Custom PC Injection Molding Factory

Delivering Expert PC Injection Molding Solutions for Durable, Reliable, and High-Performance Products Across Industries.

Resources for The Complete Guide to PC Injection Molding

What is Polycarbonate (PC)?

Polycarbonate (PC) is a colorless and transparent polymer that belongs to the category of thermoplastic materials, named for the presence of carbonate groups in its molecular chain. Based on the structure of the ester groups, polycarbonate can be classified into various types, including aliphatic, aromatic, and aliphatic-aromatic polycarbonates. Although aliphatic and aliphatic-aromatic polycarbonates have lower mechanical properties, limiting their applications in engineering plastics, aromatic polycarbonate, especially bisphenol A polycarbonate, is widely used due to its excellent performance.

Polycarbonate is known for its outstanding impact resistance, optical clarity, and durability. It has an extremely high impact strength, a wide operating temperature range (typically between 220°C and 260-320°C), good creep resistance, electrical insulation properties, and dimensional stability. The density of polycarbonate ranges from 1.20 to 1.22 g/cm³, making it an ideal substitute for glass due to its lightweight and durable nature.

The production of polycarbonate is primarily achieved through the polymerization reaction of bisphenol A (BPA) and phosgene. Due to its amorphous characteristics, polycarbonate can effectively transmit light and maintain color and strength under pressure conditions, demonstrating good environmental processing and recyclability. Its chemical structure includes organic functional groups connected by carbonate groups.

The properties of polycarbonate are similar to those of polymethyl methacrylate (PMMA), but it is more expensive, stronger, and has a wider temperature range. It is widely used in various industries, including electronics, automotive, medical, and construction, with common applications such as optical discs, safety helmets, bulletproof glass, automotive headlamp lenses, baby bottles, roofing, and other glass substitutes.

Additionally, polycarbonate exhibits excellent compatibility with certain polymers, leading to its widespread use in blends such as PC/ABS, PC/PET, and PC/PMMA. This allows polycarbonate to showcase its unique advantages in many high-demand applications.

What are the different types of PC materials?

Polycarbonate (PC) is a versatile thermoplastic that is widely used across various industries due to its exceptional properties. Based on its characteristics, applications, and modification methods, PC materials can be classified into the following categories:

1. General Purpose Polycarbonate:

General purpose polycarbonate is the most common type of PC, known for its high impact resistance, transparency, and good thermal stability, making it suitable for applications such as goggles, machine guards, and light covers.

2. Impact Modified Polycarbonate:

Impact modified polycarbonate has been specially modified to enhance its impact resistance, making it suitable for environments where high impact forces may occur, such as automotive bumpers and dashboards.

3. Flame Retardant Polycarbonate:

Flame retardant polycarbonate is enhanced with specific flame retardants to meet fire safety standards, widely used in electrical components and medical devices that require fire resistance.

4. High-Temperature Polycarbonate:

High-temperature polycarbonate can withstand high temperatures while maintaining structural integrity, suitable for applications in automotive exhaust systems and industrial equipment in high-temperature environments.

5. Low-Temperature Polycarbonate:

Low-temperature polycarbonate is designed to perform well in low-temperature environments, making it suitable for outdoor equipment and construction materials.

6. Optical Grade Polycarbonate:

Optical grade polycarbonate offers excellent optical clarity and light transmission, commonly used in the manufacture of lenses, screens, and other high-quality optical components.

7. Medical Grade Polycarbonate:

Medical grade polycarbonate meets specific regulatory requirements for medical devices, exhibiting good biocompatibility, suitable for syringes, test tubes, and various medical equipment.

8. Scratch-Resistant Polycarbonate:

Scratch-resistant polycarbonate features an enhanced scratch-resistant coating, improving surface durability, commonly used in eyewear lenses and protective equipment to ensure clarity and integrity during use.

9. Blended Polycarbonate:

Blended polycarbonate combines PC with other polymers (such as ABS or PVC) to enhance specific properties like impact resistance or chemical stability, widely used in automotive parts, consumer electronics, and medical devices.

10. Nano-Composite Polycarbonate:

Nano-composite polycarbonate incorporates PC with nanoparticles (such as clay or silica) to improve thermal conductivity, mechanical strength, and other properties, suitable for high-performance industrial applications.

11. Aliphatic Polycarbonate:

Aliphatic polycarbonate has a lower melting point and high solubility, with strong hydrophilicity. Although it has poor thermal stability, it can be used in certain low-strength applications.

12. Aromatic Polycarbonate:

Aromatic polycarbonate is the only type that has achieved industrial production, possessing excellent mechanical properties and thermal stability, widely used in the field of engineering plastics.

13. Aliphatic-Aromatic Polycarbonate:

Aliphatic-aromatic polycarbonate combines the characteristics of both aliphatic and aromatic types, but its mechanical properties remain lower, limiting its applications, though it has potential in certain specific fields.

What are the characteristics of PC?

Polycarbonate (PC) is a versatile thermoplastic polymer known for its exceptional properties, suitable for a wide range of applications. Here are the main characteristics of PC materials:

1. High Strength and Toughness:

Polycarbonate (PC) materials have extremely high impact strength, at least 250 times that of glass. This high toughness allows PC to maintain structural integrity under significant impact, making it ideal for safety applications such as helmets and protective shields.

2. Excellent Transparency:

PC materials have a light transmittance of up to 89% to 90%, demonstrating high transparency. This characteristic makes polycarbonate widely used in products requiring optical clarity, such as eyewear lenses, lighting fixtures, and automotive headlights, ensuring good light transmission and enhancing product functionality and aesthetics.

3. High-Temperature Resistance:

Polycarbonate can withstand temperatures between 220°C and 230°C while maintaining good mechanical properties. This characteristic allows PC to perform excellently in applications that require high-temperature resistance, such as electrical equipment housings and automotive components, ensuring product stability and safety.

4. Chemical Resistance:

PC materials exhibit good resistance to various chemicals (such as dilute acids and alcohols), making them suitable for applications in chemical environments. However, under high temperature and humidity conditions, PC may degrade when reacting with water, so special care is needed in specific environments to maintain long-term stability.

5. Excellent Electrical Insulation:

Polycarbonate is an excellent electrical insulator, maintaining stable insulation performance even under humid or high-temperature conditions. This makes PC significant in the manufacturing of electronic and electrical products, suitable for insulating components and electrical housings, ensuring the safety of devices.

6. Weather Resistance and Aging Resistance:

PC materials have excellent UV resistance and are not prone to aging, making them suitable for long-term outdoor use. Their weather resistance ensures that materials can maintain performance and appearance under sunlight and harsh weather conditions, making polycarbonate an ideal choice for outdoor facilities and construction materials.

7. Flame Retardancy:

Polycarbonate has low flammability characteristics, meeting flame retardancy requirements in many industries. By adding flame retardants, PC can play an important role in the manufacturing of fire-resistant products, such as fire doors and firefighting equipment, enhancing its application potential in safety fields.

8. Easy Processing:

Polycarbonate materials can be easily processed through various methods such as injection molding, extrusion, and blow molding, making them suitable for mass production. This ease of processing not only improves production efficiency but also ensures that PC has good dimensional stability, maintaining its shape during production and use.

What are the properties of PC?

Polycarbonate (PC) is a versatile thermoplastic known for its exceptional properties, making it suitable for various applications across multiple industries. Below are the key parameters and characteristics of polycarbonate material.

| Property | Metric | English |

|---|---|---|

| Density | 1.01 - 1.51 g/cc | 0.0365 - 0.0546 lb/in³ |

|

0.960 - 1.17 g/cc @Temperature 270 - 330 °C |

0.0347 - 0.0423 lb/in³ @Temperature 518 - 626 °F | |

| Water Absorption | 0.0150 - 0.700 % | 0.0150 - 0.700 % |

| Maximum Moisture Content | 0.0200 - 0.0300 | 0.0200 - 0.0300 |

| Linear Mold Shrinkage | 0.00100 - 0.0600 cm/cm | 0.00100 - 0.0600 in/in |

|

0.00700 - 0.00700 cm/cm @Temperature 80.0 - 80.0 °C |

0.00700 - 0.00700 in/in @Temperature 176 - 176 °F | |

| Linear Mold Shrinkage, Transverse | 0.00260 - 0.00900 cm/cm | 0.00260 - 0.00900 in/in |

|

0.00700 - 0.00700 cm/cm @Temperature 80.0 - 80.0 °C |

0.00700 - 0.00700 in/in @Temperature 176 - 176 °F | |

| Melt Flow | 1.00 - 139 g/10 min | 1.00 - 139 g/10 min |

| Hardness, Rockwell M | 50.0 - 123 | 50.0 - 123 |

| Hardness, Rockwell R | 72.0 - 124 | 72.0 - 124 |

| Tensile Strength, Ultimate | 30.0 - 105 MPa | 4350 - 15200 psi |

|

23.0 - 51.0 MPa @Temperature 60.0 - 120 °C |

3340 - 7400 psi @Temperature 140 - 248 °F | |

| Tensile Strength, Yield | 40.0 - 154 MPa | 5800 - 22300 psi |

| Electrical Resistivity | 10200 - 1.00e+18 ohm-cm | 10200 - 1.00e+18 ohm-cm |

| Surface Resistance | 100 - 4.20e+16 ohm | 100 - 4.20e+16 ohm |

| Dielectric Constant | 2.70 - 3.40 | 2.70 - 3.40 |

| Dielectric Strength | 11.8 - 35.0 kV/mm | 300 - 889 kV/in |

| Melting Point | 224 - 315 °C | 435 - 599 °F |

| Refractive Index | 1.51 - 1.59 | 1.51 - 1.59 |

| Haze | 0.100 - 100 % | 0.100 - 100 % |

| Gloss | 3.00 - 90.0 % | 3.00 - 90.0 % |

| Transmission, Visible | 20.0 - 93.0 % | 20.0 - 93.0 % |

| UV Transmittance | 88.00% | 88.00% |

| Processing Temperature | 249 - 320 °C | 480 - 608 °F |

| Nozzle Temperature | 227 - 343 °C | 441 - 650 °F |

| Melt Temperature | 210 - 343 °C | 410 - 650 °F |

| Mold Temperature | 32.2 - 160 °C | 90.0 - 320 °F |

| Injection Velocity | 200 mm/sec | 7.87 in/sec |

| Drying Temperature | 70.0 - 130 °C | 158 - 266 °F |

| Moisture Content | 0.0100 - 0.0400 % | 0.0100 - 0.0400 % |

| Dew Point | -28.9 - -17.8 °C | -20.0 - 0.000 °F |

| Drying Air Flow Rate | 22.7 - 28.3 l/min | 0.800 - 1.00 ft³/min (CFM) |

| Injection Pressure | 5.52 - 152 MPa | 800 - 22000 psi |

| Vent Depth | 0.00127 - 0.00762 cm | 0.000500 - 0.00300 in |

| Cushion | 0.635 cm | 0.250 in |

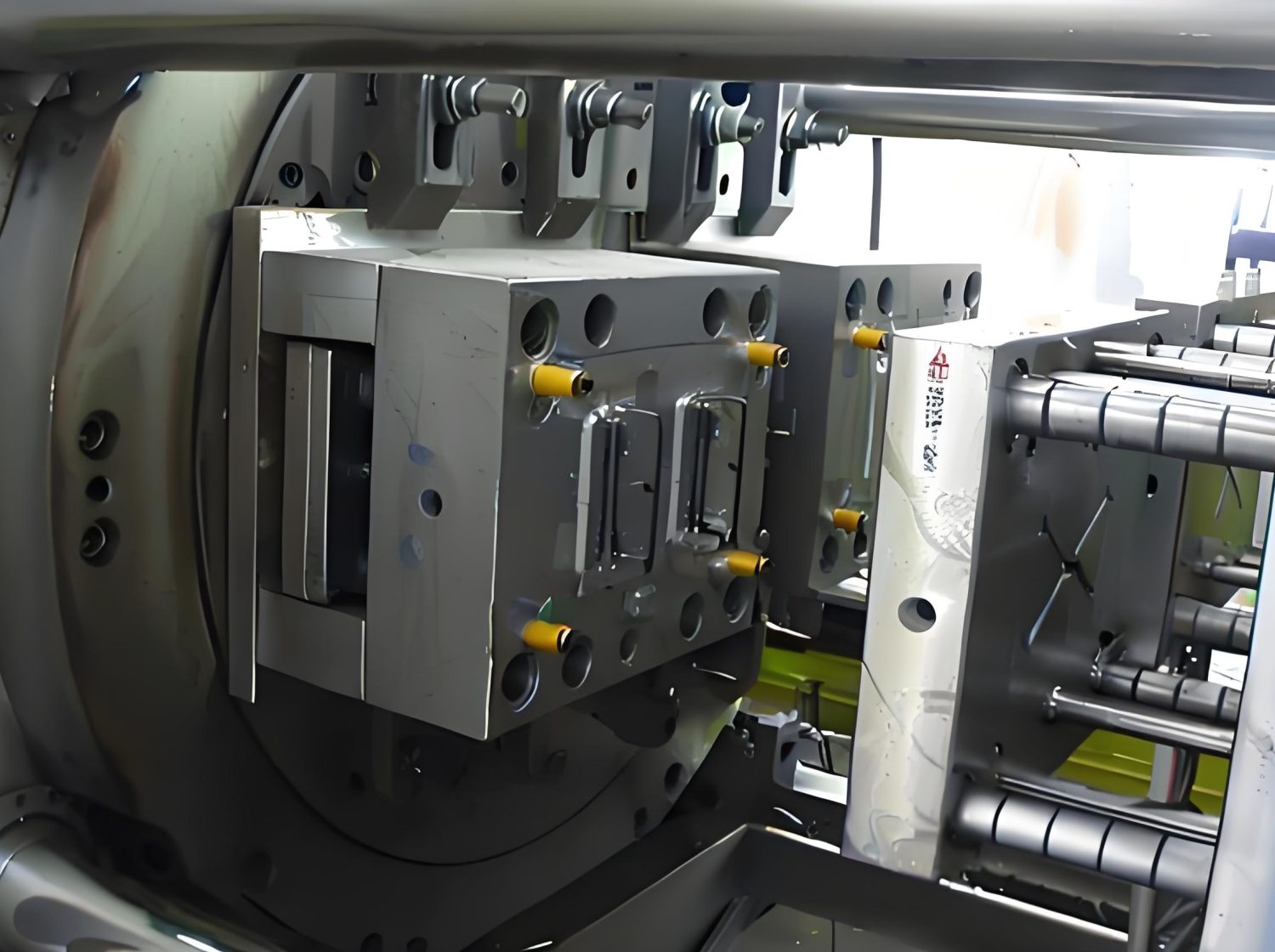

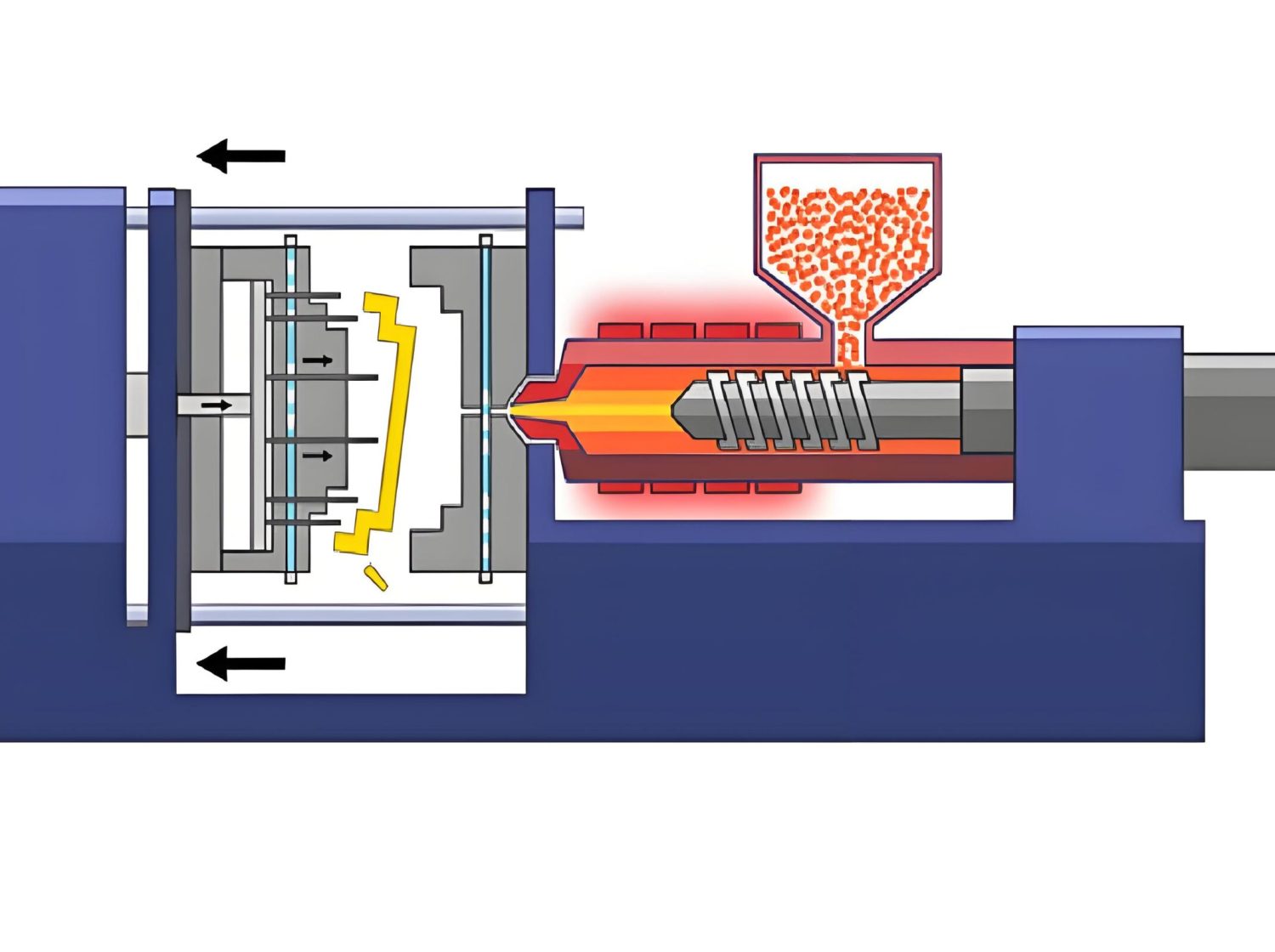

Can PC materials be injection molded?

Yes, Polycarbonate (PC) materials can be successfully injection molded, and they are widely used in various industries due to their unique properties. However, careful consideration must be given to material properties, processing conditions, and mold design to ensure high-quality results. Below is a detailed guide on PC injection molding.

1. Material Selection:

① Grade of PC: Not all PC materials are suitable for injection molding. It is essential to select PC grades with:

• High molecular weight for strength and toughness.

• Low viscosity to improve flow in the mold.

• A melting point suitable for injection molding, typically between 260°C to 320°C.

② Drying Requirements: PC is hygroscopic, meaning it absorbs moisture, which can lead to defects such as bubbles and reduced clarity. Pre-dry the material at 100°C to 130°C for 3–4 hours before processing.

2. Processing Conditions:

① Injection Temperature: The optimal range for PC is 270°C to 320°C. Exceeding 340°C may cause material degradation, discoloration, or bubbles.

② Mold Temperature: Maintain between 80°C and 120°C for optimal part quality. Higher mold temperatures improve surface finish but increase cooling time.

③ Injection Pressure: Use a range of 50 MPa to 150 MPa, depending on part complexity and size. Ensure even pressure to minimize defects.

④ Injection Speed: Moderate speeds are recommended to ensure smooth filling without overheating or shearing the material.

⑤ Cooling: PC has high thermal conductivity, making effective cooling critical to prevent warping or distortion. Water or air cooling systems are commonly used.

What are the key considerations fo PC Injection Molding?

Polycarbonate (PC) injection molding is a versatile and widely used manufacturing process, offering excellent part quality and durability. To achieve optimal results, several aspects of material handling, mold design, and processing must be considered. Below is a comprehensive guide that combines and expands on key points.

1. Material Selection and Preparation:

PC is a hygroscopic material, meaning it absorbs moisture from the environment. If not properly dried, this moisture can lead to defects such as bubbles, streaks, or reduced mechanical properties during the molding process.

① Drying: To prevent moisture-related defects, dry the PC resin at 110–120°C for 4–6 hours before processing. Ensure that the moisture content is below 0.02%.

② Material Choice: Select a high-quality PC resin suitable for the application. High molecular weight grades are ideal for parts requiring high toughness and durability.

2. Injection Molding Parameters:

The injection molding process for PC requires precise control of various parameters to ensure proper material flow, part quality, and cycle time efficiency.

① Temperature: The melt temperature for PC should be between 260–320°C, with the barrel temperature ranging from 230–310°C, depending on the part thickness. Exceeding 340°C can lead to material degradation and surface defects.

② Pressure: Injection pressure typically ranges from 70 to 140 MPa, depending on the complexity and size of the part. Proper packing pressure is also essential to ensure good part compaction and reduce shrinkage.

③ Injection Speed: The injection speed should be adjusted based on part geometry. For smaller gates, slower speeds help prevent defects like jetting, while larger gates may accommodate higher speeds for efficient filling.

3. Mold Design:

Mold design plays a crucial role in the success of PC injection molding, affecting part quality, cycle time, and ease of part ejection.

① Gate Design: Use appropriately sized gates to ensure smooth material flow and proper filling of the mold. The gate design should prevent material buildup, which can cause defects like flash or incomplete filling.

② Cooling System: A well-designed cooling system is critical for ensuring uniform cooling and reducing the risk of warpage. Water-cooled molds are ideal for rapid cooling, although air-cooled systems may be used for specific applications.

③ Mold Temperature: Maintain mold temperatures between 80–120°C. Higher mold temperatures may be required for thicker or more complex parts to ensure proper cooling and part quality.

4. Part Design:

Proper part design is essential for achieving consistent quality and minimizing defects in the molding process.

① Wall Thickness: Maintain uniform wall thickness to ensure even material flow and minimize warping. Thin walls (<1.2 mm) may result in incomplete filling, while thick walls may lead to longer cycle times and uneven cooling.

② Draft Angles: Incorporate draft angles of 1° to 3° to facilitate easy ejection and reduce the risk of part damage during removal from the mold.

③ Radii and Fillets: Avoid sharp corners as they create stress concentrations. Use radii that are at least 0.5× wall thickness for interior corners and 1.5× wall thickness for exterior corners to improve part strength and reduce stress.

④ Undercuts: Avoid undercuts in part design, as they complicate mold design and increase production costs. Parts without undercuts are easier to mold and eject.

5. Ejection and Warpage Prevention:

Ejection and warpage control are crucial for ensuring the final part's dimensional accuracy and structural integrity.

① Ejection System: Use ejection pins or plates for smooth part removal from the mold. If necessary, air-powered or hydraulic ejection systems can be employed for larger or more complex parts.

② Warpage Control: To prevent warpage, ensure uniform cooling and balanced mold design. Post-molding annealing (120–130°C for 1–2 hours) can also help relieve residual stresses and improve part stability.

6. Quality Control:

Quality control is critical to ensuring that PC injection molded parts meet the required specifications and standards.

① Inspection: Regularly inspect parts for common defects such as voids, weld lines, and surface imperfections. Monitoring key dimensions and material properties ensures that parts meet the required functional and aesthetic standards.

② Tolerances: For precision applications, maintain tight tolerances (typically ±0.005 inches) to ensure proper fit and function within assemblies.

Resources for The Complete Guide PC Injection Molding Manufacturing

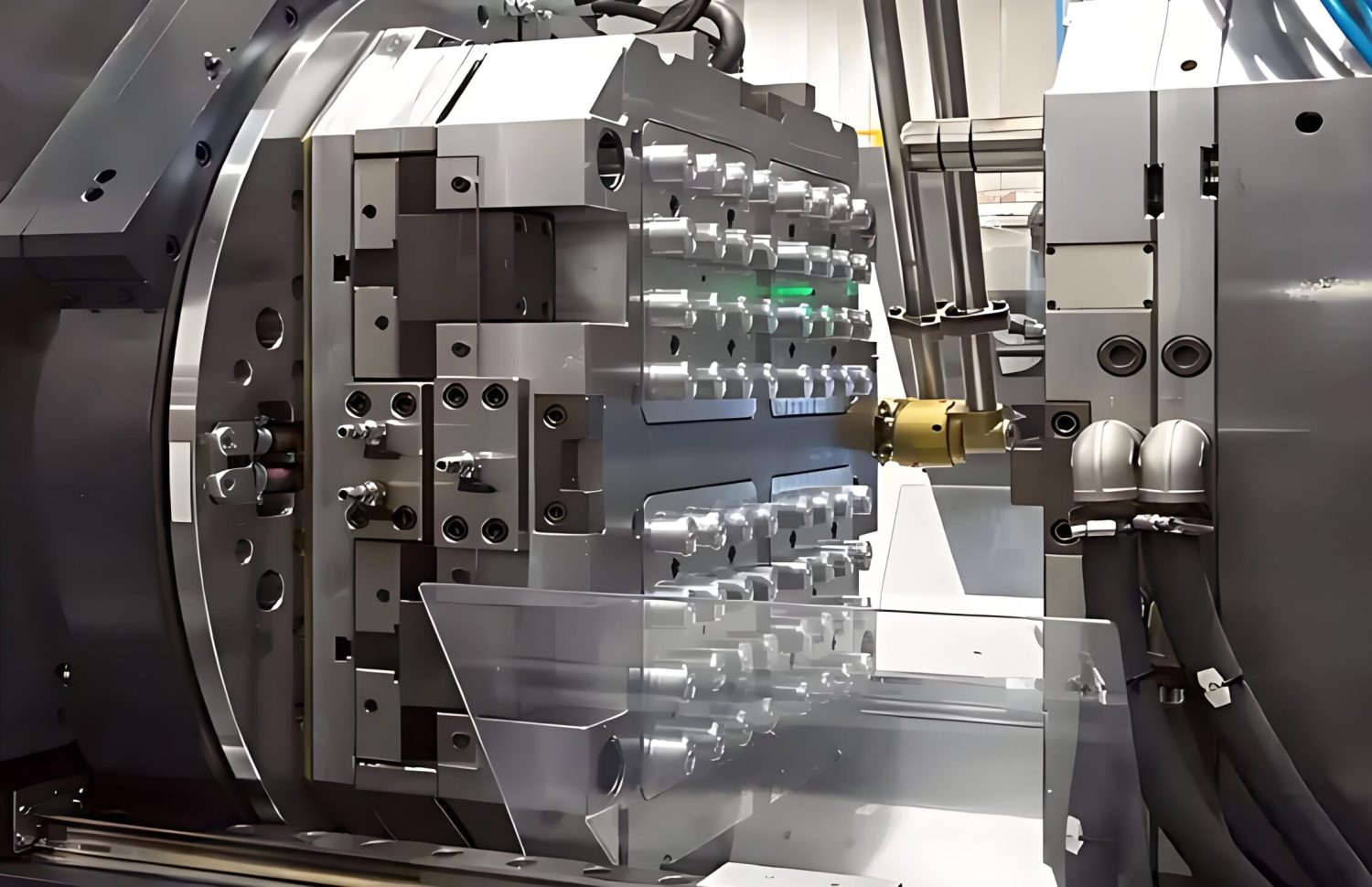

Design guidelines for PC Injection Molding

Injection molding of polycarbonate (PC) requires a well-thought-out design to ensure high-quality parts while optimizing production efficiency. The following guidelines cover key aspects such as mold design, part design, material selection, processing conditions, ejection systems, and quality control.

1. Mold Design:

① Surface Finish:

Ensure a smooth surface finish to enhance optical clarity and facilitate part ejection.

Polish molds to a mirror finish for transparent parts.

② Gate Design:

Position gates at the thickest section of the part to promote uniform filling.

Use fan or tab gates for large parts and pin-point gates for detailed areas.

③ Cooling System:

Design a uniform cooling system with channels near the mold cavity to prevent warpage and distortion.

Maintain mold temperatures between 80°C and 120°C for consistent cooling.

④ Parting Line:

Ensure the parting line minimizes flash and aligns with the ejection direction.

⑤ Draft Angle:

Use draft angles of 1-2° for non-textured parts and 3-5° for textured parts to facilitate ejection.

2. Part Design:

① Wall Thickness:

Maintain uniform wall thickness between 1.5 mm to 3.5 mm to prevent warpage and ensure even cooling.

Gradually transition between thicknesses to avoid stress points.

② Ribs and Bosses:

Rib thickness: 50-60% of the wall thickness to avoid sink marks.

Provide fillet radii at rib bases to reduce stress.

For bosses, include a core hole and ensure sufficient spacing to avoid voids.

③ Corners and Edges:

Avoid sharp corners to reduce stress concentrations.

Internal radius: 0.5 times wall thickness; external radius: 1.5 times wall thickness.

④ Threads and Bosses:

Use threaded inserts instead of molding threads directly into the part for better durability.

⑤ Text and Logos:

Prefer embossed designs over engraved ones for better moldability.

Ensure a minimum height of 0.5 mm for embossed features.

3. Material Selection:

① Material Type:

Select PC materials with high molecular weight and low viscosity for easier molding and enhanced properties.

② Material Properties:

Evaluate impact resistance, tensile strength, and thermal stability for the application.

③ Material Drying:

Pre-dry PC pellets at 120°C for 3-4 hours to minimize moisture content below 0.02%, avoiding defects like splay marks.

4. Processing Conditions:

1. Temperature:

Melt temperature: 270°C to 320°C for proper flow and to prevent thermal degradation.

2. Pressure:

Injection pressure: 1000 to 2000 bar to ensure complete mold filling.

3. Injection Speed:

Use moderate speeds to prevent flow marks and ensure proper material fusion.

4. Cooling Time:

Optimize cooling time based on wall thickness to avoid warping.

5. Ejection System:

1. Ejection Pins:

Place evenly to distribute ejection forces and avoid part distortion.

2. Vent Placement:

Include vents of 0.02 mm to 0.05 mm at the parting line and critical areas to prevent burn marks.

3. Ejection Force:

Use sufficient ejection force to ensure smooth part removal without damage.

6. Quality Control:

1. Inspection:

Regularly inspect parts for warpage, sink marks, and dimensional accuracy.

2. Testing:

Perform mechanical testing for impact resistance, tensile strength, and thermal performance.

3. Material Analysis:

Verify material properties to ensure compatibility and consistency.

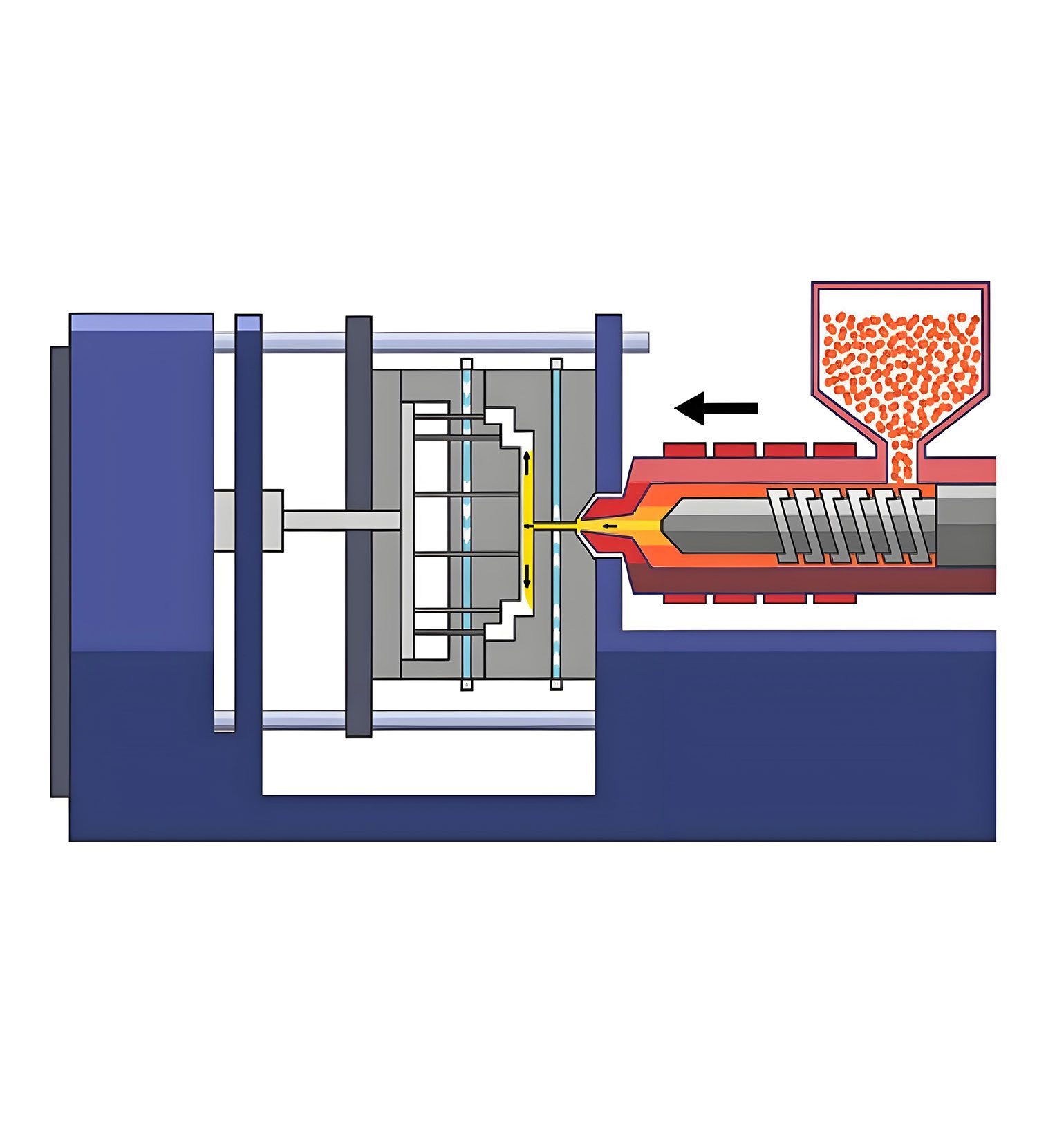

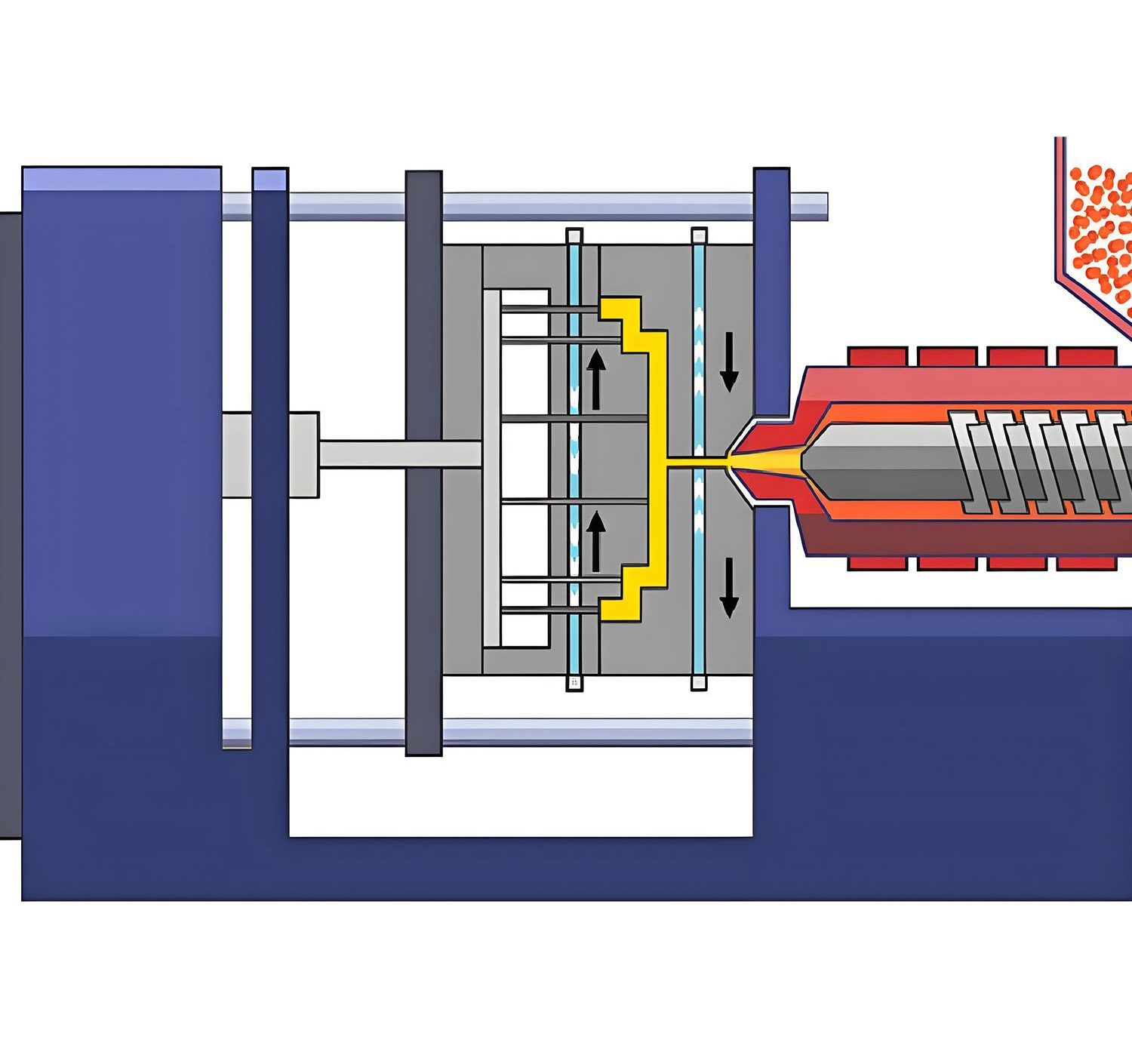

How to Perform PC Injection Molding: A Step-by-Step Guide

Polycarbonate (PC) is a versatile thermoplastic known for its impact resistance, transparency, and high heat tolerance. Processing PC requires attention to specific parameters to ensure product quality and performance. Below is a step-by-step guide:

Step 1: Material Preparation:

Polycarbonate (PC) is hygroscopic and absorbs moisture, which can cause defects such as bubbles, streaks, or surface imperfections.

① Drying: Dry the PC material at 110–130°C (230–266°F) for 3–5 hours to achieve a moisture content of less than 0.02%. This ensures proper processing without defects caused by moisture.

② Mixing: If additives or fillers are used, weigh and mix them with the PC according to the manufacturer’s instructions. Ensure that the material is free of contaminants and mixed uniformly.

Step 2: Mold Preparation:

Proper mold preparation ensures easy part ejection and prevents defects during the molding process.

① Cleaning: Ensure the mold is free of dust, moisture, and debris, which could affect the quality of the final product.

② Release Agent: Apply a release agent to the mold surfaces to prevent sticking and facilitate easy ejection of the molded part.

③ Alignment: Secure the mold properly in the injection molding machine, ensuring no misalignment that could cause mold defects.

Step 3: Material Loading and Injection Setup:

Proper injection temperature and pressure ensure that the material flows correctly into the mold, filling all cavities and ensuring consistent quality.

① Load the Material: Feed the dried PC pellets into the injection molding machine's hopper.

② Injection Temperature: Set the injection temperature between 240°C to 260°C (464°F to 500°F). The melting range for PC typically falls between 270°C to 320°C, but avoid exceeding 340°C to prevent decomposition and defects.

③ Injection Pressure: Set the injection pressure between 1000 to 2000 bar (14,500 to 29,000 psi), depending on part size and mold design.

④ Injection Speed: Control the speed to prevent material from entering the mold too quickly, which could lead to defects such as flow marks or air entrapment.

Step 4: Dwelling Phase:

The dwelling phase ensures complete filling of the mold and allows the molten PC to take the shape of the mold cavities.

① Maintain Pressure: After injection, hold pressure in the mold to allow the molten material to completely fill every detail and prevent shrinkage or voids.

② Monitor: Keep an eye on the pressure to ensure the material remains in place until it starts to cool.

Step 5: Cooling Phase:

Proper cooling prevents warping, shrinkage, and other defects, while ensuring dimensional stability of the final part.

① Cooling Time: Allow sufficient time for cooling. The cooling time will depend on the part's thickness, complexity, and mold temperature. Larger parts may require more cooling time.

② Mold Temperature: Maintain the mold temperature between 80°C to 120°C (176°F to 248°F) for optimal cooling without inducing defects like warping or sink marks.

③ Cooling Channels: Ensure that the cooling system inside the mold is efficient and evenly distributed to maintain consistent mold temperature.

Step 6: Ejection:

Proper ejection is critical for maintaining part integrity and ensuring smooth production flow.

① Ejection Mechanism: Use ejector pins or air-powered ejection systems to push the part out of the mold.

② Force Control: Adjust the ejection force to prevent damage to delicate or complex parts.

③ Post-Processing: If needed, trim excess flash or material from the part during ejection.

Step 7: Post-Processing:

Post-processing ensures the molded part meets all necessary specifications for functionality and aesthetics.

① Trimming and Deflashing: Remove any excess material (flash) left over from the molding process. This may require trimming or grinding operations.

② Surface Finishing: Depending on the end use, you may need to polish or coat parts for improved aesthetics or additional functionality (e.g., improved chemical resistance or surface durability).

③ Assembly: If the molded parts are components of a larger assembly, perform any necessary assembly or bonding operations.

Step 8: Quality Control

Ensuring the quality of the molded part is critical for maintaining product standards and customer satisfaction.

① Inspection: Regularly inspect parts for defects such as bubbles, warping, or color inconsistencies. Dimensional accuracy is essential.

② Testing: Perform testing for impact resistance, transparency, and heat tolerance, especially for critical applications.

③ Consistency: Monitor processing conditions (temperature, pressure, and cycle time) to ensure consistent part quality across production runs.

What are the advantages of PC Injection Molding?

Polycarbonate (PC) injection molding offers numerous benefits, making it an ideal material for various industries such as automotive, consumer electronics, medical devices, and more. Here’s a comprehensive look at its key advantages:

1. High Strength-to-Weight Ratio:

PC has a high strength-to-weight ratio, making it ideal for applications where weight reduction is critical. This characteristic is particularly beneficial in automotive and aerospace industries where lightweight materials contribute to efficiency and performance.

2. Impact Resistance:

Polycarbonate is renowned for its exceptional impact resistance, even in low temperatures. This makes it perfect for parts subject to impact or shock, such as automotive components, safety equipment, and protective covers.

3. Chemical Resistance:

PC is resistant to many chemicals, including acids, bases, and solvents, making it suitable for applications in harsh environments, such as chemical processing equipment and medical devices that may come into contact with corrosive substances.

4. Thermal Resistance:

Polycarbonate has a high thermal resistance, allowing it to withstand elevated temperatures without compromising structural integrity. This property makes it suitable for parts exposed to heat, such as automotive under-the-hood components and electrical enclosures.

5. Electrical Insulation:

PC is an excellent electrical insulator, which is why it is commonly used in electrical and electronic components like connectors, circuit boards, and housings for sensitive electronics.

6. Optical Clarity:

Polycarbonate offers outstanding optical clarity, making it ideal for transparent parts like optical lenses, light covers, and medical devices that require high transparency for functionality and aesthetic appeal.

7. Dimensional Stability:

PC exhibits excellent dimensional stability, which means it maintains its shape even after exposure to temperature variations and physical stress. This is crucial for applications that demand precise dimensions and tolerances.

8. Low Warpage:

Polycarbonate has low warpage during cooling, ensuring parts retain their intended shape after molding. This quality is particularly important for intricate parts that require accuracy, such as thin-walled components.

9. Easy Finishing:

The surface of PC can be easily finished through machining, grinding, or coating, making it suitable for parts that require additional processing to achieve the desired appearance or functionality.

10. Cost-Effective for High-Volume Production:

PC injection molding is a cost-effective manufacturing process, particularly for high-volume production runs. Although initial setup costs can be higher due to the creation of molds, the efficiency of the process and the ability to produce large quantities of parts quickly lead to lower per-unit costs.

11. Versatility in Design:

PC injection molding allows for the creation of highly complex geometries, including intricate designs and thin-walled parts. This versatility enables manufacturers to produce components with precise details, making it suitable for industries such as automotive and medical applications.

12. Flexibility in Color and Finish:

The process allows for color customization, as PC can be molded in a wide range of colors, and surface finishes can be tailored to meet specific aesthetic or functional requirements. Techniques like overmolding and adding colorants during processing provide design flexibility.

13. Low Shrinkage:

Polycarbonate has low shrinkage during the cooling process, ensuring parts retain their precise dimensions after molding, which is essential for parts that need to fit together perfectly or meet stringent size requirements.

14. Good Adhesion:

PC has good adhesion to other materials, allowing for the bonding of different components or the assembly of multi-material parts in various industries, such as automotive and electronics.

15. High Efficiency and Fast Production:

PC injection molding is known for its rapid production cycle times, ranging from 10 to 120 seconds. This high efficiency allows for the quick manufacture of large quantities of parts, making it ideal for meeting large order demands.

16. Consistency and Repeatability:

Once the mold is created, PC injection molding can produce thousands of identical parts with exceptional consistency. This repeatability is essential for maintaining quality standards, particularly in industries where precision is critical.

What are the disadvantages of PC Injection Molding?

Polycarbonate (PC) injection molding offers advantages in producing durable, high-quality parts, but it also has several disadvantages that can affect both production efficiency and cost-effectiveness. These include:

1. High Processing Temperature:

PC requires high processing temperatures, which can be challenging to achieve and maintain, especially for large parts. This can increase energy consumption and lead to higher operational costs.

2. High Injection Pressure:

PC typically requires high injection pressures, which can strain the equipment and complicate the molding process, particularly for larger or more intricate parts.

3. Warpage:

PC is prone to warpage, especially if the part design is not optimized for warpage prevention. This can lead to dimensional inconsistencies and higher rejection rates in the final parts.

4. Shrinkage:

Polycarbonate exhibits significant shrinkage during cooling, which can affect the part’s dimensions and accuracy. Proper mold design and temperature control are critical to managing this issue.

5. Material Properties Variation:

PC can show variations in material properties like impact resistance and tensile strength depending on the specific grade and processing conditions. This can make it challenging to maintain consistent part quality.

6. Limited UV Resistance:

PC is susceptible to degradation when exposed to UV light, which can affect its optical clarity and mechanical properties. While UV stabilizers can be added, this increases the cost and complexity of the material.

7. Limited Chemical Resistance:

While PC has good resistance to many chemicals, it is vulnerable to certain solvents and acids. This limits its use in applications where exposure to aggressive chemicals is common.

8. Brittleness at Low Temperatures:

Polycarbonate becomes more brittle at low temperatures, which makes it unsuitable for applications exposed to extreme cold environments.

9. Difficult to Weld:

PC is difficult to weld, particularly compared to other engineering plastics like ABS or PVC, which can create challenges in assembly and repair processes.

10. High Material Cost:

PC is more expensive than many other engineering plastics, particularly high-quality grades. This increases production costs, making it less cost-effective for high-volume production runs.

11. Design Limitations:

PC can be challenging to mold into complex geometries or thin walls. It also requires careful planning of features such as draft angles, wall thicknesses, and undercuts to avoid issues with mold ejection and part quality.

12. Mold Design Requirements:

PC requires specialized mold designs to ensure proper filling, cooling, and ejection. This adds complexity and cost to the injection molding process.

13. Post-Molding Operations:

Parts made from PC may require additional post-molding operations like machining or grinding to achieve the desired surface finish or dimensional accuracy, which can add to production time and cost.

14. Material Compatibility:

PC may not be compatible with certain materials or finishes, which could affect the part's performance or appearance, especially in multi-material assemblies.

Common issues and solutions in PC Injection Molding

Polycarbonate (PC) injection molding can experience various defects that affect part quality, efficiency, and material properties. Below are the common issues faced during the injection molding process of PC and their potential solutions.

1. Warpage:

Warping occurs when the molded part deforms due to internal stresses or uneven cooling, causing dimensional changes.

Causes:

① Inadequate cooling.

② Improper mold design.

③ Excessive material shrinkage.

Solutions:

① Improve the cooling system by optimizing the mold’s cooling channels.

② Design molds with uniform wall thickness to ensure even cooling.

③ Use controlled cooling to avoid rapid temperature changes.

④ Consider structural reinforcements to maintain part shape.

2. Air Traps/Vacuum Bubbles:

Air traps occur when air is trapped in the mold cavity, leading to voids or bubbles in the part.

Causes:

① Insufficient mold venting.

② High injection speeds causing air to be trapped.

Solutions:

① Enhance venting in the mold to ensure proper air escape.

② Lower injection speeds to reduce air entrapment.

③ Use vacuum-assisted systems to remove air during the injection process.

3. Short Shots:

Short shots happen when the mold cavity is not completely filled, resulting in incomplete parts.

Causes:

① Low die or material temperatures.

② Insufficient injection pressure or speed.

③ Poor exhaust conditions or inadequate material flow.

Solutions:

① Increase barrel and mold temperatures to ensure proper flow of the material.

② Boost injection pressure and speed.

③ Use a more fluid material and redesign the mold with larger gates and runners for improved flow.

4. Surface Imperfections (Flow Marks, Weld Lines, Pitting, Stretch Marks):

These surface issues occur when the material does not flow evenly or experiences rapid changes in direction or speed during injection, leading to visible defects.

Causes:

① Low mold or material temperatures.

② Improper material formulation.

③ High injection speed causing melt rupture.

Solutions:

① Increase mold and material temperatures for better flow.

② Adjust material formulations and ensure proper drying to prevent moisture-related defects.

③ Slow down injection speed and raise injection time to avoid flow marks and pitting.

④ Modify gate design to ensure better material flow and prevent weld lines.

5. Parting Line Defects:

Parting line defects are seen when the mold halves do not align properly, leaving a visible seam on the finished part.

Causes:

① Improper parting line location.

② Inadequate mold design.

③ Excessive material shrinkage.

Solutions:

① Optimize parting line location to minimize visible defects.

② Ensure precise mold alignment.

③ Adjust material formulations to reduce shrinkage and ensure better mold fill.

6. Ejection Issues:

Ejection problems arise when the molded part does not eject properly from the mold, causing damage or delays.

Causes:

① Inadequate ejection system design.

② Improper mold design or insufficient draft angles.

③ Excessive material shrinkage.

Solutions:

① Improve ejection system design by adding ejector pins or using pneumatic or hydraulic ejectors.

② Optimize mold design with appropriate draft angles to ease part release.

③ Adjust material formulations to reduce shrinkage during cooling.

7. Material Buildup & Mold Clogging:

Material buildup or clogging can cause the mold to become obstructed, leading to delays or poor-quality parts.

Causes:

① Inadequate mold cleaning.

② Excessive material viscosity.

③ Improper injection speed.

Solutions:

① Regularly clean the mold to prevent material buildup.

② Adjust the viscosity of the material by controlling temperature and material blend.

③ Optimize injection speed to prevent excess material from accumulating in the mold.

8. Material Degradation:

Degradation occurs when the PC material breaks down due to excessive exposure to heat, light, or chemicals.

Causes:

① High processing temperatures.

② Prolonged exposure to heat or air during injection.

Solutions:

① Ensure processing conditions are within the recommended temperature range.

② Use temperature-controlled systems to prevent material degradation.

③ Minimize exposure to heat and light by properly storing materials and controlling injection times.

9. Material Properties Variation:

Variation in material properties can lead to inconsistencies in the final product’s performance, including strength, transparency, or flexibility.

Causes:

① Inconsistent material formulation.

② Improper processing conditions.

③ Inadequate drying of material before molding.

Solutions:

① Adjust material formulations to ensure consistent quality.

② Optimize processing conditions, including temperature and pressure.

③ Properly dry materials before molding to avoid moisture-induced defects.

10. Part Weight and Dimension Variations:

Variations in part weight and dimensions can occur due to mold design issues or inconsistent material flow.

Causes:

① Inconsistent mold design.

② Improper processing conditions (temperature, pressure, etc.).

③ Material shrinkage.

Solutions:

① Optimize mold design to ensure uniform part filling and reduce variation.

② Fine-tune processing conditions to maintain consistent weight and dimension.

③ Adjust material formulations to reduce excessive shrinkage.

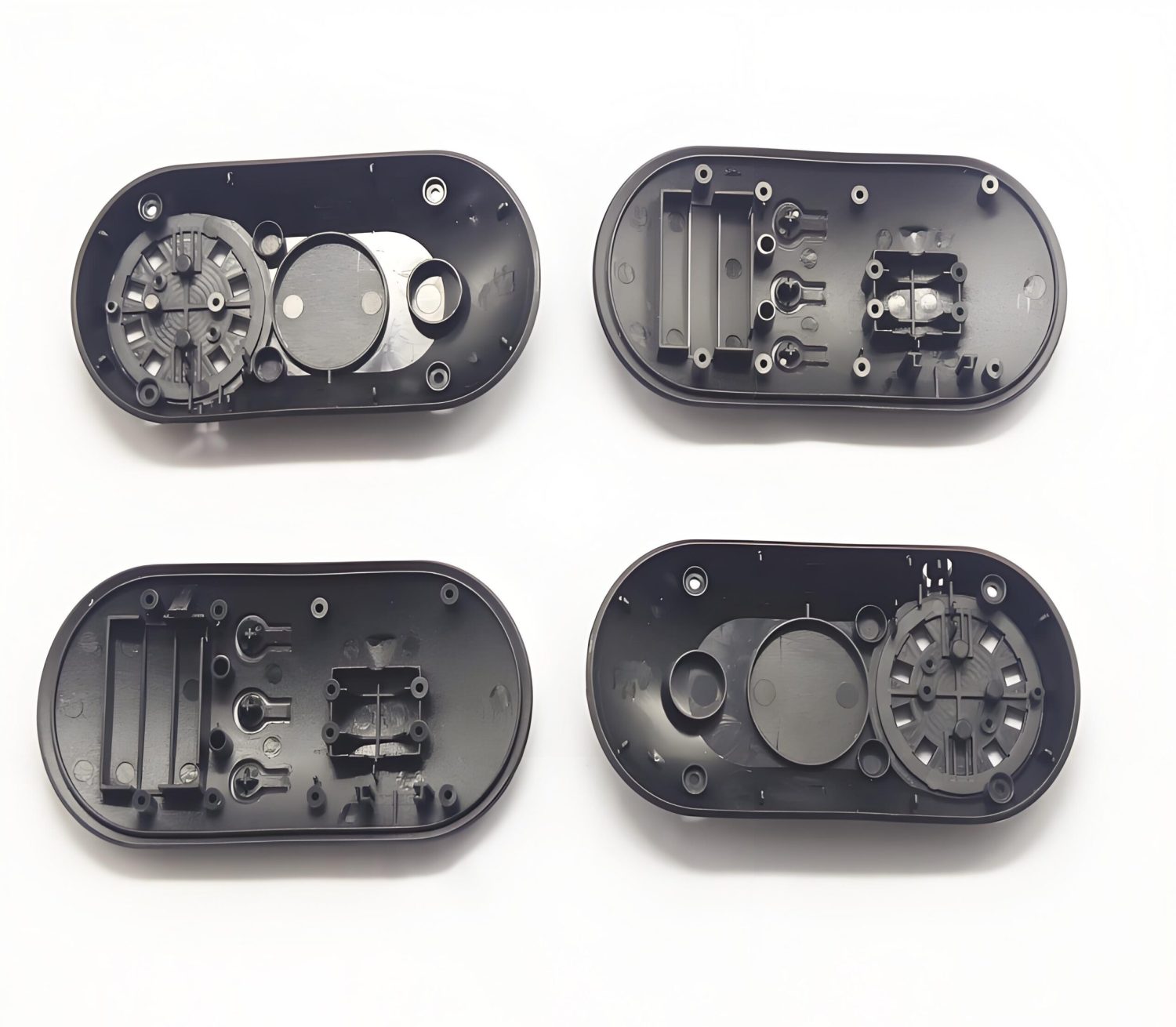

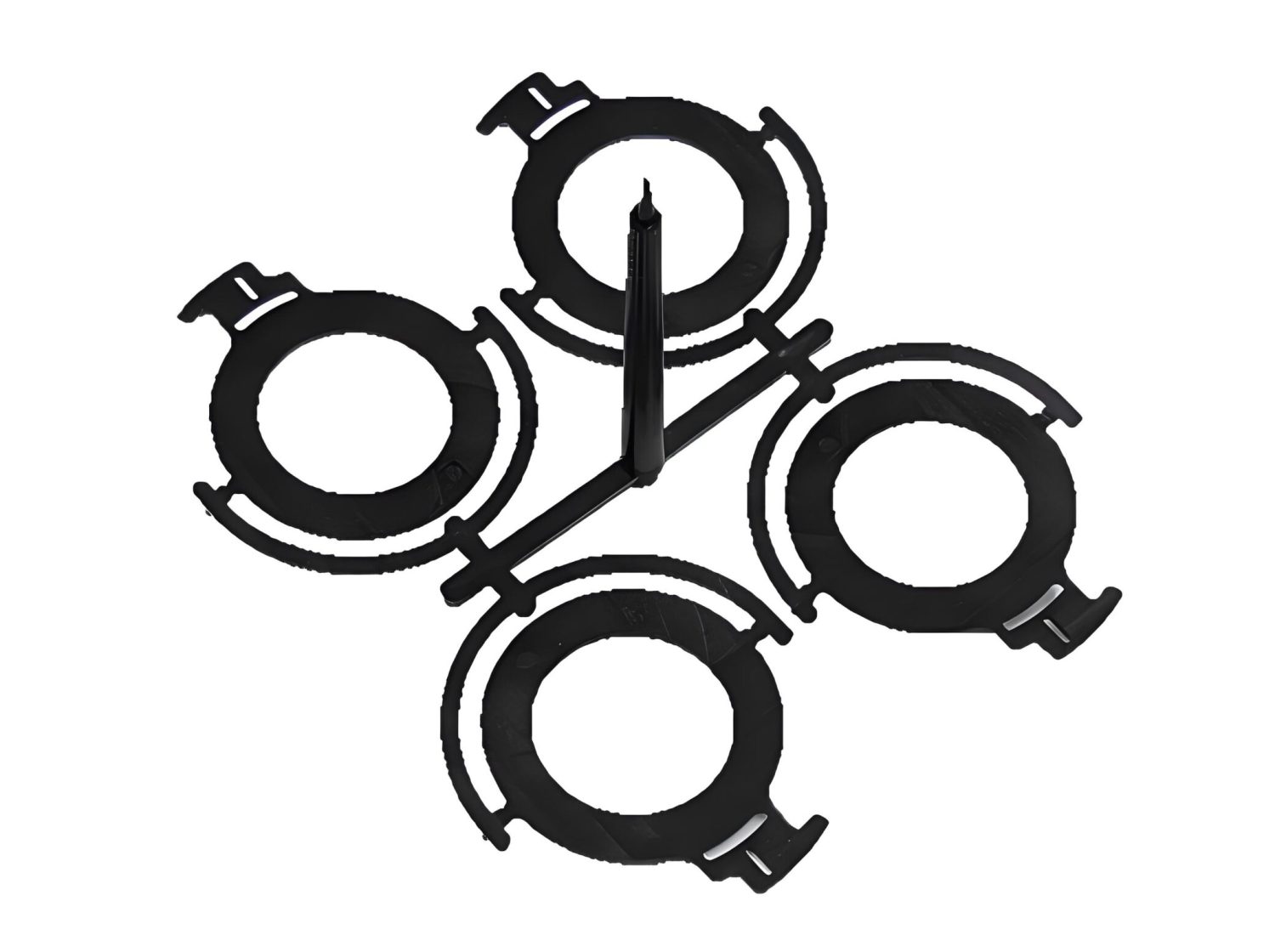

What are the applications of PC Injection Molding?

Polycarbonate (PC) injection molding is a versatile manufacturing process used across a wide range of industries, leveraging the material’s excellent properties such as impact resistance, optical clarity, and heat resistance. Below is a comprehensive overview of the applications of PC injection molding:

1. Automotive Industry:

Components: PC is widely used for automotive parts like headlight lenses, dashboards, interior trims, and exterior components. Its impact resistance, lightweight nature, and optical clarity contribute to both safety and performance in vehicles.

2. Electronics Industry:

Casings and Components: PC is commonly used for electronic device casings such as laptops, smartphones, and tablets. Its excellent insulating properties and impact resistance ensure durability and safety in electrical and electronic applications.

3. Construction Industry:

Building Materials: PC is used for skylights, roofing sheets, and window glazing, offering excellent durability, weather resistance, and optical clarity. These features make it ideal for applications requiring safety and transparency in construction.

4. Medical Devices:

Surgical Instruments and Equipment: PC is essential for manufacturing syringes, medical tubing, and surgical instruments. Its biocompatibility, ease of sterilization, and high strength make it a trusted material in healthcare applications.

5. Consumer Goods:

Everyday Products: PC is widely used for products like eyewear lenses, water bottles, and safety helmets. Its impact resistance and aesthetic versatility allow for durable and visually appealing consumer items.

6. Aerospace and Defense:

Aircraft Components: PC is employed in aircraft for cockpit windows, lenses, and instrument panels. Its combination of lightweight properties, strength, and clarity is critical in aerospace environments requiring precision and safety.

7. Optical Applications:

Lenses and Optical Components: PC is used for camera lenses, projector lenses, and eyeglasses, thanks to its optical clarity, scratch resistance, and ability to withstand high impact. It is ideal for both professional and consumer-grade optical applications.

8. Food Processing:

Equipment Components: PC is used in food processing machinery and storage containers due to its chemical resistance, impact strength, and safety for food contact. It is ideal for applications requiring repeated cleaning and sterilization.

9. Sports Equipment:

Protective Gear: PC is used in helmets, goggles, and other protective sports equipment. Its high impact resistance, lightweight design, and comfort make it essential for ensuring athlete safety and performance.

10. Toys and Games:

Plastic Toys: PC is used in action figures, dolls, and other toys that require durability and safety. Its non-toxic nature, toughness, and ability to form complex shapes make it a preferred material in toy manufacturing.

11. Packaging:

Containers and Bottles: PC is used for making packaging items like water bottles and food containers. Its impact resistance, clarity, and ability to withstand repeated use make it suitable for long-lasting and sustainable packaging solutions.

12. Electrical Components:

Connectors and Switches: PC is utilized for electrical connectors, switches, and circuit boards. Its excellent insulating properties and flame resistance ensure safety and reliability in electrical applications.

Family Molds vs. MUD Systems: Which Strategy Best Manages Multi-Part Injection Molding Projects?

Key Takeaways – Family molds produce multiple different parts in one shot, but a single compromised process window affects all cavities simultaneously. – MUD (Master Unit Die) systems use interchangeable

What is a High-Speed Injection Molding Machine?

Key Takeaways – A high-speed injection molding machine is defined by injection speed4s of 300–600 mm/s and clamp speeds exceeding 500 mm/s, compared to 100–200 mm/s for standard machines—enabling cycle

How to Improve the Precision of Injection Molds?

Key Takeaways – Mold precision is determined at every stage: part design, mold design, steel selection, machining, assembly, and process control—a weakness at any stage limits overall precision. – Properly

Optimization Solutions Provided For Free

- Provide Design Feedback and Optimization Solutions

- Optimize Structure and Reduce Mold Costs

- Talk Directly With Engineers One-On-One