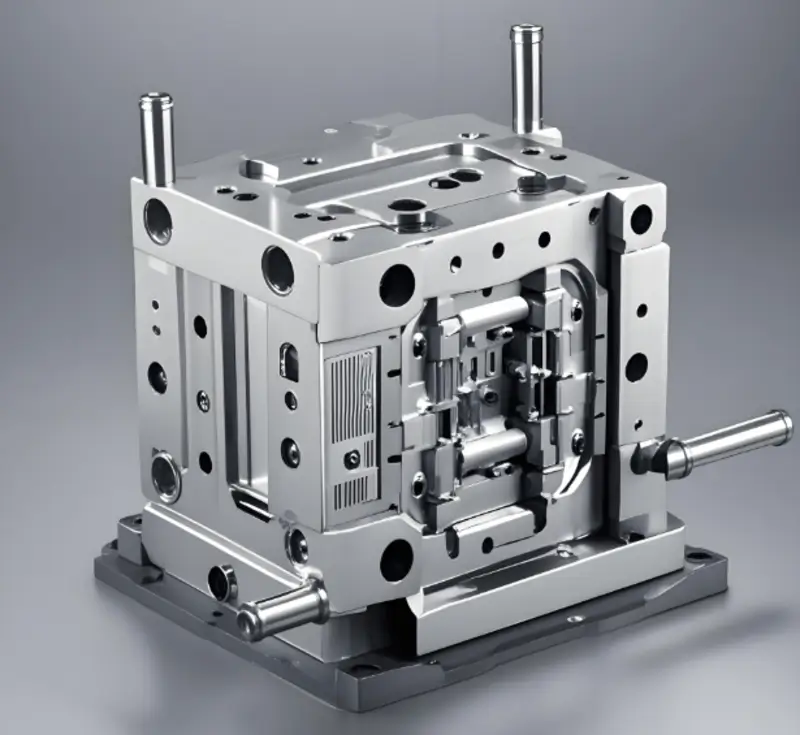

What are the Advantages of a Steel Mold?

Steel molds offer exceptional durability and precision, making them a preferred choice in various manufacturing sectors for long-term and high-volume production needs.

Steel molds provide superior durability and precision, ideal for high-volume manufacturing. They excel in heat tolerance and dimensional accuracy, reducing defects and ensuring consistent quality in industries like automotive and electronics.

Steel Molds are Suitable for Large Batches

For molds used for big production and multiple production, steel structures are usually your best bet. Invest a higher upfront investment, and these equipment can reliably last for many years with proper maintenance . For long production runs, nothing beats the strength of steel.

Suitable for a Variety of Resins

While both steel and aluminum are generally suitable for a wide range of standard injection molding resins, steel can offer advantages if you are working with more complex formulations, such as those reinforced with glass, fiber, or other additives.

Relatively soft metals like aluminum are at greater risk for scratches or other damage from certain types of additives, which can affect the finish and feel of the final part. Be sure to check the compatibility of your chosen resin, especially if it includes additives.

Suitable for Detailed Features

When you need really fine, detailed features (features that push the boundaries of injection mold design best practices, such as thin, uneven walls, small radius corners, and tighter cavity areas, for example), steel molds will generally give you better results than aluminum. The strength and hardness of steel means it is better able to hold the shape of those extremely high precision areas.

Durability

The biggest benefit of a steel mold is how long it lasts. It’s way more durable than anything else you can get. If you’re going to run a lot of parts and you’re going to use the mold for years, steel is the way to go. You have to spend more money up front, but you’ll get it back in the millions and millions of parts you can make with it. Steel can also save you more money on parts than anything else. Steel molds have a long manufacturing cycle and require relatively more manufacturing costs, making them unsuitable for scenarios such as small batches or initial trial production. The high upfront cost limits their use in startups and small businesses. Steel molds cool slowly, which increases the injection cycle time5 and affects production costs.

Steel molds are more resistant to wear than aluminum molds.True

Steel molds have higher wear resistance due to their superior strength, making them ideal for long-term, high-volume production.

Steel molds are unsuitable for precision applications.False

Steel molds are highly suited for precision applications, offering superior dimensional consistency and detail retention, especially in industries such as aerospace and electronics.

What are the Disadvantages of a Steel Mold?

Steel molds are essential in manufacturing, offering durability and precision for high-volume production across various industries.

Steel molds, while durable, are costly, have longer production times, and can be prone to corrosion without proper maintenance, impacting efficiency.

Steel molds have a long manufacturing cycle and require relatively more manufacturing costs6, making them unsuitable for scenarios such as small batches or initial trial production. The high upfront cost limits their use in startups and small businesses. Steel molds cool slowly, which increases the injection cycle time and affects production costs.

Steel molds are more durable than aluminum molds.True

Steel molds withstand higher production volumes and offer better resistance to wear and tear compared to aluminum molds.

Steel molds are always the costliest option in mold making.False

Although steel molds have a higher initial cost, they can be more cost-effective for large production runs due to their durability and longevity.

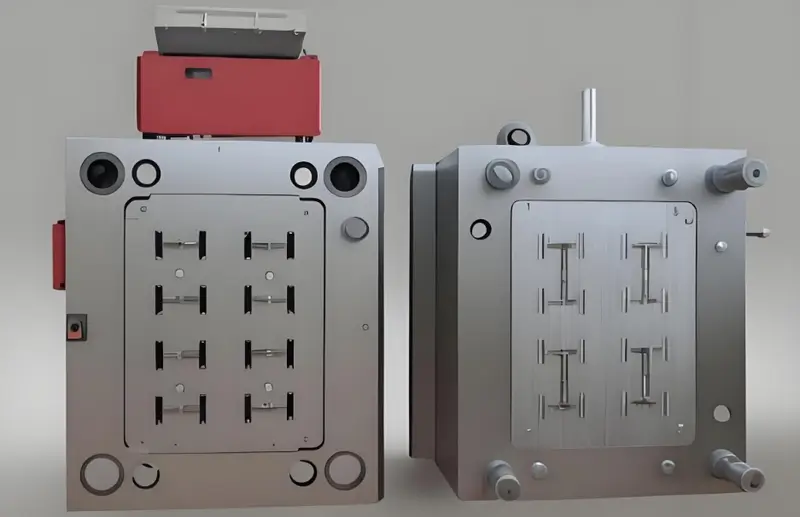

What are the Main Differences Between an Aluminum Mold And a Steel Mold?

Aluminum and steel molds differ significantly in terms of cost, durability, and application suitability in injection molding, impacting manufacturing choices.

Aluminum molds are lighter, less expensive, and suitable for prototyping and short runs; steel molds offer durability and precision, ideal for long-term, high-volume production.

There are several differences between aluminum injection molds and steel injection molds, such as turnaround time, stability, manufacturing time, flexibility, durability and wear resistance, mold cost, etc.

This comparison is usually made in the form of soft tools vs. hard tools. Next, let\’s explain in detail the main differences between steel and aluminum tooling.

Turnaround Time

Aluminum injection molds are made from aluminum blanks by using CNC machining and finishing operations. In some cases, if the cavity must have sharp corners that cannot be obtained by milling, additional electrical discharge machining (EDM) is required.

Typically, the machining is mostly a mechanical process, no heat treatment is needed, and very few specialized tools are required. An average aluminum mold can be made in 10 to 15 days. Because aluminum has a higher heat transfer rate, it heats and cools seven times faster. This factor greatly reduces the overall lead time.

includes tool setup time, injection time, filling and molding time, and cooling time. Of these,mold cooling takes 50 to 80% of the cycle time.

Aluminum has a higher heat dissipation rate, so molds cool faster than steel. That means they cut overall molding cycle time.

Steel molds are made in a similar way, but with a few differences. First, the mold material is much harder and takes longer on the machine, wears out cutting tools, and requires specialized tooling. Second, extensive heat treatment operations are required to increase mold life. All of this takes time. As a result, steel molds take 2 to 5 months to complete.

Rapid heat conduction makes sure that the injected material fills the cavity evenly because it lets the liquid flow over a longer distance. Steel, on the other hand, cools slower, which means longer production cycles.

Stability

Steel injection molds are heat-hardened and are designed to last. They have minimal seams and are made from the most durable steel. That’s why they can withstand millions of parts.

Aluminum tools are made of a softer material, but some aluminum alloys have excellent strength. This allows the mold to withstand up to 5,000 parts. The average is 100-2000 parts

Manufacturing Time

Steel molds can handle the highest injection pressures and temperatures, which is why the manufacturing process can take as little as 5 to 10 seconds.

Aluminum injection molds aren’t as strong, so their pressures and temperatures are 20-30% lower than steel molds. The manufacturing time is 44-70 seconds, which is considerable when we start talking about thousands of parts.

Flexibility

Steel molds are hardened by heat treatment. This is usually done after all the basic parts have been machined and there is only a small layer of material to be ground. If some features need to be modified, it may be difficult because the hardness of the cavity is very high.

Aluminum molds are made of a softer material, and their cavities are usually made as separate parts installed in the mold base. So, it is much easier to take out the cavity and make adjustments.

Durability and Wear Resistance

Steel is made up of carbon and other elements, which gives it great strength, hardness, fatigue resistance, and heat resistance. This is why steel molds are highly wear-resistant, can withstand long-term injection pressure, and are more sustainable. They can be used over and over again for millions of molding cycles.

On the other hand, aluminum molds have a fast heat transfer rate, which causes the material to expand and contract quickly. This leads to mold dimensional instability and misalignment over time. Additionally, aluminum has a softer surface and is more susceptible to scratches and dents.

For these reasons, aluminum molds are less durable and wear-resistant compared to steel injection molds and aluminum injection molds. They are suitable for producing a few hundred to ten thousand identical injection molded parts

Mold Cost

Aluminum is cheaper. Your molding partner may quote you half the price for their aluminum compared to their steel molds. This is because of scarcity and manufacturing methods. Steel is expensive. Aluminum molds are easier to manufacture compared to steel because it is ductile and easily available.

All other factors being equal, aluminum gives you a lower tooling investment compared to steel. However, the overall value and return on investment of a mold can vary greatly—so initial price shouldn’t be your only consideration when choosing between aluminum or steel molds.

Aluminum molds are always cheaper than steel molds.False

While generally less expensive, aluminum molds may incur additional costs when used for complex designs or large production volumes.

Steel molds offer better precision and longevity.True

Steel molds provide greater precision and can withstand high-volume production without frequent maintenance or replacement.

Conclusion

So, in conclusion, when it comes to choosing between steel and aluminum for plastic injection molding , it all depends on what you need. Steel is super strong and lasts a long time, so it’s great for cranking out a ton of parts and making really complicated shapes that need to be perfect.

Aluminum, on the other hand, is cheaper, processes faster, and is perfect for prototypes and small runs. You just need to think about how much money you have, how many parts you’re going to make, how complicated the parts are, and how long you want the mold to last.

-

Explore the benefits of aluminum injection molds to understand their cost-effectiveness and suitability for low-volume production. ↩

-

Learn why steel injection molds are preferred for high-volume production and their long-term cost benefits. ↩

-

Discover how different molding materials influence the decision between aluminum and steel molds for optimal production. ↩

-

Discover how aluminum molds can provide significant cost advantages, especially for small batch production, to improve your bottom line. ↩

-

Understanding injection cycle time can help optimize production efficiency and reduce costs in manufacturing. ↩

-

Understanding the cost differences can help businesses choose the right mold for their production needs. ↩