Plastic injection molding is a widely used manufacturing process known for its efficiency, versatility, and cost-effectiveness in producing high-quality parts with complex shapes.

Plastic injection molding enables rapid, precise, and scalable production, ideal for large quantities with minimal waste. It’s widely used in automotive, electronics, and medical device industries.

Understanding the core benefits of plastic injection molding can help you determine its suitability for your specific needs. Keep reading to explore how this process optimizes both production and cost-efficiency.

Plastic injection molding is cost-effective for high-volume production.True

Plastic injection molding allows for quick, large-scale production with minimal waste, which reduces costs per unit in mass manufacturing.

Plastic injection molding is suitable only for simple designs.False

Injection molding is versatile, capable of creating complex geometries and intricate parts with high precision, making it suitable for a wide range of products.

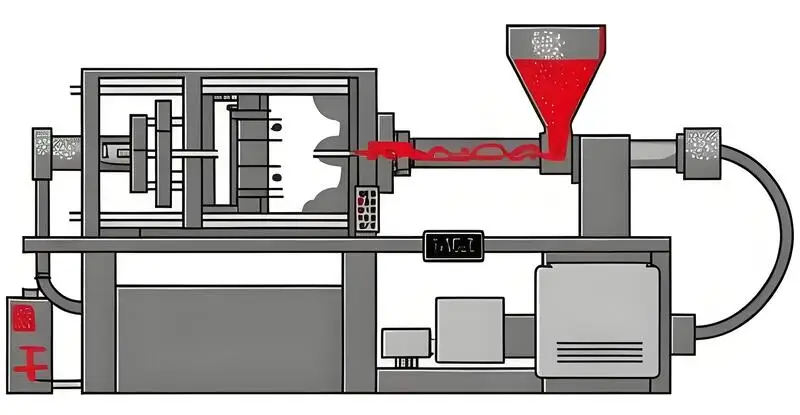

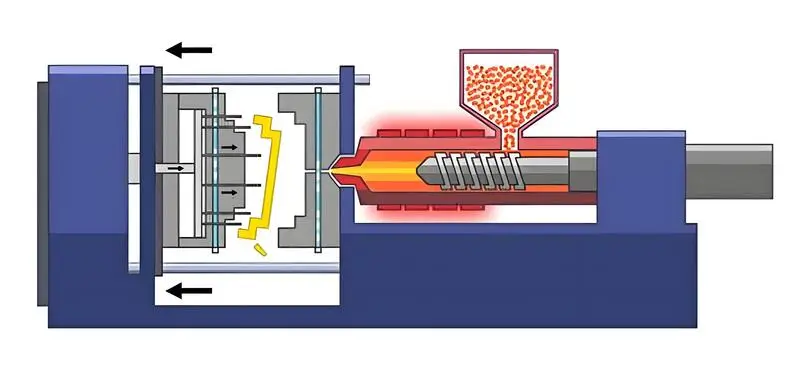

What is Plastic Injection Molding Process?

Plastic injection molding is a manufacturing process used to create precise and complex parts by injecting molten plastic into a mold. It’s widely used in industries like automotive, electronics, and medical devices.

The plastic injection molding process injects molten plastic into a mold to create precise parts, ideal for mass production in automotive, medical, and consumer goods industries.

Plastic injection molding is a way to make lots of plastic parts and products. It’s done by molten plastic resin pellets and shooting them into a mold with a lot of pressure. Once the plastic cools down and gets hard, the mold opens up and the part is taken out.

Injection molding is used for mass production of plastic parts.True

The process allows for the efficient production of large quantities of uniform plastic parts, making it ideal for industries that require consistent, high-volume manufacturing.

Injection molding is a slow process.False

Injection molding is actually a fast process due to its automated nature, with cycle times often as short as 15 to 30 seconds per part, depending on complexity.

What are the Types of Plastic Injection Molding?

Plastic injection molding encompasses several techniques tailored for various applications, from mass production to intricate, high-quality parts. Each type offers distinct benefits depending on the material and end use.

Plastic injection molding types include standard, multi-material, and overmolding, used in automotive, consumer goods, and electronics. Each method offers distinct benefits regarding cost, materials, and complexity for various applications.

Thermoplastic Injection Molding

Thermoplastics, as the name suggests, get more pliable (turn into liquid) when heated. Thermoplastic injection molding1 is the most commonly used type, using thermoplastic materials like polypropylene (PP), polyethylene (PE), nylon (PA), and acrylic resins to make functional parts.

Thermoset Injection Molding

Thermoset materials, on the other hand, set or solidify when heated. It\’s a one-time molding process where you put pliable thermoset plastics into a heated mold to shape them into their final form. This process uses thermoset materials like epoxy resins or phenolic resins to make parts.

Liquid Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding2, also known as Liquid Injection Molding (LIM), is a thermoset process that involves mixing two liquid compounds and curing them in a mold using a platinum catalyst to produce flexible silicone parts. LSR products are tough and long-lasting, able to withstand extreme temperatures, making them ideal for demanding applications.

Multi-material injection molding provides more flexibility in design.True

This method allows combining different materials in a single part, enhancing functionality and performance.

Overmolding always results in better part durability.False

While overmolding improves grip and protection, it doesn't guarantee higher durability for all applications. The design and material choices significantly affect part strength.

What are the Advantages of Plastic Injection Molding?

Plastic injection molding offers high efficiency, precision, and cost-effectiveness, making it a top choice for manufacturing complex and large-scale products.

Plastic injection molding is an efficient manufacturing method offering quick production, minimal waste, and high precision, suitable for mass-producing accurate parts for diverse industries.

Flexibility

-

Production Flexibility:Injection molds are designed and made to be flexible. You can customize them to fit the shape, size, and function of your product. You can also make them to meet other requirements you have. Injection molding3 machines are easy to use and take care of. This means you can use them to make lots of different products.

-

Flexibility in Mold Making Process:Also, the process of making injection molds is not only precise but also highly flexible. This means once we produce the mold, it is easy to change the type of material and the colors of the production.

-

Flexibility of Color and Material:Plastic injection molding is a flexible process. It’s flexible in the materials you can use, and it’s flexible in the colors you can choose. That’s good news for OEMs because it gives them design freedom. It’s especially good news when you compare it to metals. You can use a lot of different materials.To get the color you want, you can adjust the plastic, additives, and biocompatibility in the molding process to make transparent parts or different colors. But if you want a product with multiple colors, you can use coating molding.Picking the right materials and colors for your project is two of the most important parts of making plastic parts. Because there are so many of these two, you can pick from almost anything.

Cost-Effectiveness

-

Saving Labor Costs:Compared to other types of molding processes, the labor costs of injection molding operations are relatively low. The ability to produce high-quality parts with high productivity helps reduce manufacturing costs through efficiency and effectiveness.Injection molding equipment requires less labor, which is due to the fact that they usually use automatic door control and fully automatic tools to achieve streamlined operations and continuous production.Molding equipment usually comes with automatic pouring, automation process tools, to keep operations simplified and large-scale production in the minimum of monitoring.

-

Reducing Costs:Most of the plastic molding work is done by machines and robots. For plastics, this is an automated process4. Any injection company knows that automation reduces manufacturing costs, which greatly reduces daily expenses. If labor costs are minimized, the total cost of production will naturally be minimized, while cost savings will also be transferred to potential customers.At present, the process is considered to be environmentally friendly5. If waste production is minimal, it is clear that people will like it. injection molding machine equipped for co injection molding effectively utilize excess plastic, promoting efficient material usage and cost-effectiveness in manufacturing processes.

Efficiency and Precision

-

Increase Production Speed:First, compared to other methods, injection molding is faster, which makes it more efficient because it has a high production output rate.The speed depends on the complexity and size of the mold, but there is only about 15-120 seconds between each molding cycle. Because the cycle time is so short, you can produce more injection molded parts in a given production time.

-

High Production Efficiency:One of the biggest benefits of plastic injection molding is that it’s super efficient. It’s really fast, and that makes it more efficient and cost-effective. Each cycle only takes about 15-120 seconds, and the speed can vary.Injection molding is one of the most common technologies for long-term production because it has a short cycle. Depending on how complicated the mold is, the cycle time is only about 15 to 30 seconds between cycles.

-

Product High Precision:Injection technology achieves high-precision plastic products by precisely controlling parameters such as injection pressure and speed. In addition, the accuracy and life of the mold are also improved, further ensuring the quality and stability of the product.As a highly accurate processing method, plastic injection molding technology can be used to produce almost any type of diversified plastic parts. While there are indeed some design restrictions, the manufacture of injection molds ensures the high precision of molded products.

Environmental Protection and Part Consistency

- Environmental Protection:Nowadays, sustainability is a big deal, so it’s important for product developers to pick a process that helps the environment and cuts down on waste. Injection molding is not only an efficient process, but it’s also really green because it only uses the plastic it needs to make the parts. Any parts that don’t pass inspection or get thrown away can be recycled and used again.As people become more aware of the importance of protecting the environment, injection molding technology is also moving in a more environmentally friendly direction. By improving the design of molds and adjusting the process parameters, we can reduce energy consumption and waste generation.At the same time, recycling and reusing waste plastic products is also becoming more popular, which helps to reduce environmental pollution.

-

Waste Reduction:Plastic injection molding processes don’t generate much waste after production compared to traditional manufacturing processes. The only waste plastic comes from sprues and runners. But any unused or discarded plastic can be re-ground and recycled for future use.

-

Consistency of Parts:To make a lot of plastic parts that are all the same, you need a process that can make them the same every time. Injection molding is a good way to do that. You use the same mold to make every part, and you use machines that are always getting better at making parts.

Injection molding minimizes material waste.True

By utilizing precision molds, injection molding ensures minimal waste, making it more environmentally friendly and cost-effective.

Injection molding is always the cheapest manufacturing option.False

While injection molding can be cost-effective for large volumes, initial mold costs can be high, making it less economical for smaller production runs.

What are the Applications of Plastic Injection Molding?

Plastic injection molding is a versatile manufacturing process used to produce a wide range of products across many industries, from automotive to electronics.

Plastic injection molding is crucial for automotive, electronics, medical, and consumer goods, offering high precision, fast production, and cost efficiency, ideal for complex and high-volume manufacturing.

Automotive Industry

In the car biz, plastic injection molding is used a lot to make everything from dash parts to bumpers, lights, and inside parts. It lets you make a lot of complicated parts that are all the same and last a long time.

Consumer Goods

Consumer goods manufacturers depend on plastic injection molding to produce durable, high-quality parts6 in large volumes. This process guarantees that finished products meet aesthetic and functional requirements. Whether it’s kitchen appliances or electronic casings, plastic injection molding is the go-to method for manufacturing consumer goods.

Medical Devices

Plastic injection molding is super important in the medical device industry7 for making really precise parts that meet really strict rules. It lets you make stuff out of materials that work with your body and are good for all kinds of medical things.

Packaging Industry

Plastic injection molding is a big deal in the packaging industry. It’s how we make containers, caps, and other packaging parts. It’s great because it lets us design and use all kinds of materials to make all kinds of packaging.

Plastic injection molding is widely used in the automotive industry.True

The automotive industry uses plastic injection molding for parts like dashboards, bumpers, and lights, benefiting from the process's precision and efficiency.

Plastic injection molding is used only for small, consumer products.False

Plastic injection molding is not limited to small items; it is also used for large parts like automotive components, industrial machinery, and medical devices.

Conclusion

Plastic injection molding8 is a super versatile and super efficient manufacturing process that has revolutionized the production of plastic parts across a wide range of industries.

Its ability to produce complex parts with high precision, consistency, and cost-effectiveness makes it the go-to choice for many manufacturers. As technology continues to advance, injection molding is likely to evolve even further, offering even more capabilities and sustainability in the future.

-

Explore this link to understand the significance and applications of thermoplastic injection molding in various industries. ↩

-

Discover the advantages of LSR molding, especially its flexibility and durability for demanding applications. ↩

-

Explore the advantages of injection molding, including flexibility, cost-effectiveness, and efficiency in production. ↩

-

Discover how automation in manufacturing can reduce costs and improve efficiency, making production more streamlined. ↩

-

Learn how injection molding minimizes waste and promotes recycling, making it a sustainable choice for manufacturers. ↩

-

Discover insights on how this process guarantees the durability and quality of manufactured goods. ↩

-

Learn about the critical importance of injection molding in creating precise and compliant medical devices. ↩

-

Learn about What is the plastic injection molding process? Injection molding is an efficient and precise manufacturing process suitable for producing a wide array of plastic components with intricate geometries. ↩