Injection molding plays a pivotal role in the New Energy Vehicle (NEV) industry, offering innovative solutions for lightweight, high-performance parts. This technology is integral to improving vehicle efficiency and sustainability.

Injection molding in NEVs reduces weight, enhances energy efficiency, and supports eco-friendly materials. It’s used in battery housings, connectors, and lightweight structural components, offering faster production with high precision.

As NEVs continue to evolve, injection molding’s role in delivering cost-effective, high-quality parts will become increasingly significant. Learn how these innovations drive industry growth and improve manufacturing processes.

Injection molding enhances part precision in NEVs.True

Injection molding allows for high precision and complex shapes, which are essential for producing reliable, lightweight components for NEVs.

Injection molding is too costly for use in New Energy Vehicles.False

While initial costs for injection molding can be high, its efficiency, rapid production rates, and reduced waste make it a cost-effective solution in the long run for NEV manufacturers.

What is the Core Driver of New Energy Vehicle Efficiency?

New energy vehicle efficiency hinges on advancements in battery technology, lightweight materials, and improved aerodynamics, collectively enhancing the performance and sustainability of these vehicles.

Advancements in battery technology, notably lithium-ion and solid-state batteries, are crucial for enhancing new energy vehicle efficiency by improving range, charge speed, and energy consumption.

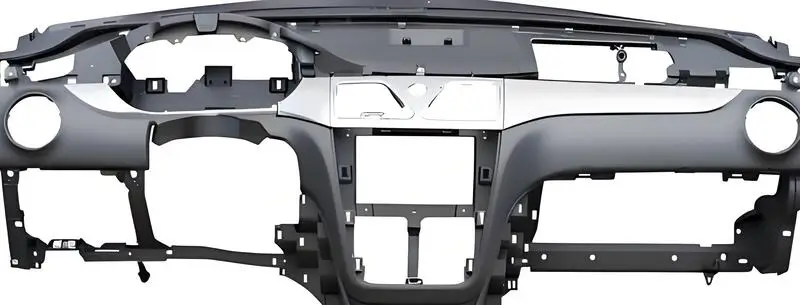

Reducing vehicle weight is paramount for improving energy efficiency and extending battery range in NEVs. Injection molding1 enables the replacement of metal parts with high-performance thermoplastics and composites, achieving weight reductions of 30–70% while maintaining structural integrity.

Key Materials and Applications

-

PEEK (Polyether Ether Ketone) and PPS (Polyphenylene Sulfide): These high-temperature-resistant polymers are widely used in motor housings, battery insulators, and sealing rings. PEEK gears, for instance, reduce weight by 70% compared to metal counterparts while offering self-lubricating properties and noise reduction.

-

Long Glass Fiber-Reinforced Thermoplastics (LFT)2: LFT composites, such as PP-GF and PA-GF, enhance structural strength in battery housings and chassis components. Direct long-fiber injection technologies (e.g., Arburg’s FDC) eliminate pre-compounding steps, reducing energy consumption by 30%.

-

Microcellular Foaming (MuCell®): By injecting nitrogen or CO2 into molten plastic, this technique creates microporous structures, cutting part weight by 10–20% without compromising performance.

Advanced battery technology is the primary factor in new energy vehicle efficiency.True

Batteries are central to energy storage and management, directly impacting vehicle range and energy usage.

Aerodynamics have no effect on new energy vehicle efficiency.False

Aerodynamics significantly affect energy consumption and range by reducing air resistance, which can improve vehicle efficiency.

How Can New Energy Vehicles Achieve Embedded Component Integration Through Insert Molding?

Insert molding integrates components directly into the structure of new energy vehicles, leading to enhanced performance and streamlined manufacturing processes.

Insert molding integrates components into vehicle structures during molding, enhancing efficiency and lowering assembly costs in new energy vehicles.

Applications in NEV Systems

-

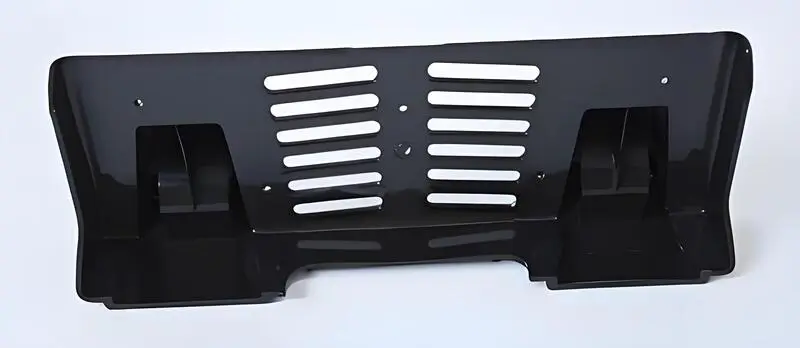

Battery Management Systems (BMS)3: Copper busbars and connectors are encapsulated with insulating plastics (e.g., PBT or PPS) to prevent short circuits in high-voltage environments. This integration also improves crash resistance and space utilization.

-

Power Electronics: Motor controllers and DC/DC converters rely on insert-molded parts4 for secure electrical connections and thermal management. For example, ARBURG’s vertical injection molding machines automate the placement of metal inserts, reducing production cycles by 25%.

-

Interior Components: Touch-sensitive panels and HVAC systems increasingly use insert-molded electronics, such as Kurz’s In-Mold Electronics (IME) technology, which embeds circuits directly into trim parts, saving 30% in weight and cost.

Insert molding reduces assembly costs in new energy vehicles.True

By embedding components during the molding process, insert molding minimizes the need for additional assembly, reducing overall costs.

All components of new energy vehicles can be integrated using insert molding.False

Not all components are suitable for insert molding; factors such as material compatibility and component size need consideration.

What is the Sustainability And Circular Economy of New Energy Vehicles?

The sustainability and circular economy of new energy vehicles focus on reducing environmental impact and promoting resource efficiency throughout the vehicle’s lifecycle.

New energy vehicles promote sustainability by using renewable resources, reducing emissions, and supporting resource recycling. They employ eco-friendly materials and designs, aiding the circular economy and decreasing waste and energy consumption.

Recycled Material Adoption

-

EU regulations now require 25% recycled content in automotive plastics by 2026. Advanced systems like ENGEL’s RecyclatePilot compensate for variability in post-consumer recycled (PCR) plastics, ensuring consistent quality during molding.

-

Bio-based Polymers5: Materials like PLA (polylactic acid) and PA 610 (derived from castor oil) are gaining traction for interior trims and non-structural parts, reducing reliance on fossil fuels.

Energy-Efficient Processes

-

Digital Twin Platforms: Sumitomo Demag’s myAssist software optimizes energy use by analyzing real-time data from injection molding machines, cutting carbon footprints by up to 15%.

-

Closed-Loop Recycling: Companies like Trinseo and SABIC are developing chemical recycling methods to convert end-of-life automotive plastics back into virgin-grade resins.

New energy vehicles reduce carbon emissions compared to traditional vehicles.True

Their reliance on renewable energy and improved efficiency contribute to lower carbon emissions throughout their use phase.

New energy vehicles are entirely sustainable.False

While they offer numerous environmental benefits, challenges still exist in battery production and end-of-life management, which must be addressed for full sustainability.

What are the Advanced Molding Technologies for New Energy Vehicle Components?

Advanced molding technologies are pivotal in producing high-quality components for new energy vehicles, enhancing performance and efficiency in the evolving automotive sector.

Advanced molding technologies enhance new energy vehicle components by increasing durability, reducing weight, and allowing complex designs, which are crucial for efficient and sustainable vehicle performance.

-

CoinSure™ Compression Molding: Tederic’s technology combines injection and compression molding to produce ultra-smooth optical parts like headlamp lenses, reducing cycle times by 30%.

-

Hybrid Molding: Combining thermoplastics with silicone or TPU (thermoplastic polyurethane) enables flexible seals for battery packs and waterproof connectors.

Smart Manufacturing Integration

-

AI-Driven Quality Control6: Systems like KraussMaffei’s APC Plus monitor melt viscosity and adjust parameters in real time, critical for processing recycled materials.

-

Industry 4.0: IoT-enabled molds and predictive maintenance reduce downtime, while platforms like Wittmann Battenfeld’s IMAGOxt track energy consumption across production lines.

Advanced molding technologies enhance the durability of new energy vehicle components.True

These technologies allow for precise manufacturing, leading to stronger, more resilient components that withstand environmental and operational stresses.

3D printing is unsuitable for producing new energy vehicle components.False

3D printing allows for complex designs and rapid prototyping, making it suitable for producing innovative and custom components for new energy vehicles.

Conclusion

Injection molding is at the heart of the NEV revolution, enabling lighter, safer, and more sustainable vehicles. From insert-molded battery systems to AI-optimized production lines, this technology continues to break barriers in design and efficiency.

As automakers race to meet net-zero targets, collaboration between material scientists, molders, and OEMs will be key to unlocking the next generation of automotive innovation.

For manufacturers, investing in advanced molding technologies and recyclable materials isn’t just a competitive edge—it’s a necessity for thriving in the electrified future.

-

Explore how injection molding enhances vehicle design and efficiency, crucial for the NEV industry. ↩

-

Learn about LFT’s role in enhancing structural strength and reducing weight in NEVs. ↩

-

Discover the importance of BMS in ensuring safety and efficiency in NEVs. ↩

-

Explore this link to understand how insert-molded parts enhance efficiency and reliability in electronic applications. ↩

-

Discover the advantages of bio-based polymers in reducing environmental impact and enhancing sustainability in automotive manufacturing. ↩

-

Learn how AI-driven quality control can optimize production efficiency and quality in injection molding, crucial for modern manufacturing. ↩