Custom PET Injection Molding Factory

PET injection molding manufacturing and design guide

Resources for The Complete Guide to PET Injection Molding

What is PET?

Polyethylene Terephthalate (PET)

Polyethylene terephthalate (PET), also known as polyester resin, is the most important type of thermoplastic polyester. It is a widely used thermoplastic polymer that belongs to the polyester family. It is mainly made up of two key monomers: ethylene glycol and terephthalic acid. When these ingredients polymerize, they form long-chain PET, which can be processed into various forms such as fibers, films, and containers.

PET is a milky white or light yellow highly crystalline polymer with a smooth and glossy surface. It has good creep resistance, fatigue resistance, abrasion resistance, and dimensional stability. It has low wear and high hardness and has the highest toughness among thermoplastic plastics. It has good electrical insulation performance, is less affected by temperature, but has poor corona resistance. It is non-toxic, weather-resistant, and has good chemical stability. It has low water absorption and is resistant to weak acids and organic solvents, but it is not resistant to hot water immersion and alkali. PET resin has a high glass transition temperature, slow crystallization rate, long molding cycle, large molding shrinkage, poor dimensional stability, brittle crystallization, and low heat resistance.

What types of PET materials are there?

Polyethylene Terephthalate (PET) is a versatile and widely used thermoplastic polymer that belongs to the polyester family. It can be classified into several types based on its structure and applications:

1. Standard PET (Polyethylene Terephthalate):

Regular PET is the most common type of PET, used in many industries because it has great chemical, thermal, and mechanical properties. It’s a semi-crystalline polymer that’s clear, strong, and keeps gases and moisture out. PET is used a lot in packaging, especially for making bottles for drinks and containers for food.

2. Amorphous PET (APET):

APET is a type of PET that doesn’t have a crystalline structure, which makes it really clear and shiny. APET is mostly used in things where you need to be able to see through it. It doesn’t change shape much when it gets hot, it’s easy to make it into shapes, and it’s pretty tough and doesn’t get messed up by chemicals.

3. Crystalline PET (C-PET):

C-PET is more crystalline than regular PET, which makes it more opaque and better at resisting heat. Because it can handle high temperatures, C-PET is often used in things that get hot, like food trays that can go in the oven. The extra crystallinity also makes it stronger, so it can take more pressure.

4. Biaxially Oriented PET (BOPET):

Biaxially oriented PET (BOPET) is a type of PET that has been stretched in two directions, making it stronger, more stable, and more see-through. BOPET films are used in lots of different industries and for packaging. It’s got great tensile strength, it’s good at keeping moisture out, and it’s a good barrier.

5. Glycol-modified PET (PETG):

Glycol-modified PET (PETG) is a material that’s modified by adding glycol during the polymerization process. This modification makes PETG more flexible and easier to process than standard PET, especially in thermoforming and extrusion. It has better transparency and impact resistance than standard PET and is commonly used in applications that require durability and clarity.

6. Recycled PET (rPET):

rPET is made from PET that has been recycled from consumer or industrial waste. Recycling PET reduces the environmental impact of plastic waste, conserves resources, and decreases greenhouse gas emissions. rPET retains many of the properties of virgin PET but may vary slightly due to differences in the recycling process.

7. Engineering-grade PET:

Engineer-grade PET is a high-performance PET designed for more demanding industrial and engineering applications. This type of PET is modified to enhance mechanical strength, heat resistance, and wear resistance. Due to its strength, dimensional stability, and resistance to wear and chemicals, engineer-grade PET is commonly used in mechanical parts, automotive components, and electrical applications.

What are the characteristics of Polyethylene Terephthalate (PET)?

PET, or polyethylene terephthalate, is a super popular kind of polyester that can be melted and then cooled down again. It’s used in all kinds of stuff, like packaging, electronics, and construction, because it’s so good at being a solid. Here’s a bunch of stuff you need to know about PET:

1. Physical Properties:

①Color and Gloss: PET materials are usually white or light yellow and have high crystallinity, with a smooth and glossy surface. PET is very clear, so you can see what’s inside the package and it looks good. You can make it either clear or not clear, and that makes it either strong or not strong.

② Density and Weight: PET is not very dense and is light, especially compared to materials like glass or metal, which makes it cheaper to transport and use.

2. Mechanical Properties:

① Strength and Rigidity: PET materials are super strong and rigid, which means they’re really tough and don’t get all bent out of shape in structural applications. They have a tensile strength of about 11,500 psi, and they’re super hard and can take a hit, so you can machine them and mold them all day long.

② Flexural and Flexibility: PET has excellent flexural resistance, able to withstand multiple folds without damage. Additionally, its flexibility can be adjusted based on processing methods, allowing it to vary between semi-rigid and rigid states.

③ Wear Resistance and Antistatic Properties: PET has excellent wear resistance and low moisture absorption, ensuring stability during prolonged use. However, PET is prone to static electricity, especially when packaging powdered materials, requiring antistatic measures.

3. Thermal Properties:

① Heat Resistance: PET has good heat resistance, with a heat distortion temperature of about 85°C. Pure PET has limited stability at high temperatures, but enhanced treatments, such as glass fiber-reinforced PET, significantly improve its heat resistance, with a heat distortion temperature of up to 225°C and even a long-term use temperature of up to 120°C.

② Glass Transition Temperature (Tg) and Melting Point: PET’s Tg usually ranges from 65°C to 80°C, depending on crystallinity, which is the temperature at which the material goes from being brittle to being ductile. PET’s melting point ranges from 240°C to 270°C, which means PET can be processed at higher temperatures without breaking down.

4. Chemical Properties:

① Chemical Resistance: PET is pretty good at resisting most chemicals (like weak acids, weak alkalis, alcohols, and oils), keeping its chemical stability in different places. But it’s not so good at resisting strong alkalis and hot water, which can make it break down.

② Moisture and Gas Barrier Properties: PET is great at keeping moisture out of your stuff. It’s also really good at keeping oxygen and carbon dioxide out of your food, which makes it last longer.

③ Antimicrobial Properties: PET also has antimicrobial properties, which makes it great for packaging food and drinks that need to be super clean.

5. Other Properties:

① Electrical Insulation: PET has great electrical insulation properties, making it perfect for use as insulation materials in electronic products and electrical devices, keeping up good electrical performance even under high temperature and high frequency. However, it has bad corona resistance.

② Dimensional Stability: PET materials are great at keeping their shape, even when the temperature changes. They stay strong and keep their good looks.

③ Recyclability and Sustainability: PET is an eco-friendly material that can be recycled, and it’s one of the most recycled plastics in the world. After recycling and processing, PET can be used to make new products like textiles, carpets, and building materials, which helps reduce pollution and waste of resources.

What are the properties of PET?

Polyethylene terephthalate (PET) is a widely used thermoplastic polymer known for its excellent mechanical, thermal, and chemical properties. Below is a comprehensive table summarizing the key properties of PET:

| Property | PET | APET | CPET | PETG | rPET |

|---|---|---|---|---|---|

| Density | 1.38-1.40 g/cm³ | 1.33-1.35 g/cm³ | 1.40-1.45 g/cm³ | 1.27-1.30 g/cm³ | 1.38-1.40 g/cm³ |

| Tensile Strength | 50-80 MPa | 50-70 MPa | 60-90 MPa | 45-65 MPa | 50-80 MPa |

| Flexural Modulus | 2000-3000 MPa | 2200-2600 MPa | 2000-3000 MPa | 2000-2400 MPa | 2000-3000 MPa |

| Elongation at Break | 50-150% | 90-120% | 30-80% | 100-150% | 50-150% |

| Heat Deflection Temp (HDT) | 70-80℃ (0.45 MPa) | 60-75℃ (0.45 MPa) | 200-220℃ (0.45 MPa) | 60-75℃ (0.45 MPa) | 70-80℃ (0.45 MPa) |

| Water Absorption | 0.1-0.4% | 0.2-0.4% | 0.1-0.3% | 0.1-0.3% | 0.1-0.4% |

| Melting Point | 250-260℃ | - | - | - | 250-260℃ |

| Light Transmission | - | Up to 90% | - | Up to 90% | - |

| Heat Resistance | - | - | Heat Resistance | - | - |

Can PET materials be injection molded?

Sure, PET (Polyethylene Terephthalate) can be injection molded. PET is a thermoplastic polymer that’s used in a lot of stuff, like bottles for drinks, food containers, and packaging.

Characteristics and Requirements of PET Injection Molding:

1. Material Characteristics:

① Thermoplastic Polymer: PET is a thermoplastic polymer that is semi-crystalline. It has a high gloss, dimensional stability, UV resistance, and good tensile strength and rigidity. It is widely used in beverage bottles, food containers, and so on.

② Moisture Absorption: PET absorbs moisture from the air, so it needs to be dried well before processing to avoid it getting messed up or not working right.

2. Key Processing Requirements:

① Drying: PET needs to be dried at 120-160°C for 4-6 hours to make sure moisture content is below 0.02% to avoid brittleness and other molding defects.

② Melting Temperature: Usually between 240-280°C. PET has a high melting point, so temperature must be tightly controlled to make sure it melts evenly.

③ Mold Temperature: Keep it between 80-120°C to make sure the material cools down right and control crystallinity, which affects the strength, transparency, and size of the final product.

④ Injection Pressure: Since PET is thick, you need more injection pressure (usually 80-140 MPa) to fill the mold and make sure your stuff is good.

⑤ Injection Speed: You gotta control it. If you don’t, you’ll warp, sink, and have all sorts of issues, especially with glass fiber-reinforced PET materials.

3. Crystallization and Mold Design:

① Crystallinity: PET can be amorphous or semi-crystalline, depending on how fast it cools. Crystallinity affects how the final product looks and how strong it is. You need to design the mold and cooling channels right.

② Mold Design: PET molds need to be well-ventilated and have fast cooling channels to prevent the material from degrading and to make sure there’s enough time for the part to cool and reduce defects.

What are the key considerations for PET Injection Molding?

PET injection molding is an important process for making lightweight, shatter-resistant, and recyclable plastic products. There are a lot of things you have to get right to do it well. Here are some of the most important things to consider when you’re doing PET injection molding. If you get these things right, you’ll be much more likely to make good parts quickly, at a high level of quality, and at a low cost.

1. Material Selection and Preparation:

① Drying Treatment: PET is very sensitive to moisture and has strong hygroscopicity. If the moisture content is too high, the material is easy to hydrolyze at high temperatures, which will reduce the molecular weight, darken the color of the product, make it brittle, and even reduce the mechanical properties. Therefore, PET must be dried before processing. Generally, the drying temperature is 150-170 degrees, and the drying time is 3-4 hours. After drying, the material can be tested for compliance by air shot method. In addition, the proportion of recycled PET used should not exceed 25%. It must be dried before use to avoid quality problems.

② Melt Temperature Control: The melt temperature of PET materials usually ranges from 270°C to 280°C. For glass fiber-reinforced PET (GF-PET), the temperature is a little higher, from 290°C to 315°C. You have to control the melt temperature properly. If the temperature is too low, the melt flow will be bad. If the temperature is too high, the molecular structure will be destroyed, and the product will not perform well.

③ Use of Recycled PET (rPET): When utilizing rPET in injection molding, the amount used should be determined based on specific application requirements. The flow rate and physical properties of rPET may differ from virgin materials, requiring testing before use, typically using 5%-100% rPET as needed.

2. Injection Machine and Mold Design:

① Injection Machine Selection: PET typically requires a screw-type injection machine, with a screw equipped with a non-return ring, and an L/D ratio of 15:1 to 20:1, with a compression ratio of about 3:1. If the L/D ratio is too high, the material will stay in the barrel for too long, causing thermal degradation; if the compression ratio is too low, the shear heating will not be enough, and the plasticization will be poor. In addition, when processing glass fiber-reinforced PET, the screw and barrel inner walls should be made of wear-resistant materials to reduce wear.

② Mold Design: The design of the mold is directly related to the dimensional stability, appearance quality, and production efficiency of the product. PET material is prone to warping, so the design of the mold must take into account the need for sufficient exhaust to prevent gas from being trapped in the product. It is recommended to use insulation plates between the mold and the injection machine template to prevent heat transfer from affecting the mold temperature. The mold temperature is usually controlled at 5-15°C to prevent the rapid crystallization of PET, which affects the transparency of the product. A reasonable gate design can ensure that the molten PET is evenly filled into the mold, avoiding product defects.

3. Injection Process Optimization:

① Injection Speed and Pressure: PET material has good fluidity, and the injection speed should be fast to prevent the material from solidifying too early in the mold. However, excessive injection speed may increase the shear rate and make the material brittle. Generally, the injection time should be controlled within 4 seconds. The injection pressure should be adjusted according to the structure of the product and the design of the mold, generally ranging from 80 MPa to 150 MPa. The injection pressure for glass fiber reinforced PET may need to be higher, around 90 MPa to 150 MPa.

② Back Pressure and Holding Pressure Control: Keep back pressure as low as you can, usually under 100 bar, to reduce screw friction and material degradation. Reasonable holding pressure time helps make sure the mold is completely full and reduces defects like bubbles and dents.

③ Residence Time and Cooling: The residence time of the material in the injection machine should not be too long, as prolonged exposure to high temperatures may lead to material degradation. When the machine is briefly stopped (less than 15 minutes), it can be cleaned using air shots; however, if the stoppage exceeds 15 minutes, polyethylene (PE) material should be used to clean the screw, and the barrel temperature should be lowered to the PE material temperature to prevent PET material decomposition.

4. Mold Maintenance and Quality Control:

① Mold Maintenance: PET molds are high-demand, and molds need to be cleaned and maintained during use. Especially when processing glass fiber reinforced PET, the glass fibers may cause wear on the molds, so the mold surface should be made of wear-resistant materials or regularly repaired. In addition, the mold venting ports should be designed reasonably to prevent excessive flash while ensuring smooth flow of the melt.

② Quality Inspection and Control: It is very important to establish a comprehensive quality control system in the process of PET injection molding. In addition to online inspection, regular dimensional inspection and physical performance test should be carried out to ensure that the product meets the requirements of the specifications. The mold temperature, melt temperature and injection parameters must be strictly controlled to ensure the surface finish, transparency and dimensional accuracy of the product.

5. Post-Molding Processing and Other Considerations:

① Post-Molding Processing: Some PET products may need further processing, like annealing or UV stabilization treatment, to make them stronger and more resistant to aging. These extra steps can really help a product last longer, especially in tough conditions.

② Color and Additive Processing: PET requires high stability for colors and additives. Using colorants or additives incorrectly can cause color differences or performance problems. Choose the right additives based on your needs to make sure your product performs and looks the way you want it to.

6. Production Efficiency and Cost Control:

① Production Cycle and Efficiency Optimization: The PET injection molding process usually takes a longer time to produce, especially for big production parts, so it’s important to optimize the cycle. By reasonably arranging the mold cooling system and optimizing injection parameters, you can effectively shorten the cycle time and reduce production costs.

② Mold and Material Costs: The design and manufacturing costs of molds are high, especially for multi-cavity molds, which can improve production efficiency but also increase maintenance costs due to their complexity. Material selection also significantly impacts overall costs; using efficient and easy-to-process PET materials can significantly reduce production costs.

Resources for The Complete Guide PET Injection Molding Manufacturing

How to perform PET Injection Molding: A Step-by-Step Guide

PET (Polyethylene Terephthalate) injection molding is a great way to make plastic stuff. It’s used a lot for packaging, making things for industry, and making things for you to buy. There are a lot of steps to making stuff with PET, and each one is important to make sure the stuff you make doesn’t suck. Here’s a detailed guide to making stuff with PET:

1. Mold Design and Preparation:

① Mold Design: The mold design is where it all starts for injection molding. Engineers use CAD (Computer-Aided Design) software to design the mold model, taking into account how the molten PET will flow, how it will cool, and how the parts will be removed from the mold. Molds are typically made from durable materials like hardened steel or aluminum to ensure they last a long time.

② Mold Preparation: Before you start, clean the mold really well and spray it with a release agent so the PET doesn’t stick when you mold it. Keep an eye on the mold for wear and tear, and fix or replace anything that’s messed up.

2. Preparation of PET Raw Materials:

① Selecting Raw Materials: Different applications have different requirements for PET materials, so you should choose the right PET grade based on your final product’s specific needs. High-quality PET raw materials make your finished product look and feel better.

② Cleaning and Drying Raw Materials: Cleaning and drying the raw materials is a critical step. PET raw materials are prone to moisture absorption, so they must be dried to an appropriate moisture level to avoid moisture affecting the flowability during melting and the strength of the molded product.

③ Weighing Materials: Weigh the PET raw materials you need accurately. Do it based on the design and production requirements. Make sure you do it right so you can make sure your production process is precise.

3. Injection Machine Setup:

① Machine Setup: Once you have the mold installed on the injection machine, you need to set the machine parameters. The most important ones are temperature, injection pressure, injection speed, and mold temperature. You need to control the temperature within a range that is good for melting PET. Injection pressure and speed affect how the molten material flows and fills up the mold cavity.

② Mold Temperature Control: The temperature of the mold directly affects how long it takes to cool down and how smooth the final product is. You should adjust the temperature settings depending on what kind of PET you’re using so that it cools down evenly.

4. Feeding and Melting Process:

① Feeding: Put the dried PET raw materials into the hopper of the injection machine. Make sure there is nothing blocking the hopper, so the feeding process won’t be interrupted. The raw materials will be pushed into the heating barrel by the screw of the injection machine.

② Melting: The raw materials of PET are gradually melted in the heating barrel, forming a uniform melt. Strict temperature control is required during this stage to ensure that PET melts smoothly and maintains enough viscosity for subsequent injection molding.

5. Injection and Filling the Mold:

① Injection Process: The screw pushes the molten PET into the mold cavity under high pressure. The injection speed and pressure must be controlled exactly to make sure the PET melt fills every part of the mold the same way. If the injection speed or pressure isn’t set right, you might end up with bubbles, short shots, or other problems.

② Holding Pressure: Once you’ve finished shooting plastic into the mold, you need to hold the pressure for a while to make sure the molten plastic fills every nook and cranny in the mold and doesn’t leave any voids or weak spots.

6. Cooling and Solidification:

① Cooling: After the mold is filled, the molten PET starts to cool. The cooling system in the mold helps remove heat from the cavity, which allows the PET to gradually solidify into the final shape. The speed and uniformity of the cooling process are important for the dimensional stability and appearance quality of the finished product.

② Controlling Cooling Time: Cooling too long makes production cycles longer. Cooling too short makes products warp or have internal stress. So, controlling cooling time is important for making good products.

7. Mold Opening and Demolding:

① Mold Opening: After the cooling process is done, the mold will open by itself. The ejection system will push the solidified molded part out of the mold. Be careful not to damage the product by moving too fast or using too much force.

② Demolding Process: Make sure the product pops out of the mold without any scratches or other surface defects. Also, check for any leftover PET material in the mold and clean the mold for the next operation.

8. Post-Molding Processing:

① Trimming and Polishing: Once the products come out of the mold, they usually have some extra material around the edges (flash) that needs to be trimmed off with knives or other tools. This step makes sure the product looks the way it’s supposed to and makes the whole product better.

② Subsequent Finishing: Depending on how you plan on using this thing, you might need to do some more sanding, polishing, or putting it together to make sure it’s ready to go.

9. Quality Inspection:

① Quality Control: After you’re done making stuff, you need to make sure it’s good. You should check to make sure it’s the right size, it looks good, and it’s made the right way. This way, you know everything you make is always the same.

② Packaging and Delivery: Qualified products are packaged and prepared for shipment or further processing.

10. Process Repetition and Monitoring:

Repetitive Operations: The PET injection molding process is going to be repeated over and over again to make a bunch of parts. While you’re doing this, you need to keep an eye on the injection machine, mold, and raw materials to make sure that each batch of products is the same quality.

What are the advantages of PET Injection Molding?

PET (Polyethylene Terephthalate) injection molding is a popular way to make plastic containers (like bottles and other stuff). It’s used in lots of industries like packaging, automotive, and electronics. Here’s a list of the main advantages of PET injection molding:

1. High Production Efficiency:

PET injection molding allows for fast, continuous production cycles that usually last between 10 and 60 seconds per cycle, depending on how complicated the parts are. This quick production time makes it perfect for big manufacturing operations, where you need to make a ton of the same parts fast and efficiently.

2. Cost-Effectiveness:

It’s super cheap, especially if you’re making a lot of them. The parts are cheap and it’s really efficient, so if you want to make a lot of them, it’s not going to cost you a lot of money. Also, you don’t need a lot of people to run it.

3. Versatility in Product Design:

PET injection molding is a great way to make all kinds of stuff. You can make simple things like bottles and you can make complicated things like car parts and stuff. It’s cool because you can make all kinds of shapes and stuff that you can’t make with other ways of making stuff.

4. Excellent Physical Properties:

PET is known for being lightweight, clear, chemically resistant, and thermally stable:

① Lightweight: Great for packaging applications that need to reduce weight.

② Clear: PET can make clear or slightly clear products with little cloudiness or distortion, good for packaging that looks good.

③ Chemically Resistant: PET can handle the damaging effects of acids, bases, and solvents, so it’s good for storing food, drinks, and medicine.

④ Heat Resistant: It has a high heat distortion temperature, so it keeps its shape at high temperatures.

5. High Dimensional Accuracy:

PET injection molding creates parts with precise dimensions and high surface quality. It is great for applications that need strict tolerances because it keeps things stable and reduces variations.

6. Low Post-Processing Requirements:

When you make parts with PET injection molding, you don't have to do much to them afterwards because they usually look good. That means you don't have to do as much stuff to them, so you can make them faster.

7. Environmental Sustainability:

PET is 100% recyclable, so it’s a great choice for the environment. Plus, when you’re making PET bottles, you don’t waste a lot of material. You can use most of the stuff that’s left over, or you can recycle it.

8. Sterilization and Food Safety:

PET can be sterilized using different methods (like high-pressure sterilization and gamma radiation), which makes it good for medical, pharmaceutical, and food contact applications. It’s FDA approved for food and beverage packaging, so you know it’s safe and clean.

9. Low Moisture Absorption:

PET has low moisture absorption. This is good because it means that food and medical stuff won’t get contaminated or go bad.

10. Wide Temperature Range:

PET can handle temperatures from -40°C to 120°C, so it’s good for both cold and hot applications without affecting how it works.

11. Minimal Warping:

With injection molding, you don’t have to worry about parts warping. The process guarantees that all parts come out the same size and shape every time.

12. Adaptability to Additives:

PET can be mixed with additives to make it stronger and more flexible, so it can be customized for different industries.

What are the disadvantages of PET Injection Molding?

PET (Polyethylene Terephthalate) injection molding has some disadvantages that can affect production efficiency, material properties, and overall costs. Here are the main disadvantages:

1. Brittleness and Low Impact Resistance:

PET is a pretty brittle material that can crack or break under force or impact, especially when it’s cold. That’s why PET products can get messed up during shipping or use, especially if they need to take a big hit.

2. High Mold and Processing Costs:

Making PET bottles requires special molds that can be expensive to design, make, and take care of. PET needs hot molds (about 80-100°C) to melt and flow well, so the molds need to handle high heat and spread heat well. Also, making molds can take a long time, especially if the shape is complicated or very precise, and could take months. This means it costs more to make small batches, and keeping and replacing molds can be expensive over time.

3. Long Molding Cycles and High Shrinkage Rates:

PET is a special kind of plastic. When you make stuff out of PET, it takes a long time to cool down and get hard. That makes it take a long time to make stuff out of PET. When PET gets cold, it gets smaller. Usually, it gets 1.5% to 2.5% smaller. Because it gets smaller, the stuff you make out of PET might not be the right size. To make sure the stuff you make out of PET is the right size, you have to make the mold and the process really, really good. If you don’t make the PET cool down right, the stuff you make might have problems inside that make it break or bend.

4. Temperature Sensitivity and Precise Control Required:

PET is super sensitive to processing temperatures. Too hot, it degrades. Too cold, it doesn’t flow well and you get bad parts. So, you need to control the temperature of the plastic during the injection process. You need to control the melt temperature, the mold temperature, and the cooling time. If any of these temperatures fluctuate, it affects the quality of the part. This makes the equipment more expensive and harder to run.

5. Limitations in Color Selection and Post-Molding Processing:

PET materials are naturally transparent, which makes it difficult to get consistent and vibrant colors during molding. You can use color masterbatches to color PET, but the colors may not match between different batches of products. Also, PET products often need secondary processing, like annealing, to get rid of internal stresses and make sure they don’t warp or crack when you use them. These extra steps take more time and money.

6. Environmental and Sustainability Issues:

PET can be recycled, but it’s not easy or cheap. Recycling and reprocessing PET usually involves chemical or mechanical recycling processes, which are energy-intensive and expensive. In some cases, recycled PET may not be as good as virgin PET, so it can’t be used for everything. Plus, even though PET helps reduce the demand for single-use plastics, it doesn’t break down naturally, so it can cause long-term environmental problems if it’s not disposed of properly.

7. High Requirements for Molds:

Because PET has high requirements for temperature, pressure, and flowability, the design of the mold must be very precise, and the manufacturing of the mold must have high precision and quality surface treatment. The manufacturing and maintenance costs of the mold are not only high, but also, once the mold is damaged or needs to be adjusted, the entire production line may need to stop, resulting in additional time and economic losses.

8. Variability in Material Properties:

PET is a semi-crystalline material. Its properties change when you process it. The way you process it affects how much it crystallizes, how strong it is, and how clear it is. For example, the temperature, how fast it cools, and how much pressure you use all affect these properties. If you don’t control the process well, you’ll get a lot of variation in how the product performs. This means your final product will have a lot of variation and won’t be as good. Also, PET is sensitive to moisture. If it gets wet, it gets more brittle and its mechanical properties go down. This makes it even harder to control the process.

9. Limited Chemical Resistance:

PET can resist some chemicals. However, it doesn’t do well with certain solvents, acids, and bases. In some harsh chemical environments, PET products can swell, crack, or get worse in other ways. This means that PET isn’t good for some specific chemical industries.

Common issues and solutions in PET Injection Molding

When we’re doing PET injection molding, there are always some problems that affect product quality and production efficiency. If we can solve these problems, it will help us make better products. Below is a detailed analysis of some common issues and their solutions.

1. Appearance Issues of the Molded Parts

① Wavy Surface of Molded Parts:

Problem Cause: If the gate or other parts are too narrow, the molten plastic may push against partially solidified molded parts, creating ripples on the surface. This happens more in thin areas of injection molded parts, and uneven mold design or temperature can make it worse.

Solution: To solve this problem, we can increase the diameter of the gate, raise the temperature of the nozzle and mold, and increase the injection speed to prevent the plastic from cooling too early when it enters the mold cavity. In addition, we can adjust the position of the cooling water inlet in the mold to be away from the gate area to achieve more uniform cooling.

② Silver Streaks or Yellowing of Molded Parts:

Problem Cause: Moisture in the plastic, gases not being fully expelled, or excessive use of additives can cause silver streaks or yellowing during the injection process. This may be due to not drying enough, not mixing evenly, or burning the material in the barrel.

Solution: Strengthening the drying process of the raw materials, appropriately raising the mold temperature, and reducing the injection speed during the injection process can help reduce silver streaks. Additionally, controlling the amount of additives and ensuring material uniformity can effectively prevent yellowing or surface defects in the molded parts.

③ Surface Dents:

Problem Cause: Dents on the surface are caused by uneven mold temperature or not enough cooling time during the cooling process.

Solution: If you increase the injection flow rate and holding pressure, you can fill the mold better and avoid dents when the plastic cools. Also, if you hold the pressure longer, the plastic will cool more before you take it out of the mold, and you won’t get dents.

④ Weld Lines:

Problem Cause: When the plastic flow in the mold separates and then comes back together, it may not fully join, creating weld lines on the surface of the part. This can be caused by the design of the mold, the way the plastic is injected, or the plastic not being able to flow well enough.

Solution: To reduce the occurrence of weld lines, you can increase the injection speed and pressure, optimize the mold temperature, and ensure smooth plastic flow in the mold cavity. You can also enlarge the gate size or change the gate position to improve plastic flow and minimize the formation of weld lines.

2. Shape and Structural Issues of Molded Parts

① Warped Deformation of Molded Parts:

Problem Cause: If the mold temperature is too high or cooling is insufficient during the cooling process, the plastic may bend or twist due to uneven shrinkage.

Solution: Lowering the mold temperature and extending the cooling time will make sure that the molded part doesn’t get local shrinkage during cooling. Also, optimizing mold design to make sure the wall thickness is uniform will help prevent uneven stress distribution during cooling.

② Unmelted Material:

Problem Cause: Sometimes when you inject stuff, some of the stuff doesn’t melt all the way and you get little chunks of unmelted stuff on the outside of your thing. This usually happens when you don’t heat your stuff up enough or you don’t dry it enough.

Solution: Increase the temperature of the barrel or extend the heating time for the raw materials to ensure they are fully melted. Also, make sure the drying machine is working properly so there is no moisture left.

③ Short Shots (Insufficient Filling of the Mold Cavity):

Problem Cause: Short shots happen when the plastic doesn’t fully fill the mold cavity, leaving you with an incomplete part. It’s usually because you didn’t have enough injection pressure, the material didn’t flow well, or the mold wasn’t designed right.

Solution: If you want to fix short shots, you can do a few things. You can crank up the pressure and speed of the injection. You can also shoot more plastic into the mold. You can even hold the pressure on the mold longer. If you want to make sure the plastic flows really well, you can make sure the mold is designed right. You want to make sure the gates and flow paths are big enough so the plastic can flow into the mold.

3. Material and Process Issues

① Bubble Issues:

Problem Cause: The problem is that PET materials are super thirsty. If you don’t dry them out enough before you start messing with them, they’ll get all wet and start making bubbles when you heat them up. That makes your parts look bad and weakens them.

Solution: Make sure the materials are really dry before you process them so the moisture level is below what you need. Also, when you inject the material, increase the back pressure to push the air out of the material so you don’t get bubbles.

② Dimensional Instability:

Problem Cause: Dimensional instability is often caused by mold design, not controlling injection parameters properly, or the material shrinking unevenly.

Solution: Make sure the walls are the same thickness all the way around. Put the gates and runners where they make sense. Control the injection speed, pressure, and cooling time. Adjust the settings for the material you're using so the parts come out the right size.

4. Mold Issues

① Insufficient Temperature in the Hot Runner:

Problem Cause: If the temperature is not enough in the hot runner system, the molten plastic will gradually cool in the runner, causing the flowability to decrease, affecting the filling effect of the mold cavity.

Solution: The hot runner insulation measures need to be strengthened to ensure that the temperature is within the appropriate range. At the same time, the hot nozzle temperature should be raised appropriately to prevent the plastic from cooling too early before entering the mold cavity.

② Insufficient Cooling of the Mold:

Problem Cause: Mold cooling water passages are blocked or contaminated, or the cooling time is insufficient, resulting in uneven mold temperatures, which affects the cooling rate and molding quality of the parts.

Solution: Cleaning the mold cooling water channels regularly to ensure the cooling system is unobstructed is essential. Also, extending cooling time appropriately ensures that the molded parts are fully solidified before demolding.

What are the Applications of PET Injection Molding?

PET (Polyethylene Terephthalate) injection molding is a flexible and versatile manufacturing process that is widely used across many industries. PET is known for its high strength, chemical resistance, good transparency, and recyclability. It plays a significant role in modern manufacturing. Here are the main application areas of PET injection molding and their specific subdivisions:

1. Packaging Industry:

① Beverage Packaging: PET bottles are the kings of the global beverage packaging market. They’re light, strong, see-through and can be recycled. They’re perfect for packaging water, soda, juice and milk.

② Food Packaging: PET is also used in food packaging, like condiments and cooking oils, to make sure food is safe and easy to use.

③ Pharmaceutical and Cosmetic Packaging: PET is used for packaging pharmaceuticals, cosmetics, and other products. It has good sealing and stability, so it can ensure the quality of the products.

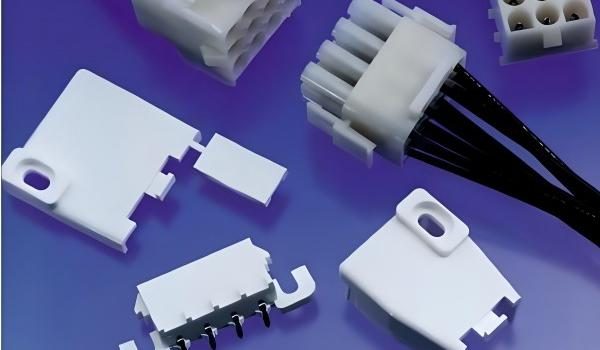

2. Electronic and Electrical Industry:

① Precision Parts: PET is used to make precision parts for electronic equipment, like connectors and housings, to make sure the equipment works well.

② Insulating Materials: PET film is used a lot in making things like capacitors and insulating sheets because it’s really good at insulating.

3. Textile Fiber Industry:

Polyester Fiber: PET Fiber (Polyester) is the most widely used synthetic fiber. It has good wrinkle resistance, wear resistance, and shape retention. It is widely used in clothing, home textiles, and industrial textiles.

4. Construction and Building Materials Industry:

① Insulation Materials: PET is used in the construction field to make insulation materials and sound insulation boards. It has good weather resistance and stability and is suitable for making lightweight, high-strength, environmentally friendly, and energy-saving building materials.

② Decorative Panels: PET is also used in making floors and decorative panels, which give you nice and strong materials to use in your modern buildings.

5. Medical and Health Industry:

Medical Packaging Materials: PET materials are non-toxic and odorless, and are widely used in medical packaging, infusion sets, hemodialysis machines, and other medical supplies to make sure they are safe and reliable.

6. Other Industries:

① Automotive Industry: PET is used in car interiors and functional parts, like dashboards, interior decoration parts, etc.

② Daily Chemical Personal Care: PETG is often used in high-end daily chemical packaging. Because of its good transparency and chemical resistance, it can improve the appearance and brand image of the product.

How Does Rib Design Impact Mold Flow and Cooling Efficiency?

Key Takeaways Ribs are structural features used to increase part stiffness without increasing overall wall thickness. However, improper rib design significantly impacts **Mold Flow** (causing hesitation or short shots) and

How Do Ribs Function in Reducing Plastic Part Weight and Improving Structural Integrity?

Key Takeaways Ribs are thin, wall-like features projecting from the nominal wall of a plastic part, designed to add stiffness and strength without increasing overall wall thickness. By allowing engineers

How Do Material Properties Influence Rib Design in Plastic Injection Molding?

Key Takeaways Effective rib design relies heavily on the shrinkage characteristics of the selected polymer. While ribs increase part stiffness and Moment of Inertia without significantly increasing cycle time, improper

Optimization Solutions Provided For Free

- Provide Design Feedback and Optimization Solutions

- Optimize Structure and Reduce Mold Costs

- Talk Directly With Engineers One-On-One