Choosing the right tonnage for your injection molding machine is crucial for optimizing production efficiency, cost, and part quality. The right choice can save time and material, improving your project’s outcome.

Select injection molding machine tonnage based on part size, material, and molding complexity. A machine with too much tonnage can cause excessive wear, while insufficient tonnage can lead to defects.

Understanding how tonnage affects your injection molding process is key. Explore how choosing the right machine size based on project specifics can enhance performance and minimize issues.

Higher tonnage always ensures better part quality.False

Too much tonnage can lead to overcompensation, increasing wear and defects. The correct tonnage balances pressure and part precision.

Choosing the right tonnage reduces material waste.True

Appropriately matched tonnage optimizes injection pressure, reducing material wastage and ensuring better part consistency.

What is the Basic Concept of Injection Molding Machine Tonnage?

Injection molding machine tonnage refers to the clamping force required to hold the mold closed during injection. It’s a critical factor for ensuring the quality and precision of molded parts.

Injection molding machine tonnage is measured in tons and determines the force needed to close the mold. Sufficient tonnage prevents mold damage and ensures accurate, high-quality parts during the injection process.

Clamping Force Calculation

F=A P

where F is the clamping force, A is the projected area of the mold cavity, and P is the pressure of the plastic melt in the cavity.

The clamping force of an injection molding machine, also known as the tonnage, is essentially the maximum pressure that the injection molding machine can apply to keep the mold closed while the part is being molded. The clamping force is usually measured in tons (T).

In short, this force ensures that the mold remains closed throughout the injection cycle, which can prevent the plastic melt from leaking from the parting line of the mold.

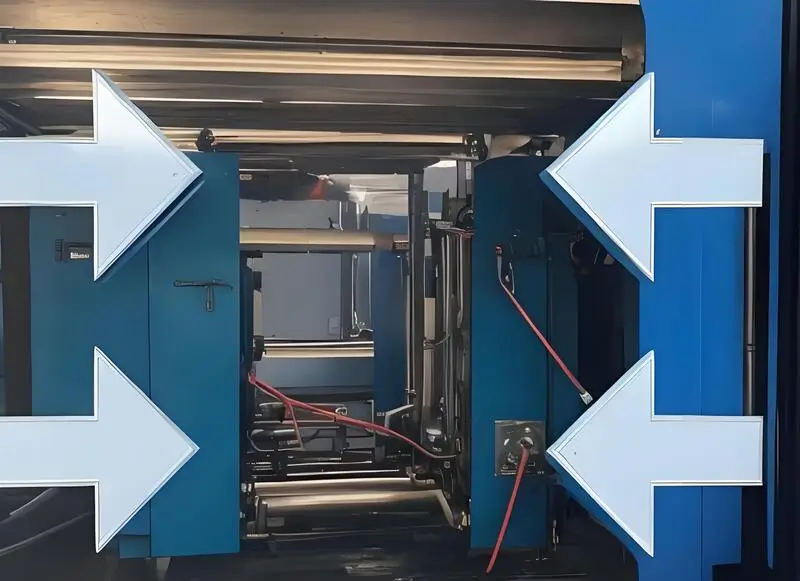

Main Components of an Injection Molding Machine

To understand why injection molding machine tonnage1 is important, you need to know the main components of an injection molding machine:

-

Injection Unit: This includes the screw, barrel, nozzle, etc. that melt and inject plastic pellets into the mold cavity.

-

Clamping Unit: This includes the moving platen, stationary platen, clamping mechanism, etc. that provide the clamping force and keep the mold closed.

-

Control System: This includes the computers, sensors, control panels, etc. that control various parameters of the injection and clamping process.

-

Drive System: This includes the hydraulic or electric drive systems that provide the power needed for injection and clamping.

Working Principle of Clamping Force

The clamping force is applied by the clamping device of the injection molding machine. When the mold is closed, the clamping mechanism of the machine presses the moving and fixed platens of the mold tightly together so that they can resist the pressure of the plastic melt in the cavity during injection molding.

The clamping force2 needs to be strong enough to prevent the molten plastic from leaking out from the parting line of the mold, but it should not be too large to avoid unnecessary damage to the mold and equipment.

Higher machine tonnage always produces better parts.False

The ideal tonnage depends on part design and material. Too much tonnage can lead to excessive pressure, causing defects.

Machine tonnage affects molding accuracy and cycle time.True

Proper tonnage ensures accurate part formation and reduces defects, while improper tonnage can lead to longer cycle times and lower quality.

What is the Importance of Choosing the Right Injection Molding Machine Tonnage?

Selecting the right tonnage for your injection molding machine is crucial for maximizing efficiency, product quality, and minimizing defects during production.

Choosing the right tonnage ensures the proper clamp force to prevent defects like short shots or flash. It balances the mold cavity’s pressure requirements, reducing energy consumption and improving cycle times.

Impact on Product Quality

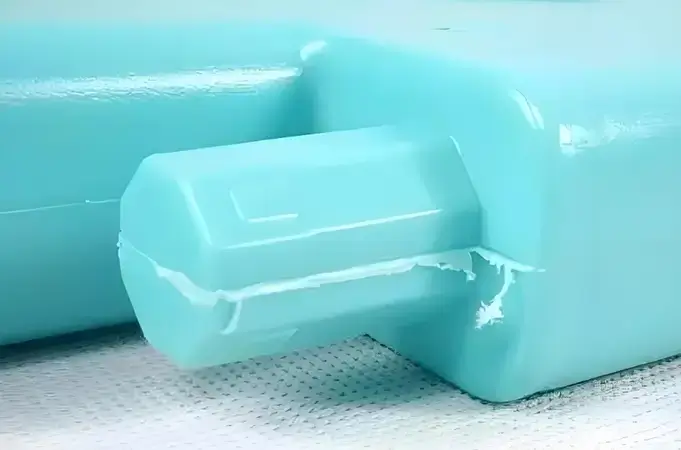

The clamping force directly affects the quality of the product. If the clamping force is insufficient, the mold cannot be completely closed during the injection molding process, and the plastic melt will leak out from between the molds.

This will cause defects such as burrs and flash on the surface of the product, affecting the surface finish and function of the product. For high-precision products, insufficient clamping force is even more serious, because insufficient clamping force will cause dimensional deviations and affect the performance of the product.

Impact on Production Efficiency

Appropriate tonnage (clamping force) ensures the stability and continuity of the production process. If the clamping force is insufficient or incorrect, the following may occur: the mold cannot be closed normally, resulting in production interruptions and affecting production efficiency, which will affect production efficiency.

On the contrary, excessive clamping force will increase the wear of the mold and the injection molding machine, shorten their service life and increase maintenance and replacement costs.

Impact on Cost Control

Correctly selecting the tonnage of the injection molding machine is important for controlling production costs. Selecting a machine with too high a tonnage will increase equipment procurement and energy costs, increasing total expenditures.

On the contrary, if the tonnage of the selected machine is too low, it may not meet production requirements, which will further increase equipment expenditures as well as investment costs. Therefore, a reasonable selection of the tonnage of the injection molding machine can maximize the use of resources and reduce production costs.

Impact on Production Safety

Excessive clamping force will cause unnecessary wear of the mold and injection molding machine, increase the chance of equipment failure and damage, and affect production safety.

In addition, excessive clamping force may pose a threat to the safety of operators and machines. Therefore, choosing the right injection molding machine tonnage can not only improve production efficiency and product quality, but also ensure the safety of the production process.

Correct machine tonnage improves product quality in injection molding.True

Appropriate tonnage ensures the mold is properly clamped, preventing defects and enhancing part quality.

A larger machine tonnage always improves production.False

Too large of a machine tonnage can lead to unnecessary energy consumption and excessive clamp force, potentially damaging the mold or causing over-compaction of the plastic material.

What are the Steps to Determine the Tonnage of an Injection Molding Machine?

Determining the right tonnage for an injection molding machine is crucial for ensuring efficient production and preventing machine damage. This process involves calculating the clamping force based on part size and material.

To determine the tonnage of an injection molding machine, calculate the clamping force needed by multiplying the surface area of the molded part by the material’s injection pressure. The formula helps ensure accurate machine selection and efficient molding.

Understanding Specific Requirements of the Product and Mold

First, you need to know the size, shape, material of the product to be produced, and its behavior during the molding process in detail. Then, based on the product design and production requirements, determine the size of the mold, the number of cavities, and the arrangement of the cavities.

-

Product Size and Shape:The size and shape of the product directly affects the way the mold is designed and the way the clamping force is calculated. For example, large-sized products usually require larger molds and higher clamping forces. In addition, products with complex shapes may require higher precision and clamping forces.

-

Material Characteristics:Different materials have different flow and pressure characteristics during the injection molding process. For example, ABS requires higher injection pressure during injection molding than PP. Some engineering plastics require higher injection pressure and appropriate screw compression ratio design to achieve better molding effects. Therefore, understanding these behaviors of each material is important if you want to figure out how much clamping force is needed.

-

Mold Design: The size of the mold, the number of cavities, and the arrangement of these cavities all directly affect the calculation of the clamping force. If the mold has multiple cavities, their arrangement also needs to be considered when calculating the clamping force, but for a single-cavity mold, this is relatively easy. In addition, the mold design needs to consider the cooling system, gate design, and other factors that may affect the calculation of the clamping force.

Calculating the Projected Area of the Mold Cavity

To calculate injection molding tonnage, you need to know the cavity projection area. Specifically, the projection area refers to the vertical projection area of the cavity on the parting line. When calculating, you need to add the projection areas of all cavities together, and the layout of multi-cavity molds needs to be considered.

-

Calculating the Projected Area for Single-Cavity Molds:For single-cavity molds, calculating the projected area is pretty simple. You just need to calculate the vertical projected area of the product on the parting line. For example, if a product is 100mm 50mm, the projected area is 100mm 50mm = 5000mm².

-

Calculating the Projected Area for Multi-Cavity Molds:For multi-cavity molds, you need to calculate the total projected area of all the cavities3. For example, if a product is 100mm 50mm and the mold design has four cavities arranged in 22, the projected area of a single cavity is 100mm 50mm = 5000mm². The total projected area of the four cavities is 5000mm² 4 = 20000mm².

Determining the Pressure of Plastic Melt in the Cavity

Different materials have different flow and pressure characteristics during injection molding. Generally, you can refer to the data provided by the material supplier or determine it based on past experience. Generally speaking, for thermoplastics, the cavity pressure is usually 20-40 MPa.

-

Pressure Characteristics of Common Materials:Here are the cavity pressure ranges for several common plastic materials4:

-

ABS: 30-40MPa

-

PP: 20-30MPa

-

PE: 20-25MPa

-

PVC: 25-35MPa

-

PC: 30-40MPa

-

Factors Affecting Pressure Characteristics:The pressure of the plastic melt in the cavity is influenced by several factors, including:

-

Material flowability

-

Injection speed

-

Mold temperature

-

Product thickness

Therefore, when determining the cavity pressure, these factors need to be comprehensively considered to ensure the accuracy of the calculation.

Calculating the Required Clamping Force

To determine the required clamping force5, apply the formula above F=A * P. Remember that in order to ensure the stability and safety of the production process, a safety margin of 10-20% is usually added to the calculated clamping force.

-

Example Calculation of Clamping Force:Let\’s take an example of a product with dimensions of 100mm 50mm. The material used is ABS and the cavity pressure is 30MPa. The mold design is single-cavity.First, let\’s calculate the projected area of the mold cavity. The projected area is 100mm 50mm = 5000mm².Next, let\’s calculate tonnage. The clamping force is equal to the projected area multiplied by the cavity pressure, which is 5000mm² * 30MPa = 150000N, which is approximately 15 tons. Adding a 20% safety margin, the required clamping force is about 18 tons. Therefore, choosing a 20-ton clamping force injection molding machine is more appropriate.

-

Choosing the Safety Margin:In actual production, to ensure the stability and safety of production, a certain safety margin is usually added to the calculated clamping force. Generally, the safety margin is 10-20%. The specific choice of safety margin can be determined based on the product requirements and actual production situation.

Considering Special Production Requirements

For some special products and production requirements, we also need to consider other factors. For example:

Multi-cavity molds: If we use multi-cavity molds, we need to consider the impact of cavity arrangement on clamping force.

Precision products: For products that require high precision and high quality, we may need to use a higher clamping force injection molding machine.

Large thin-walled products: Because the plastic melt flows and cools quickly, such products may require a larger clamping force during the molding process.

-

Special Requirements of Multi-Cavity Molds:The cavity arrangement in a multi-cavity mold has a significant effect on the force that needs to be applied when clamping. For example, if there are two rows and two columns (2×2), the required clamping force is different from one row and four columns (4×1). The molds of the second type (called 4×1 because there are four cavities in one row) are longer than molds with two cavities side by side, so they require relatively more pressure when closing. Therefore, when designing a multi-cavity mold, the appropriate cavity arrangement should be selected to ensure that the clamping force is evenly distributed.

-

Special Requirements of Precision Products:For precision products that require both precision and high quality, an injection molding machine with a larger clamping force should be selected to ensure that the mold is completely closed during the injection molding process. Take a company that produces electronic components as an example, its tolerances are very fine: up to ±.01mm. If it wants to reliably produce good products, it must choose an injection molding machine with a larger clamping force to ensure production stability and product quality.

-

Special Requirements of Large Thin-Walled Products:When producing large thin-walled objects by injection molding, a larger clamping force is required because the plastic melt flows and cools very quickly. For example, when producing car bumpers, the product size is large and the wall thickness is thin, so an injection molding machine with a higher clamping force is required to ensure product quality.

Tonnage affects the machine's ability to prevent part deformation.True

Correct tonnage ensures proper clamping pressure, preventing part warpage or deformation during the molding process.

Higher tonnage machines are always better.False

Choosing the correct tonnage is more important than selecting a larger machine. Overestimating tonnage can lead to increased costs and energy consumption without improving production.

What are the Case Studies?

Selecting the correct tonnage for an injection molding machine is crucial for optimizing efficiency and preventing defects. We will examine real-world cases to highlight key considerations.

Choosing the right tonnage ensures sufficient clamping force to prevent mold opening during injection. It affects product quality and cycle time. Key factors include material type, mold design, and part size.

Case 1: Small Precision Electronic Products

A company wants to make a small precision electronic product that’s 30mm 20mm 10mm, made of ABS plastic. The mold is designed with four cavities arranged in 2*2.

-

Find the projected area of the mold cavity: The projected area of each cavity is 30mm 20mm = 600mm², and the total projected area of the four cavities is 600mm² 4 = 2400mm².

-

Find the cavity pressure: According to the ABS material molding guide, the cavity pressure is about 30MPa.

-

Calculate the required clamping force: Clamping force = 2400mm² * 30MPa = 72000N, which is about 7.2 tons. Add a 20% safety margin, and the required clamping force is about 8.6 tons. So, it’s better to choose a 10-ton clamping force injection molding machine.

Case 2: Car Bumper

A company wants to make a car bumper that’s 1500mm 400mm 200mm, made of PP plastic. The mold is a single cavity.

-

Find the projected area of the mold cavity: The projected area is 1500mm * 400mm = 600000mm².

-

Find the cavity pressure: According to the PP material molding guide, the cavity pressure is about 25MPa.

-

Find the clamping force needed: Clamping force = 600000mm² * 25MPa = 15000000N, or about 1500 tons. Add a 20% safety factor, and the clamping force needed is about 1800 tons. So, a 2000-ton clamping force injection molding machine is more suitable.

Case 3: Large Thin-Walled Container

A company wants to make a big, thin-walled container that’s 200mm 200mm 200mm, out of PE plastic. The mold is a single cavity.

-

Figure out the projected area of the mold cavity: The projected area is 200mm * 200mm = 40000mm².

-

Figure out the cavity pressure: According to the PE material molding guide, the cavity pressure is about 20MPa.

-

Figure out the clamping force you need: Clamping force = 40000mm² * 20MPa = 800000N, which is about 80 tons. Add a 20% safety factor, and you need about 96 tons of clamping force. So, you should use a 100-ton clamping force injection molding machine.

Choosing the right tonnage reduces production defects in injection molding.True

Correct tonnage prevents mold opening and improves mold accuracy, resulting in fewer defects in final parts.

Larger tonnage machines always result in better product quality.False

While larger tonnage may be necessary for certain parts, it can lead to higher costs and longer cycle times for smaller parts.

What are the Common Problems And Solutions for Choosing the Tonnage of an Injection Molding Machine?

Choosing the right tonnage for your injection molding machine is essential for optimizing performance and preventing defects. Understanding key factors can lead to smoother production processes.

Choosing the right injection molding machine tonnage is crucial to avoid under or overloading. Key factors include part size, material type, and injection speed. The correct tonnage ensures high-quality parts and efficiency while preventing machine strain.

Insufficient Clamping Force

Problem: If the clamping force is not enough, the mold will not be completely closed during the injection process, which will cause flash and burrs, affecting the quality of the product.

-

Solution:Recalculate the clamping force, and consider all relevant factors in the calculation.

-

Solution: Optimize the cavity layout when designing the mold to reduce the required clamping force.

-

Solution: When selecting equipment, consider a certain safety factor to avoid insufficient clamping force.

Excessive Clamping Force

Problem: Too much clamping force can increase equipment costs and cause unnecessary wear and tear on the mold and equipment.

-

Solution: Calculate the required tonnage (clamping force) accurately to avoid excessive safety margins.

-

Solution: Choose the right injection molding machines and don\’t blindly pursue high-tonnage equipment.

-

Solution:Optimize mold design to reduce the need for high clamping force.

Clamping Force Calculation for Multi-Cavity Molds

Problem: The cavity arrangement of multi-cavity molds has a significant impact on clamping force, and it is easy to make errors in the calculation.

-

Solution: Choose the right cavity arrangement based on the actual situation to make sure the clamping force is evenly distributed.

-

Solution: Use professional software to simulate and calculate to make sure the clamping force is calculated correctly.

-

Solution: When designing multi-cavity molds, consider the impact of cavity arrangement on clamping force and optimize the design plan.

Using the correct tonnage prevents overloading the injection molding machine.True

Correct tonnage ensures that the machine operates within its capacity, preventing strain and maintaining efficiency.

Higher tonnage always results in better injection molding quality.False

Higher tonnage may be necessary for larger molds, but it doesn't always guarantee better quality. Too much tonnage can cause issues like overpacking or warping of the parts.

Conclusion

Choosing the right tonnage when using an injection molding machine6 is critical to the success of any project.

By understanding the basic concepts of injection molding machine tonnage, the importance of choosing the right tonnage, the steps to determine tonnage, real-life case analysis, and common problems and their solutions, you will be able to better guide yourself in choosing the tonnage and size injection molding machine.

By choosing the right tonnage injection molding machine in the manufacturing process, you can improve efficiency and quality control, while strictly controlling costs and ensuring the safety of the production process.

In this article, we have compiled some detailed case studies, hoping that these case studies can provide valuable references for selecting injection molding machine tonnage and help your injection molding project succeed.

-

Selecting the correct tonnage is vital for product quality, machine efficiency, and avoiding unnecessary damage to molds. ↩

-

Understanding clamping force is crucial for ensuring product quality and preventing defects in injection molding processes. ↩

-

Understanding how to calculate the total projected area is crucial for accurate mold design and ensuring the quality of the final product. ↩

-

Knowing the cavity pressure ranges for different materials helps in selecting the right material and settings for injection molding processes. ↩

-

Calculating the required clamping force accurately is essential for choosing the right injection molding machine and ensuring production stability. ↩

-

Learn about Injection Molding Machines a Comprehensive Guide: An injection molding machine is a piece of equipment that is widely used in industrial production. ↩