Introduction

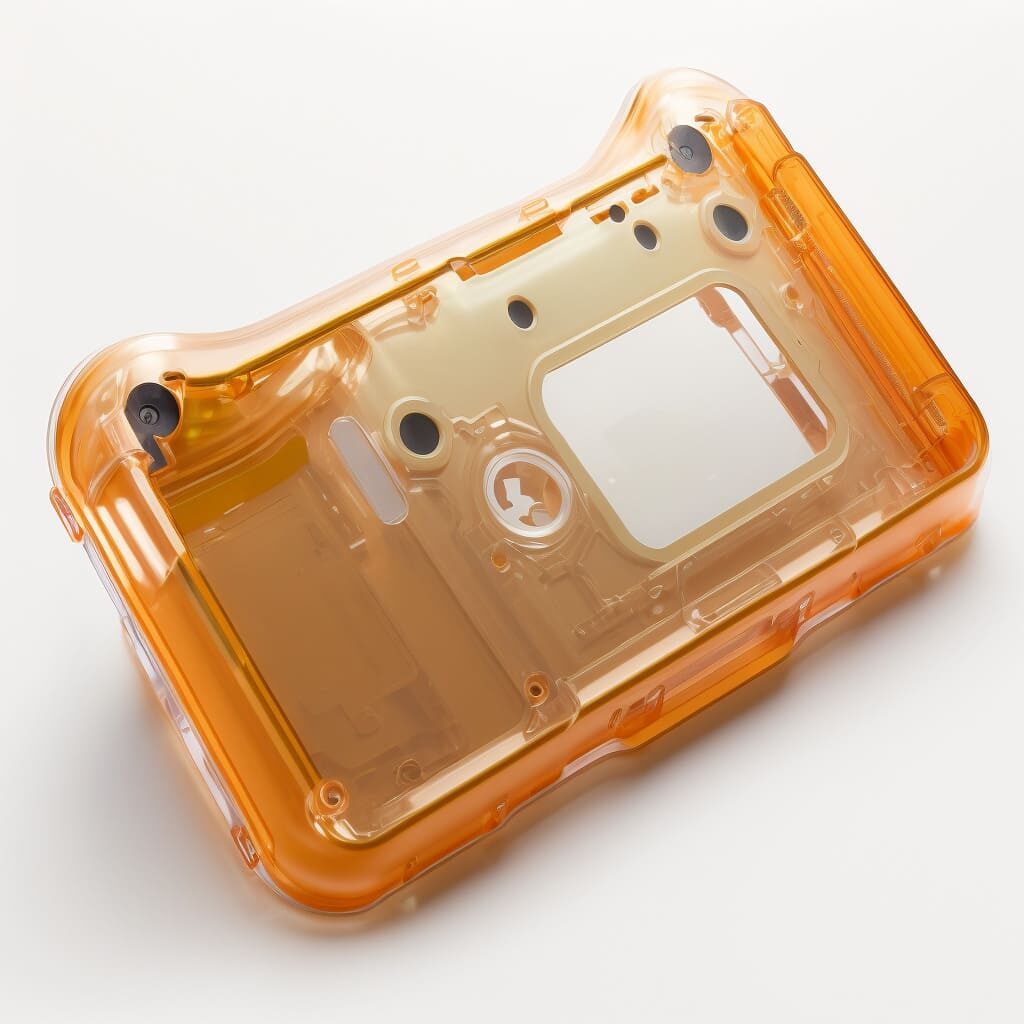

Design is a critical component of injection molding as it forms the basis of producing high-quality plastic parts. When designing for injection molding, various factors must be carefully considered for optimal results. In this article we will examine its significance as well as provide some key steps that may improve your design process.

At the design stage, key decisions about material selection, part geometry, tooling design and process parameters must be made that will ultimately have an effect on manufacturability, functionality and cost-effectiveness of your final product. By employing best practices and following an organized strategy approach during your injection molding design process you can increase its efficiency and effectiveness.

This article’s purpose is to offer valuable insights and guidance for enhancing your injection molding design process. We will outline key steps and strategies you can utilize in optimizing designs for successful injection molding – this can improve part quality, lower production costs and streamline manufacturing operations overall.

As we progress through this article, we will cover key considerations such as collaboration with injection molding project makers, designing for manufacturability, using simulation tools, material selection and optimizing tool design; conducting rigorous design iterations and testing and conducting thorough design iterations/testing cycles. By becoming acquainted with and applying these key steps you will be equipped to improve your injection molding design process and produce better results.

Stay tuned for our upcoming sections where we will investigate each step in depth, providing practical tips and insights that can help your injection molding design process.

II. Collaborating with Mold Makers

A. Early Involvement of Mold Makers in the Design Process

Collaboration with mold makers is a critical aspect of improving your injection molding design process. By involving mold makers early on in the injection molded part design stage, you can leverage their expertise and experience to enhance the manufacturability of your parts. Here are some key reasons why early involvement of mold makers is beneficial:

- Moldability Considerations: Mold makers have in-depth knowledge of the injection molding process and can provide valuable insights into the moldability of your design. They can identify potential challenges or issues that may arise during production and offer suggestions for improvement.

- Tooling Requirements: Collaborating with mold makers allows you to understand the specific tooling requirements for your design. They can advise on the optimal mold configuration, gating options, and ejection system design to ensure smooth production.

- Design Improvements: Mold makers often have a wealth of experience working with various designs and materials. Their input can help you identify opportunities for design improvements, such as optimizing nominal wall thickness , adding draft angles, or eliminating undercuts, to facilitate easier demolding and reduce production costs.

B. Leveraging Their Expertise for Moldability Considerations and Design Improvements

Mold makers possess specialized knowledge and expertise that can significantly contribute to the success of your injection molding design process. Here’s how you can leverage their expertise:

- Collaborative Design Reviews: Conduct design reviews with mold makers to evaluate the manufacturability of your design. They can provide valuable feedback on features that may pose challenges during the molding process and suggest modifications to improve moldability.

- Design for Tooling: Mold makers understand the intricacies of tool design and construction. By involving them early in the design process, you can ensure that your design aligns with the capabilities and limitations of the chosen mold. This collaboration helps avoid potential rework or delays down the line.

- Iterative Feedback: Foster an open line of communication with mold makers throughout the design process. Regularly seek their input and incorporate their feedback into design iterations. This iterative approach allows for continuous improvement, leading to better moldability and overall product quality.

Remember, collaboration with mold makers should be an ongoing process. By actively involving them from the initial stages of design, you can tap into their expertise, optimize your injection molding process, and ultimately achieve better results.

III. Designing for Manufacturability

A. Considering Factors such as Wall Thickness, Parting Lines, and Draft Angles

When designing for injection molding, it is essential to consider several factors that influence manufacturability. By addressing these factors during the design phase, you can optimize your designs for efficient production and minimize potential defects. Here are key considerations to keep in mind:

- Wall Thickness: Optimal wall thickness is crucial for successful injection molding. Design parts with uniform wall thickness to promote consistent filling and cooling during the molding process. Avoid significant variations in wall thickness, as this can lead to issues like sink marks, warping, or uneven shrinkage.

- Parting Lines: Parting lines are the separation points between mold halves. Carefully plan the location of parting lines to ensure they align with the intended functionality and aesthetics of the final product. Avoid placing parting lines in critical areas that may affect part performance or create visible parting line marks.

- Draft Angles: Incorporating draft angles into your design allows for easy part ejection from the mold cavity. Draft angles are slight tapers applied to vertical walls or features. They help avoid surface imperfections, reduce friction during ejection, and prevent damage to the mold. Generally, a draft angle of 1 to 2 degrees is recommended as a starting point.

B. Optimizing Designs to Minimize Defects and Ensure Ease of Manufacturing and Assembly

Design optimization is essential to minimize defects and ensure smooth manufacturing and assembly processes. Here are some strategies to optimize your designs:

- Simplify Part Geometry: Minimize complex geometries that can lead to challenges during molding or assembly. Simplifying part geometry can enhance moldability and reduce production costs.

- Consider Assembly Features: If your product requires assembly, design features such as snap fits or interlocking mechanisms to facilitate easy and secure assembly. Ensure that assembly features align with the capabilities of the injection molding process.

- Eliminate Undercuts: Undercuts are features that prevent the straightforward ejection of a part from the mold. Minimize or eliminate undercuts to simplify mold design and enhance part release during demolding.

- Design with Cosmetics in Mind: If the appearance of the part is critical, pay attention to cosmetic surfaces. Avoid visible knit lines or sink marks by optimizing gate locations and melt flow paths. Incorporate appropriate textures or surface finishes to achieve the desired cosmetic outcome.

By considering factors such as wall thickness, parting lines, draft angles, and optimizing designs for manufacturability, you can reduce the likelihood of defects and ensure ease of manufacturing and assembly. These design considerations play a crucial role in achieving high-quality injection molded parts.

IV. Utilizing Simulation Tools

A. Benefits of Simulation Tools in Predicting Design Behavior

Simulation tools are valuable resources in the injection molding design process. They allow you to virtually simulate and analyze the behavior of your design before moving to actual manufacturing. Here are the key benefits of utilizing simulation tools:

- Predictive Analysis: Simulation tools enable you to predict and visualize how your design will behave during the injection molding process. You can simulate factors such as material flow, cooling, and part filling to identify potential issues and optimize the design parameters.

- Early Detection of Problems: By running simulations, you can identify potential design flaws or manufacturing challenges early in the design phase. This helps you address these issues proactively, saving time and resources that would have been spent on physical prototypes or trial-and-error iterations.

- Optimization of Process Parameters: Simulation tools allow you to experiment with different process parameters, such as injection speed, melt temperature, or cooling time. By analyzing the effects of these parameters, you can optimize the manufacturing process for improved part quality, reduced cycle times, and cost efficiency.

B. Identifying and Resolving Potential Issues Before Manufacturing

Simulation tools help you identify and resolve potential issues that could arise during the injection molding process. Here’s how simulation tools can assist in this process:

- Part Filling Analysis: Simulations can reveal potential challenges related to part filling, such as air traps, inadequate flow, or excessive pressure. By analyzing these issues beforehand, you can optimize gate locations, modify runner designs, or adjust injection parameters to ensure complete and consistent part filling.

- Cooling Analysis: Simulations allow you to analyze the cooling process and predict potential cooling-related issues, such as non-uniform cooling or warpage. By optimizing the cooling channel layout and adjusting cooling time, you can ensure proper cooling and reduce the risk of defects.

- Warp Prediction: Simulations help predict the possibility of part warpage due to residual stresses or uneven cooling. By identifying areas prone to warpage, you can make design modifications, adjust cooling strategies, or incorporate features like ribs or gussets to minimize the risk.

By utilizing simulation tools, you can gain valuable insights into the behavior of your design and make informed decisions before manufacturing. These tools empower you to optimize your design for better performance, reduce the risk of defects, and save time and costs associated with physical prototyping and trial-and-error iterations.

V. Material Selection Considerations

A. Importance of Selecting Suitable Materials for Injection Molding

The selection of appropriate materials is crucial in injection molding design. The choice of material impacts the performance, functionality, and overall quality of the injection molded molten plastic parts. Here’s why selecting suitable materials is important:

- Material Properties: Different materials offer distinct mechanical, thermal, and chemical properties. Consider the specific requirements of your application, such as strength, flexibility, temperature resistance, or chemical compatibility, when selecting a material. Choosing the right material ensures that your parts meet the desired performance criteria.

- Moldability: Each material has its own set of moldability characteristics. Some materials have better flow properties, while others may require higher injection temperatures or longer cooling times. By selecting a material that is well-suited for the injection molding process, you can achieve better part quality, reduced cycle times, and improved manufacturing efficiency.

- Cost Considerations: Material costs can vary significantly, and it’s important to strike a balance between performance requirements and budget constraints. Consider the overall cost-effectiveness of the material, factoring in its performance, availability, and any secondary operations required after molding.

B. Understanding Material Properties and Their Impact on the Molding Process

To make informed material selections, it’s crucial to understand how material properties can impact the injection molding process. Here are key considerations:

- Melt Flow Characteristics: The melt flow rate (MFR) of a material determines its ability to flow and fill the mold cavity during injection. Higher MFR materials flow more easily, while lower MFR materials may require higher injection pressures. Understanding the melt flow characteristics of different materials helps optimize process parameters for successful molding.

- Shrinkage: Different materials exhibit varying degrees of shrinkage as they cool and solidify. It’s important to account for the shrinkage rate of the material in the design phase to ensure accurate part dimensions. Adjustments can be made to the mold design, such as incorporating appropriate shrinkage allowances or designing for dimensional stability, to mitigate the effects of shrinkage.

- Warpage Tendencies: Some materials are more prone to warpage than others due to their molecular structure or cooling characteristics. Understanding the warpage tendencies of materials allows you to optimize the cooling process, mold design, and part geometry to minimize warpage and achieve dimensional accuracy.

- Compatibility with Secondary Operations: Consider any post-molding processes your parts may require, such as painting, printing, or assembly. Ensure that the selected material is compatible with these secondary operations to avoid any compatibility issues or quality concerns.

By understanding material properties and their impact on the molding process, you can make informed decisions during material selection. Consider factors such as melt flow characteristics, shrinkage, warpage tendencies, and compatibility with secondary operations. This knowledge enables you to choose suitable materials that optimize both the performance of the final part and the efficiency of the injection molding process.

Conclusion:

In conclusion, improving your injection molding design process requires a holistic approach that encompasses collaboration, design optimization, utilization of simulation tools, material selection considerations, and more. By implementing these key steps and strategies, you can enhance the efficiency, quality, and cost-effectiveness of your injection molding projects.