Improving multi-cavity injection molds can boost efficiency, reduce costs, and enhance production quality. Key strategies include optimizing cooling channels, using high-quality materials, and ensuring mold balance.

Improving multi-cavity injection molds involves optimizing mold design for uniform flow, reducing cycle times, and enhancing cooling efficiency. It helps achieve consistent part quality and lower production costs, benefiting industries such as automotive and electronics.

By refining mold design and ensuring balanced cavity filling, you can significantly enhance mold performance. Delve deeper into the design principles that make multi-cavity molds more efficient and cost-effective.

Optimizing cooling channels improves the efficiency of multi-cavity molds.True

Optimizing cooling ensures even temperature distribution, reduces cycle time, and enhances part quality.

Multi-cavity molds always require a higher upfront investment.False

Although multi-cavity molds have higher initial costs, their ability to produce more parts per cycle can lead to lower overall costs in high-volume production.

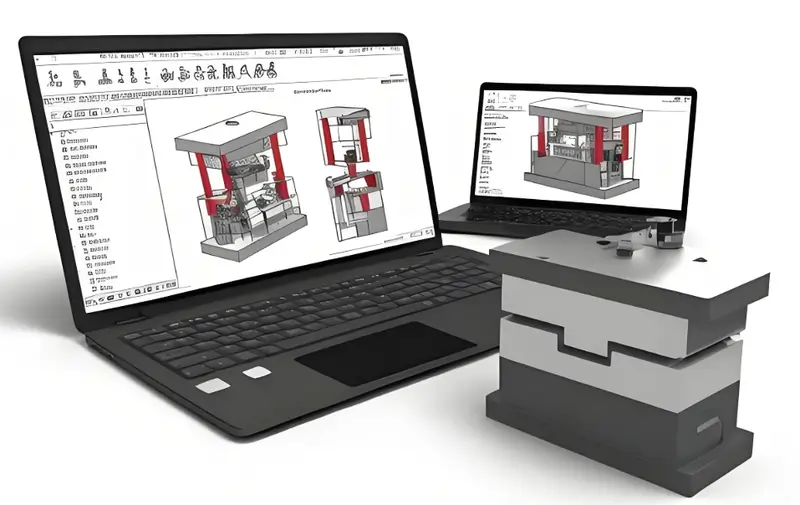

What are the Design Optimizations for Multi-cavity Injection Molds?

Multi-cavity injection molds enhance production efficiency by allowing multiple parts to be molded simultaneously. Design optimizations focus on improving balance, reducing cycle times, and ensuring uniform part quality.

Design optimizations for multi-cavity injection molds include cavity balancing, gate design, and runner system adjustments. These improvements enhance uniform flow, reduce cycle times, and minimize part defects, leading to cost-effective and high-quality production.

Cavity Layout Optimization

In the cavity layout, the use of reasonable methods can effectively reduce the generation of material waste and mold wear during the plastic injection molding process and improve productivity.

When designing a multi-cavity mold, the cavities should be aligned to ensure uniform material flow and minimize filling time1 differences.

Also, it is important to design the required distances between cavities for they should not interfere with each other. Simulation and analysis of the mold cavity layout can be made easier through the use of a computer aided design software interface (CAD2).

Runner Design Optimization

The runner system design3 is vital especially in the multi-cavity injection molding process being used in the production line. Further improvements of the runner design can also help decrease the injection pressure, enhance the filling rate, and eliminate defects.

Some of the most popular runner structures include sequential gating and balanced runners, with specific choices depending on the shape and size of the product.

In practice, application of the CFD simulation in running design can actually help to cope with flow distributive and air bubble problems, enhancing the Runner product quality.

Parting Line Design

Designing a reasonably good parting line may help in avoiding high demolding resistance while at the same time preventing the deterioration of the product surface.

When designing parting lines, smooth surfaces should be chosen to avoid sharp edges and uneven areas, while ensuring the strength and rigidity of the parting line.

In addition, regarding the design of the parting line, it is necessary to take into account the complexity of processing molds and their assemblies, choosing those schemes that are easy to process and maintain in order to improve efficiency.

Optimized multi-cavity molds reduce cycle times in mass production.True

Design optimizations such as balanced cavities and efficient cooling systems can significantly reduce cycle times, enhancing production speed and reducing costs.

Multi-cavity molds always require more expensive tooling than single-cavity molds.False

Although multi-cavity molds have a higher initial tooling cost, they can be more cost-effective in the long run due to the ability to produce more parts per cycle, leading to lower per-unit production costs.

What Kind of Injection Mold Material and Injection Molding Material to Choose?

Selecting the right injection mold material and molding material is crucial for product quality and production efficiency. Understanding your specific needs ensures optimal material selection.

Choosing the right injection mold material depends on factors like durability, cost, and application. Common materials include steel and aluminum for molds, while options like ABS, polycarbonate, and polypropylene are popular for molded parts.

Mold Materials

The effect of choosing appropriate mold materials on the lifetime and quality of the mold and the final product is rather crucial.

The most used types of mold materials are steel, aluminum alloys and copper alloys. Choosing high tensile mates riail, wear resisting material is beneficial for mold life and cutting down maintenance cycle.

For example, high-strength tool steel (such as H13, P20) can improve the mold\’s wear resistance and thermal stability, suitable for high-precision and demanding product production.

Plastic Materials

The properties of plastic materials influence a product’s quality and its ability to perform on the market.

When choosing the type of plastic material the injection molding manufacturer should consider the location where the product will be used and the expected performance of the product so that the right material such as polypropylene (PP), polyethylene (PE), polystyrene (PS) is used, the incorporation of proper fillers as well as plasticizers into the plastic material helps in improving on flow of the material and mechanical properties.

For special applications such as medical devices and food packaging, environmentally friendly and non-toxic materials meeting relevant standards should be chosen.

Aluminum molds are cheaper but wear out faster than steel molds.True

Aluminum molds are cost-effective for short-run production but wear out quicker due to their lower durability compared to steel molds.

Polycarbonate is the best material for all injection molded parts.False

While polycarbonate is versatile, it may not be the best for all applications due to its higher cost and specific material properties that may not suit every product need.

How to Improve the Injection Molding Cooling System?

Optimizing the cooling system in injection molding can significantly reduce cycle times, improve part quality, and enhance overall production efficiency.

Improving the cooling system in injection molding can be achieved by optimizing coolant flow, adjusting cooling channel design, and using advanced temperature control. These enhancements reduce cycle times and prevent defects like warping or sink marks.

Cooling Circuit Design

The design of the cooling circuit plays a significant role in the cooling performance of multi-cavity molding. A reasonable cooling circuit can also distribute the coolant uniformly to the cooling channels4so as to avoid local hot spots on the mold.

Among cooling circuits, the simplest are straight-through and serpentine circuits with certain choices defining by the structure of the mold and the shape of the product. Using computer simulation technology for cooling circuit simulation and analysis can optimize cooling effects and enhance production efficiency.

Coolant Selection

The selection of coolant directly affects the cooling performance and production efficiency of the production line. Coolants include: liquids (such as water, oil) and gases (such as air).

Water has high thermal conductivity and fast heat dissipation, but it is easy to rust; oil has good lubricity and corrosion resistance, but low thermal conductivity; air cooling is suitable for specific situations, but the efficiency is not as good as liquid cooling. In actual production, it is necessary to choose the right coolant according to product requirements to improve the cooling capacity.

Temperature Control Systems

Efficient regulation of temperature affects the reduction of dimensions variation and the surface finish of a product. Using advanced temperature control equipment, such as hot runner systems and mold temperature controllers, wisely-used help to maintain the optimal temperature, thus, shortening the cooling time and increasing overall productivity.

Through mold temperature regulation in real-time, factors that affect the quality of the final product can be handled and the process can be made more stable.

Efficient cooling systems reduce cycle times in injection molding.True

By optimizing the cooling process, you can shorten cycle times, improve part quality, and boost overall productivity.

Increasing coolant flow always improves cooling efficiency.False

Excessive coolant flow can lead to uneven cooling, which might cause defects. Proper cooling channel design and balanced coolant flow are key to effective temperature control.

What are the Injection Molding Process Optimizations?

Injection molding process optimizations improve efficiency, reduce waste, and enhance product quality. Key techniques focus on speed, precision, and material savings.

Optimizing injection molding involves reducing cycle time, enhancing part consistency, and minimizing material waste. Key strategies include adjusting temperatures, improving mold design, and using automation for faster production.

Injection Process Parameter Optimization

Injection molding process parameters significantly impact product quality and production efficiency. Adjusting injection pressure, velocity, clamping time and cooling time may help to minimize the defects and increase the productivity levels.

Application of injection molding simulation software like moldflow used for parameter simulation and analysis can for the decision of the right parameter for steady and efficient processes.

Molding Process Optimization

Optimizing the molding process can enhance the surface quality and dimensional accuracy of products. Some of the frequently used molding processes are gas assist molding, melt compression molding and hot runner mold.

Choosing the right molding processes, as well as the equipment and technology, has a direct impact on the increase in production speed and the quality of the product.

For instance, the gas assisted molding aims to apply high pressure gas into the mold, creating a process that results to molding of a thin shell structure that helps in cutting down more on the material consumption and the overall weight of the final product, in addition to enhancing the dimensional accuracy, and a superior surface finish.

Post-Processing Optimization

Optimizing post-processing can further enhance the surface quality and mechanical properties of products. Such operations involved are post processing which may be done through annealing, spraying, and electroplating among others. Specific post-processing technologies depending on the client’s requirements can enhance the product’s properties and appearance.

For instance, applying annealing can foster the removal of internal stresses and at the same time improve on the dimensional stability and mechanical properties; through spraying and electroplating, one can increase on surface hardness and the corrosion resistance hence prolonging the life of the product and also the appearance.

Optimizing injection molding improves product consistency.True

By adjusting temperature and pressure parameters, manufacturers can ensure uniformity in part quality across batches.

Injection molding optimizations always lead to lower costs.False

While optimizations can reduce waste and improve efficiency, initial setup costs for advanced techniques may offset savings in some cases.

What is Injection Molding Quality Control?

Injection molding quality control ensures the consistency, precision, and reliability of molded products by monitoring and maintaining key parameters throughout the production process.

Injection molding quality control involves inspecting material consistency, temperature, pressure, and part dimensions to ensure products meet specified standards. It helps reduce defects, improve reliability, and lower production costs by identifying issues early.

Online Inspection

The use of online inspection helps to detect the problem in the production line as and when it occurs, hence minimizing the chances of huge scrapage. With the help of the online inspection facilities like laser scanner, ultrasonic detector, infrared thermographs, the dimensions, the shape and the quality of the surface of the products can be monitored live ensuring the quality of products.

For example, laser scanners can be used to measure geometric and shapes measuring the size deviations and deformations while on the other hand ultrasonic detectors can be used to detect the bubbles and internal cracks thus certifying that internal quality is checking.

Process Control

The benefits of process control include improved production efficiency as well as the quality of the final product. A stable process control system should be established, and injection pressure, temperature, speed and time should be controlled by advanced control algorithms and equipment.

For example, a computer integrated manufacturing system (CIM) can better control the manufacturing process and products through automation, and can monitor the process in real time, thereby improving the efficiency and quality of the produced products.

Quality Management System

Implementing an effective quality assurance system and/or using internationally recognized models such as ISO9001 can improve a company\’s competitiveness and customer satisfaction.

Arranging quality audits and assessments can easily find solutions to any problems, thereby promoting better improvements in production processes and management processes, and continuously improving product quality during the production process.

For example, introducing total quality management (TQM) can improve overall quality management because it can ensure stable and continuous improvement of products.

Injection molding quality control is crucial for minimizing defects.True

By monitoring key parameters during production, quality control helps detect issues early and ensures products meet required specifications.

Quality control in injection molding can be skipped in low-volume production.False

Even in low-volume runs, quality control remains essential to maintain product consistency and avoid costly errors or defects.

What is the Future Outlook for Multi-Cavity Injection Molds?

Multi-cavity injection molds5 are becoming increasingly vital in manufacturing for their ability to produce high volumes of parts quickly and efficiently. As industries demand more cost-effective solutions, multi-cavity molds are poised for continued growth.

Multi-cavity injection molds enable faster production by using multiple cavities in a single mold. This reduces cycle time and increases efficiency, making them ideal for high-volume production, especially in industries like automotive and consumer goods.

Considering the identified dynamics of technological progress and modifying market requests, the enhancement of multicable injection molds will have new challenges as well as perspectives.

In the future, due to the use of new type of materials, processes and technologies, the design and manufacturing of multi-cavity injection molds will enter into the direction of smartification and more automation and this will enhance the production efficiency and quality of the products.

For example, the implementation of artificial intelligence and machine learning will allow intelligent optimization of molds’ design and manufacturing, increasing production speed and preventing defects.

Moreover, environmentally friendly and energy saving will become the new development tendency of multi-cavity injection mold, adopting green material to solve the problem of resources waste and environmental pollution, pursuing sustainable development.

Multi-cavity injection molds increase production efficiency.True

By allowing multiple parts to be produced simultaneously, multi-cavity molds reduce overall cycle time, enhancing production rates and reducing costs.

Multi-cavity injection molds are always cheaper than single-cavity molds.False

While multi-cavity molds may initially cost more, their efficiency and higher output can lead to greater cost savings in high-volume production, justifying the investment.

Conclusion

Improving multi cavity injection mold is a systematic project and in order to upgrade them they have to be optimized and enhanced at the design, materials, cooling system, processing technology, as well as quality control systems level.

With the attempt of reasonable design, high technique application, and scientific management, production rate and product quality could be remarkably improved, which help to increase the market adaptability and sustainable development potentiality.

In the process of improving multi-cavity molds, implementing cavity pressure sensing technology is a crucial step. This technology is not only applicable to single cavity molds6 but also supports complex family molds. When working with liquid silicone rubber, precise cavity pressure sensing helps control the filling status of each cavity, thereby enhancing product consistency and quality.

Additionally, a well-designed wall thickness is essential for ensuring mold performance and product quality. By integrating these technologies and design elements, the production efficiency and product pass rate of multi-cavity injection molds can be significantly improved.

-

Learn about How to Calculate the Filling Time of an Injection Molding Machine? Accurate filling time is crucial for injection molding, primarily reflected in the following aspects. ↩

-

Learn about Computer-aided design :CAD is the use of computers to aid in the creation, modification, analysis, or optimization of a design. ↩

-

Learn about Hot Runner Systems in Injection Molds: Principles, Design, and Applications : Hot runner systems are super important in plastic molding. ↩

-

Learn about The Importance of Cooling Channels : cooling channels are channels in a mold through which a cooling agent can flow to accelerate the cooling process and make it more uniform. ↩

-

Learn about Multi Cavity Injection Molds vs. Family Injection Molds : A multi-cavity mold has more than one cavity of the same part, and it produces more than one part per production cycle. ↩

-

Learn about Single-Cavity vs. Multi-Cavity Injection Molding : Injection molding may be facilitated by means of a single- or multi-cavity mold . ↩