Low-volume injection molding offers a cost-effective solution for producing small batches of parts quickly, ideal for prototyping and short-run production needs.

Low-volume injection molding reduces upfront tooling costs, making it suitable for producing smaller quantities of parts. It offers flexibility in design changes and is commonly used in industries like automotive, medical, and consumer goods.

Understanding the benefits and limitations of low-volume injection molding can help optimize your production strategy. Dive deeper into how it compares to high-volume molding and when it’s best applied.

Low-volume injection molding reduces overall production costs.True

Low-volume injection molding eliminates the need for expensive tooling and large production runs, making it cost-effective for smaller quantities.

Low-volume injection molding is only suitable for prototype parts.False

Low-volume injection molding is also used for small-scale production, offering flexibility for industries requiring limited quantities of high-quality parts.

What is Low-Volume Injection Molding?

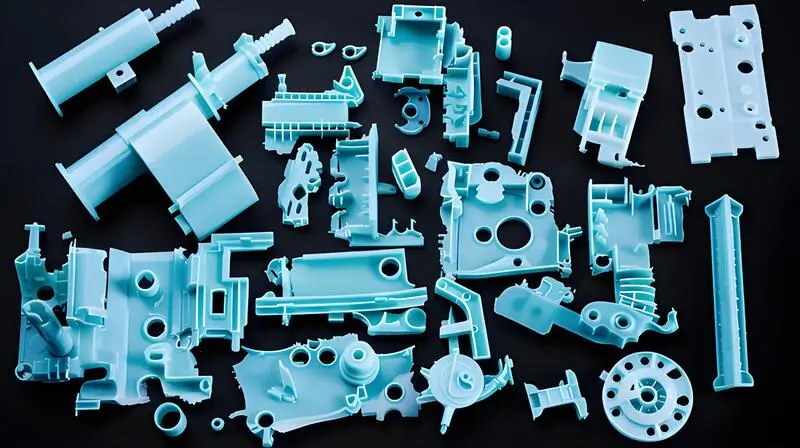

Low-volume injection molding is a cost-effective solution for producing small quantities of high-quality plastic parts. It’s ideal for prototypes, small batches, and customized production runs.

Low-volume injection molding involves producing a limited number of parts with reduced tooling and setup costs, making it suitable for prototyping or small production runs. It balances cost-efficiency with precision and quality, perfect for industries needing fewer parts.

Low-volume injection molding is a production method used for plastic high volume injection molding with rapid tooling. It provides hundreds of parts for pilot production to simulate mass-produced parts for pre-production testing and verification. It also produces end-use parts on demand for small-volume production runs.

Low-volume injection molding is ideal for prototyping and small batches.True

It reduces costs and lead times, making it suitable for testing and small production runs.

Low-volume injection molding is always cheaper than high-volume molding.False

While low-volume molding reduces upfront costs, high-volume molding may offer better cost efficiency when producing large quantities.

What Materials are Used in Low-Volume Injection Molding?

Low-volume injection molding uses various materials tailored to specific production needs, balancing cost-efficiency with high-quality output.

Materials commonly used in low-volume injection molding include thermoplastics like ABS, polycarbonate, and nylon. These materials offer flexibility, strength, and ease of molding, ideal for prototypes and short production runs.

Low-volume injection molding is a versatile process that works with a variety of materials like thermoplastics1, thermosets2, and elastomers. Out of these materials, thermoplastics are the most popular because they’re easy to mold and have a wide range of properties. Thermosets are used for parts that need to be able to handle high heat, and elastomers are used for parts that need to be flexible.

When choosing materials for low-volume injection molding, you have to think about a lot of things. You have to think about how the part is going to perform, what the requirements are, and how much it’s going to cost. You also have to think about how the material is going to process, like how fast it’s going to flow 、manufacturing methods and how thick it is.

Nylon is commonly used in low-volume injection molding.True

Nylon offers excellent strength, wear resistance, and versatility, making it a popular choice in low-volume injection molding.

Metal parts are commonly used in low-volume injection molding.False

While some metal parts may be molded using metal injection molding (MIM), they are not typically used in standard low-volume injection molding processes due to cost and material limitations.

How Does Low-Volume Injection Molding Work?

Low-volume injection molding is a manufacturing process ideal for producing small quantities of parts with high precision, cost-effectively and quickly.

Low-volume injection molding uses specialized molds to produce small batches of parts, reducing setup costs and time. It’s commonly used in prototyping, medical, and automotive industries. It offers rapid production and precise part design.

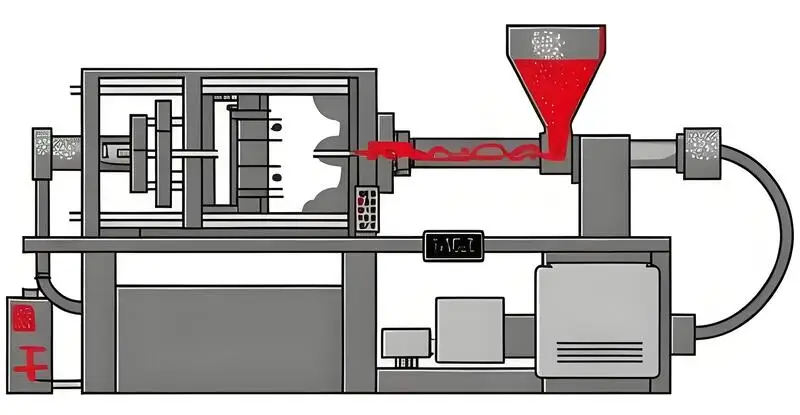

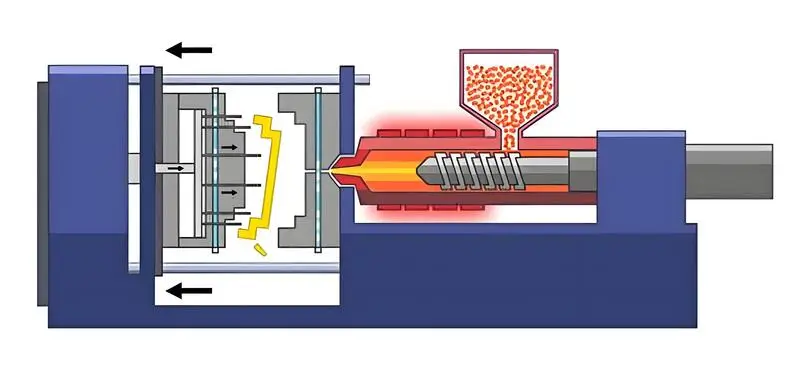

Low-volume injection molding is a specialized process used to produce small batches of plastic parts. It involves using an injection molding machine that melts plastic pellets and injects them into a mold. Once the mold cools, the part is ejected. It involves injecting molten plastic into the mold cavity under high pressure, which then solidifies to form the desired part.

An injection molding machine is a complicated piece of equipment that has a lot of parts. It has a hopper, a barrel, a screw, and a mold. The hopper is where the plastic pellets are kept. The barrel is where the plastic pellets are melted. The screw is used to push the melted plastic into the mold. The mold is where the part is made.

Low-volume molding is a multi-step process that includes mold design, material selection, injection molding, and part finishing. Mold design is the creation of a mold for making the part.

Material selection is choosing the right material for the part based on the part’s characteristics and requirements. Injection molding is the production of parts. Part finishing is any post-processing that is needed, such as trimming or painting.

Low-volume injection molding is cost-effective for small production runs.True

Low-volume injection molding reduces setup costs and material waste, making it ideal for producing small quantities with high precision.

Low-volume injection molding is only suitable for prototypes.False

While commonly used for prototyping, low-volume injection molding is also effective for short-run production, offering cost efficiency without compromising quality.

What is the Process of Small-Batch Injection Molding?

Small-batch injection molding is ideal for limited production runs, offering flexibility and cost-effectiveness for prototype and custom products. It ensures high-quality parts with fast turnaround times.

Small-batch injection molding allows for efficient production of low-volume runs, reducing costs while maintaining product quality. It is often used for prototypes, testing, and limited-edition products. The process is ideal for reducing startup expenses compared to large-scale molding.

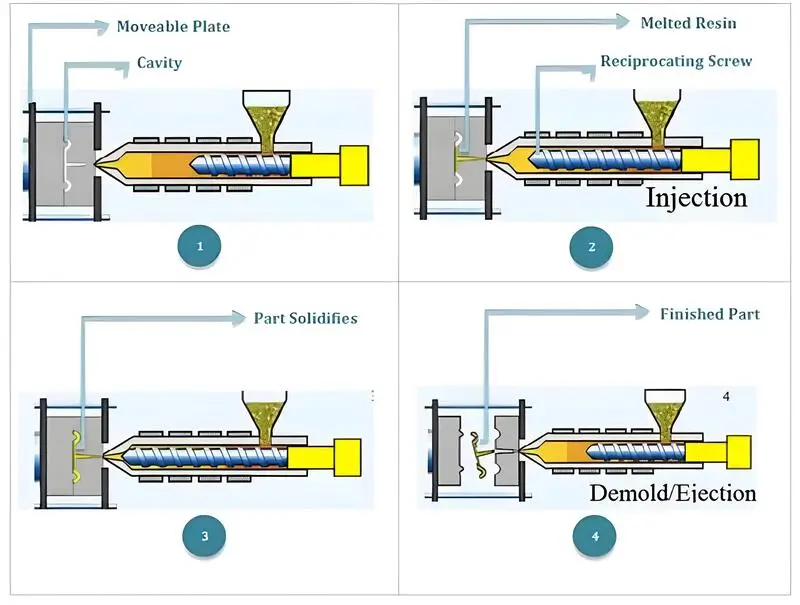

Mold Preparation

The mold for making the plastic product you want needs to be prepared in advance. This includes designing, making, and installing the mold. When you design the mold, you need to think about the shape, size, and material properties of the product you want. When you make the mold, you need to think about things like what material to use and how accurate the mold needs to be.

Plastic Material Preparation

You need to choose and process plastic materials according to the requirements of the products you want to make. Usually, you heat plastic pellets or powder until they melt, and then you shoot the melted plastic into a mold using a machine.

Injection

Injection is when you shoot hot plastic into a mold using a machine. You have to control things like how hard you shoot it, how fast you shoot it, and how hot it is to make sure it comes out right.

Cooling

After you shoot the plastic, you have to wait for it to cool and harden. How long it takes and how hot it has to be depends on what kind of plastic you’re using and how thick it is.

Mold Opening

After the mold has cooled, it’s time to open it up and get the parts out. There are a lot of ways to open a mold, including manual, mechanical, and hydraulic.

Deslagging, Trimming, and Processing

After the parts are taken out of the injection mold, they need to be deslagged, trimmed, and processed to remove excess plastic material, flatten the surface, and process the required holes.

Inspection and Packaging

Finally, we need to inspect the finished product to make sure it’s good enough, then we put it in a box and send it to you.

Small-batch injection molding reduces production costs for prototypes.True

Small-batch molding minimizes setup costs and material waste, making it an affordable choice for low-volume production.

Small-batch injection molding is unsuitable for high-volume production.False

Small-batch molding can be scaled up for higher volumes, but its cost-efficiency is most beneficial for low to medium quantities.

What are the Main Advantages of Small-Batch Injection Molding?

Small-batch injection molding offers flexibility and cost-efficiency, ideal for producing low quantities of parts with high precision, catering to industries like automotive, medical, and consumer goods.

Small-batch injection molding enables efficient production of small quantities with lower setup costs, making it ideal for prototypes or low-volume runs. Benefits include reduced waste, faster turnaround, and the ability to easily make design changes during production.

Reduce Product Delivery Cycle

Compared to the old way of making things, rapid prototyping3 makes it faster and easier to make a few things.

It’s used in lots of industries like jewelry, dentistry, medical equipment, cars, planes, and more. 3D printing is used to make final products, spare parts, and prototypes for casting. It saves time and makes it easier to make things.

The whole small batch injection molding4 process means shorter delivery times. In mold design, the use of aluminum, which is known for its soft properties, makes the mold manufacturing process easier and faster. Since low volume injection molds arrive at manufacturing plants much faster and are produced in small quantities, production speed is fast.

In many cases, this can speed up time to market a lot, which is good for both small and big product teams. The production cycle of steel molds is long, usually from about 1 month to several months, not including the time for modification and adjustment. Small batch prototype customization can start production in as fast as 1 day.

Path to Expanding Production Scale

Small batch production is a way to scale up production. It bridges the gap between making prototypes and making them better or perfect. So if the last product was impressive, it can lead to more orders and steady demand for years.

Buying small can speed up time to market. It also saves you from having to buy one machine to do a lot of machines. Plus, you can go from small batch to big batch. So, as long as you get your product to market fast, you can make more money.

Reduced Time to Market

Technology is changing, which means a constant need for innovation. This puts product developers on a heavy task of designing and redesigning. If not, their products will lose market relevance.

But small batch production can take the pressure off developers. It reduces the inventory burden by only producing products that can be sold and sustained. It increases the success rate and optimizes the supply chain. It also reduces the lead time, which means the product can be on the market in days or weeks.

Injection molding is super fast. From mold design to production cycle, you’ll have your product in no time! It’s so fast and efficient, you can actually see your ideas come to life way faster than other processes.

Reduce Costs

The manufacturing cost of batch production changes as the number of products produced increases. For small batch product needs, larger batch manufacturing will save expensive mold investment and greatly save time and labor costs.

The common belief that if you produce more, you can save money is not true. This theory is only valid when buying household goods, not in manufacturing. The unit cost of an item also depends on the materials used.

Injection molding is a cheap way to make a small number of things because it uses less stuff and people.

Another way companies save money is by investing in tooling. For example, if you have a high-volume production that requires hardened tool steel to hold the machine, it can be expensive because you have to order a bunch of repair tools. With low volumes, you only have to replace the worn parts at a lower cost, which reduces overhead costs.

Also, companies that make a lot of stuff have the lowest minimum orders. The reason is that they have to pay for the setup and tooling with each production run. But small-batch manufacturers have lower overhead costs, so they don’t have a minimum order quantity. So, small-batch manufacturers don’t get stuck with obsolete inventory. If the design or market demand changes.

If you’re looking for small-volume plastic manufacturing, small-volume plastic molding is a great way to make parts without needing a minimum order. You can also avoid getting products from obsolete inventory. All of this translates into effective cost savings.

Some plastic materials can be made by either small-volume replication of prototypes or by large-scale production with steel molds, but if the mold is opened, the mold cost is very high.

If there isn’t a big demand for the product, the high mold opening fee will make the product cost a lot more to make, and that will make the product not as good of a deal for people to buy.

Secondly, because the small-batch production orders are too small and there is no profit, general mold factories will not accept them. Even if we want to open molds for production, we can\’t find a processing factory willing to accept the order.

But for the prototype factory, small-batch production is a very cost-effective business. Even if the profit is appropriately concessionary than the prototype customization, the prototype factory is very happy to accept it.

From the customer\’s perspective, even though the production costs to make one product has gone up, the total cost to make all the products has gone down.

Flexible Market Adjustment

With fast and efficient capabilities, users can adapt to market changes more quickly, grasp customer demand dynamics in a timely manner, and provide customers with personalized customization services.

Usually, after you design and develop new products, the big worry is that you can’t guarantee that people will want to buy them.

If you open the mold and start mass production without thinking, if it doesn’t sell well, you will lose money.

If the market feedback is good and the demand is strong, we can produce and supply in small batches while preparing to open the mold for large-scale production. If the sales are not good, we can also stop production in time and adjust the product according to the feedback from the consumer market.

Small batch production is a great choice for flexible design improvements. For example, some design aspects may no longer be appealing to customers. It’s easy to make changes without a big impact on the whole order. So you can adjust to the market flexibly.

Make High-Quality Parts

Even though we use softer mold materials, we can still make highly durable and fully functional parts with small-batch plastic injection molding.

Aluminum has a better heat transfer rate than steel, which means we don’t have to worry as much about where we put cooling lines. It also gives us more room for more mold parts. So, small-batch plastic manufacturing gives us more design flexibility and makes the gap between prototyping and mass production smaller.

Injection molding5 takes your ideas and turns them into real, dependable, precise products with amazing polish! It’s an amazing process that starts with great input to get great output.

Everything comes out with a great surface finish, perfect details, and can make great parts no matter how complicated they are.However, the CNC machining process requires precise control of parameters such as wall thickness to ensure part dimensions are accurate and structurally complete.

Small-batch injection molding is cost-effective for low-volume production.True

The reduced tooling and setup costs make small-batch injection molding ideal for producing limited quantities, allowing for cost savings on low-volume runs.

Small-batch injection molding is only useful for prototypes.False

While it’s perfect for prototypes, small-batch injection molding is also effective for low-volume production runs where flexibility and fast turnaround are crucial.

What are the Key Applications of Low-Volume Injection Molding?

Low-volume injection molding is essential for prototyping and small-batch production, offering a cost-effective solution for industries like automotive, medical devices, and consumer goods.

Low-volume injection molding is ideal for small production runs, rapid prototyping, and custom parts. It provides flexibility, reduced lead times, and lower production costs, making it popular in sectors such as aerospace, healthcare, and electronics.

Rapid Prototyping

It’s a great way to prototype plastic parts. It has advantages like quick and cheap production, easier testing and verifying designs before making mass production tools, and easier improvements.

Low-Volume Injection Molding

It’s also great for making small amounts of parts, which is a cheap way to do it, especially if you don’t have a lot of money to make a lot of parts. It’s cheaper than injection molding and you can make small amounts of parts, so you can change your mind and make something else if you want to.

custom Injection Molding

As the name implies, on-demand manufacturing6 allows businesses to make parts as they need them. This means they don’t have to keep a lot of inventory on hand, which saves on storage costs. It also makes it easier to respond to changes in demand, which is why low-volume plastic injection molding is a good fit for businesses in unpredictable industries.

Low-volume injection molding is only suitable for prototypes.False

Low-volume injection molding is also ideal for small production runs, offering a cost-effective solution for manufacturing custom parts in various industries.

Low-volume injection molding always costs less than high-volume production.False

While low-volume injection molding reduces upfront costs, it may not always be cheaper than high-volume production for large quantities, where economies of scale are a factor.

Conclusion

So, in conclusion, low-volume injection molding is a versatile and efficient way to bring your designs to life without the high costs and large quantities. With advanced materials and technologies, you can iterate quickly, meet niche market demands, and get to market faster.

As industries continue to move toward more customized and agile manufacturing, low-volume injection molding7 will be a key tool for innovation, helping you stay competitive in a rapidly changing world.

-

Exploring the benefits of thermoplastics can help you understand why they’re the most popular choice for low-volume injection molding, offering ease of molding and versatile properties. ↩

-

Understanding the use of thermosets can guide you in selecting materials for high-temperature applications, ensuring durability and performance. ↩

-

Explore how rapid prototyping accelerates product development across various industries, saving time and resources. ↩

-

Discover the efficiency of small batch injection molding in speeding up production and reducing time to market. ↩

-

Learn about Injection Molding: A Comprehensive Guide: Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with high accuracy and repeatability. ↩

-

Discover the advantages of on-demand manufacturing, including reduced inventory costs and increased responsiveness to market changes. ↩

-

Explore how low-volume injection molding can save costs and increase flexibility in production, ideal for startups and small businesses. ↩