Insert molding is an advanced injection molding process where metal or other materials are placed into the mold before plastic is injected, creating a strong bond between the materials.

Insert molding combines metal or other inserts with plastic by injecting plastic around the inserts. This process is common in automotive, electronics, and medical device manufacturing, offering durability and reducing assembly costs.

Understanding the nuances of insert molding can help you choose the best process for your products, improving both strength and cost efficiency. Dive deeper to explore how insert molding can streamline your production.

Insert molding reduces the need for additional assembly.True

By combining the insert and plastic in one molding step, the process eliminates the need for separate assembly, saving time and cost.

Insert molding is always more expensive than traditional injection molding.False

While insert molding may have higher setup costs due to the inserts, it can be more cost-effective in the long run by reducing assembly and labor expenses.

What is the Basic Principle of Insert Molding?

Insert molding combines metal or other materials with plastic, creating strong, multi-functional parts in one molding process. This method is commonly used in industries like automotive and electronics.

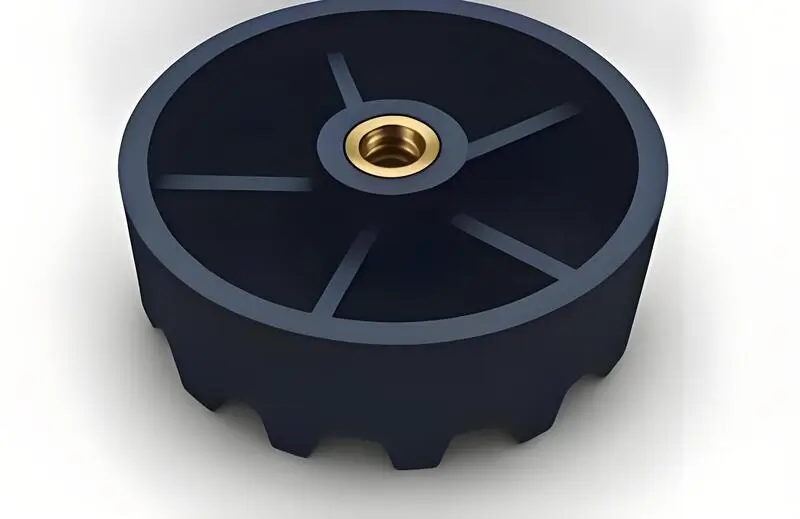

Insert molding involves placing a pre-formed insert (such as metal) into a mold, then injecting plastic around it. This creates a single, integrated part. It’s widely used for producing durable, complex components like electrical connectors and automotive parts.

Insert Preparation

The preformed insert is cleaned to ensure that it can from a bond with the plastic material and that it undergoes surface treatment. Common surface treatment methods include coating, sandblasting, and oxidation.

Mold Preparation

It is kept at the prescribed position within the mold to ensure that it does not move during the injection process1 and is properly secured. The mold design require to be precise to avoid the insert to be damaged or moved unnecessarily during injection.

Injection Molding

Melting of the plastic material takes place and the material is then injected into the mold and it surrounds the insert. Thus, temperature, pressure and speed of injection has to be controlled effectively so that the plastic material has an equal distribution over the insert and the required shape is formed.

Cooling and Demolding

After the manufacturing of the plastic material, it cools and solidifies in the mold cavity, and then the mold is opened and the finished part is ejected. Special attention should be paid to the rate and time of cooling as it may result in such problems as warping2 or shrinkage3.

Insert molding improves part strength.True

By combining different materials, insert molding creates stronger parts that benefit from both the durability of metal and the versatility of plastic.

Insert molding is only used for small, simple parts.False

Insert molding can be applied to both small and large, complex parts, making it versatile for a wide range of applications.

What are the Advantages of Insert Molding?

Insert molding integrates metal or other materials into plastic components, offering durability and precision. It’s widely used in industries such as automotive, electronics, and medical devices.

Insert molding combines multiple materials in one part, increasing strength and reducing assembly costs. It also provides excellent precision, making it ideal for complex designs in automotive, electronics, and medical industries.

Enhanced Part Strength

Inserts made of metal or any other material of higher strength are usually useful in increasing the hardness and toughness of the plastic parts. This is even more relevant for those components that are to be loaded or suffer from stresses and strains in their operation.

Reduced Assembly Steps

The cavity and plastic part containing the insert can eliminate the assembly process after the traditional injection molding process, thereby reducing costs and time.

Increased Functionality

Insert molding can enable products to obtain improved additional functions such as conductivity, wear resistance and corrosion resistance. For example, in electronic products, metal inserts4 molding can be used to achieve electrical contact and shielding.

Design Flexibility

In terms of creating various structures, insert molding does enable the production of complex structures and has better usage of design freedom to fulfil other innovative designs. By optimizing mold design, components with complex geometries and integrated functionalities can be produced.

Insert molding enhances part strength by integrating multiple materials.True

By combining materials like metal and plastic, insert molding creates stronger, more durable components that are ideal for heavy-duty applications.

Insert molding is always more expensive than standard injection molding.False

While insert molding can have higher upfront costs, it can reduce long-term expenses by minimizing assembly and material waste, making it cost-effective for complex parts.

What are the Application Areas of Insert Molding?

Insert molding is used in industries such as automotive, electronics, medical devices, and consumer products. It enables the integration of metal or other materials into plastic parts, providing enhanced functionality and durability.

Insert molding is commonly used in automotive, electronics, and medical device manufacturing. It allows for the insertion of metal components into plastic parts, providing strength, conductivity, and other essential properties.

Automotive Industry

Insert molding is widely used in automotive applications to produce rigorous parts such as headlamps, dashboards, and door handles. Insert molding not only improves the strength and durability of automotive parts, but also reduces the weight of the car, thereby improving fuel efficiency.

Electronics Industry

Insert molding can produce connectors and switches, sensor bodies and a variety of other complex but precision-engineered parts where reliability is a priority. The insert molding process in electronic products eliminates post molding assembly while improving product consistency and reliability.

Medical Industry

Insert molding can produce enclosures for medical instruments, operation locality instruments and other elements of high sanitation and quality requirements. Application of insert molding in the medical industry protects the final product from environmental hazards apart from enhancing the firmness of manufactured service gadgets to accommodate sophisticated functionalities such as sensor features and small intricate diagnostic tools.

Consumer Goods Industry

Insert molding can be used to produce materials with a long expected service life, such as tool housings and household appliances. Insert molding in consumer products can provide aesthetic styling and comprehensive functional improvements, thereby improving the competitiveness of products.

Insert molding improves part durability by combining metal and plastic.True

Insert molding strengthens parts by incorporating metal inserts, making them more durable and functional for specific applications.

Insert molding is only used in large-scale production.False

Insert molding is used in both small and large-scale productions, providing flexibility for various manufacturing needs.

What are the Technical Points of Insert Molding?

Insert molding combines plastic injection molding with the insertion of pre-made components (like metal parts), offering a cost-effective way to create durable, multi-material products.

Insert molding involves placing an insert into the mold cavity before injection, allowing plastic to flow around the insert. It enhances part strength and functionality, commonly used in automotive, electronics, and medical industries.

Insert Material Selection

Depending on the need for bonding to the plastic, the strength needed and the environment it will be used in, the material for the insert needs to be chosen. There are a number of variants used as insert materials, of which steel, aluminum and ceramics and glass fibers are some.

Surface Treatment

The insert surface should be clean and treated, and some processes such as the coating and grinding process increase the bonding strength of the insert to the plastic material. Coating influences bearing both the adhesion strength and, more importantly the final product appearance and functionality.

Mold Design

The mold design must be designed in a way that they do not move during injection, and also the mold must take into consideration the thermal expansion of the insert and flow of the plastic material. The precision and stability of the mold design directly affect the quality of the product.

Injection Parameter Control

When injecting, temperature, pressure, and injection speed are critical to avoid a molding defect that may hinder the functionality of the produce. Parameters of injection have an influence not only on the external appearance of the product and its dimensions, but also on the internal structure and its characteristics.

Insert molding improves part strength by bonding materials.True

The plastic forms a strong bond with the insert, enhancing part durability and performance.

Insert molding is suitable only for high-volume production.False

Insert molding can be used in both low and high-volume production, depending on part complexity and cost-effectiveness.

What is the Quality Control of Insert Molding?

Quality control in insert molding ensures precise, defect-free parts by monitoring every stage of the process, from material selection to final inspection.

Insert molding quality control involves inspecting insert placement, mold design, material compatibility, and part consistency. Key steps include visual checks, measurement, and testing for defects like short shots or warping.

Raw Material Inspection

Carry out a rigid quality check on inserts as well as plastics materials with regards to the composition analysis and check the physical performance of the material to meet the required quality.

Mold Maintenance

Maintenance and proper care of molds helps in preserving the molds’ accuracy and functionality to avoid compromising the quality of the products through poor molds.

Process Monitoring

Dependent on monitored parameters, which include, among others, temperature, pressure, and flow during the injection, use sensors and data acquisition systems to detect abnormalities and correct them.

Product Testing

Carry out complete quality check on finished insert molded parts to check visible check, dimensional check and physical performance check to meet design and performance characteristics.

Quality control in insert molding is necessary for defect-free parts.True

Proper quality control processes prevent defects, ensuring that inserts are placed correctly and parts meet specifications.

Quality control in insert molding is only about visual inspection.False

Quality control goes beyond visual checks, including measurements, material testing, and functionality tests to ensure complete part integrity.

What are the Challenges And Solutions of Insert Molding?

Insert molding involves placing inserts into a mold before injection. This method is popular for creating durable parts, but it presents challenges like alignment and material compatibility.

Insert molding challenges include insert misalignment, inconsistent material bonding, and mold design complexity. Solutions involve precise insert placement, proper material selection, and optimized mold designs to improve efficiency and quality.

Fixing and Positioning of Inserts

Inserts can shift or warp because of the injection pressure or bulge because of heat during the injection process. Solutions include the further improvement of the mould design, the addition of fixing means for the insert, and the best settings of the injection process which decrease the movement of the insert.

Bonding Strength Between Insert and Plastic

If the bond strength between the insert and the plastic is low, the component will fail prematurely. There are several ways to improve the bond strength, namely selecting the right type of insert and/or applying surface treatment.

Molding Complex Geometries

For parts with complex shapes or customization, insert molding may face problems such as poor filling and poor cooling. Optimizing mold design and injection molding process parameters5 may enhance the flow of plastic and its cooling.

Production Costs

A major disadvantage of insert molding is the relatively high start-up cost of the mold, especially when used for small production runs. There are several ways to minimize production costs, including multiplexing molds, increasing the automation of processing equipment, and minimizing production costs.

Insert molding creates stronger parts with metal inserts.True

The method combines plastic and metal components, making the resulting part more durable and functional, especially for automotive or electronic applications.

Insert molding always requires complex molds.False

While mold complexity can vary, efficient design and technology have made insert molding more accessible for simpler parts as well.

What is the Difference Between Insert Molding And Traditional Injection Molding?

Insert molding and traditional injection molding are both widely used in manufacturing, but they differ in the way components are integrated into plastic parts.

Insert molding involves placing metal or other materials into a mold before injecting plastic, while traditional injection molding simply injects plastic into a mold. Insert molding allows for complex part assemblies in one step, reducing costs and production time.

Process Flow

Insert Molding:

- Insert the preformed insert into the mold and then make sure that it is firmly attached.

- When the mold is prepared, injection molten plastic material into the mold and allow the material to solidify while enclosing the insert and creating the part.

- Cool and demold6 to remove the finished part.

Traditional Injection Molding:

- Inject molten plastic material into the mold, filling the cavity.

- Plastic cools and solidifies to make the part.

- Cool down and demould to get the finished part.

Application Range

- Insert Molding: Primarily used for making high tensile, tough and multipurpose structural parts, hardware, auto mobile appliances, electronic goods, and health products.

- Conventional Injection Molding: Used majorly in production of different plastics goods, including packing material, home appliances and other durable and non-durable consumer goods.

Advantages

Insert Molding:

-

Strengthens the parts and longevity.

-

Makes it possible to have multifunction integration which has some effect in decreasing the number of assembly steps.

-

Offers more design flexibility.

Traditional Injection Molding:

-

Mature process with a wide range of applications.

-

High levels of production, suitable for mass production.

-

Relatively lower cost.

Challenges

Insert Molding:

-

Problems in clamping and locating inserts.

-

Neccessity of a high bond strength between the insert and the plastic.

-

More work piece complexity and corresponding higher amount of Introduction of materials and more closeness and higher precision of work piece edges.

Traditional Injection Molding:

-

Limited part strength and durability.

-

Requires subsequent assembly steps, increasing production costs.

-

Relatively lower design flexibility.

Insert molding is ideal for creating multi-material parts.True

Insert molding allows the integration of metal or other components directly into the plastic during the molding process, making it suitable for multi-material applications.

Insert molding is always more cost-effective than traditional injection molding.False

While insert molding can save costs on assembly, the initial setup and tooling for insert molding can be more expensive than traditional injection molding depending on the complexity of the design.

What are the Industry Standards And Specifications for Insert Molding?

Insert molding integrates metal or other materials into plastic parts, offering high durability and design flexibility. It’s essential for applications where strength and complexity are needed.

Industry standards for insert molding emphasize precise control of temperature, pressure, and material compatibility. Specifications include mold design, tolerance limits, and insertion processes. Key benefits include stronger parts and reduced assembly costs.

ISO 9001

Quality management system standard. It is an operational tool that aims at improving the quality management process for insert molding.

ISO 14001

EMAS the environmental management system standard to facilitate the achievement and maintenance of environmental protection throughout the production process.

ISO 13485

Standard for medical device, useful for the insert molding enterprises who provide medical devices.

IATF 16949

An automobile industry quality management system standard related to insert molding enterprises in the manufacturing of automobile parts.

These standards include quality, environmental, health and safety management standards which assist the enterprises towards attaining efficient safe and sustainable production in the insert molding process.

Insert molding integrates materials for stronger parts.True

Insert molding ensures durability by embedding metal or other inserts, enhancing the strength and longevity of the final product.

Insert molding is only suitable for simple parts.False

Insert molding is versatile and can accommodate complex part designs with intricate inserts, making it suitable for a variety of applications.

Conclusion

As a kind of advanced manufacturing process, insert injection molding process has many advantages and wide application prospect. Through choosing the right insert materials, achieving the best design of mold, besides, controlling the injection parameters correctly it is possible to produce the high-quality and high-performance multi-lobe components.

As the technological world continues to get advanced and the market needs get-more specialized, the insert molding will be used in even more sectors putting the manufacturing industry in more efficient, intelligent, and sustainable pedestal. To enterprises, understanding and applying of this technology will give more chances andpower in the competition of market share.

-

Learn about What are the Steps of the Injection Molding Process? Injection molding is a process used to make a lot of plastic parts. ↩

-

Learn about Injection Molding : The Causes of Warpage : Identifying warpage is one of the easiest aspects of injection molding. ↩

-

Learn about Injection moulding – how to avoid plastic shrinkage : Plastic shrinkage is an unfortunate consequence of the injection moulding process. ↩

-

Learn about What you need to know about injection molding with metal inserts? Injection molding with metal inserts is a process that has become increasingly popular in recent years. ↩

-

Learn about Injection Molding Parameters : Injection molding parameters are the critical factors that influence the quality and efficiency of the molding process. ↩

-

Learn about Demolding in Injection Molding: Techniques and Best Practices : Demolding of plastic parts is the last step in the injection molding process. ↩