Introduction: An injection molding machine, also known as an injection machine or molding machine, is the primary piece of equipment used to create plastic products of various shapes from thermoplastics or thermosetting plastics. It’s the most important piece of equipment in the plastic injection molding process.

Injection molding machines are used all over the place to make plastic parts, from medical equipment to all kinds of tools, from the aerospace industry to the car industry, and even to everyday stuff and kids’ toys.

Lots of the parts, or even the whole thing, are made by plastic injection molding. Just look around, and if you see something plastic, it was probably made by an injection molding machine.

In the operation of the injection molding machine, the injection unit is responsible for injecting the molten plastic into the plastic injection molds in each injection molding cycle, thereby completing the production process of plastic products . This article is all about how injection molding machines work.

What is the Working Principle of an Injection Molding Machine?

Injection molding machines have two main functions: heating plastic pellets to make it melt and applying high pressure to molten plastic to make it eject and fill the mold cavity. Here’s how it works:

Using the thermophysical properties of plastics, the material is added from the hopper to the barrel. The barrel is heated by a heating ring to melt the material. A screw driven to rotate by an external power motor is installed in the barrel. Under the action of the screw, the material is transported forward and compacted along the screw groove.

The material is gradually plasticized, melted, and homogenized by the dual effects of external heating and screw shearing. When the screw rotates, the material is pushed to the screw head by the friction and shear force of the screw groove after being melted.

At the same time, the screw retreats under the reaction of the material, so that the screw head forms a material storage space and completes the plasticization process.

Then, the screw injects the molten material in the storage chamber into the mold cavity through the nozzle at high speed and high pressure. After the molten material in the cavity is pressure maintained, cooled, solidified and shaped, the mold is opened, and the shaped product is ejected from the mold.

Plastic Melting

First, you put plastic particles or powder into the hopper of the injection molding machine. Then, you send the plastic material into the heating cylinder through the screw drive. There is a heater in the heating cylinder. The heater heats the plastic to the melting temperature. The screw rotates and pushes the melted plastic into the injection cylinder.

Injection

The injection cylinder has a piston. When the screw pushes the molten plastic into the injection cylinder, the piston moves forward and pushes the plastic into the mold.

During the injection process, the injection molding machine controls the injection speed, pressure, time, and other parameters through the control system to ensure the quality and accuracy of the plastic injected into the mold.

Cooling

When the plastic is injected into the mold, it will be cooled by cooling water. The cooling water flows through the cooling channel in the mold, taking away the heat and causing the plastic to cool and solidify quickly. The cooling time is adjusted according to factors such as the type and thickness of the plastic to ensure the quality of the plastic product.

Opening the Mold

Once the plastic has cooled and hardened, the injection molding machine uses its control system to open the mold and remove the finished plastic part. The machine uses mechanical, hydraulic, or pneumatic methods to open the mold, depending on the size and structure of the mold.

What are the Components of the Injection Molding Machine?

The injection molding machine is usually made up of an injection system, a mold clamping system, a hydraulic transmission system, an electrical control system, a lubrication system, a heating and cooling system, a safety monitoring system, and so on.

Injection System

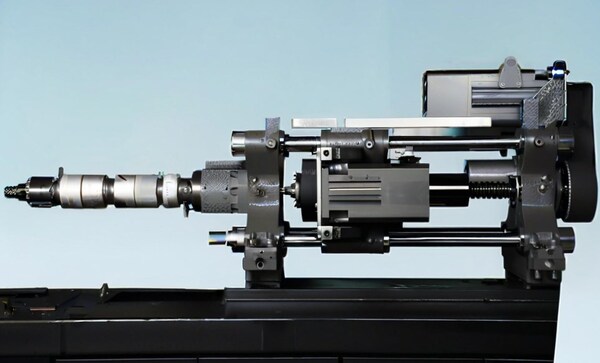

The injection system is one of the main components of the injection molding machine. There are generally three main forms: plunger type, screw type, and screw pre-plastic plunger injection type. The screw type is currently widely used.

Its function is that in one cycle of the injection molding machine, a certain amount of plastic can be heated and plasticized within a specified time, and then the molten plastic is injected into the mold cavity through the screw at a certain pressure and speed. After the injection is completed, the molten material injected into the mold cavity is kept in shape.

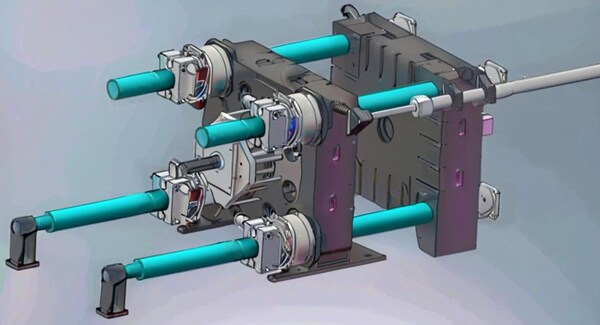

Mold Clamping System

The mold clamping system is responsible for closing, opening, and ejecting the mold. It also provides enough force to keep the mold closed and resist the pressure from the molten plastic entering the mold cavity. This prevents the mold from opening and ensures that the product turns out well.

The mold clamping system is made up of a mold clamping device, a mold adjustment mechanism, an ejection mechanism, front and rear fixed templates, a mobile template, a mold clamping cylinder, and a safety protection mechanism.

Hydraulic System

The hydraulic transmission system is there to give power for all the different things the injection molding machine needs to do, and to make sure that all the different parts of the injection molding machine have the right amount of pressure, speed, temperature, and everything else they need.

It is mainly made up of various hydraulic components and hydraulic auxiliary components, among which the oil pump and the motor are the power source of the injection molding machine. Various valves control the oil pressure and flow rate to meet the various requirements of the injection molding process.

Electrical Control System

The electrical control system and the hydraulic system work together to meet the needs of the injection molding machine, like pressure, temperature, speed, time, and different program actions.

It is mainly made up of electrical appliances, electronic components, instruments, heaters, sensors, etc. There are generally four control methods, manual, semi-automatic, fully automatic, and adjustment.

Heating/Cooling System

The heating system is used to heat the barrel and the injection nozzle. The barrel of the injection molding machine generally uses an electric heating coil as a heating device, which is installed on the outside of the barrel and is detected in sections with a thermocouple. Heat is conducted through the barrel wall to provide a heat source for material plasticization;

The cooling system is mainly used to cool the oil temperature.

If the oil temperature is too high, it will cause various faults, so the oil temperature must be controlled. Another place that needs cooling is near the discharge port of the material pipe to prevent the raw material from melting at the discharge port, resulting in the failure of the raw material to be discharged normally.

Lubrication System

The lubrication system is a circuit that provides lubrication conditions for the relative motion parts of the dynamic plate, mold adjustment device, connecting rod hinge, etc. of the injection molding machine, so as to reduce energy consumption and increase the life of parts. Lubrication can be regular manual lubrication or automatic electric lubrication.

Safety Protection And Monitoring System

The safety device of the injection molding machine is mainly used to protect the safety of people and machines. It is mainly composed of safety doors, hydraulic valves, limit switches, photoelectric detection elements, etc., to achieve electrical-mechanical-hydraulic interlocking protection.

The monitoring system mainly monitors the oil temperature, material temperature, system overload, and process and equipment failures of the injection molding machine, and indicates or alarms when abnormal conditions are found.

What are the Categories of Injection Molding Machines?

Horizontal Injection Molding Machine

A horizontal injection molding machine is a commonly used type. It has the advantage of having the center line of the injection assembly concentric or consistent with the center line of the clamping assembly and parallel to the installation ground.

It has the advantages of low center of gravity, stable operation, convenient mold installation, operation and maintenance, large mold opening, and small space height; but it occupies a large area, and is widely used in large, medium and small machines.

Vertical Injection Molding Machine

The characteristic of this machine is that the clamping device and the injection device are arranged in a straight line and perpendicular to the ground.

It has the advantages of small floor space, easy mold assembly and disassembly, easy installation of inserts, relatively uniform plasticization of materials falling from the hopper, easy automation, and easy automatic line management of multiple machines.

But it’s not easy for the product to fall out automatically after being ejected, and it must be removed by hand, which is not easy to achieve automatic operation.

The vertical injection molding machine sealing machine is suitable for small injection molding machines, generally more for injection molding machines below 60 tons (60 tons refers to the clamping force), and not suitable for large and medium-sized machines.

Angle Injection Molding Machine

The injection direction and mold interface are on the same plane. It is particularly suitable for flat products where gate marks are not allowed in the machining center. It occupies a smaller area than a horizontal injection molding machine, but the inserts placed in the mold are prone to tilt and fall. In addition, injection molding machines also include screw injection molding machine .

Multi-Mode Turntable Injection Molding Machine

It is a special injection molding machine with multi-station operation. Its characteristic is that the manual packing machine mold clamping device adopts a turntable structure, and the mold rotates around the rotating shaft.

This type of injection molding machine fully utilizes the plasticizing ability of the injection device, which can shorten the production cycle and improve the production capacity of the machine.

So, it is especially good for making a lot of stuff that takes a long time to cool and shape or needs more time for the extra stuff you put in it. But because the mold is big and has a lot of parts, the thing that holds it together isn’t very strong, so this kind of machine is used a lot for making things like plastic shoe bottoms.

What is the Operation Method of the Injection Molding Machine?

The Action Program of the Injection Molding Machine

Nozzle forward → injection → pressure holding → pre-plasticization → retraction → nozzle retreat → cooling → mold opening → ejection → needle withdrawal → door opening → door closing → mold clamping → nozzle forward.

Injection Molding Machine Operation Items

There are several things to pay attention to when operating an injection molding machine, including operating the control panel, operating the electrical control cabinet, and operating the hydraulic system.

The injection process action, feeding action, injection pressure, injection speed, ejection type selection, barrel temperature and current, voltage monitoring, injection pressure and back pressure adjustment, etc.

Control of Injection Molding Process Conditions

Currently, many injection molding machine manufacturers have developed various program control methods, which are roughly: injection speed control, injection pressure control, injection cavity plastic filling control, screw back pressure and speed control, and other plasticizing state control.

The purpose of achieving process control is to improve product quality and maximize machine efficiency.

Preparation Before Injection Molding

Before molding, there is a lot of stuff to do. For example: check the processing performance of the material (check the plasticity, moisture content, etc.); dyeing and particle selection before processing the raw material; preheating and drying the particles; cleaning and preheating the inserts; cleaning the trial mold and barrel, etc.

What is the Injection Molding Machine Work Process ?

The injection molding machine is one of the main equipment for injection molding. The main function of the injection molding machine is to melt various forms of plastics evenly, and inject the molten material into the mold cavity with sufficient pressure and speed to cool and shape it. So what is the working process of the injection molding machine?

Heating, Pre-Plasticization

The screw is driven by the traditional system to transport the barrel material forward. Due to the shearing and friction of the screw and the machine cylinder, the material gradually melts. A certain amount of molten plastic has accumulated at the head of the barrel.

Under the pressure of the melt, the screw slowly backs out. The distance the screw backs out is adjusted by the metering device according to the amount needed for one shot. When the predetermined shot size is reached, the screw stops turning and backing out.

Mold Closing And Locking

The clamping mechanism pushes the movable mold plate and the movable mold part installed on the movable mold plate to close and lock the fixed mold part on the fixed mold plate to ensure that enough clamping force is provided to lock the mold during molding.

Injection Device Moves Forward

When the mold is closed, the whole injection seat is pushed and moved forward so that the injection machine nozzle fits the main runner of the injection mold completely.

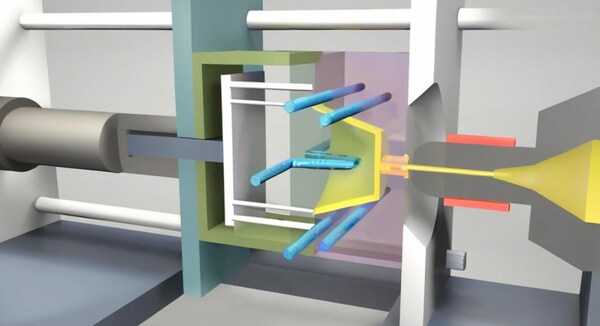

Injection And Pressure Holding

Once the nozzle of the injection machine is properly aligned with the gate of the mold, the injection hydraulic cylinder is activated, pushing the screw forward in relation to the barrel. This action forces the molten plastic, which has accumulated at the front of the barrel, into the mold cavity with enough pressure.

As the temperature of the plastic drops, it shrinks. To ensure that the plastic parts are dense, dimensionally accurate, and have the desired mechanical properties, it is necessary to maintain a certain pressure on the molten plastic in the mold cavity to compensate for the shrinkage of the plastic parts.

Pressure Relief

When the melt freezes at the gate, the pressure can be relieved.

Injection Device Retreats

After the pressure relief is done, the screw can rotate and pull back to do the next feeding and pre-plasticization. After the pre-plasticization is done, the injection device pulls back from the main runner of the mold.

Mold Opening And Ejection of Plastic Parts

Once the plastic parts in the mold cavity have cooled and taken shape, the clamping mechanism opens the mold and ejects the plastic parts from the mold.

What are the Uses of Injection Molding Machines?

Injection molding machines can make a lot of stuff. They can make plastic products with complex shapes, sizes or dense textures with metal inserts in one go. They are widely used in defense, electromechanics, automobiles, transportation, building materials, packaging, agriculture, culture, education, health and people’s daily life.

As a result, they have become one of the fastest growing and most produced plastic machinery. There are too many products that injection molding machines can make, for example:

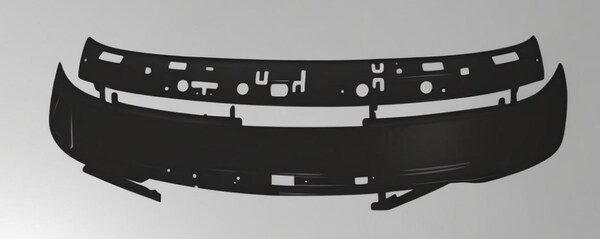

Automobile Manufacturing Industry

Injection molding machines are a big deal in the car-making biz. They’re used to make all sorts of car parts, like headlights, bumpers, door handles, dashboards, tires, steering wheels, and so on.

With the rapid development of the automobile industry, the application scope of injection molding machines has become more and more extensive, and the advancement of injection molding technology has also improved the quality and performance of auto parts.

Medical Industry

Medical products like medical syringes, instruments, blood analysis systems, etc., are also made using injection molding machines in the medical industry.

These products need to have high purity, corrosion resistance, high pressure resistance, non-toxicity, no odor and other characteristics, and injection molding machines can meet these strict requirements.

Electronics Industry

Injection molding machines are also very important in the electronics industry. They are used to produce the shells and internal plastic accessories of electronic products such as laptops, mobile phones, LCD screens, televisions, digital cameras, MP3s, etc., as well as keyboards, buttons, etc.

In the electronics industry, compactness and high-precision production technology are essential, and injection molding machines can provide such production technology.

Home Appliance Industry

In the home appliance industry, plastic injection molding machine are widely used to produce the shells and accessories of various home appliances such as washing machines, air conditioners, televisions, refrigerators, etc.

Using injection molding machines not only makes production faster, but also makes sure the products look good and are good quality.

What are the Advantages of Injection Molding Machines?

Efficient Production

Plastic injection molding machines utilize advanced control technology to achieve efficient production lines, thereby enhancing production efficiency. It automatically completes the entire production process according to the preset program, can achieve continuous production, mass production, and shorten the production cycle.

High Product Quality

The products made by electric injection molding machines are of the same size and weight, and the surface is smooth and flawless. By controlling the injection molding process accurately, the accuracy and consistency of the product can be guaranteed.

High Degree of Automation

Injection molding machines can perform a bunch of stuff like automatic feeding, automatic transportation, and automatic filling during the production process, which means you don’t need as many people and you can make more stuff.

Wide Range of Uses

Injection molding machines produce a wide range of products, which can be widely used in many fields such as automobiles, electronics, medical treatment, machinery, packaging, etc., and can meet the needs of different industries.

Conclusion

Injection molding machines are the main equipment for manufacturing plastic products. They complete the whole process from melting raw materials to shaping finished products through precise operation procedures. The work of injection molding machines includes heating, injection, cooling, and mold opening of plastics.

Each step is finely controlled by the injection system, mold clamping system, hydraulic system, etc. to ensure production efficiency and product quality. Injection molding machines are widely used in many industries such as automobiles, medical treatment, electronics, and home appliances.

Their high efficiency and automation make them play an important role in modern industry. In general, injection molding machines not only promote the development of plastic manufacturing technology, but also demonstrate their irreplaceable importance in meeting the needs of various industries for the quality and production efficiency of plastic products.